Energy saving control method and energy saving system for boiler automatic combustion

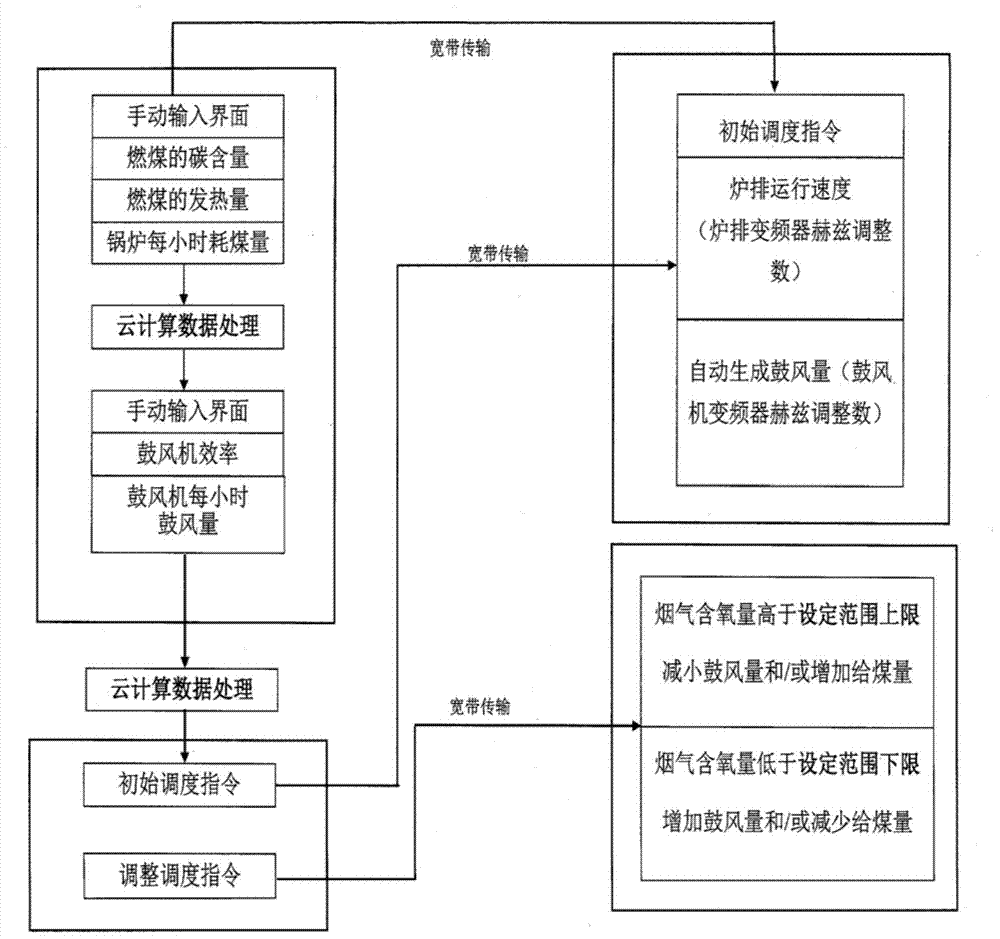

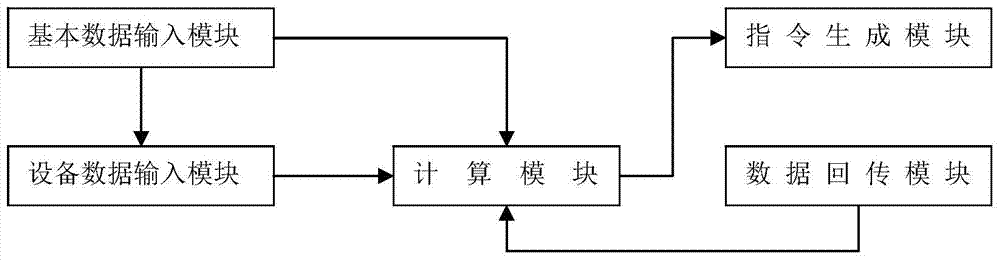

A technology of energy-saving control and energy-saving system, which is applied in the combustion method, combustion control, air supply adjustment and other directions, can solve the problem of precise control method, no problems such as blast volume and oxygen content, achieve high thermal efficiency, solve the problem of good and bad, and reduce work the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0022] The terms in this manual are introduced as follows:

[0023] 1. Coal consumption: the amount of coal consumed by the boiler per hour, unit: ton / hour (T / h), under normal circumstances, the coal consumption of a 100T boiler is about 13 tons per hour.

[0024] 2. Boiler thermal efficiency: COP (Coefficient Of Performance), that is, the conversion ratio between the energy consumed by the boiler operation and the heat generated, referred to as the heating energy efficiency ratio.

[0025] 3. Standard coal: also known as coal equivalent, which has a unified calorific val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com