Production method of mining cable rubber sheath material

A production method and sheath material technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of air bubbles, easy generation of impurities, low quality of rubber sheath materials, etc., to reduce waste and avoid knots. The effect of blocks, ease of processing and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0026] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

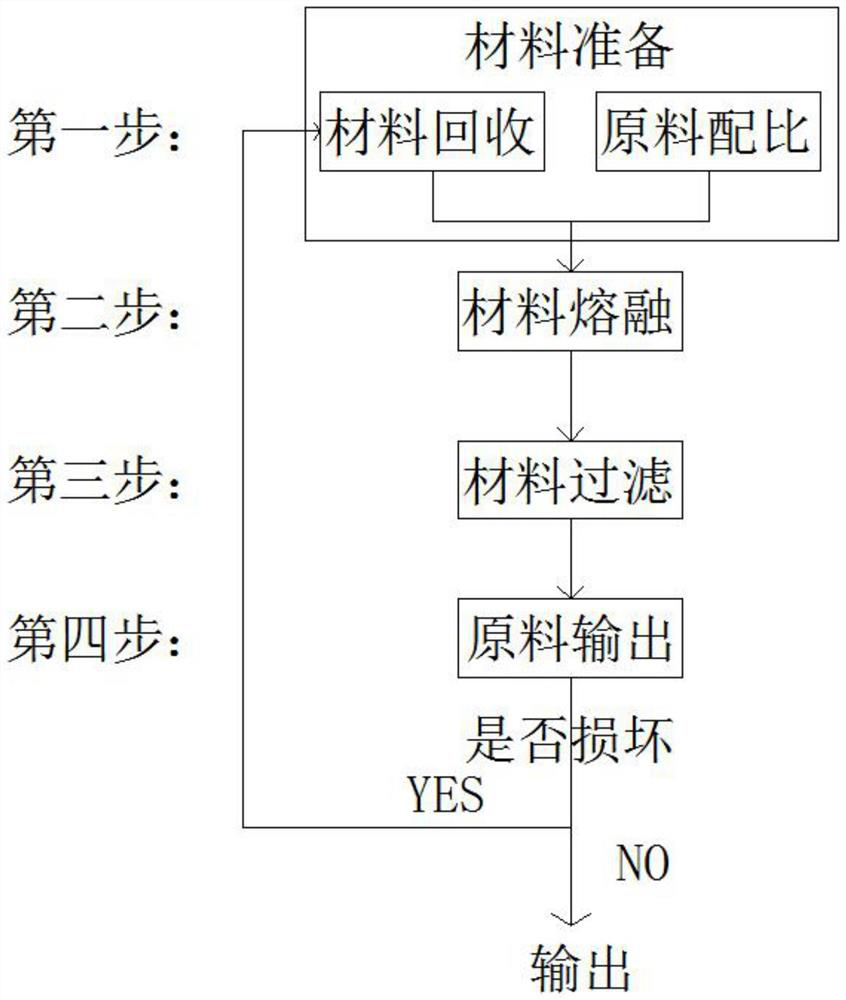

[0027] Such as Figure 1 to Figure 3 As shown, a kind of mining cable rubber sheath material production method provided by the embodiment of the present invention, the production method process steps are:

[0028] The first step: material preparation, divided into raw material ratio material preparation and material recycling;

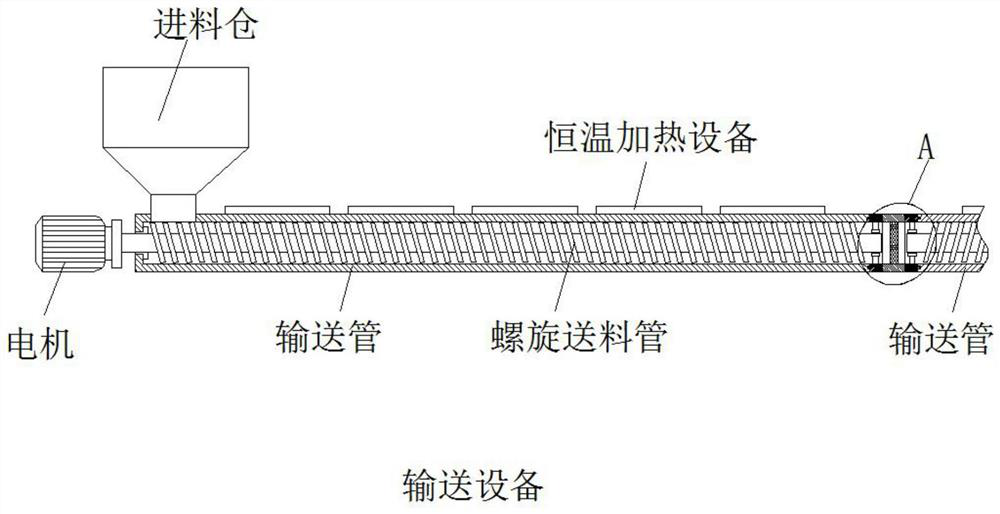

[0029] The second step: the material is melted, and the rubber material is melted by the rubber melting equipment, and then transported to the rear end after melting;

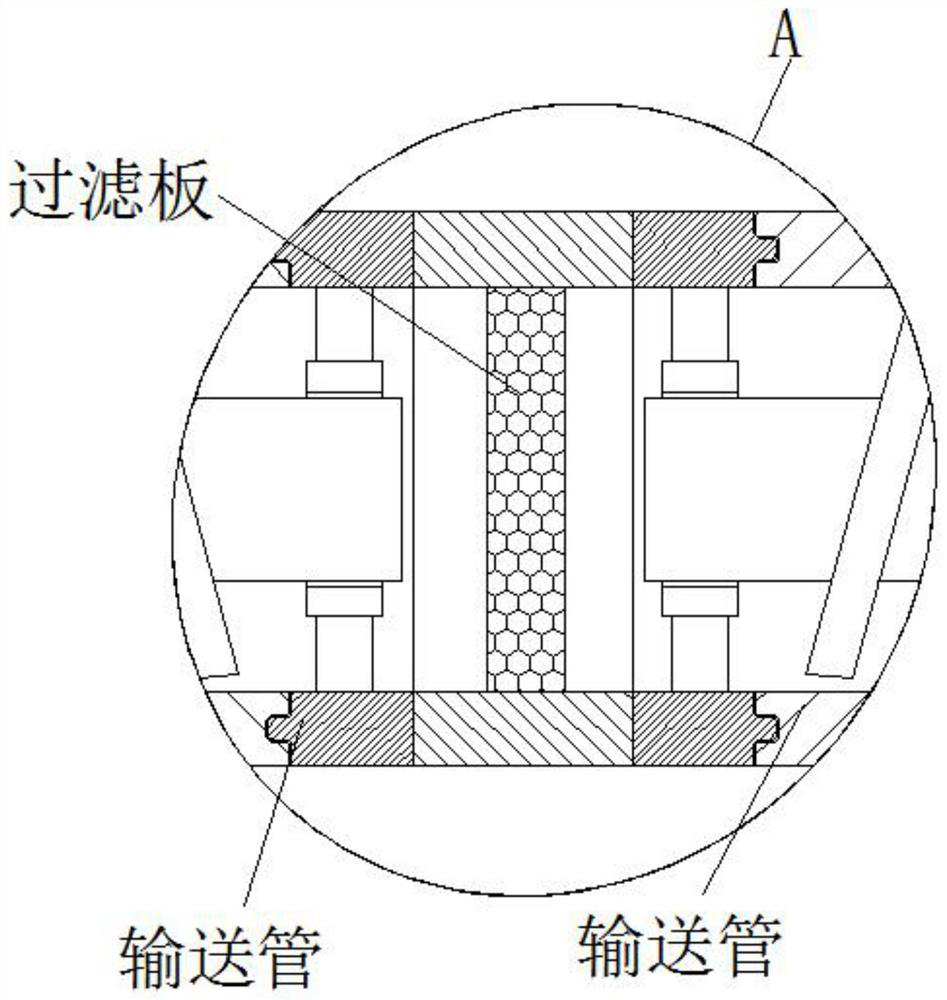

[0030] The third step: material filtration, the melted material passes through the conveying equipment, and the conveying equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com