Method for preparing lilial key intermediate namely tert-butylphenol-alpha-methylbenzene acrolein

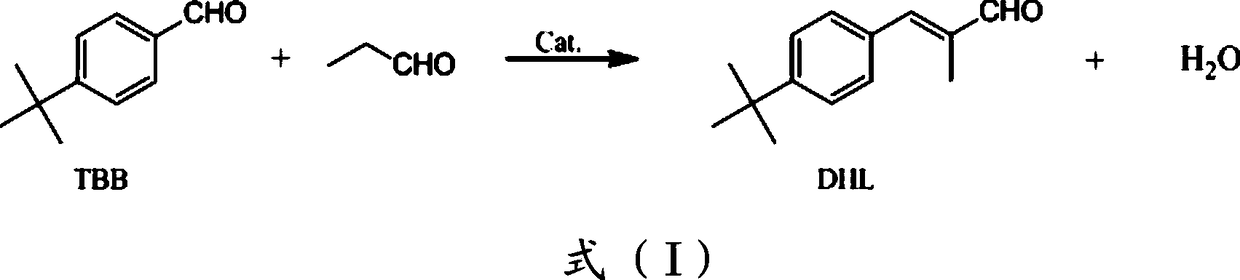

A technology of methacrolein and p-tert-butyl, which is applied in the field of preparation of p-tert-butyl-α-methylphenylacrolein, the key intermediate of lilial, can solve the problem of difficult to realize large-scale industrial production and increase industrialization Problems such as manufacturing cost and low conversion rate of TBB can achieve the effect of easy realization of industrial production, avoiding reaction hot spots and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Under nitrogen protection, add 47kg of propionaldehyde and 70.5kg of anhydrous methanol into a dry and clean batching kettle, stir and mix at room temperature to obtain 117.5kg of propionaldehyde methanol solution, which is ready for use.

[0051] Main reaction stage:

[0052] Under the protection of nitrogen, add 110.5kg of p-tert-butylbenzaldehyde (TBB), 75kg of anhydrous methanol and 3kg of potassium hydroxide into a dry and clean condensation kettle, start stirring, control the temperature of the kettle at 20°C, and add 99kg of Prepared propionaldehyde methanol solution. During the dropwise addition process, the temperature of the kettle was always controlled at 20°C, and crystal DHL was gradually precipitated as the reaction progressed. After the dropwise addition was completed, the reaction was incubated for 1 h.

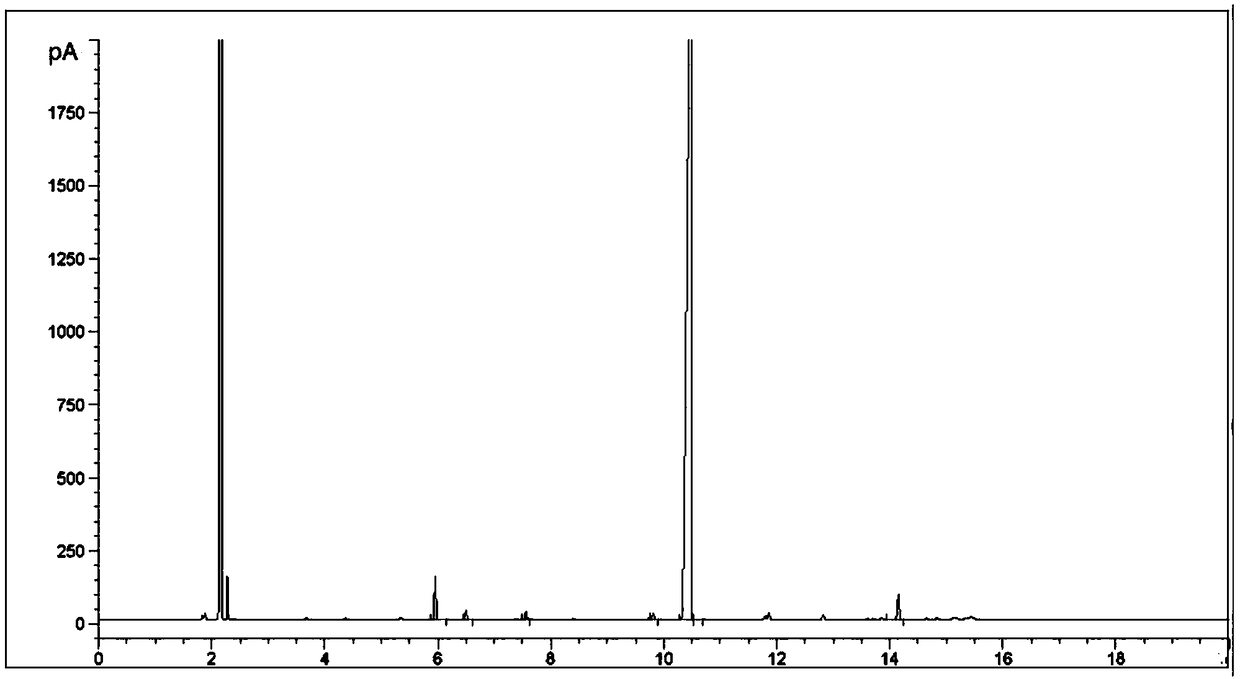

[0053] Reaction finishes, and 3.2kg acetic acid is added dropwise, to neutralize catalyst potassium hydroxide. Sampling, GC results: TBB 9.55%, DHL ...

Embodiment 2

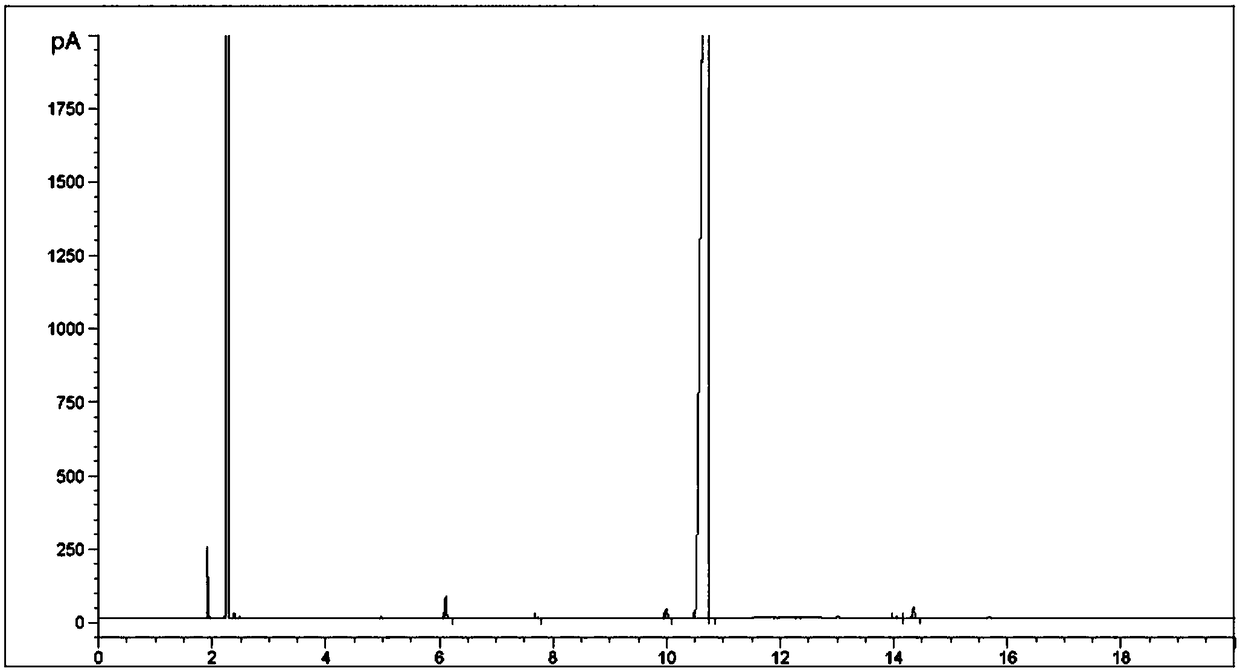

[0059] Reaction condition is identical with embodiment 1, difference only is: increase propionaldehyde total amount, make the mol ratio of main reaction stage propionaldehyde and TBB be 1.05: 1;

Embodiment 3

[0061] Reaction condition is identical with embodiment 1, difference only is: increase propionaldehyde total amount, make the mol ratio of main reaction stage propionaldehyde and TBB be 1.10: 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com