Technology for producing iron fine powder through red mud fluidized bed method

A fluidized bed method and iron fine powder technology, which is applied in the field of iron and steel production, can solve the problems of reduced reduction efficiency, poor economy, waste of energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

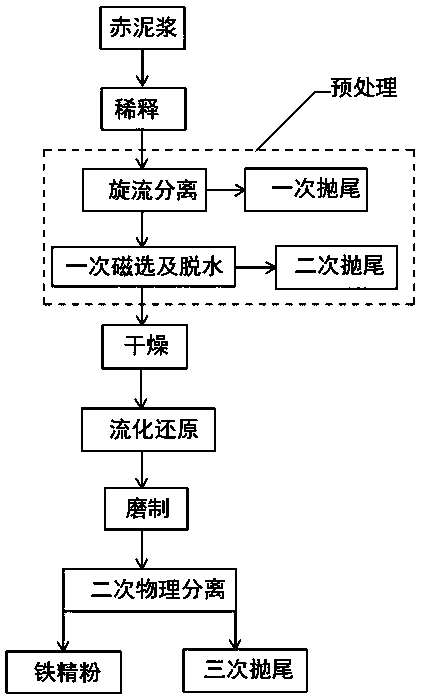

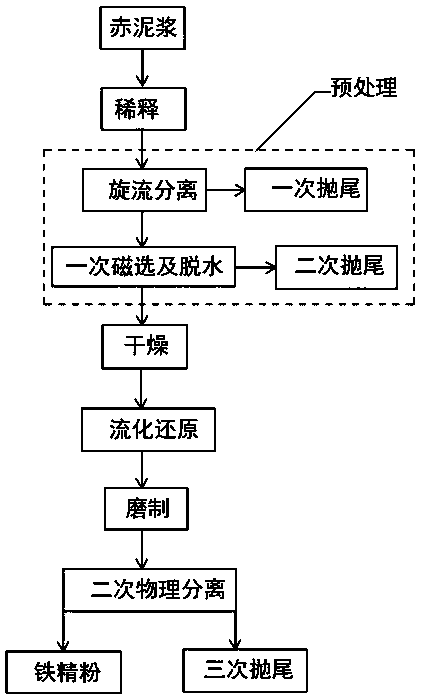

Method used

Image

Examples

Embodiment 1

[0030] 1) Dilution: Red mud components used in this example: TFe 16.33%, SiO 2 17.21%, Al 2 o 3 19.91%, and a small amount of others; take out the red mud slurry from the sedimentation washing tank produced by alumina, dilute and adjust the solid content of the red mud slurry to 16%, and then use the screening equipment to screen out the coarse particles in the red mud slurry ;

[0031] 2) Pretreatment: The screened red mud slurry is sent to the hydrocyclone for gravity separation, and the overflow is sent back to the washing and settling tank produced by alumina in step 1) to dilute the red mud slurry; the bottom flow is subjected to magnetic separation , the magnetic field strength of magnetic separation is 1600 gauss. After dehydration treatment, the pretreatment of red mud is completed to obtain coarse iron powder; after the pretreatment of red mud is combined with cyclone separation and magnetic separation separation, the main elements of coarse iron powder are obtained...

Embodiment 2

[0036] 1) Dilution: Red mud components used in this example: TFe 16.33%, SiO 2 17.21%, Al 2 o 3 19.91%, and a small amount of others; take out the red mud slurry from the sedimentation washing tank produced by alumina, dilute and adjust the solid content of the red mud slurry to 18%, and then use the screening equipment to screen out the coarse particles in the red mud slurry ;

[0037] 2) Pretreatment: The screened red mud slurry is sent to the hydrocyclone for gravity separation, and the overflow is sent back to the washing and settling tank produced by alumina in step 1) to dilute the red mud slurry; the bottom flow is subjected to magnetic separation , the magnetic field strength of magnetic separation is 1500 gauss. After dehydration treatment, the pretreatment of red mud is completed to obtain coarse iron powder; after the pretreatment of red mud is combined with cyclone separation and magnetic separation separation, the main elements of coarse iron powder are obtained...

Embodiment 3

[0042] 1) Dilution: Red mud components used in this example: TFe 16.33%, SiO 2 17.21%, Al 2 o 3 19.91%, and a small amount of others; take out the red mud slurry from the sedimentation washing tank produced by alumina, dilute the solid content of the red mud slurry to 15%, and then use the screening equipment to screen out the coarse particles in the red mud slurry ;

[0043] 2) Pretreatment: The screened red mud slurry is sent to the hydrocyclone for gravity separation, and the overflow is sent back to the washing and settling tank produced by alumina in step 1) to dilute the red mud slurry; the bottom flow is subjected to magnetic separation , the magnetic field strength of magnetic separation is 2000 gauss, after dehydration treatment, the pretreatment of red mud is completed to obtain coarse iron powder; after the pretreatment of red mud is combined with cyclone separation and magnetic separation separation, the main elements of coarse iron powder are obtained Content: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com