A kind of method for preparing protofilm loose ester

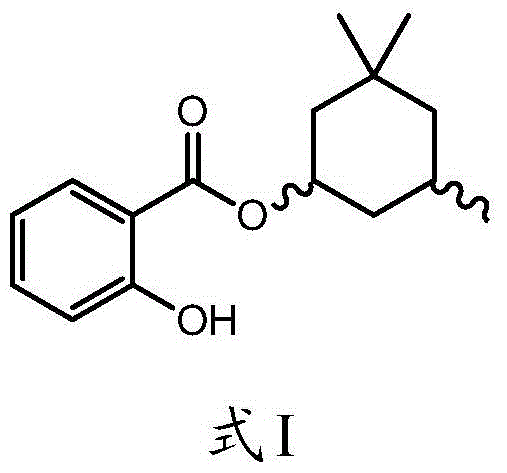

A kind of original film loose ester, a single technology, applied in the field of daily chemical industry, can solve the problem of not giving the three-dimensional information of the product HMS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] According to the method for preparing the original membrane loose ester provided by the invention, it has the following beneficial effects:

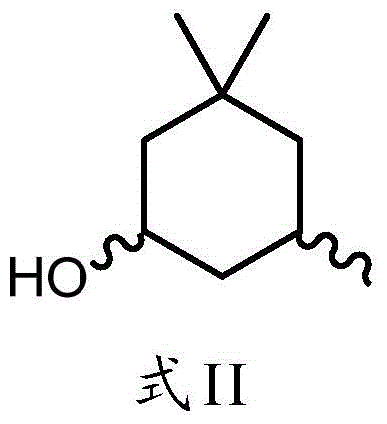

[0074] (1) After the isophorone hydrogenation reduction reaction is finished, the stereoselectivity of the product isophorol is cis:trans≤1:1, and the method of epimerization can be used to obtain the cis isomer Isophorol with a ratio of trans isomer greater than 85:15, which provides guarantee for the subsequent preparation of high-quality promembrane loose ester;

[0075] (2) Using the method of epimerization, any ratio of cis:trans>1:1 isophorol can be obtained, and the epimerization reaction does not need to use other catalysts, only after the reaction is completed It can be completed by properly adjusting the temperature and hydrogen pressure in the reactor, and the operation is simple and the effect is remarkable;

[0076] (3) The isophor alcohol prepared according to the method provided by the present invention has a purit...

Embodiment 1

[0083] (1) Add 2000kg isophorone and 14.0kg Ru / C (based on the total weight of Ru / C, containing Ru5.1wt% and water content 45.4%) in the hydrogenation reactor, close the hydrogenation reactor, and replace with nitrogen The air in the reactor was replaced three times with hydrogen, and the nitrogen in the reactor was replaced three times. The hydrogen pressure in the reactor was set at 0.8MPa, the stirring was started, and the temperature was raised to 80°C to start hydrogenation. Until no hydrogen was absorbed, samples were taken for GC analysis. The cis form is 33.27%, the trans form is 66.52%, the total content is 99.79%, cis form:trans form=0.5.

[0084] (2) Epimerization: Raise the hydrogen pressure in the reactor to 1.4MPa, raise the temperature in the reactor to 140°C, and take a sample after stirring for 5 hours. The cis form is 89.89%, the trans form is 9.84%, and the total content is 99.73% %, cis:trans=9.14.

[0085] (3) The temperature of the material in the reacto...

Embodiment 2

[0089] (1) in hydrogenation reactor, add 2000kg isophorone, embodiment 1 reclaims Ru / C catalyst 10.6Kg and 2.0Kg fresh Ru / C catalyst (based on Ru / C gross weight, wherein containing Ru5.1%, Moisture content 45.4%), close the hydrogenation kettle, replace the air in the kettle with nitrogen three times, and then replace the nitrogen in the kettle with hydrogen three times, set the hydrogen pressure in the kettle at 1.2MPa, start stirring, heat up to 110°C to start hydrogenation, Until the hydrogen is no longer absorbed, samples are taken for GC analysis, the cis form is 10.10%, the trans form is 89.68%, the total content is 99.78%, cis form:trans form=0.11.

[0090] (2) Epimerization: Raise the hydrogen pressure in the reactor to 1.6MPa, raise the temperature in the reactor to 150°C, and take a sample after stirring for 7 hours. The cis form is 90.35%, the trans form is 9.35%, and the total content is 99.70% %, cis:trans=9.66.

[0091] (3) Cool the material in the kettle to 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com