Non-sodium chloride environment-friendly type coal-saving combustion adjuvant special for cement

An environmentally friendly, sodium chloride technology, used in cement production, fuel, solid fuel and other directions, can solve problems such as incompleteness, and achieve the effects of extending service life, protecting the environment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

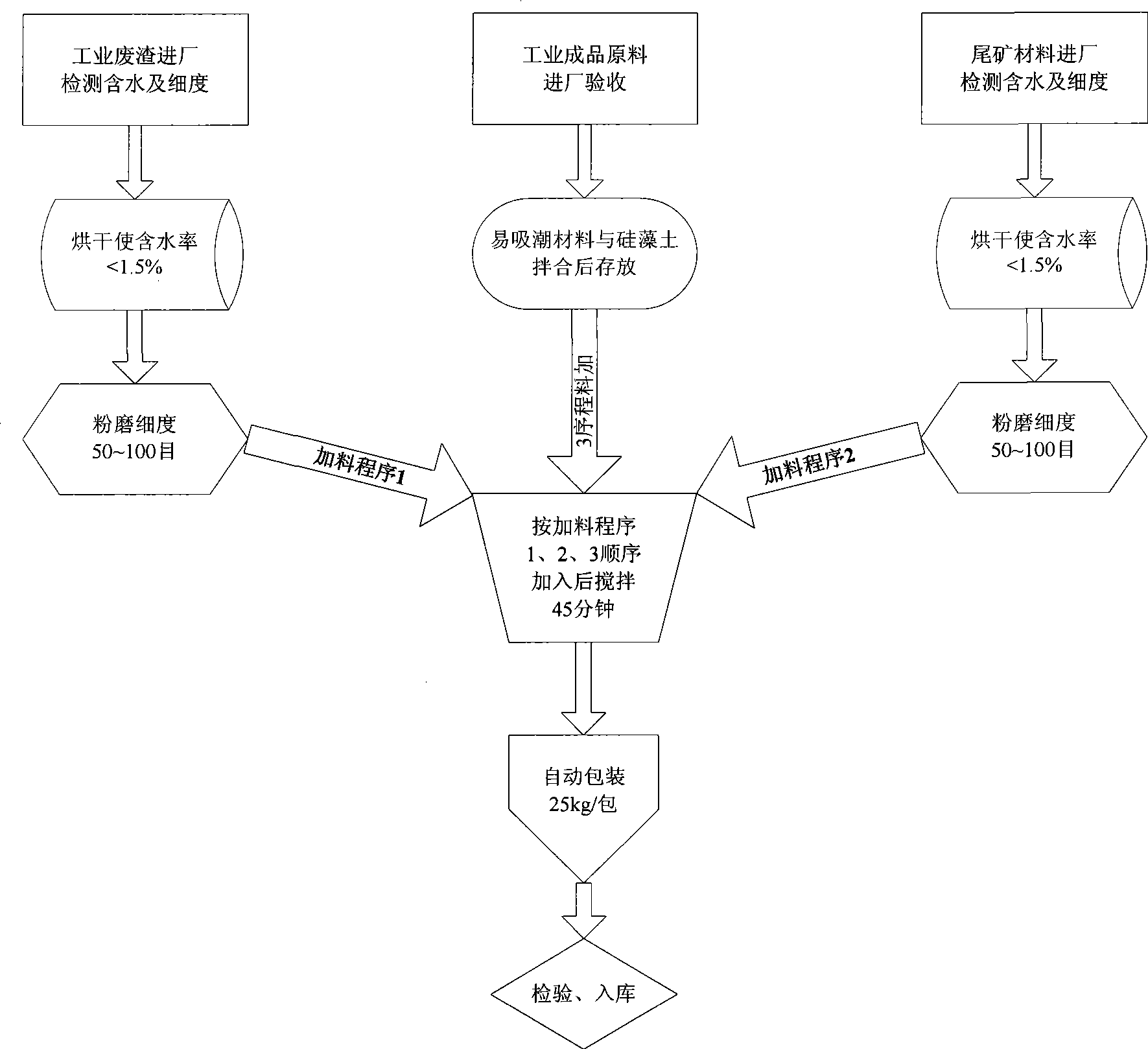

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the weight percent that coal-saving combustion aid comprises: barium titanate in the barium compound, two kinds of mixtures of barium fluoride 5%, boric acid in the boride, borax two kinds of mixtures 5% and boric acid, borax in industrial production 5% waste residue, 5% mixture of ammonium carbonate and strontium carbonate in carbonate, 5% waste residue in industrial production of ammonium carbonate and strontium carbonate, 5% mixture of ammonium dichromate and potassium dichromate in chromium compound , 5% of ammonium fluoride and potassium fluoroaluminate mixture in fluoride and 5% of waste residue in the industrial production of ammonium fluoride and potassium fluoroaluminate, magnesia and magnesium carbonate two kinds of mixture or magnesium oxide and magnesium carbonate industry 5% waste residue in production, 5% mixture of potassium permanganate and sodium permanganate in manganese compounds, 5% mixture of nickel nitrate and copper nitrate in nitrate...

Embodiment 2

[0050] Embodiment 2, the percentage by weight that the coal-saving combustion aid comprises: barium titanate in the barium compound, two kinds of mixtures of barium fluoride 5%, boric acid in the boride, two kinds of mixtures of borax 5% and boric acid, borax in industrial production 5% waste residue, 5% mixture of ammonium carbonate and strontium carbonate in carbonate, 5% waste residue in industrial production of ammonium carbonate and acid-resistant strontium, 5% mixture of ammonium dichromate and potassium dichromate in chromium compound , 5% mixture of ammonium fluoride and potassium fluoroaluminate in fluoride and 5% of waste residue from industrial production of ammonium fluoride and potassium fluoroaluminate, potassium permanganate and sodium permanganate in manganese compounds 5% mixture, 5% mixture of nickel nitrate and copper nitrate in nitrate, 6% mixture of ammonium molybdate and molybdenum hexafluoride in molybdenum, 5% of tungsten carbide and tungsten trioxide in...

Embodiment 3

[0058] Embodiment 3, the weight percent that coal-saving combustion aid comprises: barium titanate in the barium compound, two kinds of mixtures of barium carbonate 5%, boric acid in the boride, borax two kinds of mixtures or boric acid, industrial waste slag 5% in the production of borax , 8% mixture of ammonium carbonate and strontium carbonate in carbonates and 5% of waste residue in industrial production of ammonium carbonate and strontium carbonate, 3% of ammonium dichromate and potassium dichromate in chromium compounds and dichromic acid Ammonium and potassium dichromate industrial waste residue 5%, magnesium oxide, magnesium carbonate two kinds of mixture or magnesium oxide, magnesium carbonate production industrial waste residue 5%, manganese compound potassium permanganate, high Two mixtures of sodium manganate 5%, potassium permanganate, sodium permanganate industrial waste residue 10%, nickel nitrate and copper nitrate in nitrate 5%, ammonium molybdate and molybdenu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com