Rare earth-doped fluoride lanthanum potassium nano fluorescent marking material and preparation method thereof

A technology of fluorescent labeling and nano-fluorescence, applied in luminescent materials, chemical instruments and methods, fluorescence/phosphorescence, etc., to achieve good application potential, simple preparation process, and easy control of synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

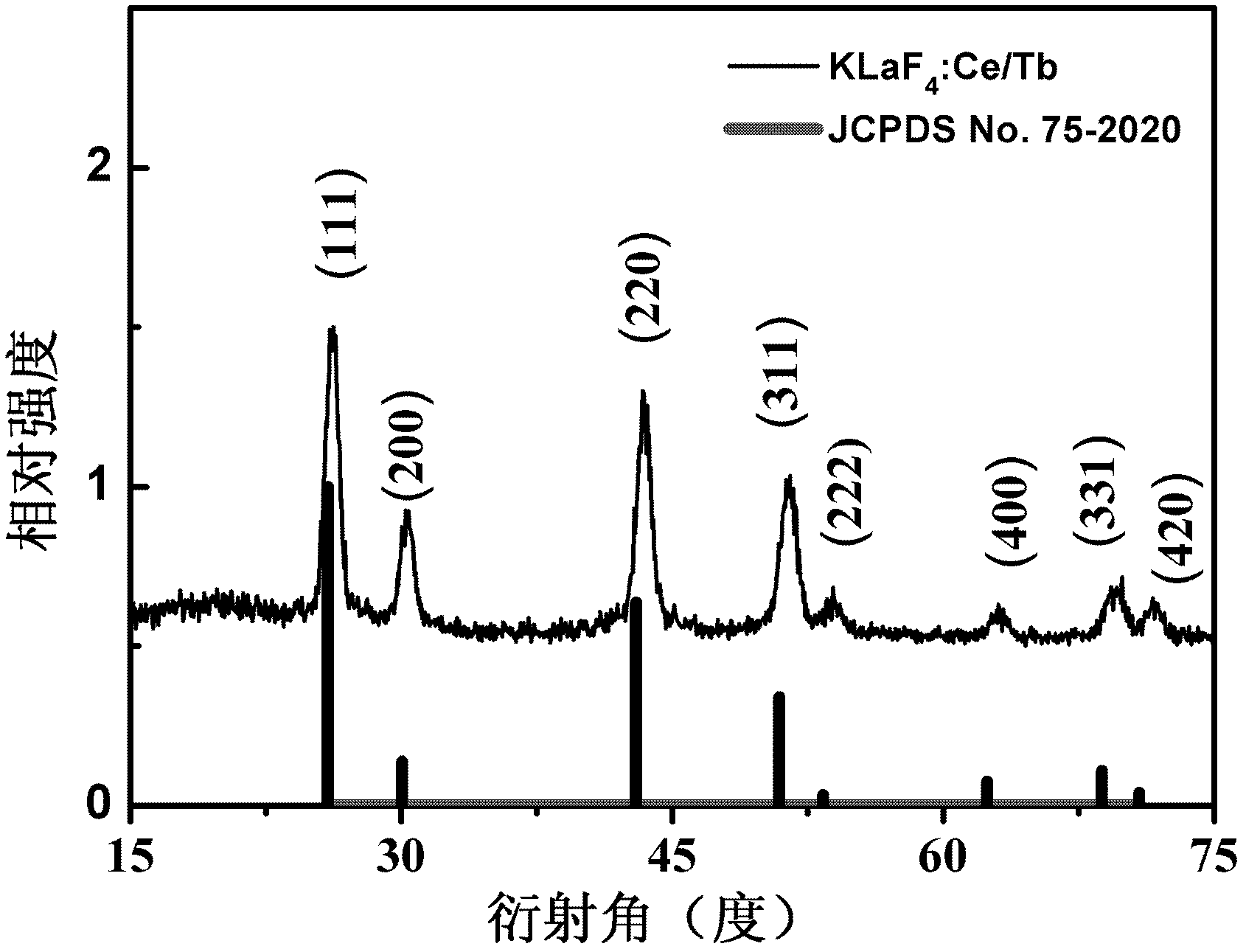

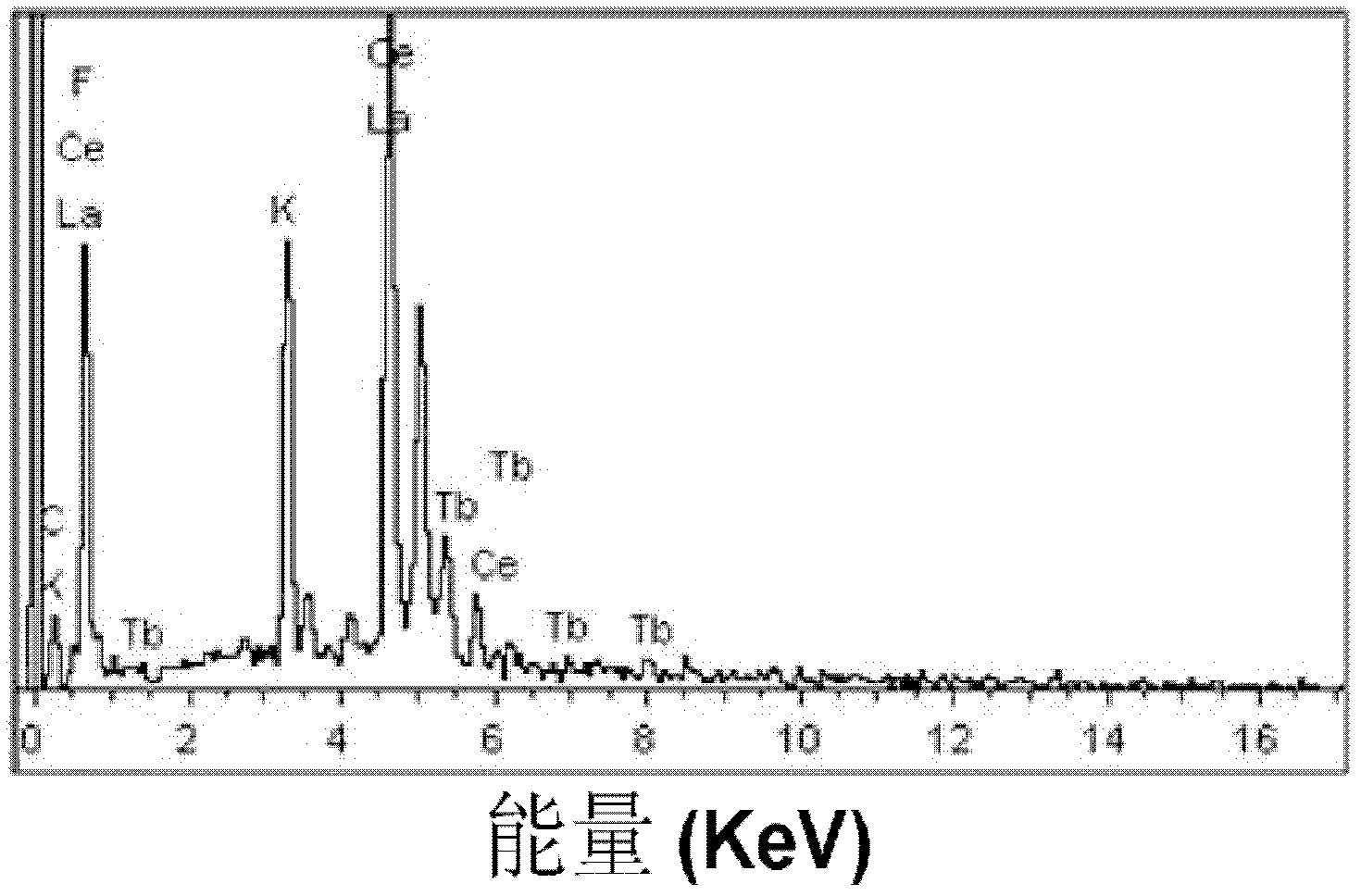

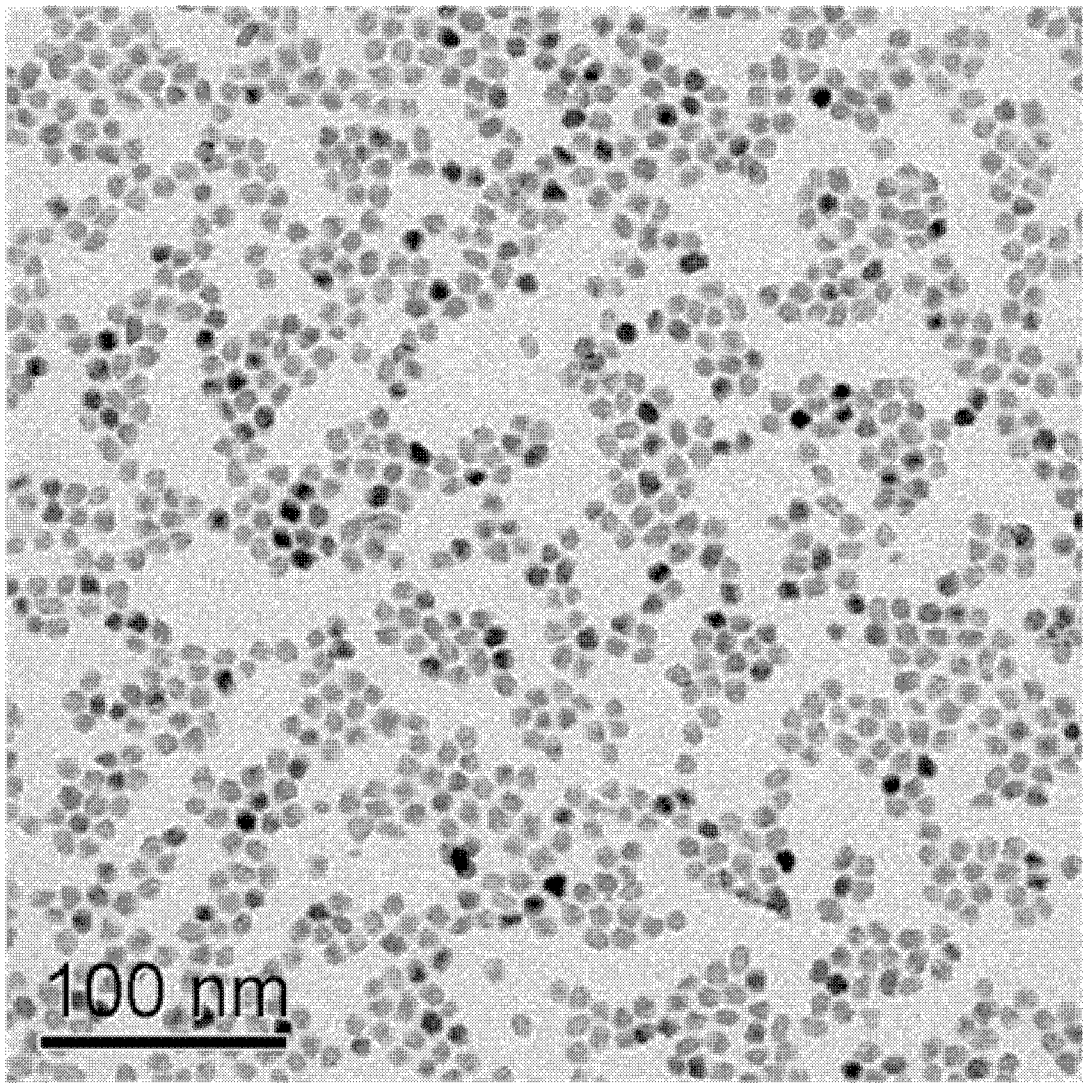

[0024] Example 1: KLaF 4 : Preparation of 0.05Ce / 0.05Tb nanocrystals, first weigh 0.1730g CF 3 COOK, 0.4788g La (CF 3 COO) 3 , 0.0266g Ce (CF 3 COO) 3 and 0.0266g Tb (CF 3 COO) 3 into a three-hole flask, and then add 8 mL of oleic acid, 10 mL of oleylamine and 2 mL of octadecene solvent. Then pass in N 2 The temperature was raised to 100 °C for 10 min under the same conditions, so that the solid reactant was dissolved until transparent, and then heated to 320 °C for 1 h. After cooling to room temperature, add 20 mL of ethanol for precipitation, centrifuge and wash to obtain oil-soluble KLaF 4: 0.05Ce / 0.05Tb nanocrystals. Disperse the nanocrystals in 20 mL of cyclohexane, add 15 mL of a dichloromethane solution in which 20 mg of nitrous tetrafluoroborate is dissolved, mix and react for 1 h, and then centrifuge to re-disperse the obtained precipitate in dimethylformamide, add 0.1 After 1 h of stirring reaction and exchange of g phosphoethanolamine, the precipitate was ...

example 2

[0025] Example 2: KLaF 4 :0.01Nd 3+ Preparation of nanocrystals, first weigh 0.1730g CF 3 COOK, 0.5267g La (CF 3 COO) 3 , 0.0054g Nd(CF 3 COO) 3 into a three-hole flask, and then add 9 mL of oleic acid, 9 mL of oleylamine and 2 mL of octadecene solvent. Then pass in N 2 The temperature was raised to 120 °C for 10 min under the same conditions, so that the solid reactant was dissolved until transparent, and then heated to 330 °C and reacted for 1.5 h. After cooling to room temperature, add 20 mL of acetone for precipitation, centrifuge and wash to obtain oil-soluble KLaF 4 :0.01Nd 3+ Nanocrystalline. Disperse the nanocrystals in 30 mL of cyclohexane, add 30 mL of a dichloromethane solution in which 30 mg of nitrous tetrafluoroborate is dissolved, mix and react for 1 h, and then centrifuge to re-disperse the obtained precipitate in dimethylformamide, add 0.2 After 1 h of stirring reaction and exchange of g phosphoethanolamine, the precipitate was obtained by centrifuga...

example 3

[0026] Example 3: KLaF 4 : Preparation of 0.02Er / 0.18Yb nanoparticles, first weigh 0.1730g CF 3 COOK, 0.4256g La (CF 3 COO) 3 , 0.0112g Er(CF 3 COO) 3 and 0.1019g Yb (CF 3 COO) 3 into a three-hole flask, and then add 10 mL of oleic acid, 8 mL of oleylamine and 2 mL of octadecene solvent. Then pass in N 2 The temperature was raised to 130 °C for 10 min under the same conditions, so that the solid reactant was dissolved until transparent, and then heated to 340 °C for 0.5 h. After cooling to room temperature, add 20 mL of acetone for precipitation, centrifuge and wash to obtain oil-soluble KLaF 4 : 0.02Er / 0.18Yb nanocrystals. Disperse the nanocrystals in 10 mL of cyclohexane, add 10 mL of a dichloromethane solution dissolved in 10 mg of nitrous tetrafluoroborate, mix and react for 0.5 h, and then centrifuge to re-disperse the obtained precipitate in dimethylformamide. After 0.05g of phosphoethanolamine was stirred and exchanged for 0.5h, the precipitate was obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com