Tire tread rubber composition and tire using same

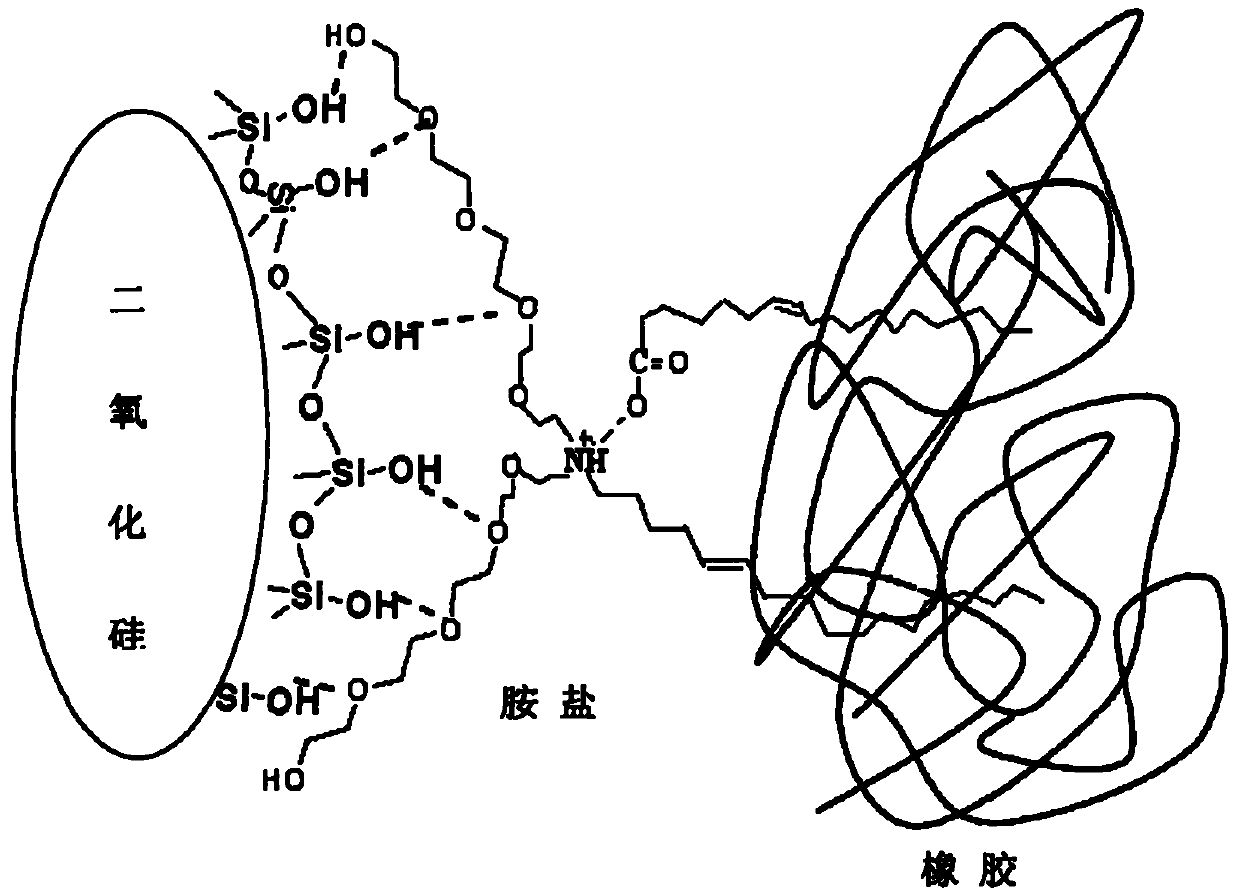

A rubber composition and rubber technology, applied in the field of pneumatic tires and tire tread rubber compositions, can solve problems such as difficult dispersion, difficult processing, and affecting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

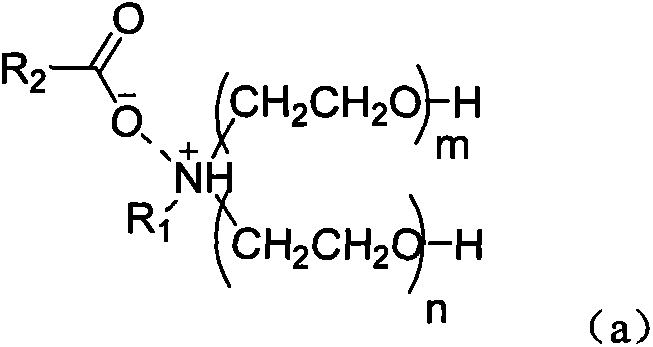

[0031] In a 500ml round-bottom flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.1mol of octadecylamine polyoxyethylene ether with the number of ethoxy groups m+n and 60 (provided by Nantong Aonuo Chemical Co., Ltd.) , 0.15mol of palmitic acid (provided by Tektronix (Zhangjiagang) Co., Ltd.), heated to 80°C to melt it all, added 50ml of ethanol, and then reacted in a reflux state until the solution was clear and transparent, changed to a distillation state to remove the solvent, cooled to below 60°C, The ammonium salt product was obtained.

[0032] 1.2 Preparation and performance test of rubber composition

[0033] 1.2.1 Sample preparation

[0034] According to the formula shown in Table 1, use a 1.6-liter Banbury internal mixer (produced by FARREL Company), mix rubber, silicon dioxide, and other compounds other than sulfur and vulcanization accelerators for 6 minutes and raise the temperature to 160 ° C to obtain master batch, and cool the master b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com