Liquid crystal polymer with ion groups and preparation method for liquid crystal polymer

A liquid crystal polymer, ionic group technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor compatibility of polymers of different polarities, phase separation of crystalline and amorphous polymers, and performance degradation, etc. Improved interface compatibility, low shrinkage, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

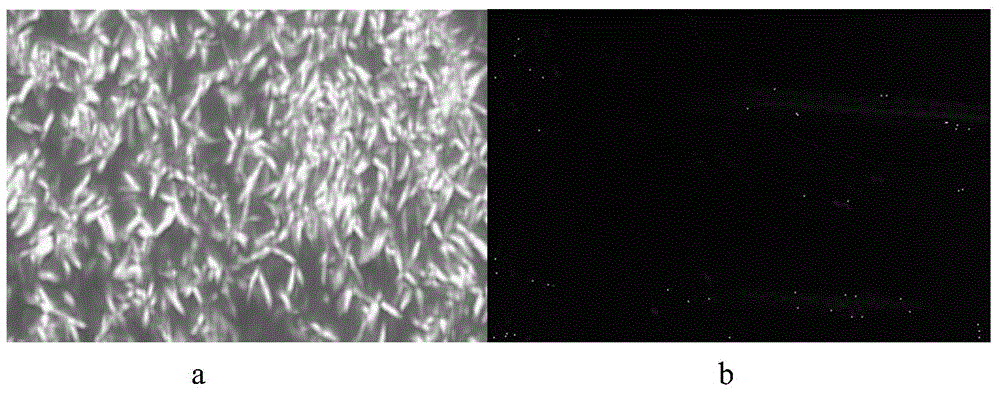

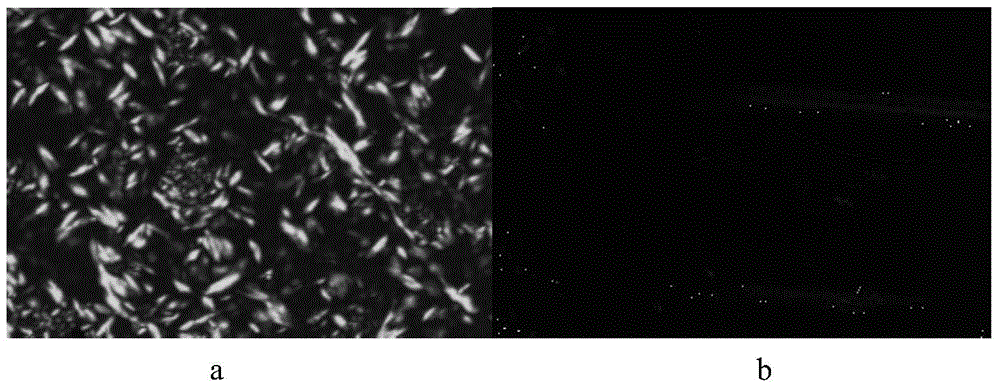

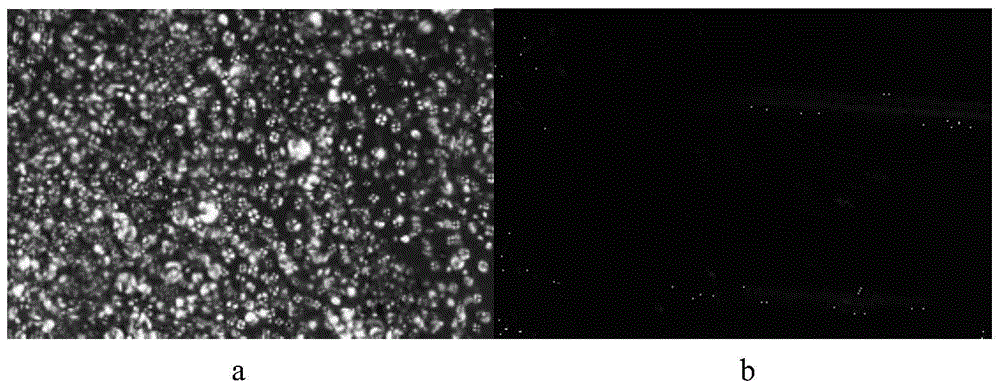

Image

Examples

Embodiment 1

[0041] (1), weigh 0.395mol of hydroquinone, 0.1mol of 4,4'-diphenol, 0.005mol of bright yellow, 0.4mol of adipoyl chloride and 0.1mol of terephthaloyl chloride, and set aside;

[0042] (2), hydroquinone, 4,4'-diphenol and bright yellow are dissolved in DMF, obtain mixed solution I;

[0043] (3), adding 79mL of pyridine into the mixed solution I to obtain the mixed solution II;

[0044] (4) Dissolve adipoyl chloride and terephthaloyl chloride in DMF, slowly add to the mixed solution II, stir for 30 minutes; raise the temperature to 110°C, react for 36 hours; obtain the mixed solution III;

[0045] (5) Add ethanol to the mixed solution III to precipitate, wash and filter for many times, and dry in vacuum to obtain a liquid crystal polymer with ionic groups, with a weight average molecular weight of 17,000.

Embodiment 2

[0047] (1), weighing 0.39mol of hydroquinone and 0.1mol of 1,4-butanediol, 0.01mol of bright yellow, 0.4mol of adipoyl chloride and 0.1mol of sebacoyl chloride, stand-by;

[0048] (2), hydroquinone, 1,4-butanediol and brilliant yellow are dissolved in DMF, obtain mixed solution I;

[0049] (3), adding 79mL of pyridine into the mixed solution I to obtain the mixed solution II;

[0050] (4) Dissolve adipoyl chloride and sebacoyl chloride in DMF, slowly add to the mixed solution II, stir for 30 minutes; raise the temperature to 110°C, react for 36 hours; obtain the mixed solution III;

[0051] (5) Add ethanol to the mixed solution III to precipitate, wash and filter for many times, and dry in vacuum to obtain a liquid crystal polymer with ionic groups, with a weight average molecular weight of 20,000.

Embodiment 3

[0053] (1), weigh the bisphenol A of 0.48mol, the bright yellow of 0.02mol, the adipoyl chloride of 0.4mol and the terephthaloyl chloride of 0.1mol, stand-by;

[0054] (2), bisphenol A and bright yellow are dissolved in solvent DMF, obtain mixed solution I;

[0055] (3), adding 79mL of pyridine into the mixed solution I to obtain the mixed solution II;

[0056] (4) Dissolve adipoyl chloride and terephthaloyl chloride in DMF, slowly add to the mixed solution II, stir for 30 minutes; raise the temperature to 110°C, react for 36 hours; obtain the mixed solution III;

[0057] (5) Add ethanol to the mixed solution III to precipitate, wash and filter for many times, and dry in vacuum to obtain a liquid crystal polymer with ionic groups, with a weight average molecular weight of 24,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com