A preparation method of hyperbranched polymer modified boron nitride thermally conductive and insulating composite material

A hyperbranched polymer and composite material technology, which is applied in the field of preparation of hyperbranched polymer modified boron nitride thermally conductive and insulating composite materials, can solve the problem of reducing the inherent thermal conductivity of BN fillers, limited thermal conductivity enhancement rate of composite materials, BN and Solve problems such as weak matrix interaction, achieve the effect of improving interfacial compatibility, excellent mechanical properties, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

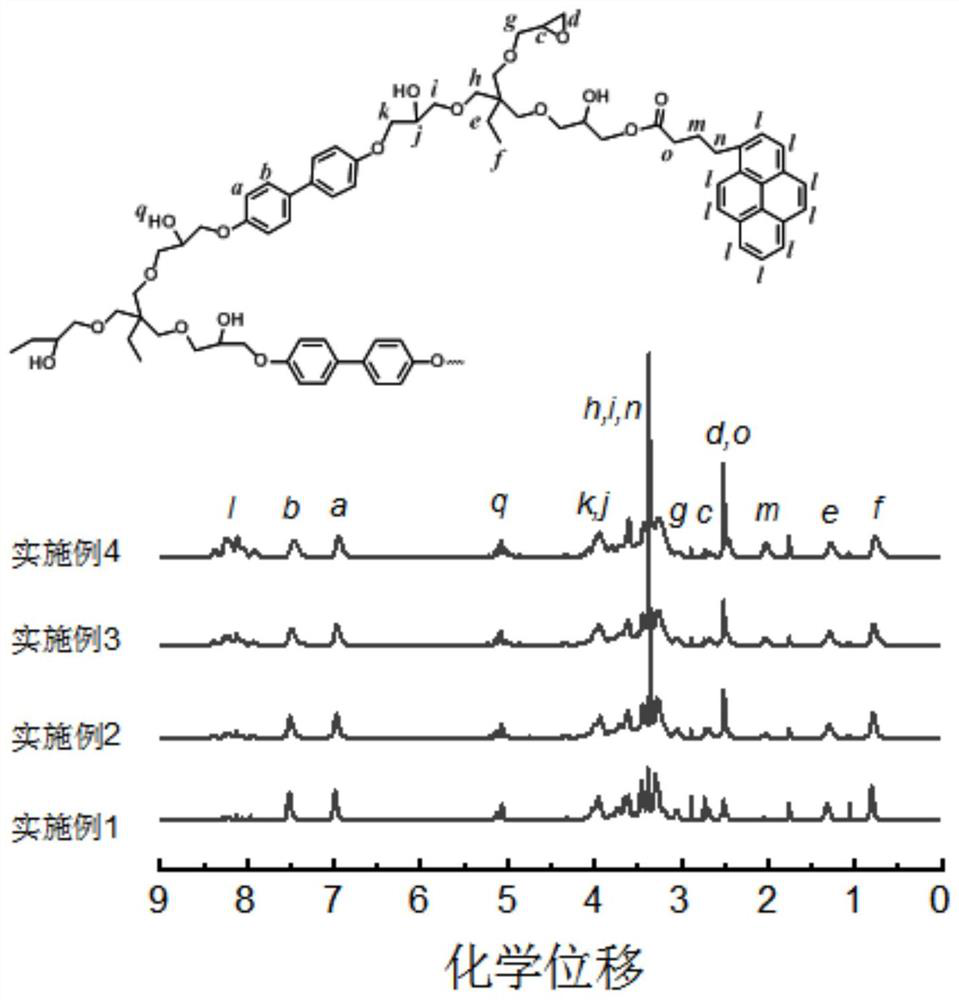

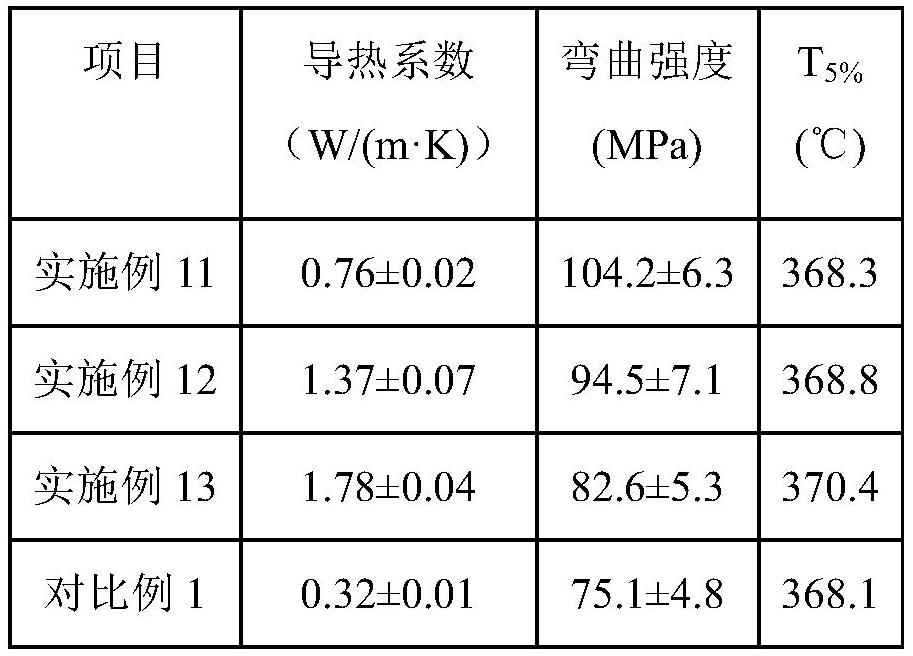

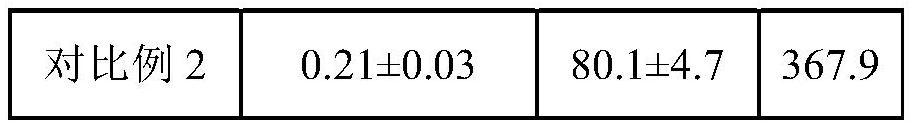

Embodiment 1

[0034] Embodiments 1 to 9 are methods for non-covalent modification of BN by using hyperbranched polymers containing both epoxy groups and polycyclic aromatic groups at the ends to obtain hyperbranched polymer-modified boron nitride; Examples 10-24 are methods for preparing thermally conductive and insulating composite materials by using hyperbranched polymer modified boron nitride in Example 1; Comparative Examples 1-4 are prepared by using unmodified boron nitride and commercial silica as thermally conductive fillers A method of thermally conducting insulating composite materials.

[0035] Example 1:

[0036] A preparation method of hyperbranched polymer modified boron nitride, comprising the steps:

[0037] (1) 4,4'-biphenol (3.73g, 20mmol), trimethylolpropane triglycidyl ether (18.14g, 60mmol) and tetrabutylammonium bromide (1.93g, 6mmol) were added in sequence In a single-necked flask, after reacting at 100 ° C for 6 hours, the epoxy value was titrated by the hydrochlor...

Embodiment 2

[0040] A preparation method of hyperbranched polymer modified boron nitride, comprising the steps:

[0041] (1) 4,4'-biphenol (3.73g, 20mmol), trimethylolpropane triglycidyl ether (18.14g, 60mmol) and tetrabutylammonium bromide (1.93g, 6mmol) were added in sequence In a single-necked flask, after reacting at 100 ° C for 6 hours, the epoxy value was titrated by the hydrochloric acid acetone method to 0.38, 1-pyrene butyric acid (4.46 g, 8.5 mmol) was added to the reaction mixture, and the system was continued at 100 ° C. The reaction was carried out for 4 hours.

[0042] After the reaction was over, it was precipitated in excess hot water to obtain a viscous yellow solid, which was then redissolved with THF. The above dissolution-precipitation was repeated three times, and finally the obtained precipitate was washed with a large amount of deionized water, and then vacuum-dried at 50° C. for 12 hours to obtain a hyperbranched polyether containing both epoxy groups and polycycli...

Embodiment 3

[0045] A preparation method of hyperbranched polymer modified boron nitride, comprising the steps:

[0046] (1) 4,4'-biphenol (3.73g, 20mmol), trimethylolpropane triglycidyl ether (18.14g, 60mmol) and tetrabutylammonium bromide (1.93g, 6mmol) were added in sequence In a single-necked flask, after reacting at 100 ° C for 6 hours, the epoxy value was titrated by the hydrochloric acid acetone method to 0.38, and 1-pyrene butyric acid (7.35 g, 25.5 mmol) was added to the reaction mixture, and the system continued at 100 ° C. The reaction was carried out for 4 hours. After the reaction was over, it was precipitated in excess hot water to obtain a viscous yellow solid, which was then redissolved with THF. The above dissolution-precipitation was repeated three times, and finally the obtained precipitate was washed with a large amount of deionized water, and then vacuum-dried at 50° C. for 12 hours to obtain a hyperbranched polyether containing both epoxy groups and polycyclic aromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com