Preparation method of inorganic-organic composite particle and its special-purpose equipment

A technology of organic polymers and composite particles, which is applied in the treatment of dyed polymer organic compounds, etc., can solve the problems of difficult control of process conditions, unstable product quality, and large footprint, and achieve surface smoothness and flatness. Compact, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

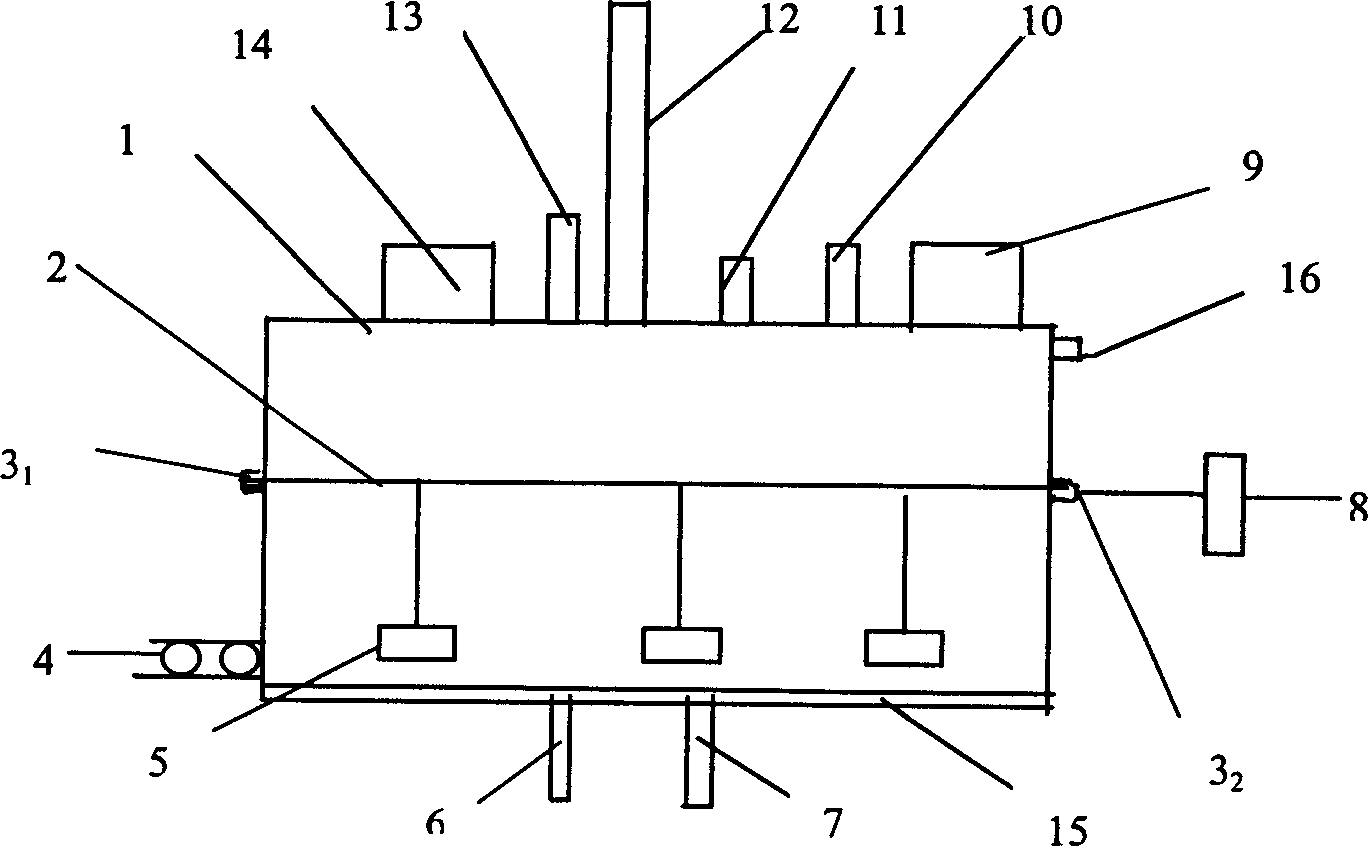

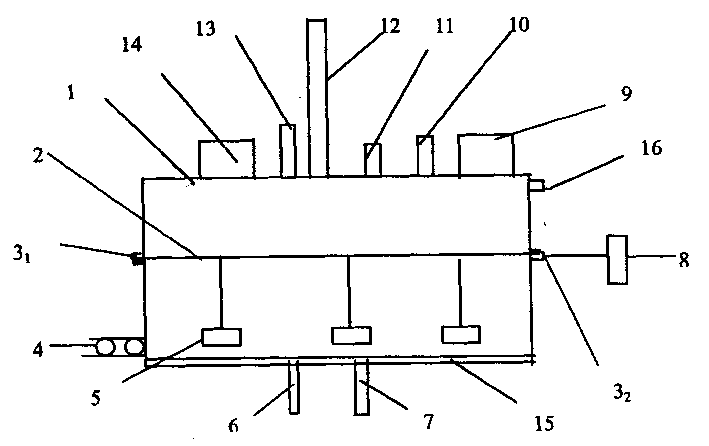

[0021] 1 Weigh 200Kg light calcium carbonate from the attached figure 1 Add it into the feeding hole of the reaction kettle shown, start the motor to stir, adjust the stirring speed to 50rpm, start heating at the same time, heat the reactant to 110°C, and maintain it at 110±5°C, and stir for 30min.

[0022] 2 Weigh 1.5 Kg of titanate coupling agent TMC-TTS (plant acid type monoalkoxy titanate) and 1.5 Kg of liquid paraffin, and mix them uniformly to obtain a coupling agent mixture.

[0023] 3 Add the coupling agent mixture obtained in step 2 into the reaction kettle, and stir at a stirring speed of 120 rpm for 70 min.

[0024] 4 Weigh 5Kg of stearic acid, break it into powder in advance, slowly add it into the reaction kettle, stir at 70±10rpm, stir for 40±10min.

[0025] 4 inspection. Take a sample of 10-20g reaction sample, add it to a round bottom flask equipped with a stirring device, add 600ml of distilled water, start stirring, stir at a stirring speed of 1000rpm for 1...

Embodiment 2

[0028] 1 Weigh 200Kg light calcium carbonate from the attached figure 1 Add it into the feeding hole of the reaction kettle shown, start the motor to stir, adjust the stirring speed to 50rpm, start heating at the same time, heat the reactant to 115°C, and maintain it at 110±5°C, and stir for 40min.

[0029] 2 Weigh 1.5Kg of titanate coupling agent TMC-TTS, 1.5Kg of liquid paraffin, mix uniformly, then add 5Kg of oleic acid, and further mix uniformly to obtain a modified mixed solution.

[0030] 3 Add the modified mixed solution obtained in step 2 into the reaction kettle, and stir for 150 min at a stirring speed of 115 rpmr.

[0031] 4 inspection. Take a sample of 20g of reaction sample, add it to a round bottom flask equipped with a stirring device, add 500ml of distilled water, start stirring, stir at a stirring speed of 500rpm for 20min, let stand for 10min, observe that there is no inorganic powder particle precipitation at the bottom of the flask, and the powder If the ...

Embodiment 3

[0034] 1 Weigh 200Kg light calcium carbonate from the attached figure 1 Add it into the feeding hole of the reaction kettle shown, start the motor to stir, adjust the stirring speed to 50rpm, start heating at the same time, heat the reactant to 110°C, and maintain it at 110±5°C, and stir for 30min.

[0035] 2 Weigh 1.0 Kg of KH-570 silane coupling agent (chemical name: γ-methacryloxypropyltrimethoxysilane) and 1.0 Kg of liquid paraffin, and mix them uniformly to obtain a coupling agent mixture.

[0036] 3 Adjust the temperature of the reactant to 95°C, adjust the stirring speed to 115rpm, and spray the coupling agent mixture obtained in step 2 evenly from the feeding hole of the reactor to the reactant in the reactor, and stir at 120rpm after spraying Speed stirring for 50min.

[0037] 4 Weigh 5Kg of stearic acid, break it into powder in advance, slowly add it into the reaction kettle, stir at 70±10rpm, stir for 40±10min.

[0038] 4 inspection. Sampling 20g reaction sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com