A kind of rubber composition for engineering tire tread and application

A technology of rubber composition and engineering tire, which is applied in the fields of rubber composition for tread of engineering tires and pneumatic tires, which can solve the problems affecting the service life and safety, accelerated aging of tires, increased wear, etc., and achieve good processing effect, Improved tear resistance and reduced processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

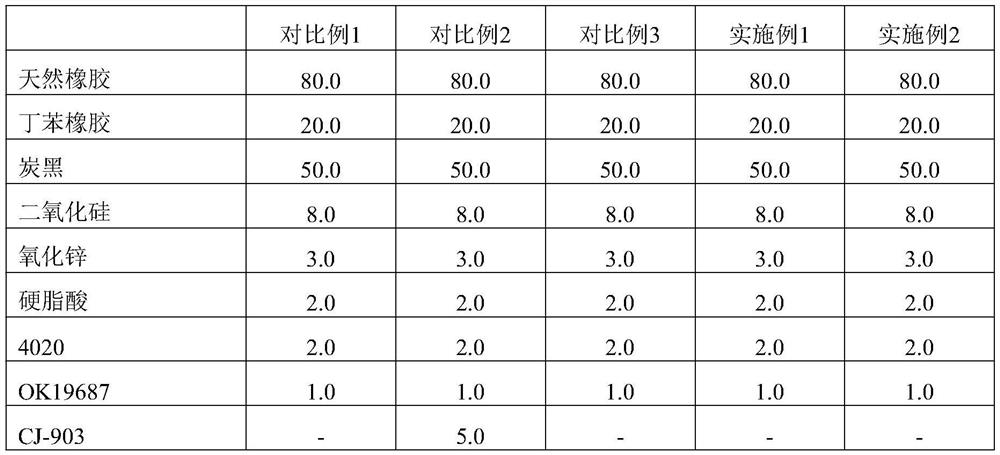

[0024] The present invention will be further explained below with examples, but the scope of the present invention is not limited to these examples, of course. Comparative Examples 1-6 and Examples 1-3.

[0025] Components and sources used in the examples and comparative examples are as follows:

[0026] Natural rubber, Yunnan 5# standard rubber

[0027] Styrene butadiene rubber, Shenhua Chemical Industry Co., Ltd.;

[0028] Silica, Evonik's highly dispersed silica VN3;

[0029] Silane coupling agent, Evonik's Si69;

[0030] Tear-resistant resin CJ-903, Changzhou Changjing Chemical Co., Ltd.;

[0031] Zinc Oxide, Dalian Zinc Oxide Factory;

[0032] Stearic acid, Tyko Browning;

[0033] Antiaging agent 4020, Jiangsu Sunon Chemical Co., Ltd.;

[0034] Protective wax OK19687, Bairuimei Special Materials Co., Ltd.;

[0035] Sulfur, Fengcheng Fuhua Chemical Co., Ltd.;

[0036] Accelerator CZ, Qingdao Huaheng Auxiliary Factory;

[0037] Accelerator DPG, Tianjin Organic Che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com