A kind of epoxy resin composition and its preparation method and application

A technology of epoxy resin and composition, which is applied in the field of epoxy resin composition and its preparation, can solve the problems affecting the reliability of power transmission, lack of synergy between mechanical properties and electrical properties, etc., and achieve improvement of casting process and settlement phenomenon , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

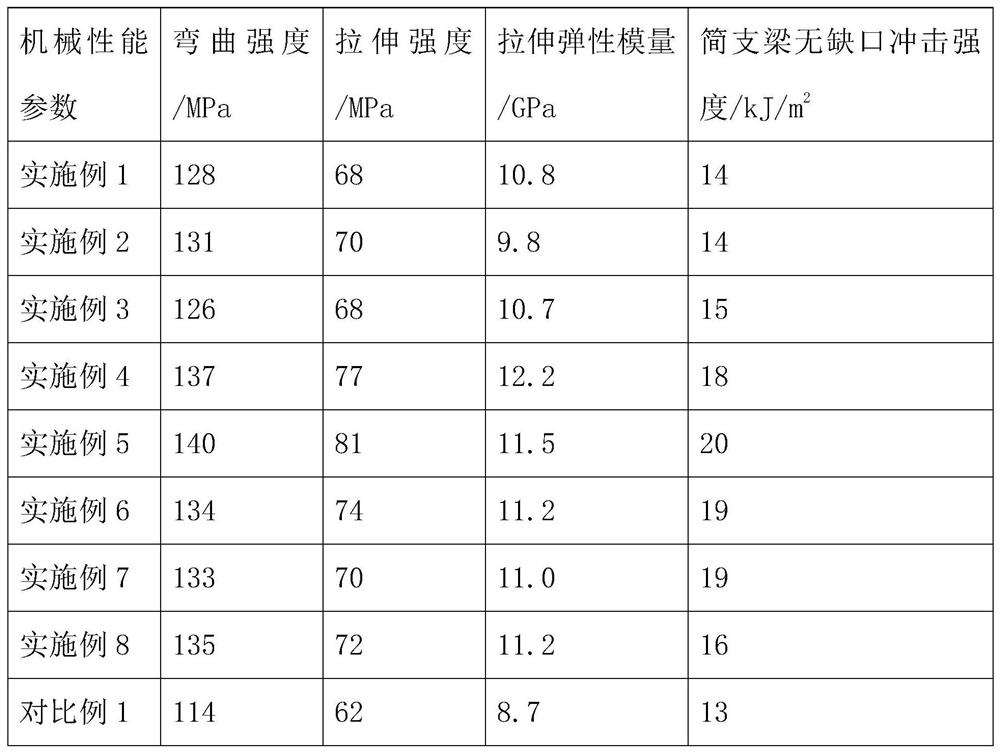

Examples

Embodiment 1

[0032] An epoxy resin composition comprising the following components: 66.6g of bisphenol A type epoxy resin, 33.4g of triphenyl glycidyl ether methane, 60g of methyltetrahydrophthalic anhydride, dimethylbenzylamine 0.3g, spherical α-Al 3 o 2 340 g of particles (the first particle fraction: the second particle fraction=7:3, the median diameter of the first particle fraction is 20, and the median diameter of the second particle fraction is 8), polybutadiene rubber particles 8g.

[0033] The preparation method of above-mentioned epoxy resin composition is as follows:

[0034] Preheat 66.6g of bisphenol A type epoxy resin and 33.4g of triphenylglycidyl ether methane in the same tank at 130°C for 4h, degas and stir for 0.5h, and spherical α-Al 3 o 2 146g of granules and 8g of polybutadiene rubber granules were added to the above-mentioned material tank, degassed and stirred for 3 hours, the above-mentioned degassed and stirred was carried out under a vacuum of 200Pa, and the s...

Embodiment 2

[0038] An epoxy resin composition comprising the following components: 66.6g of bisphenol A type epoxy resin, 33.4g of triphenyl glycidyl ether methane, 60g of methyltetrahydrophthalic anhydride, dimethylbenzylamine 0.3g, spherical α-Al 3 o 2 Particle 300g (the first particle fraction: the second particle fraction=7:3, the median diameter of the first particle fraction is 20, the median diameter of the second particle fraction is 8), fused silica powder 40g (in The position diameter is 15), polybutadiene rubber particles 8g.

[0039] The preparation method of above-mentioned epoxy resin composition is as follows:

[0040] Preheat 66.6g of bisphenol A type epoxy resin and 33.4g of triphenylglycidyl ether methane in the same tank at 130°C for 4h, degas and stir for 0.5h, and spherical α-Al 3 o 2 128g of granules, 18g of fused silicon micropowder and 8g of polybutadiene rubber granules were added to the above-mentioned material tank, and degassed and stirred for 3 hours. The ab...

Embodiment 3

[0044] An epoxy resin composition, comprising the following components: 50g of bisphenol A epoxy resin, 3,4-epoxy-6-methylcyclohexanecarboxylic acid-3′,4′-epoxy-6 - Methylcyclohexane methyl ester 50g, methyltetrahydrophthalic anhydride 47g, methylendomethylenetetrahydrophthalic anhydride 23g, dimethylbenzylamine 0.3g, spherical α-Al 3 o 2 Particle 320g (the first particle fraction: the second particle fraction=7:3, the median diameter of the first particle fraction is 20, the median diameter of the second particle fraction is 8), fused silica powder 40g (in The position diameter is 15), polybutadiene rubber particles 8g.

[0045] The preparation method of above-mentioned epoxy resin composition is as follows:

[0046] Bisphenol A type epoxy resin 50g and 3,4-epoxy-6-methylcyclohexanecarboxylic acid-3′,4′-epoxy-6-methylcyclohexanemethyl ester 50g in the same tank Preheat at 130℃ for 4h, degas and stir for 0.5h, spherical α-Al 3 o 2 150g of granules, 11g of fused silica pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com