A kind of modified calcium carbonate and its preparation method and application

A calcium carbonate and modification technology, which is applied in the field of modified calcium carbonate and its preparation, can solve the problems of small inert organic groups, weak force, and weak intermolecular force, so as to improve mechanical properties and increase filling capacity , Reduce the effect of processing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

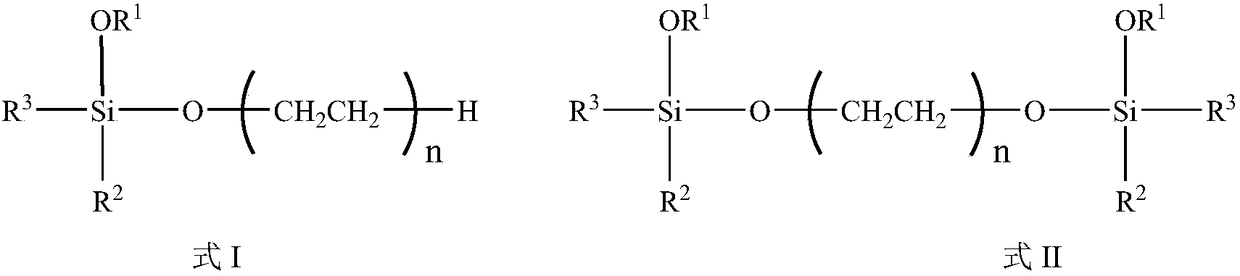

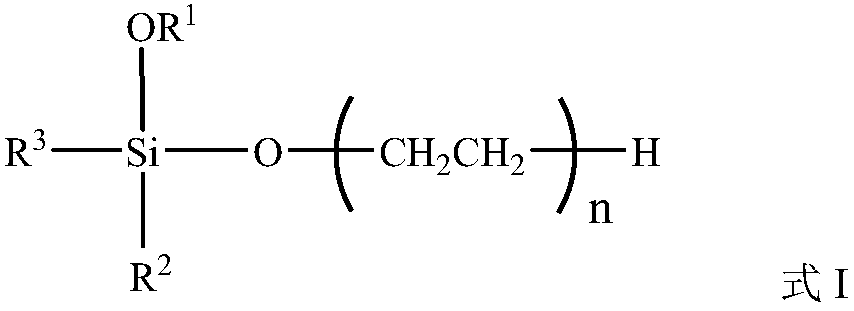

[0021] The calcium carbonate modifying agent used in the present embodiment is the mixture shown in formula I of structure, and wherein degree of polymerization n is 5; R 1 is methyl; R 2 is methoxy; R 3 for—CH 2 NH 2 or—CH 2 CH 2 NH 2 .

[0022]

[0023] The preparation method of the above-mentioned calcium carbonate modifier is: add 50 mass parts petroleum ether, 20 mass parts aminomethyl trimethoxysilane and 80 mass parts aminoethyl trimethoxysilane in the reactor, after stirring evenly, add 50 mass parts Parts by mass of single-ended hydroxyl polyethylene with a polymerization degree of 5, after reflux reaction at 60°C for 0.5h, distill off petroleum ether and produced methanol at 100°C, then heat up and distill under reduced pressure to remove unreacted aminomethyl Trimethoxysilane and aminoethyltrimethoxysilane, that is, aminoalkoxysilane modified with hydroxyl-terminated polyethylene, that is, modifier.

[0024] A kind of modified calcium carbonate, adopts ab...

Embodiment 2

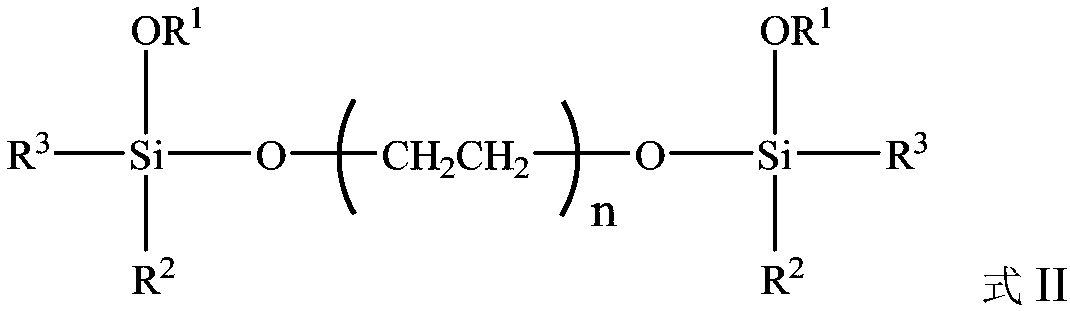

[0029] The calcium carbonate modifying agent structure used in the present embodiment is as shown in formula II, and wherein n is 120; R 1 is ethyl; R 2 is methyl; R 3 for—CH 2 CH 2 CH 2 NHCH 2 CH 2 NH 2 .

[0030]

[0031] The preparation method of the above-mentioned calcium carbonate modifier is: add 150 mass parts of n-hexane, 100 mass parts of N-aminoethyl-aminopropylmethyldiethoxysilane in the reactor, after stirring evenly, add 400 mass parts Double-ended hydroxyl polyethylene with a degree of polymerization of 120, after reflux reaction at 100°C for 8 hours, distill off the produced ethanol and n-hexane at 100°C, then heat up and distill under reduced pressure to remove unreacted N-aminoethyl- Aminopropylmethyldiethoxysilane, which is an aminoalkoxysilane modified by hydroxyl-terminated polyethylene.

[0032] A kind of modified calcium carbonate, adopts above-mentioned modifying agent to carry out modification gained, and concrete preparation method mainly ...

Embodiment 3

[0037] The structure of the calcium carbonate modifier used in this embodiment is shown in formula II, which is a mixture of two kinds of aminoalkoxysilanes modified by hydroxyl-terminated polyethylene, wherein modifier 1 is: n is 80, R 1 is ethyl, R 2 is ethoxy, R 3 for—CH 2 CH 2 CH 2 NH 2 , Modifier 2 is: n is 80, R 1 is ethyl, R 2 is methyl, R 3 for—CH 2 CH 2 CH 2 NH 2 .

[0038]The preparation method of the above-mentioned calcium carbonate modifier is: add 300 mass parts of toluene, 20 mass parts of tetrahydrofuran, 90 mass parts of aminopropyltriethoxysilane and 10 mass parts of aminopropylmethyldiethoxysilane in the reactor Silane, after stirring evenly, add 280 parts by mass of hydroxyl-terminated polyethylene with a degree of polymerization of 80, reflux at 70°C for 5 hours, distill out the ethanol, tetrahydrofuran and toluene at 100°C, then heat up The unreacted aminopropyltriethoxysilane and aminopropylmethyldiethoxysilane were distilled off under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com