High-heat-resistance PVC/ABS alloy material modified by nanometer calcium carbonate filling material and preparation method thereof

A technology of nano-calcium carbonate and alloy materials, which is applied in the field of high heat-resistant PVC/ABS alloy materials and their preparation, and can solve problems such as mechanical performance degradation, PVC fluidity deterioration, and unfeasible products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

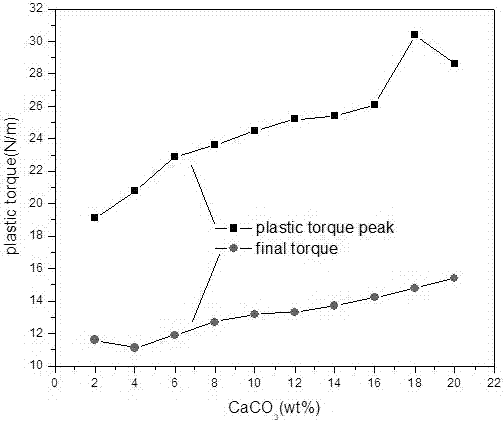

[0034] (1) The raw materials are configured according to the following mass parts: 78 parts of PVC, 10 parts of ABS; 6 parts of nano-calcium carbonate; 0.2 parts of pentaerythritol diphosphite; 1 part of calcium-zinc composite stabilizer; 1 part of methoxysilane; 2 parts of dioctyl dicarboxylate; 2 parts of glyceryl monostearate.

[0035] (2) Drying the mass parts of PVC at 80°C for 1 hour;

[0036] (3) Drying the mass parts of ABS at 80°C for 3 hours;

[0037] (4) Mechanically stir and mix the dried PVC / ABS with the aforementioned mass parts of nano-calcium carbonate, heat stabilizer, antioxidant, internal lubricant, and plasticizer for 20 minutes at a stirring rate of 5000 rpm;

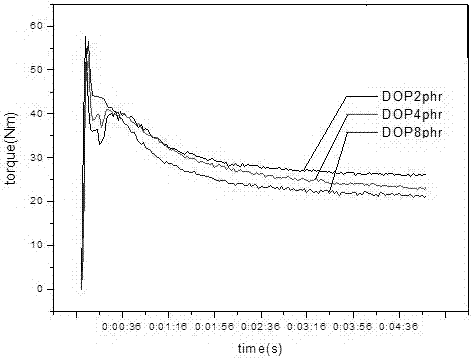

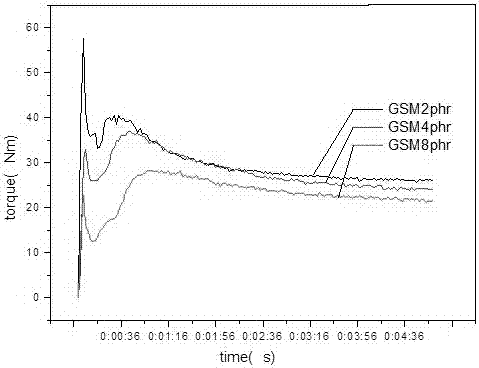

[0038] (5) Add the mixture in step (4) and the silane coupling agent in parts by mass to a torque rheometer for molding. The processing technology of the torque rheometer is as follows: the torque rheometer The heating zone is divided into three zones, and the temperature of the three heating zone...

Embodiment 2

[0045] (1) The raw materials are configured according to the following mass parts: 60 parts of PVC, 7 parts of ABS; 20 parts of nano-calcium carbonate; 0.3 parts of 2,8-di-tert-butyl-4-methylphenol; 2 parts of lead salt composite stabilizer; 1 part of epoxy silane; 5 parts of dioctyl phthalate; 5 parts of glyceryl monostearate.

[0046](2) Drying the mass parts of PVC at 75°C for 2 hours;

[0047] (3) Drying the mass parts of ABS at 80°C for 3 hours;

[0048] (4) Mechanically stir and mix the dried PVC / ABS with the aforementioned mass parts of nano-calcium carbonate, heat stabilizer, antioxidant, internal lubricant, and plasticizer for 30 minutes at a stirring rate of 5000 rpm;

[0049] (5) Add the mixture in step (4) and the silane coupling agent in parts by mass to a torque rheometer for molding. The processing technology of the torque rheometer is as follows: the torque rheometer The heating zone is divided into three zones, and the temperature of the three heating zones ...

Embodiment 3

[0056] (1) The raw materials are configured according to the following mass parts: 28 parts of PVC, 5 parts of ABS; 48 parts of nano-calcium carbonate; 0.3 parts of 2,8-di-tert-butyl-4-methylphenol; 1 part of OBS organic base stabilizer; Aminosilane, 2 parts; Dicapryl phthalate 8 parts; Glyceryl monostearate 8 parts.

[0057] (2) Drying the mass parts of PVC at 85°C for 2 hours;

[0058] (3) Drying the mass parts of ABS at 75°C for 4 hours;

[0059] (4) Mechanically stir and mix the dried PVC / ABS with the above mass parts of nano-calcium carbonate, heat stabilizer, antioxidant, internal lubricant, and plasticizer for 25 minutes at a stirring rate of 3000 rpm;

[0060] (5) Add the mixture in step (4) and the silane coupling agent in parts by mass to a torque rheometer for molding. The processing technology of the torque rheometer is as follows: the torque rheometer The heating zone is divided into three zones, and the temperature of the three heating zones is controlled at 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com