Epoxy resin and preparation method and application thereof

A technology of epoxy resin and methoxy, which is applied in the field of epoxy resin and its preparation, can solve the problems of restricting the application of crystalline epoxy resin, and achieve the effects of low dielectric loss, low processing viscosity and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 4'-(3-hydroxyphenoxy)biphenol

[0041] 1) Preparation of 4-methoxy-4'-hydroxybiphenyl

[0042] In a three-neck flask equipped with mechanical stirring, a condenser and a nitrogen inlet and outlet, 187.5 grams (1 mole) of 4,4'-dihydroxybiphenyl was dissolved in 500 milliliters of 10 wt% sodium hydroxide aqueous solution. At room temperature (25° C.), 90 g (1 mole) of methylating reagent dimethyl carbonate was added dropwise in 3 hours. After the reaction, the white solid was filtered and rinsed with 1000 ml of 10 wt% sodium hydroxide aqueous solution. The obtained solid was dissolved in boiling water, and the insoluble matter was removed by hot filtration. At 70°C, adjust the pH of the solution to ≤6 with 20 wt% hydrochloric acid. The resulting white solid was filtered and recrystallized from ethanol to give white crystals. The yield was 52%.

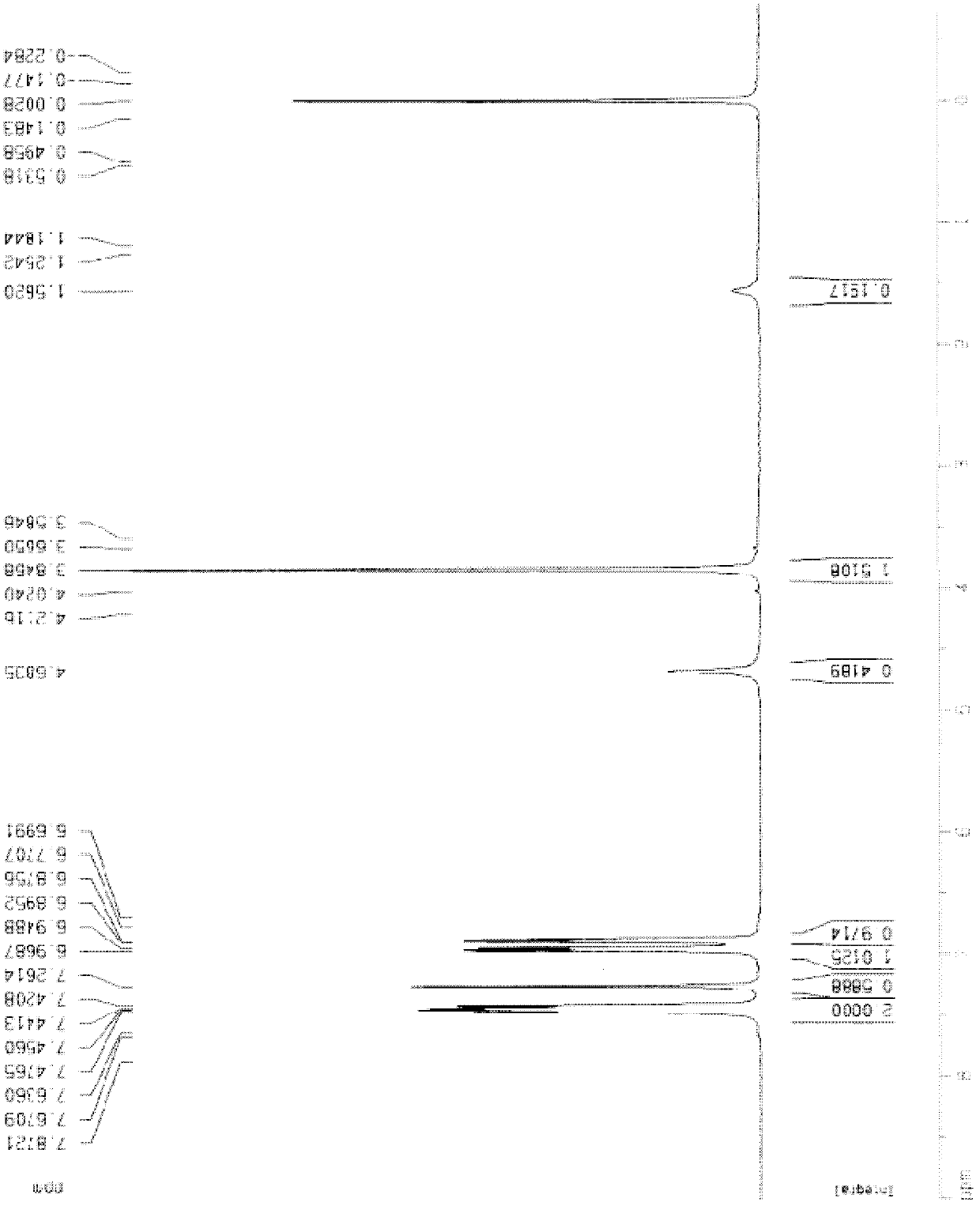

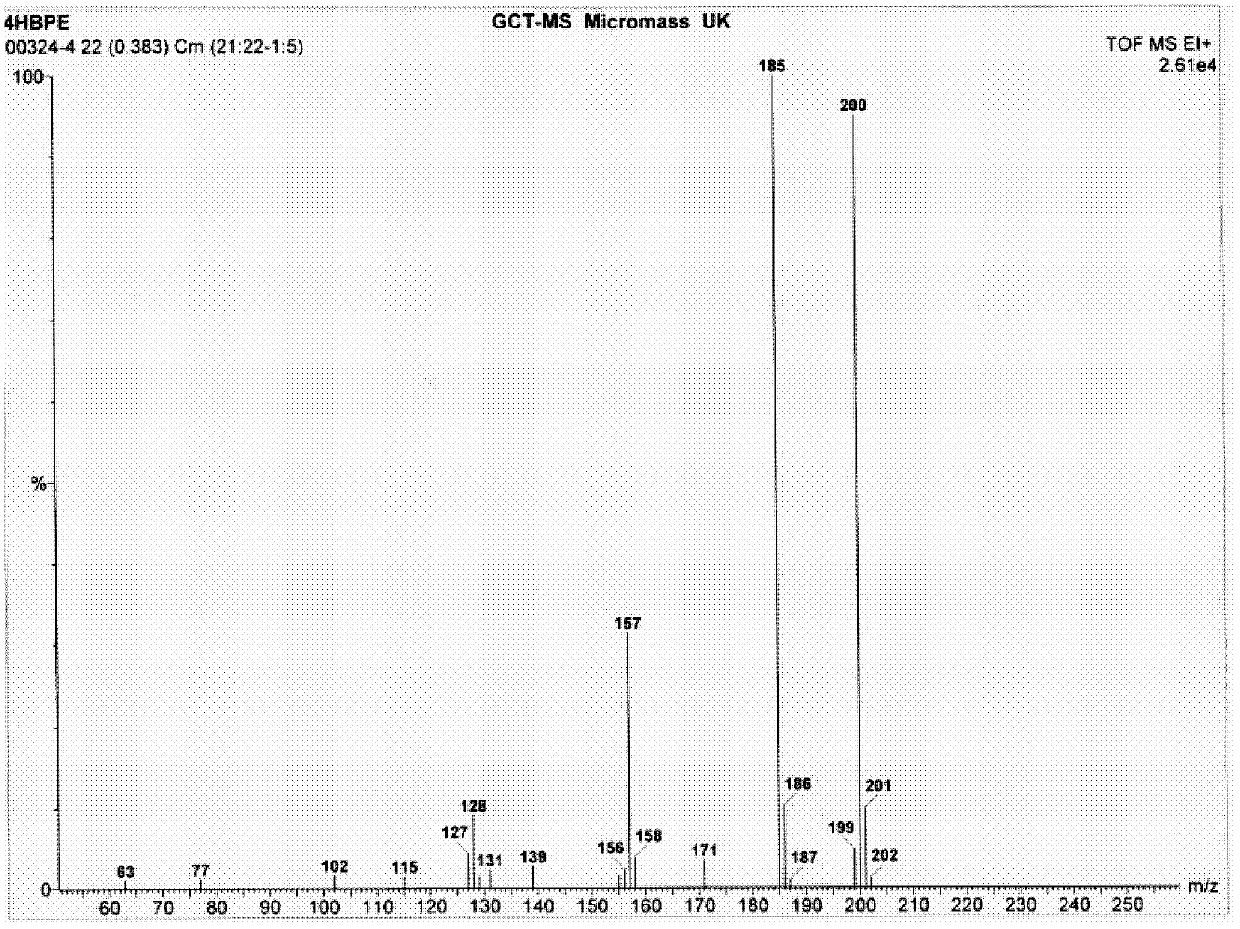

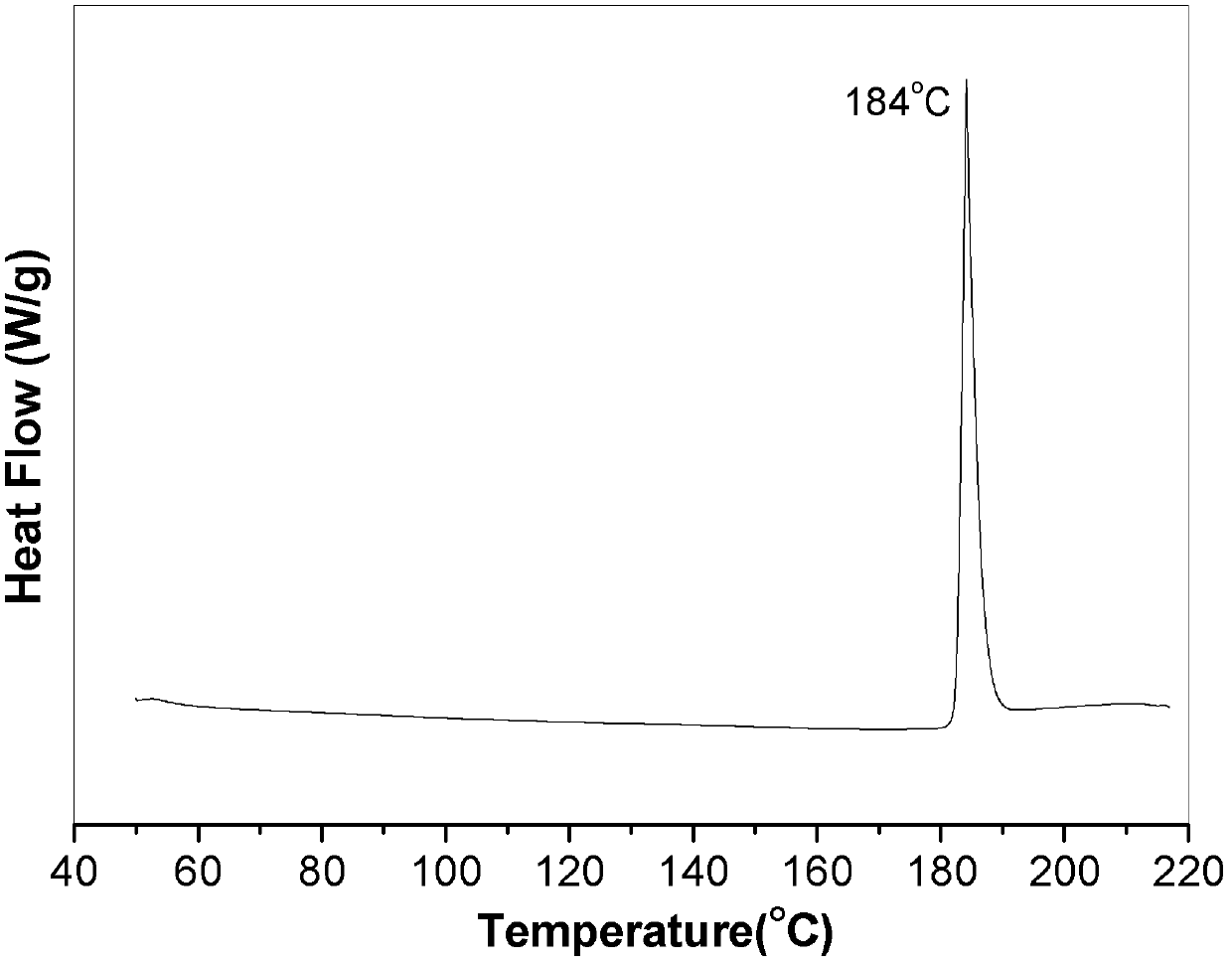

[0043] The structural detection data of this compound are as follows (the proton nuclear magnetic spectrum, mass ...

Embodiment 2

[0065] Example 2 4'-(3-hydroxyphenoxy)biphenol

[0066] 1) Preparation of 4-methoxy-4'-hydroxybiphenyl

[0067] In a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen inlet and outlet, 93.75 grams (0.5 moles) of 4,4'-dihydroxybiphenyl was dissolved in 500 milliliters of 10% wt sodium hydroxide aqueous solution. At room temperature (25° C.), 63 g (0.5 mol) of methylating reagent dimethyl sulfate was added dropwise in 3 hours. After the reaction, the white solid was filtered and rinsed with 500 ml of 10 wt% sodium hydroxide aqueous solution. The obtained solid was dissolved in boiling water, and the insoluble matter was removed by hot filtration. At 70°C, use 20%wt hydrochloric acid to adjust the pH of the solution to ≤6. The resulting white solid was filtered and recrystallized from ethanol to give white crystals. The yield is 55%.

[0068] The structural detection data of this compound are as follows (the proton nuclear magnetic spectrum, m...

Embodiment 3

[0087] Example 3 4'-(3-hydroxyphenoxy)biphenol

[0088] 1) Preparation of 4-methoxy-4'-hydroxybiphenyl

[0089] In a three-necked flask equipped with mechanical stirring, a condenser and a nitrogen inlet and outlet, 46.88 grams (0.25 moles) of 4,4'-dihydroxybiphenyl was dissolved in 250 milliliters of 8% wt potassium hydroxide aqueous solution. At room temperature (25° C.), 71 g (0.5 mol) of methylating reagent methyl iodide was added dropwise within 3 hours. After the reaction, the white solid was filtered and rinsed with 500 ml of 8 wt % potassium hydroxide aqueous solution. The obtained solid was dissolved in boiling water, and the insoluble matter was removed by hot filtration. At 70° C., adjust the pH of the solution to ≤6 with 18% wt hydrochloric acid. The resulting white solid was filtered and recrystallized from ethanol to give white crystals. The yield is 58%.

[0090] The structural detection data of this compound are as follows (the proton nuclear magnetic spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com