High-gloss polypropylene resin composition, preparation method and applications thereof

A polypropylene resin and high gloss technology is applied in the field of preparing high gloss polypropylene composite materials and high gloss polypropylene resin compositions. easy-to-shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

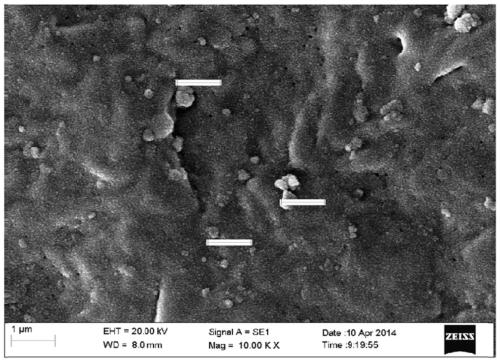

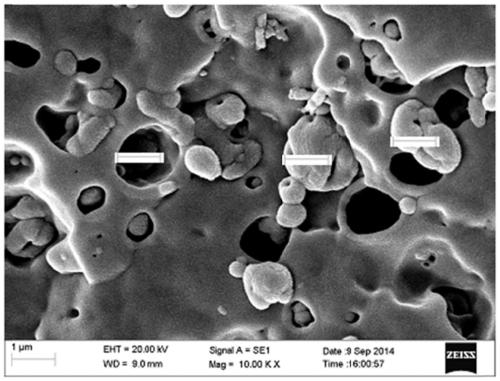

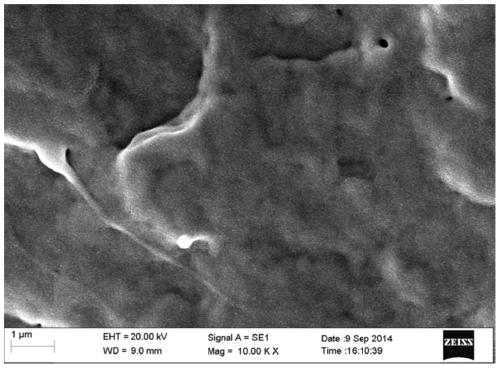

Image

Examples

preparation example 1-4

[0038]The following preparation examples 1-4 of the present invention are used to prepare the high-gloss polypropylene matrix resin, that is, the synthesis of the polypropylene polymer is carried out by using a 70,000 tons / year double-loop pipe-single gas phase reactor Sphripol polymerization device, And using a twin-screw extruder to add selected additives to prepare the required high-gloss polypropylene matrix resin. In the polymer preparation device, a conventional amount of Ziegler-Natta catalyst is used, and a D-Donor type electron donor is provided.

[0039] In the following preparation examples 1-4, the specific preparation methods of the high-gloss polypropylene matrix resin include:

[0040] (1) Pass into ethylene, propylene and hydrogen in the double loop pipe liquid phase reactor, carry out random copolymerization, form ethylene-propylene random copolymer;

[0041] (2) Transporting the gained ethylene-propylene random copolymer to the gas phase reactor, continuing ...

Embodiment 1

[0057] The high gloss polypropylene resin material described in this embodiment, its preparation raw material comprises the component of following mass content:

[0058]

[0059] The preparation method of the polypropylene resin described in this example includes mixing each component according to the above-mentioned selected content ratio, and performing conventional resin extrusion granulation through a twin-screw extruder.

Embodiment 2

[0061] The high gloss polypropylene resin material described in this embodiment, its preparation raw material comprises the component of following mass content:

[0062]

[0063] The preparation method of the polypropylene resin described in this example includes mixing each component according to the above-mentioned selected content ratio, and performing conventional resin extrusion granulation through a twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com