Preparation method for black abrasion-resistant micro-arc oxidization ceramic layer of magnesium alloy

A micro-arc oxidation, magnesium alloy technology, applied in anodizing, coating, surface reaction electrolytic coating and other directions, can solve the problems of cumbersome process, uneven color, easy to fall off, etc., achieve simple process, obvious industrial value, Strong corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

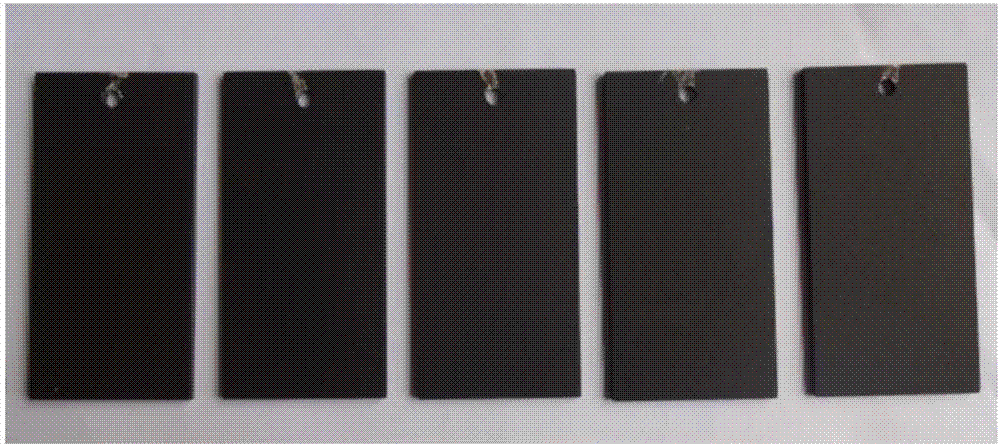

Embodiment 1

[0022] The parts to be processed are AZ80 test pieces (100mm×50mm×3mm), and the specific operation steps are as follows:

[0023] (1) Pretreatment: Use sandblasting to clean the surface of the parts, then wash with water to remove residues, and use ultrasonic waves to degrease in absolute ethanol, and finally clean with deionized water and dry with hot air.

[0024] (2) Solution configuration: sodium silicate 12g / L, potassium fluoride 8g / L, potassium hydroxide 15g / L, triethanolamine 15ml / L, ammonium metavanadate 2g / L, sodium orthovanadate 6g / L, nano SiC 5g / L, nano-graphite 3g / L.

[0025] (3) Micro-arc oxidation: Clamp the pretreated parts on the anode and immerse them all in the electrolyte. The parameters of micro-arc oxidation are: voltage 400V, frequency 600Hz, duty cycle 20%, oxidation time 25min. During the micro-arc oxidation process, the electrolyte was continuously stirred and cooled with circulating water, and the measured temperature of the electrolyte was 35°C.

...

Embodiment 2

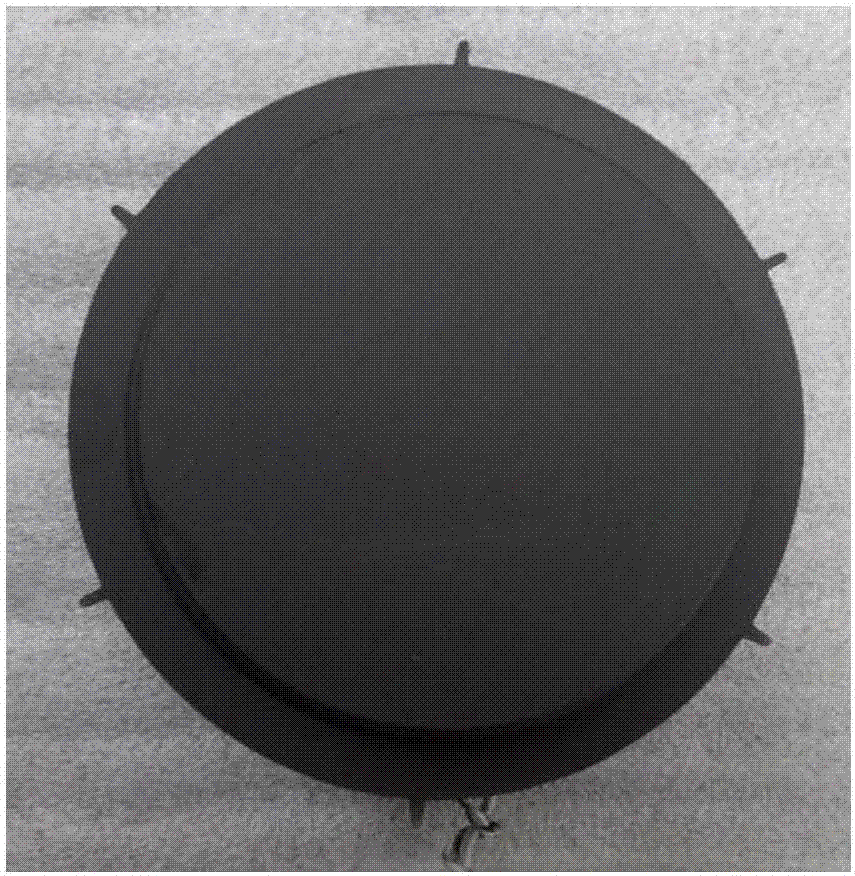

[0029] The part to be processed is the ZK60 sealing cover, and the specific operation steps are as follows:

[0030] (1) Pretreatment: Use sandblasting to clean the surface of the parts, then wash with water to remove residues, and use ultrasonic waves to degrease in absolute ethanol, and finally clean with deionized water and dry with hot air;

[0031] (2) Solution configuration: sodium silicate 5g / L, potassium fluoride 15g / L, potassium hydroxide 25g / L, triethanolamine 5ml / L, ammonium metavanadate 6g / L, sodium orthovanadate 2g / L, nano SiC 6g / L, nano-graphite 2g / L.

[0032] (3) Micro-arc oxidation: Clamp the pretreated parts on the anode and immerse them all in the electrolyte. The parameters of micro-arc oxidation are: voltage 550V, frequency 600Hz, duty cycle 35%, oxidation time 20min. During the micro-arc oxidation process, the electrolyte was continuously stirred and cooled by circulating water, and the actual temperature of the electrolyte was 28°C.

[0033] (4) Post-pr...

Embodiment 3

[0036] The part to be processed is the AZ80 rear sphere, and the specific operation steps are as follows:

[0037] (1) Pretreatment: Use sandblasting to clean the surface of the parts, then wash with water to remove residues, and use ultrasonic waves to degrease in absolute ethanol, and finally clean with deionized water and dry with hot air;

[0038] (2) Solution configuration: sodium silicate 5g / L, potassium fluoride 10g / L, potassium hydroxide 40g / L, triethanolamine 10ml / L, ammonium metavanadate 2g / L, sodium orthovanadate 6g / L, nano SiC 4g / L, nano-graphite 2g / L.

[0039] (3) Micro-arc oxidation: Clamp the pretreated parts on the anode and immerse them all in the electrolyte. The parameters of micro-arc oxidation are: voltage 550V, frequency 400Hz, duty cycle 20%, oxidation time 35min. During the micro-arc oxidation process, the electrolyte was continuously stirred and cooled with circulating water, and the measured temperature of the electrolyte was 35°C.

[0040] (4) Post-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com