Patents

Literature

43 results about "Sodium orthovanadate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium orthovanadate is the inorganic compound with the chemical formula Na₃VO₄·2H₂O (sodium orthovanadate dihydrate). It is a salt of the VO³⁻₄ oxyanion. It is a colorless, water-soluble solid.

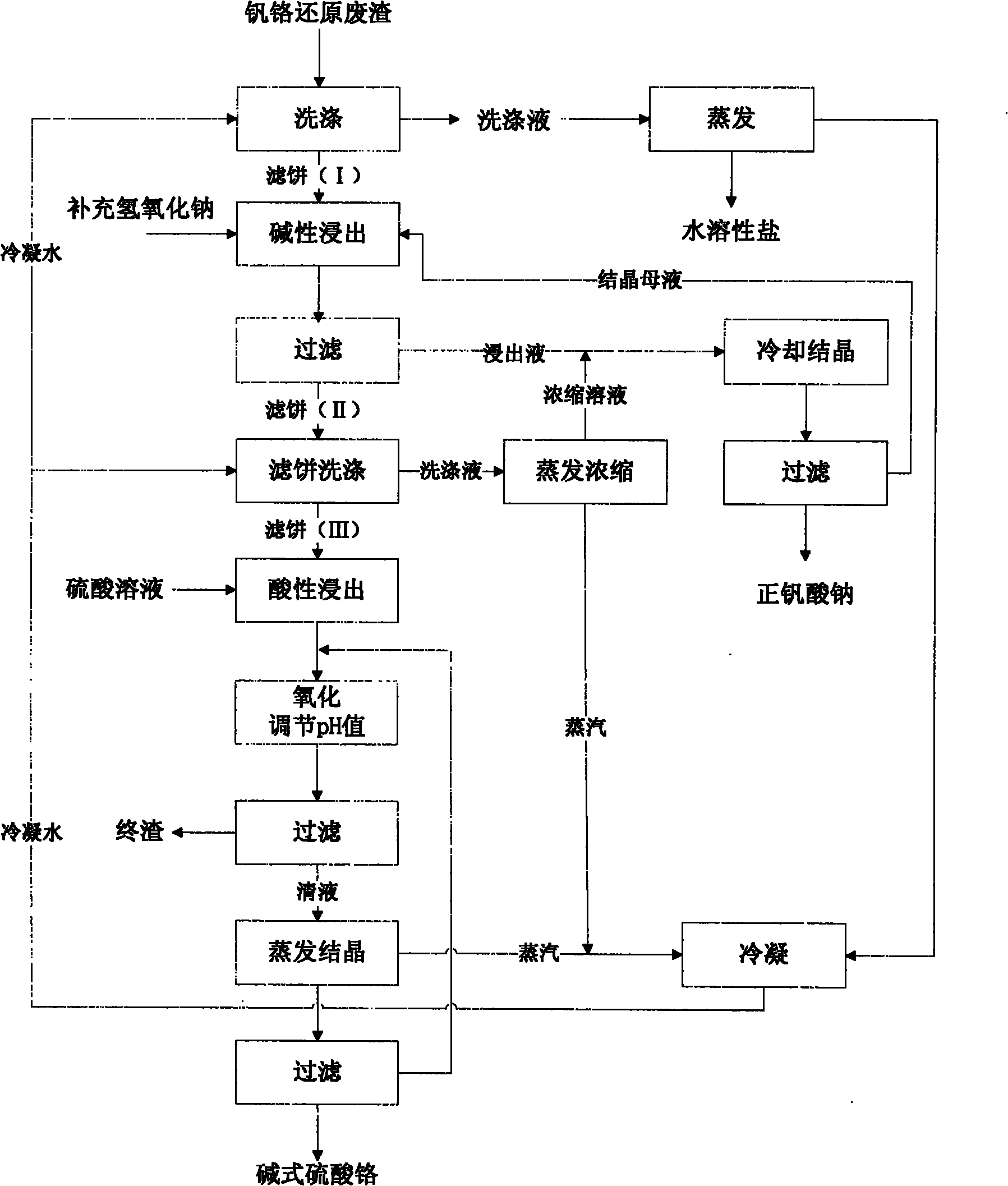

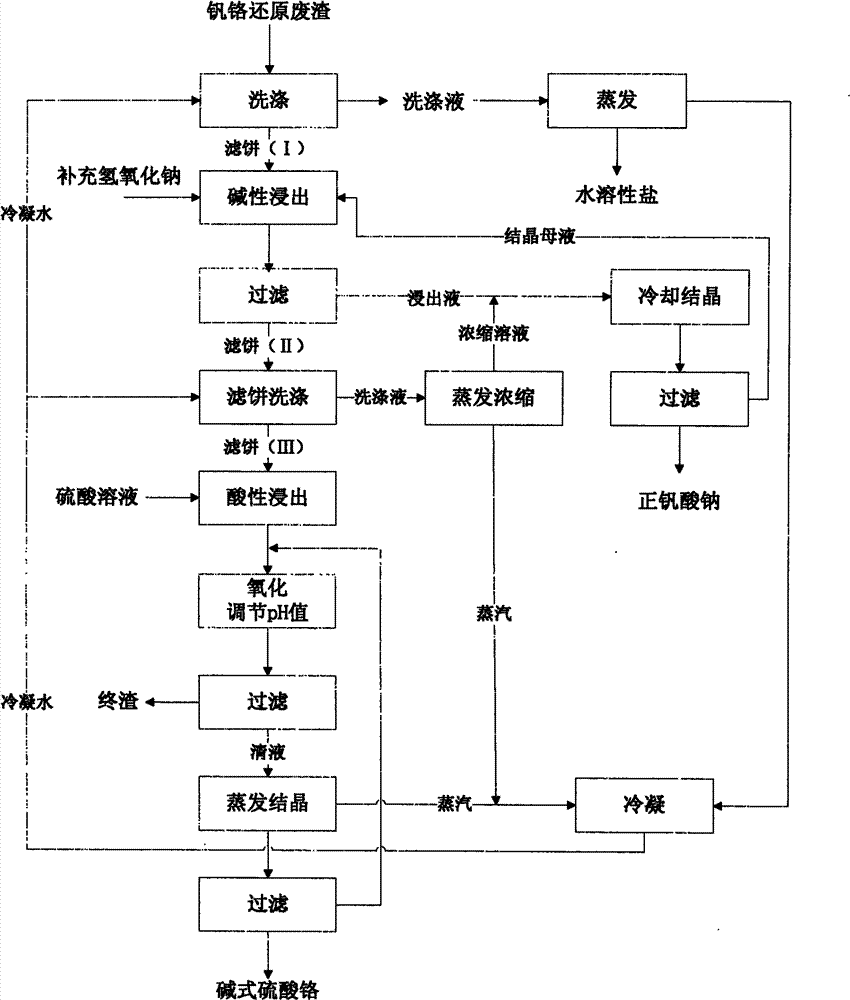

Method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue

ActiveCN102329964ASimple processEase of industrial productionProcess efficiency improvementWater solubleSodium orthovanadate

The invention relates to a method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue. The method comprises the following main steps of: after removing water-soluble salts through slurrying and washing, extracting vanadium from the rest vanadium-chromium reduced waste residue by oxidizing in an alkaline solution; meanwhile, realizing the vanadium-chromium separation; cooling and crystallizing a leaching solution to obtain obtaining a sodium orthovanadate product; carrying out acid leaching on the vanadium-chromium reduced waste residue subjected to vanadium extraction; and preparing a basic chromium sulfate product after removing impurities, evaporating and crystallizing. According to the invention, the purity of the sodium orthovanadate product prepared by the method is higher than 93%, the content of Cr2O3 in the basic chromium sulfate can reach 24%, the content of Fe is lower than 0.1%, and the requirements on the basic chromium sulfate I type product in the HG / T 2678-2007 are met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

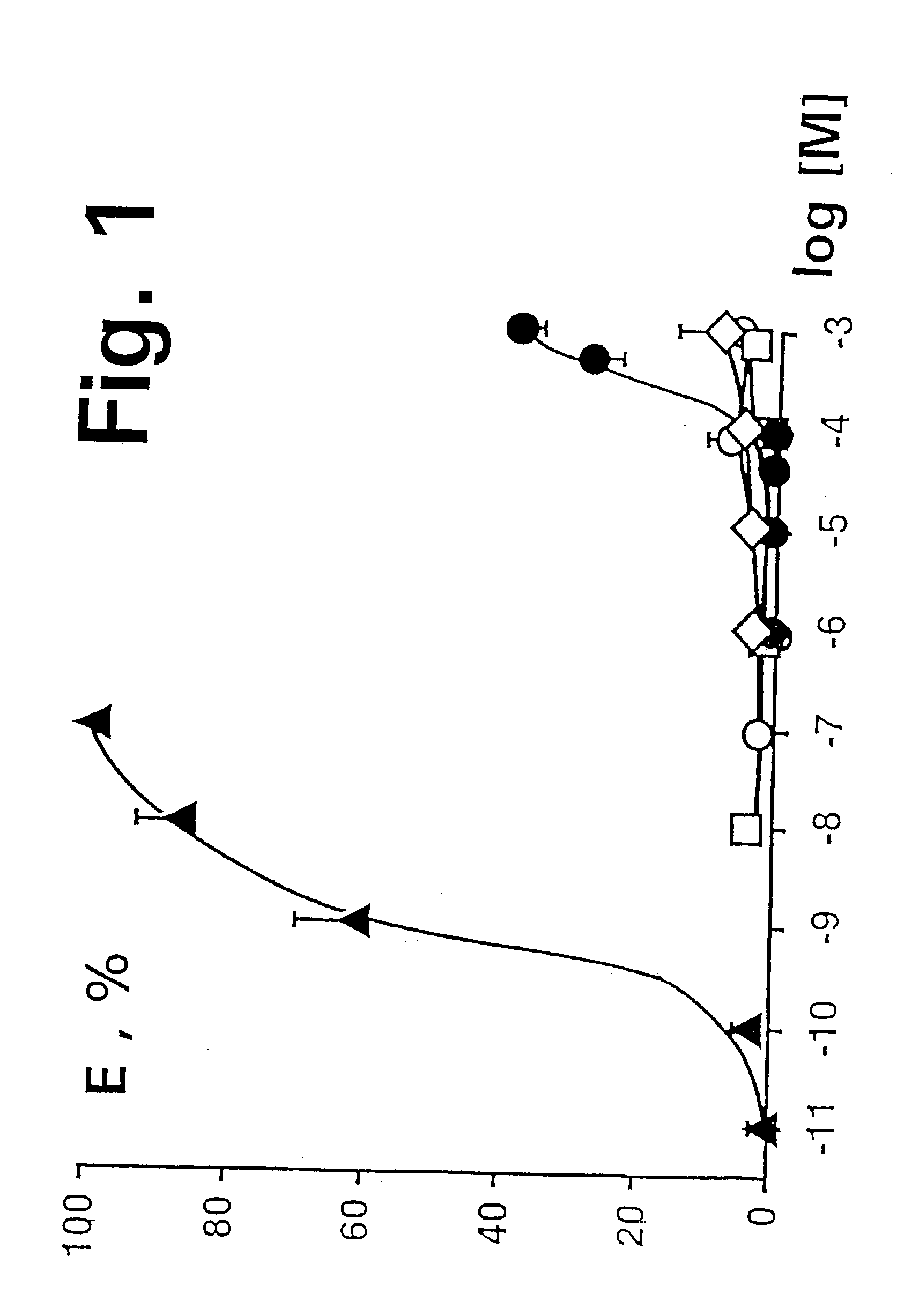

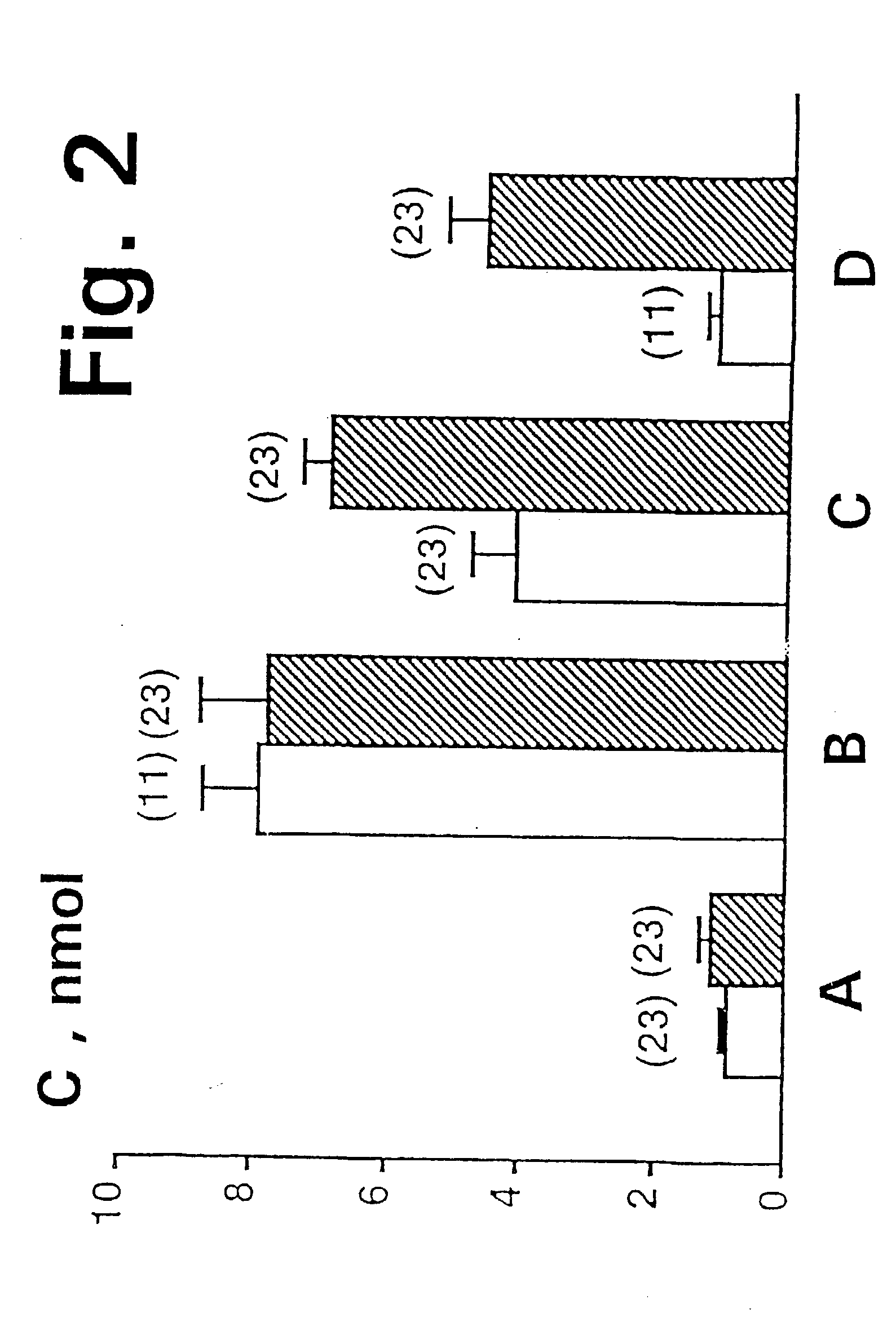

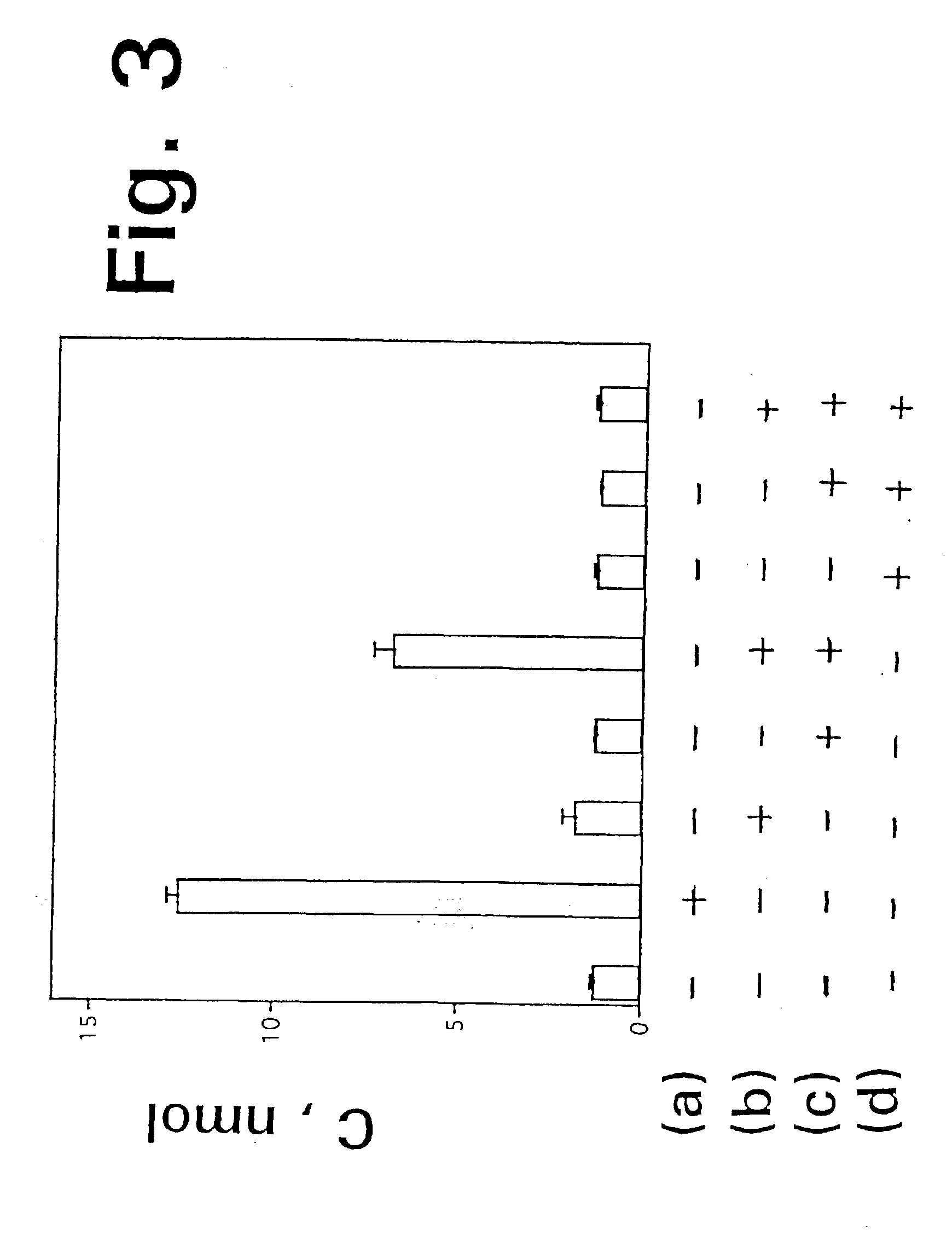

Combination of amines and vanadium (IV)/(V) compounds for the treatment and/or prevention of diabetes mellitus

Combinations comprising vanadium (IV) / (V) compounds and pharmaceutically acceptable amines selected from the group of semicarbazide-sensitive amine oxidase (SSAO) substrates are insulin mimickers. Preferred vanadium (IV) / (V) compounds are vanadyl salts, vanadyl complexes and vanadates (e.g. sodium orthovanadate). Preferred amines are tyramine and benzylamine. A here-discovered synergism between the vanadium compound and the amine makes the effective concentration of vanadate in the combination one order of magnitude lower than the corresponding of vanadate alone. Consequently the combination has much lower toxicity than the known vanadium compound alone, which is a crucial advantage of the former for its use in the treatment and / or prevention of Diabetes mellitus.

Owner:UNIV DE BARCELONA

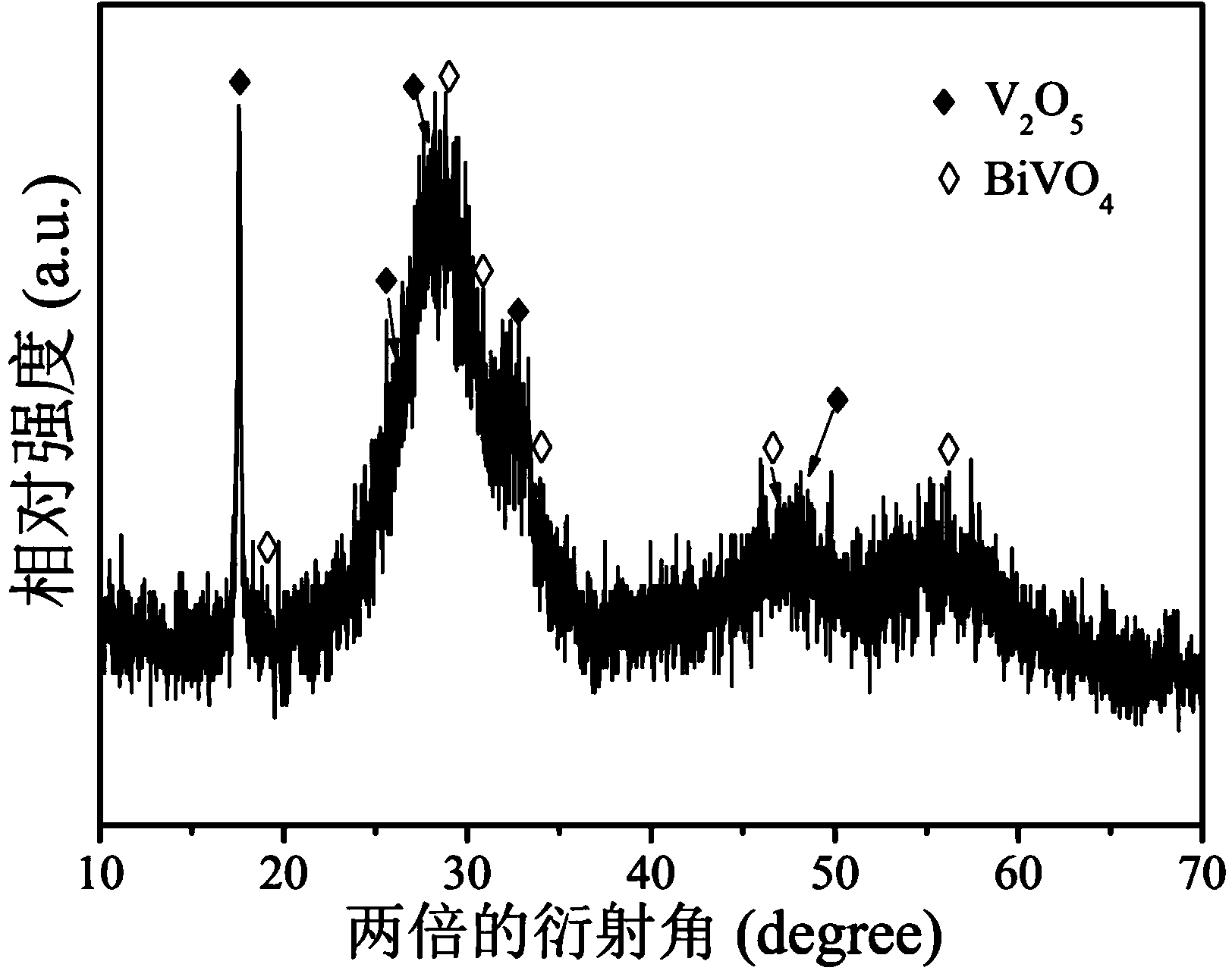

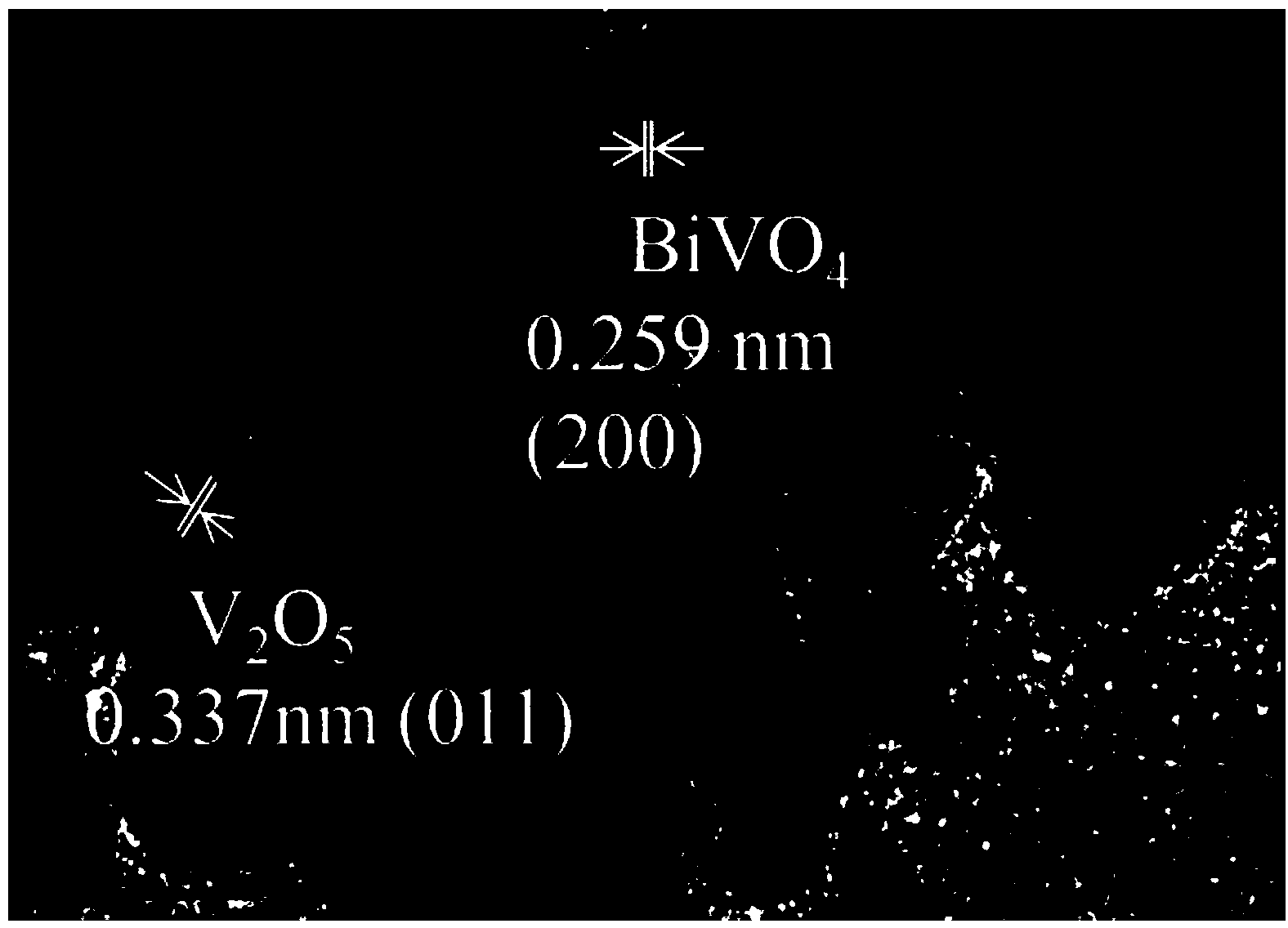

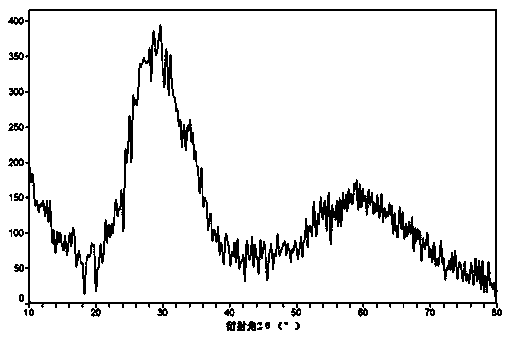

Preparation method of V2O5/BiVO4 (vanadium pentoxide/bismuth vanadium oxide) nanorod composite photocatalyst

InactiveCN103908960AStrong photoresponseHigh catalytic activityMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsVanadium oxideLight response

The invention discloses a preparation method of a V2O5 / BiVO4 (vanadium pentoxide / bismuth vanadium oxide) nanorod composite photocatalyst, anf belongs to the technical field of pollution control. The method comprises the steps of preparing a sodium oleate solution and a Na3VO4 (sodium orthovanadate) solution firstly, adding Bi(NO3)3.5H2O (bismuth nitrate pentahydrate) into the sodium oleate solution while stirring violently, then adding the Na3VO4 solution into a mixed solution of Bi(NO3)3 and sodium oleate, transferring into a reaction still for hydrothermal reaction, cooling a sample, extracting liquid supernatant with acetone, separating, washing the sample with cyclohexane and ethyl alcohol, separating, and drying under a vacuum condition, so as to obtain the V2O5 / BiVO4 nanorod composite photocatalyst. The V2O5 / BiVO4 composite semiconductor photocatalyst has the strong visible light response and the high catalytic activity and has the good application value and application prospect in the field of degradation of organic pollutants.

Owner:DALIAN UNIV OF TECH

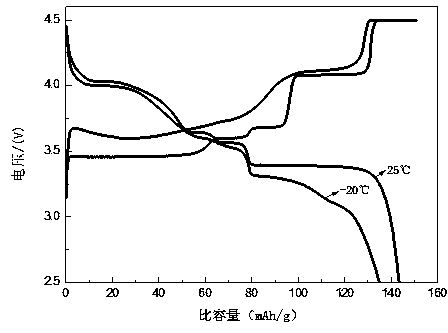

Preparation method of precursor of lithium iron phosphate-lithium vanadium phosphate composite

ActiveCN103833083AWide variety of sourcesSimple processIron compoundsPhosphorus compoundsVanadateOxide

The invention relates to a preparation method of a precursor of a lithium iron phosphate-lithium vanadium phosphate composite. The preparation method comprises the following steps of (1) placing graphene oxide turbid liquid with the mass percentage of 1-3% into a stirring reaction kettle with an ultrasonic device to carry out ultrasonic treatment for 0.2-2.0h; (2) simultaneously adding 0.08-0.12mol / L ferric sulfate solution and 0.16-0.24mol / L sodium orthovanadate into the stirring reaction kettle at the speed of 200-600mL / h, controlling the stirring speed at 50-400rpm, regulating the pH value of the solution to 2-8 by using ammonium hydroxide, and reacting for 0.5-4.0h; (3) adding polyaniline, stirring, ageing, filtering, cleaning and drying to obtain the precursor. According to the invention, the precursor of the lithium iron phosphate-lithium vanadium phosphate composite, which is synthesized through the in-situ growing of ferric vanadate on graphene oxide, is fine and uniform in particle; the electrochemical properties of the synthesized lithium iron phosphate-lithium vanadium phosphate composite cathode material are excellent.

Owner:CENT SOUTH UNIV

Method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue

ActiveCN102329964BSimple processEase of industrial productionProcess efficiency improvementWater solubleSodium orthovanadate

The invention relates to a method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue. The method comprises the following main steps of: after removing water-soluble salts through slurrying and washing, extracting vanadium from the rest vanadium-chromium reduced waste residue by oxidizing in an alkaline solution; meanwhile, realizing the vanadium-chromium separation; cooling and crystallizing a leaching solution to obtain obtaining a sodium orthovanadate product; carrying out acid leaching on the vanadium-chromium reduced waste residue subjected to vanadium extraction; and preparing a basic chromium sulfate product after removing impurities, evaporating and crystallizing. According to the invention, the purity of the sodium orthovanadate product prepared by the method is higher than 93%, the content of Cr2O3 in the basic chromium sulfate can reach 24%, the content of Fe is lower than 0.1%, and the requirements on the basic chromium sulfate I type product in the HG / T 2678-2007 are met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

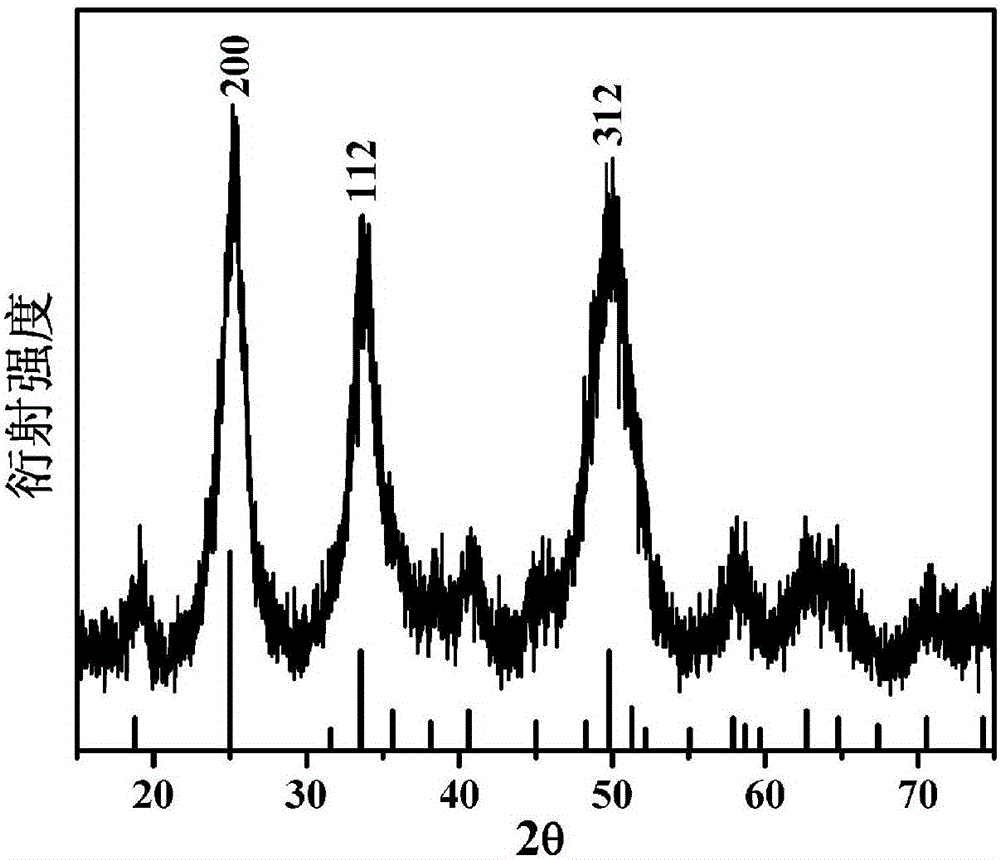

Yttrium vanadate nanoparticles, rare earth ion-doped yttrium vanadate nanoparticles and preparation method of yttrium vanadate nanoparticles and rare earth ion-doped yttrium vanadate nanoparticles

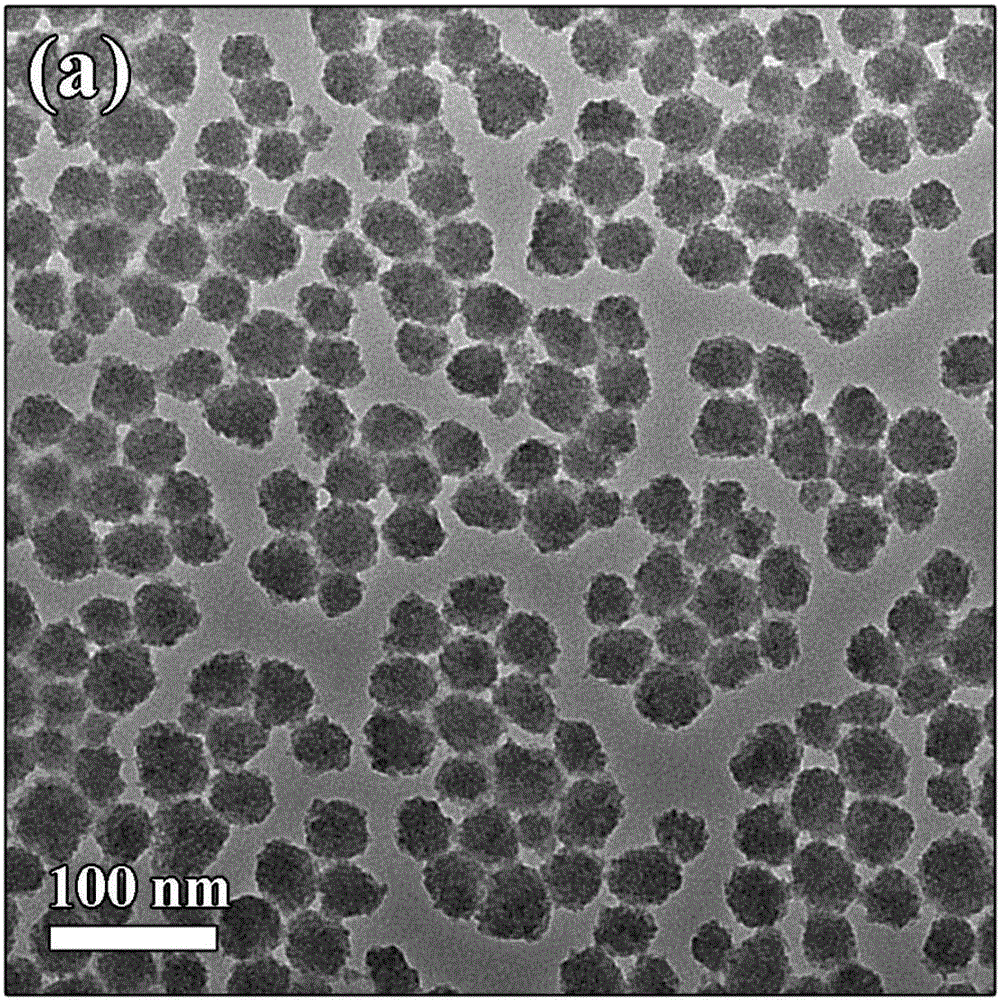

InactiveCN105733584AGood water solubilityControl shapeNanoopticsLuminescent compositionsSolubilityFluorescence

The invention provides yttrium vanadate nanoparticles, rare earth ion-doped yttrium vanadate nanoparticles and a preparation method of the yttrium vanadate nanoparticles and the rare earth ion-doped yttrium vanadate nanoparticles, and belongs to the technical field of fluorescent nanomaterials.The preparation method comprises the steps that sodium orthovanadate dodecahydrate, rare-earth chloride hexahydrate, polyacrylic acid and water are mixed according to a certain proportion, pH is regulated, reacting under stirring is performed at room temperature, or the mixture is transferred into a three-necked bottle to be subjected to a reaction at the temperature of 60 DEG C-90 DEG C, and the water-soluble yttrium vanadate nanoparticles and the water-soluble rare earth ion-doped yttrium vanadate nanoparticles can be obtained.The method is simple in process, convenient and rapid to operate, low in cost, friendly to the environment and good in technological repeatability; the obtained nanoparticles have the good water solubility, are small in particle size and have the huge application potential on medical imaging and fluorescence labeling.

Owner:JILIN UNIV

Preparation method of supercapacitor electrode material vanadium sulfide nanoflower

ActiveCN108046320AHigh specific capacityImprove cycle lifeHybrid capacitor electrodesVanadium compoundsCapacitanceHigh energy

The invention discloses a preparation method of supercapacitor electrode material vanadium sulfide nanoflower. The method comprises the following steps that 1, sodium orthovanadate dodecahydrate and thioacetamide are prepared into a precursor solution, wherein the mass ratio of sodium orthovanadate dodecahydrate to thioacetamide is 1: (1.2-3.5), and the mass concentration of sodium orthovanadate dodecahydrate is 0.02-0.05 g / mL; 2, the precursor solution is subjected to a hydrothermal reaction, a product obtained after the reaction is completed is washed and dried, and the vanadium sulfide nanoflower is obtained. The prepared vanadium sulfide nanoflower is of a three-dimensional structure, stacking of flake vanadium sulfide is well avoided, the specific surface area of vanadium sulfide is increased, the vanadium sulfide nanoflower is used as an electrode material of a supercapacitor, higher specific capacity can be obtained, the circulation service life is prolonged, and high energy density and power density are achieved; the maximum specific capacity of the prepared vanadium sulfide nanoflower can reach 500.4 F g<-1>, after circulation is conducted 500 times or above, the specificcapacity still reaches 459.4 F g<-1>, and the capacitance retention rate is 91.9%.

Owner:CHONGQING UNIV

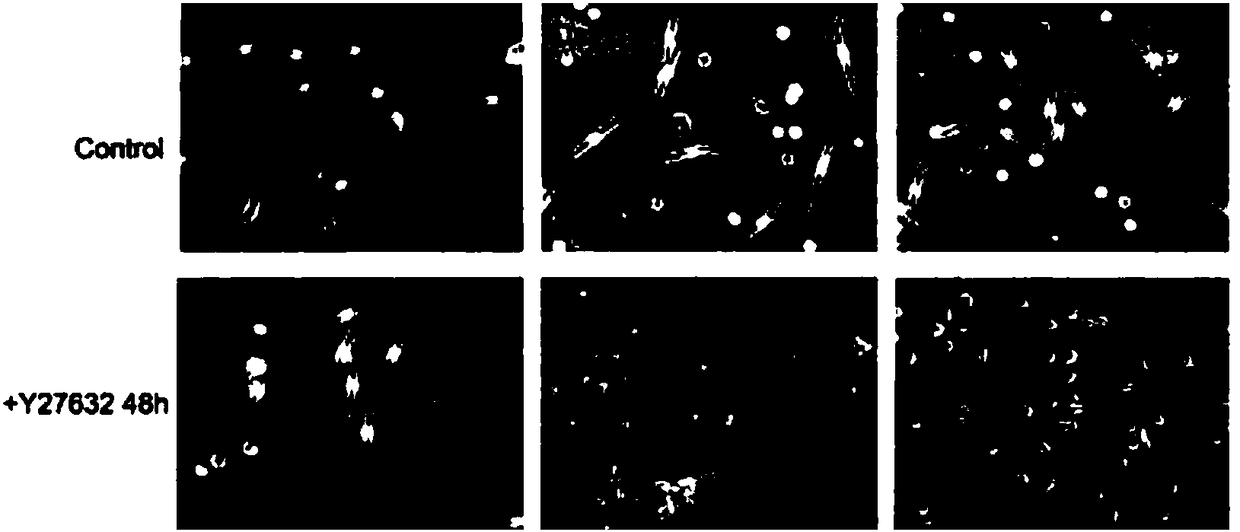

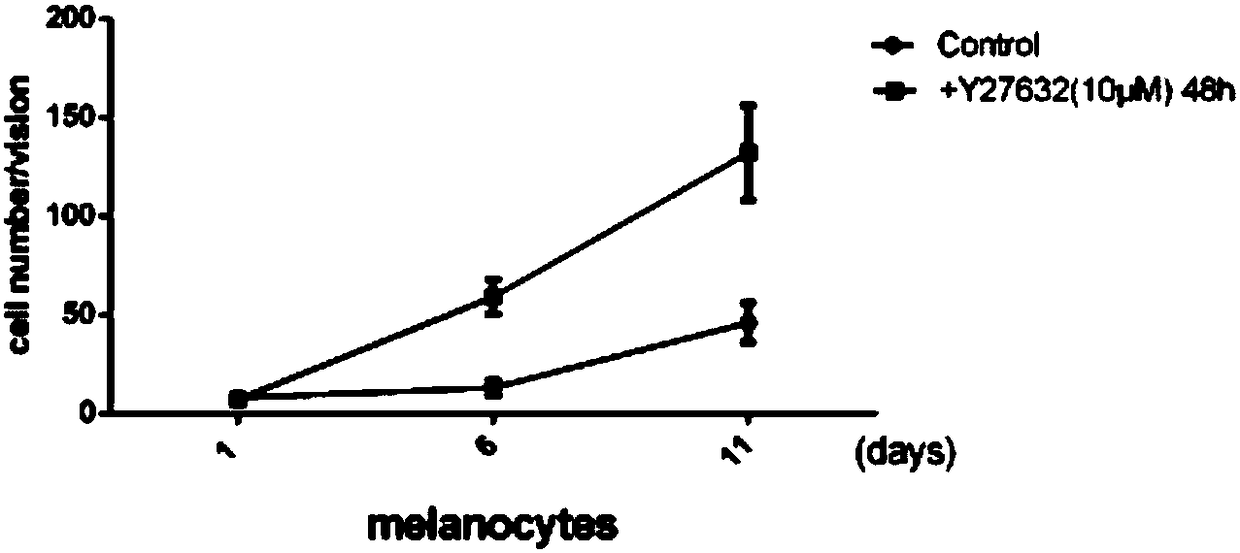

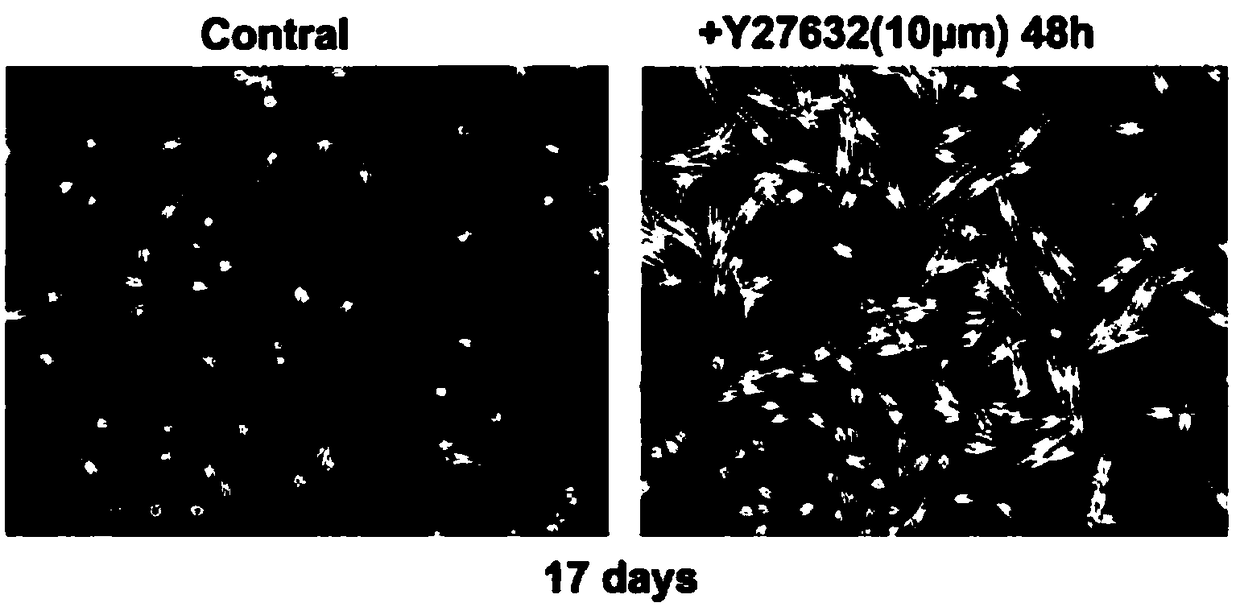

Method for efficient separation and culture of human primary melanin cells

ActiveCN108192856AImprove separation efficiencyShort training periodCell dissociation methodsEpidermal cells/skin cellsAdditive ingredientClonal growth

The invention belongs to the technical field of cell culture, and in particular relates to a method for efficient separation and culture of human primary melanin cells. According to the method provided by the invention, an ROCK inhibitor is added to a culture medium which consists of the following ingredients: a Ham's F-12 medium, dibutiryl cyclic adenosine monophosphate, 3-isobutyl-1-methylxanthine, sodium orthovanadate, phorbol 12-myristinate 13-acetate, fetal calf serum and double-antibody; on the basis of mutual actions of the various ingredients, the melanin cells can achieve cloning growth, so that a culture cycle can be shortened by half and separation efficiency of the melanin cells can be greatly improved; the separation and culture method provided by the invention is simple and easy to operate and is low in amount of medium ingredients; and large-scale production of the human primary melanin cells is achieved.

Owner:SHANDONG UNIV

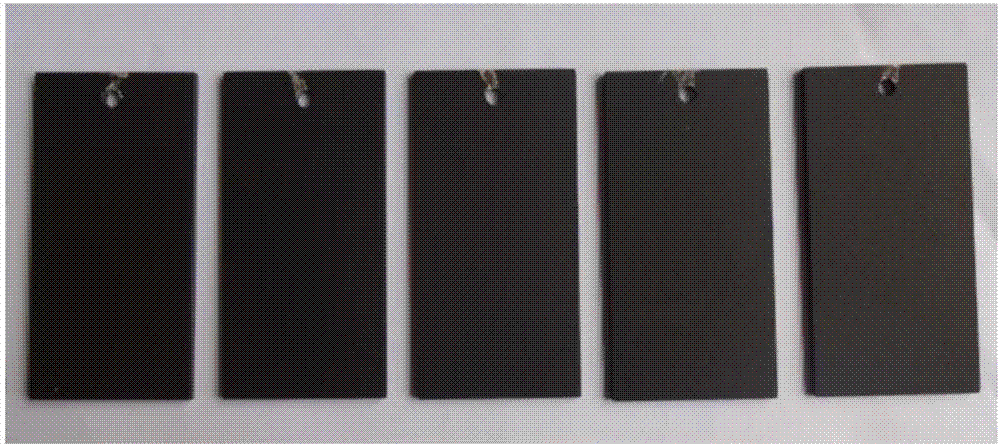

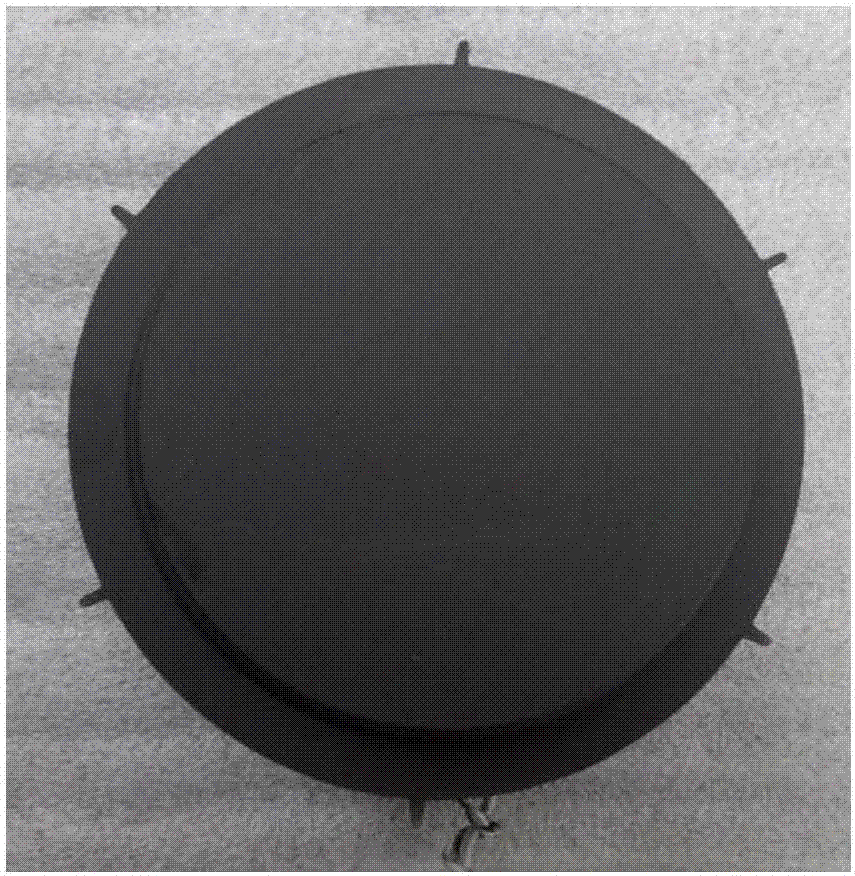

Preparation method for black abrasion-resistant micro-arc oxidization ceramic layer of magnesium alloy

ActiveCN108004581AImprove corrosion resistanceImprove stabilityAnodisationPlasma electrolytic oxidationPotassium fluoride

The invention provides a preparation method for a black abrasion-resistant micro-arc oxidization ceramic layer of a magnesium alloy. The magnesium alloy is dipped into electrolyte to be subjected to micro-arc oxidization so that the black abrasion-resistant micro-arc oxidization ceramic layer can be prepared; the electrolyte comprises 5-20 g / L of sodium silicate, 5-15 g / L of potassium fluoride, 1-60 g / L of potassium hydroxide, 5-25 g / L of triethanolamine, 2-6 g / L of ammonium meta-vanadate, 2-6 g / L of sodium orthovanadate, 2-10 g / L of nanometer SiC and 2-5 g / L of nanometer graphite. The black abrasion-resistant ceramic layer of the magnesium alloy can reach the level 9 according to 350 h of a neutral salt spray test, the Vickers hardness HV can reach 553-605, the friction coefficient is 0.08-0.14, the abrasion rate is 0.006-0.009 mg / min, the beneficial effects that stability is good, color is uniform and color fading is not prone to occurrence are all achieved, and the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is very suitable for preparing an optical collimator and other systems. The preparation method for the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is simple in technological process, convenient to operate, small in pollution and remarkable in industrial value.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

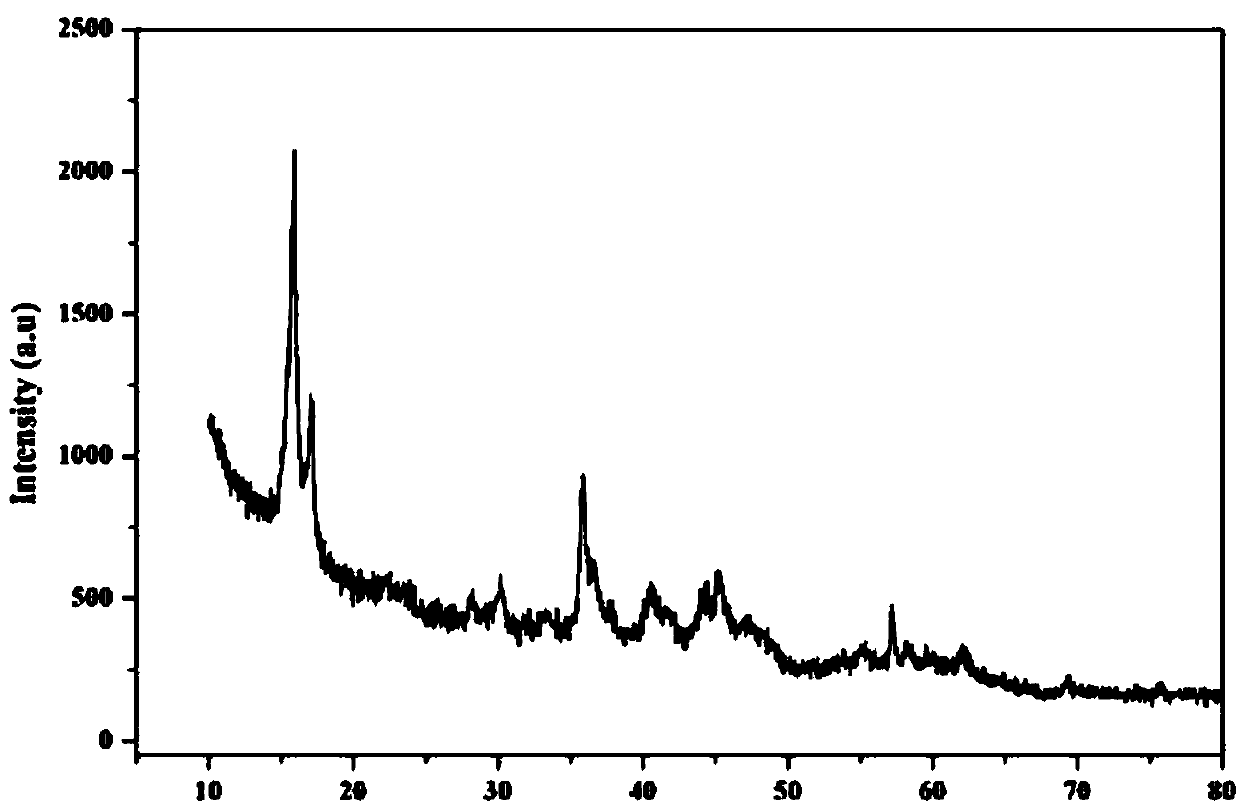

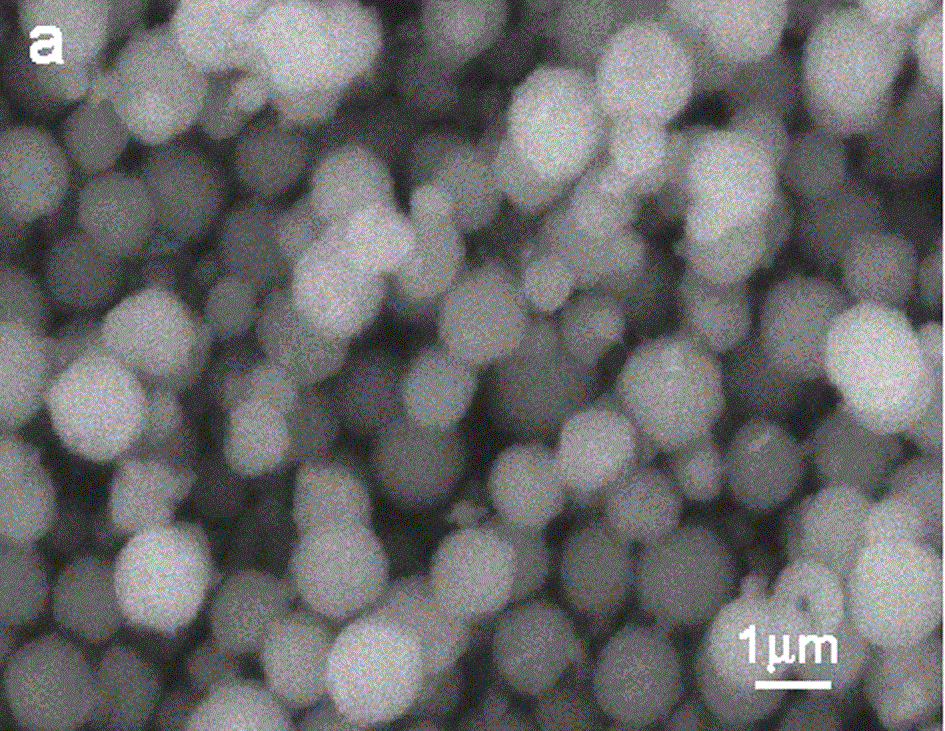

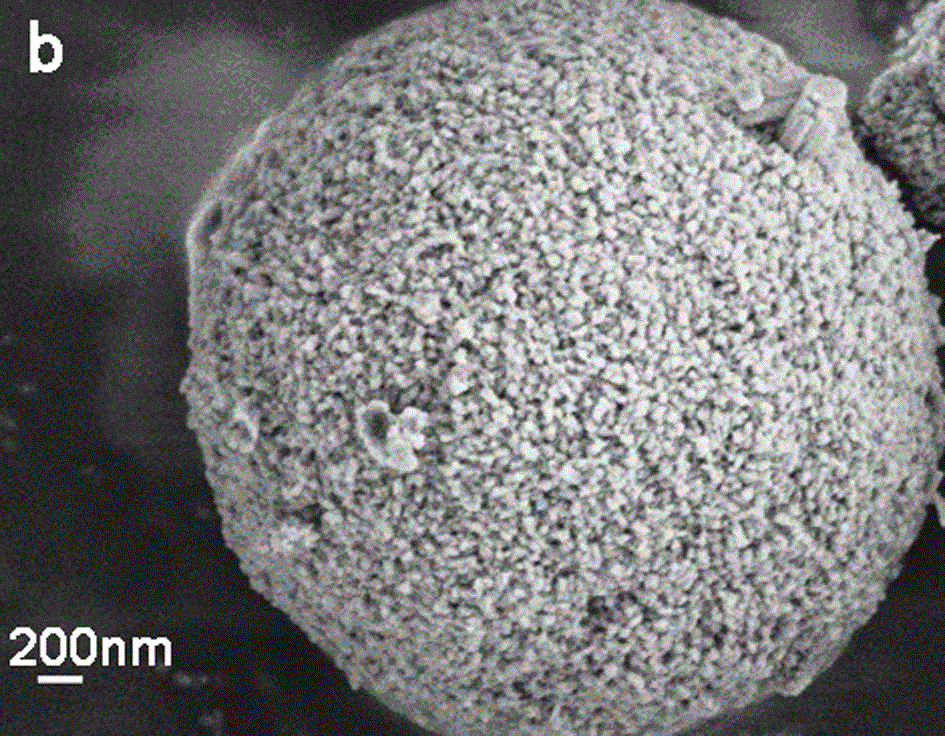

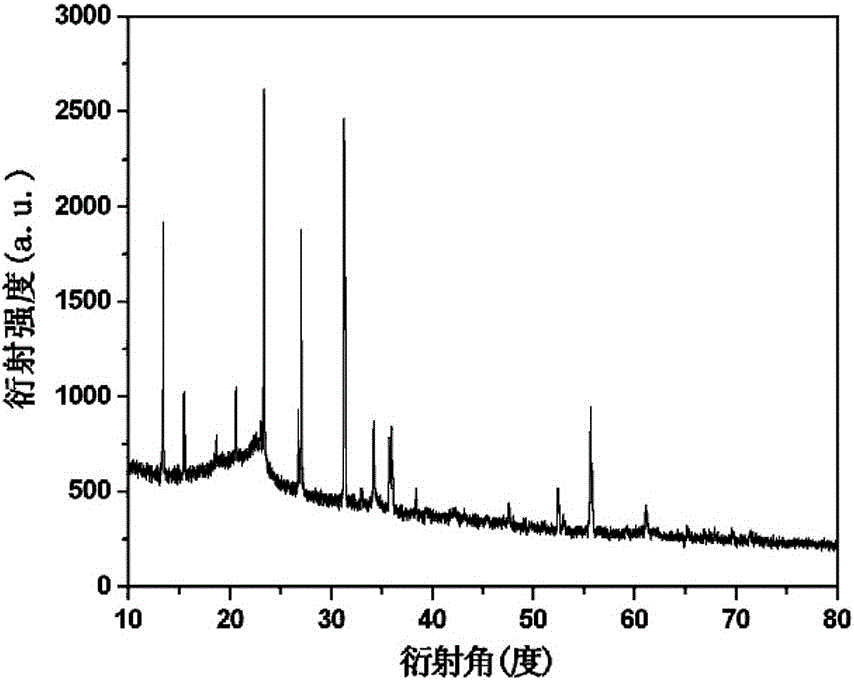

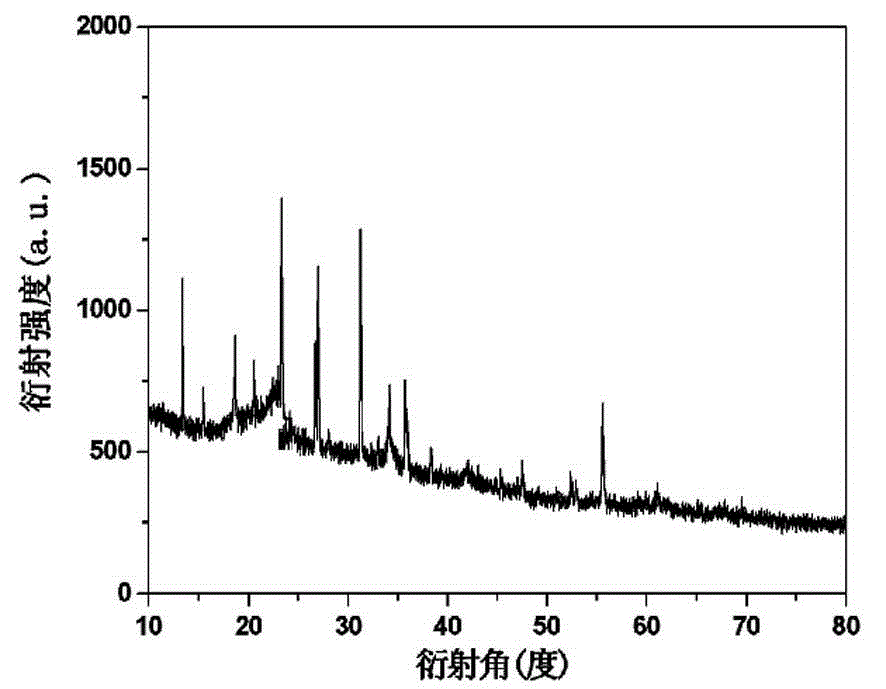

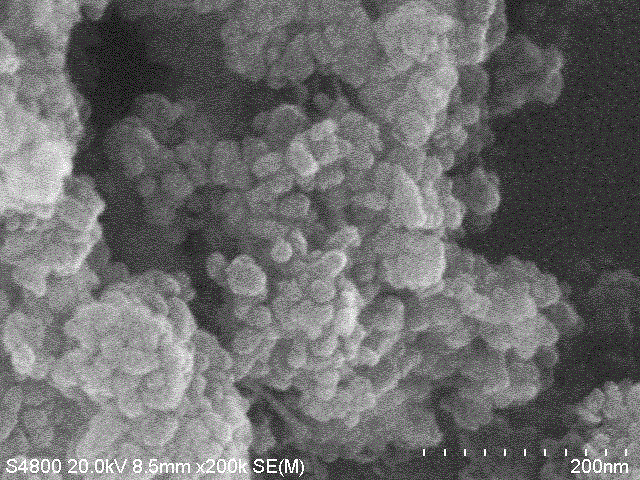

Calcium vanadate microsphere material and preparation method and application thereof

InactiveCN105712401ARich material fieldsStrong UV-visible light absorption propertiesVanadium compoundsNanoparticleMicrometer

The invention discloses a calcium vanadate microsphere material and a preparation method thereof.The chemical constitution of the calcium vanadate microsphere material is Ca2V2O7, calcium vanadate microspheres are assembled by nanoparticles and have a three-dimensional hierarchical structure, and the diameter ranges from 0.5 micrometer to 2 micrometers.The preparation method of the calcium vanadate microsphere material comprises the steps that 1, soluble calcium salt and sodium orthovanadate are prepared into a mixed solution according to the Ca-V mole ratio of 1:(1-3); 2, the pH of the mixed solution is regulated to be 9-10 through an acid solution, uniform stirring is performed, and then reacting is performed for 2-48 h at the temperature of 140 DEG C-200 DEG C to obtain a crude product solution; 3, the crude product solution obtained in the step 2 is cooled to room temperature, and an obtained precipitate is washed and dried to obtain the calcium vanadate microsphere material.According to the preparation method, the pure-phase Ca2V2O7 microsphere material with the three-dimensional hierarchical structure is prepared for the first time.The microsphere material is synthesized through a one-step hydrothermal method and a wet method, the reacting conditions are mild, the technology is simple, controllable in condition and suitable for batched production, and a good technical foundation is laid for application research.

Owner:SHIJIAZHUANG UNIVERSITY

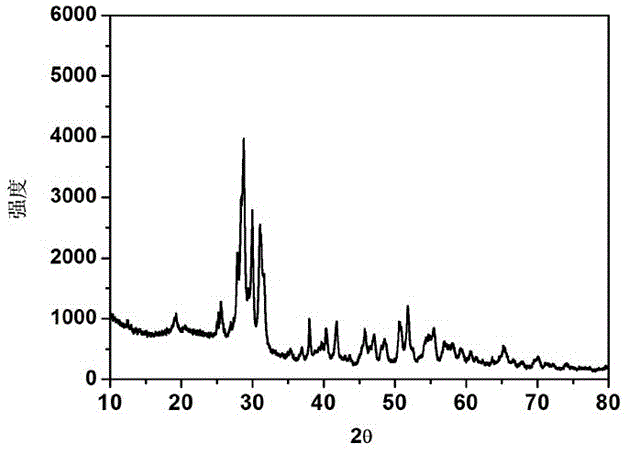

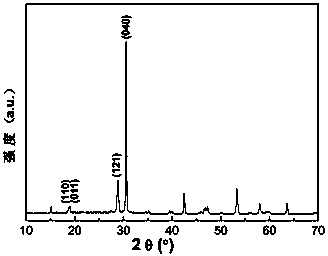

Method for synthesis of (010) preferred orientation bismuth vanadate powder by glycerol preparation hydrothermal process

ActiveCN104328479AImprove performanceMild reaction conditionsPolycrystalline material growthFrom normal temperature solutionsBismuth vanadateGlycerol

The invention discloses a method for synthesis of (010) preferred orientation bismuth vanadate powder by glycerol preparation hydrothermal process, relates to a method for the synthesis of bismuth vanadate powder, and solves the problems that preferred orientation along the b axis of the vanadate powder synthesized by methods in the prior art is very difficult to achieve, and catalytic performance is poor. The method is as follows: bismuth nitrate pentahydrate is dissolved in glycerol dilute nitric acid solution, then added with sodium orthovanadate dodecahydrate, and stirred, the obtained suspension is added into a reaction kettle foe reaction for 6-24h, and the (010) preferred orientation bismuth vanadate powder is obtained by cooling, filtering, washing, drying and grinding. The synthesized bismuth vanadate powder presents a high (010) preferred orientation, is conducive to improvement of the catalytic performance, and is suitable for industrialized production.

Owner:JILIN NORMAL UNIV

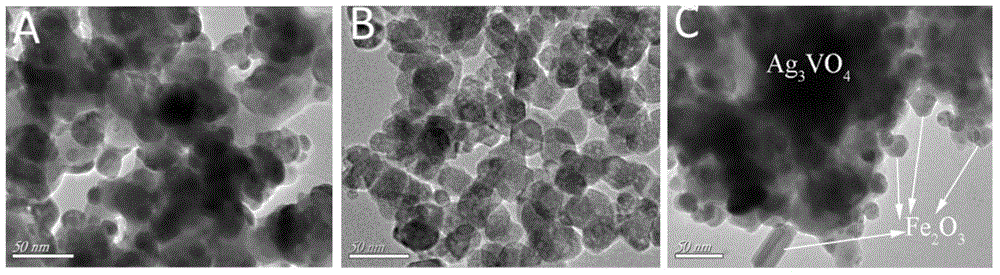

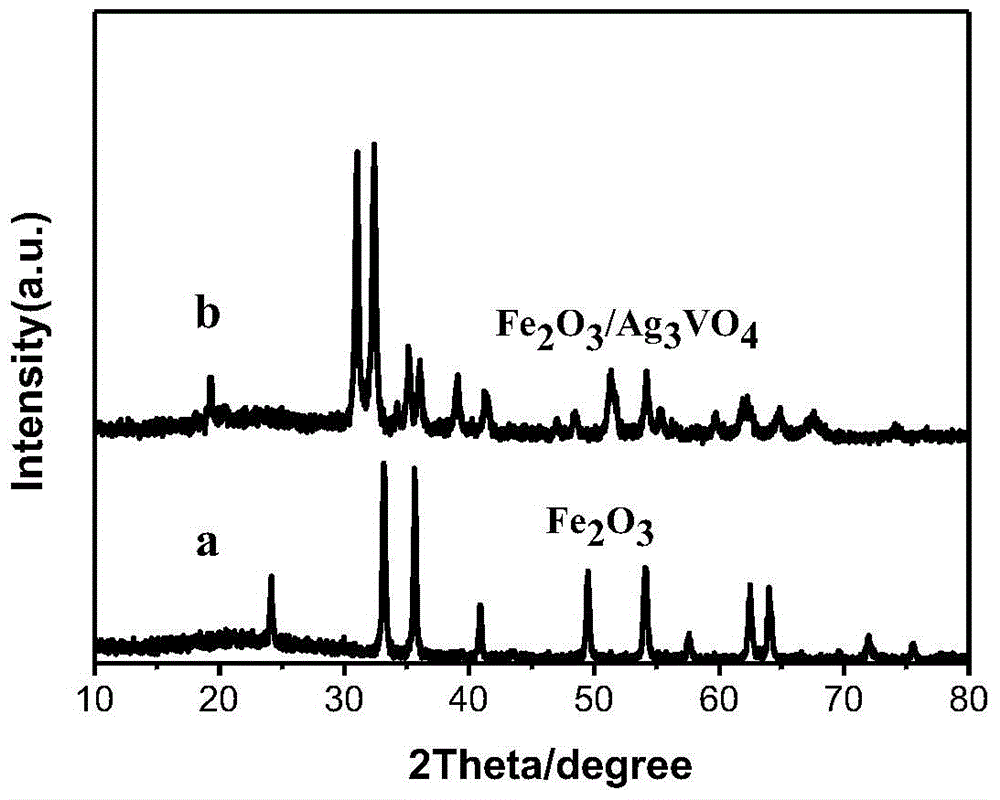

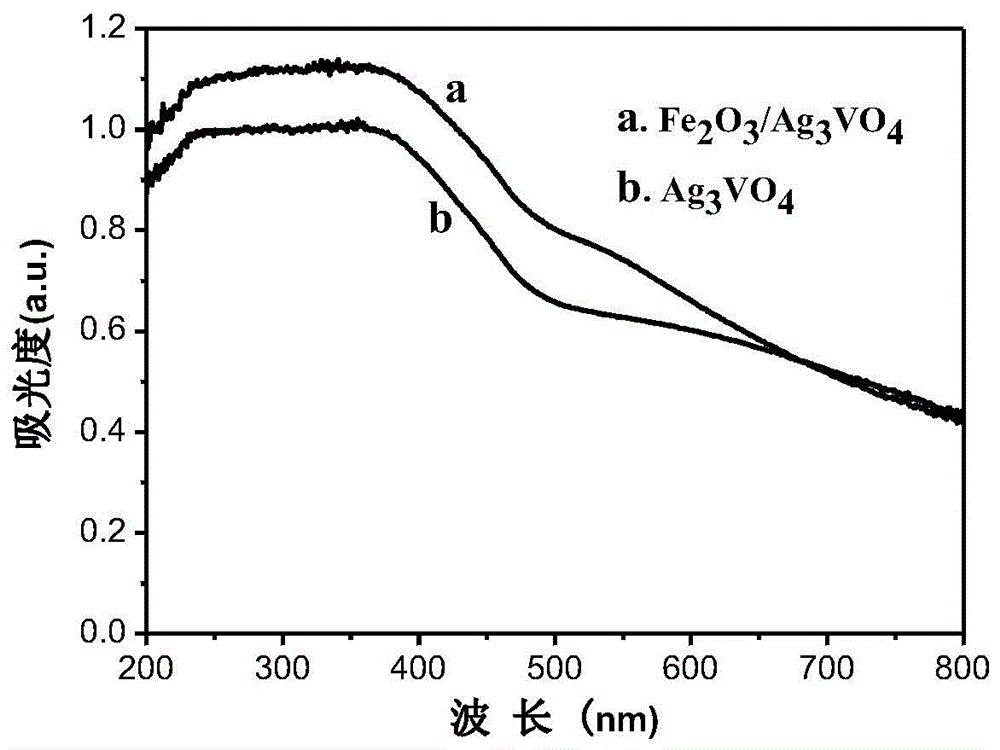

Fe2O3/Ag3VO4 composite photocatalyst and preparation method thereof

ActiveCN105170160ASimple methodLow costWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsWater bathsDistilled water

The invention provides a Fe2O3 / Ag3VO4 composite photocatalyst and a preparation method thereof. Iron oxide is put into distilled water to be subjected to ultrasonic dispersion and is stirred in a constant-temperature water bath to obtain iron oxide dispersion liquid A; silver nitrate dissolves in the dispersion liquid A to obtain mixed liquid B; sodium orthovanadate dodecahydrate dissolves in the constant-temperature water bath through stirring to obtain a solution C; the solution C is dropwise added into the mixed liquid B in the constant-temperature water bath under the even-stirring condition, and mixed liquid D is obtained after dripped adding is completed and performs constant-temperature reaction under the stirring condition; an obtained solid product is washed and dried after reaction to obtain the composite photocatalyst. The composite photocatalyst preparation can be performed at more moderate temperature, and the preparation method has the advantages of saving energy and reducing consumption. A silver vanadate photocatalyst is modified by utilizing Fe2O3, the visible light absorption characteristic of silver vanadate is improved, and the rhodamin B degradation rate under visible light exposure for 60 minutes can be up to 96.1%.

Owner:JIANGSU UNIV

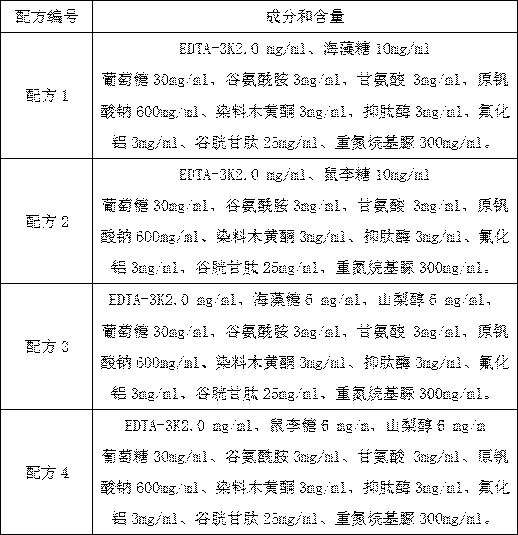

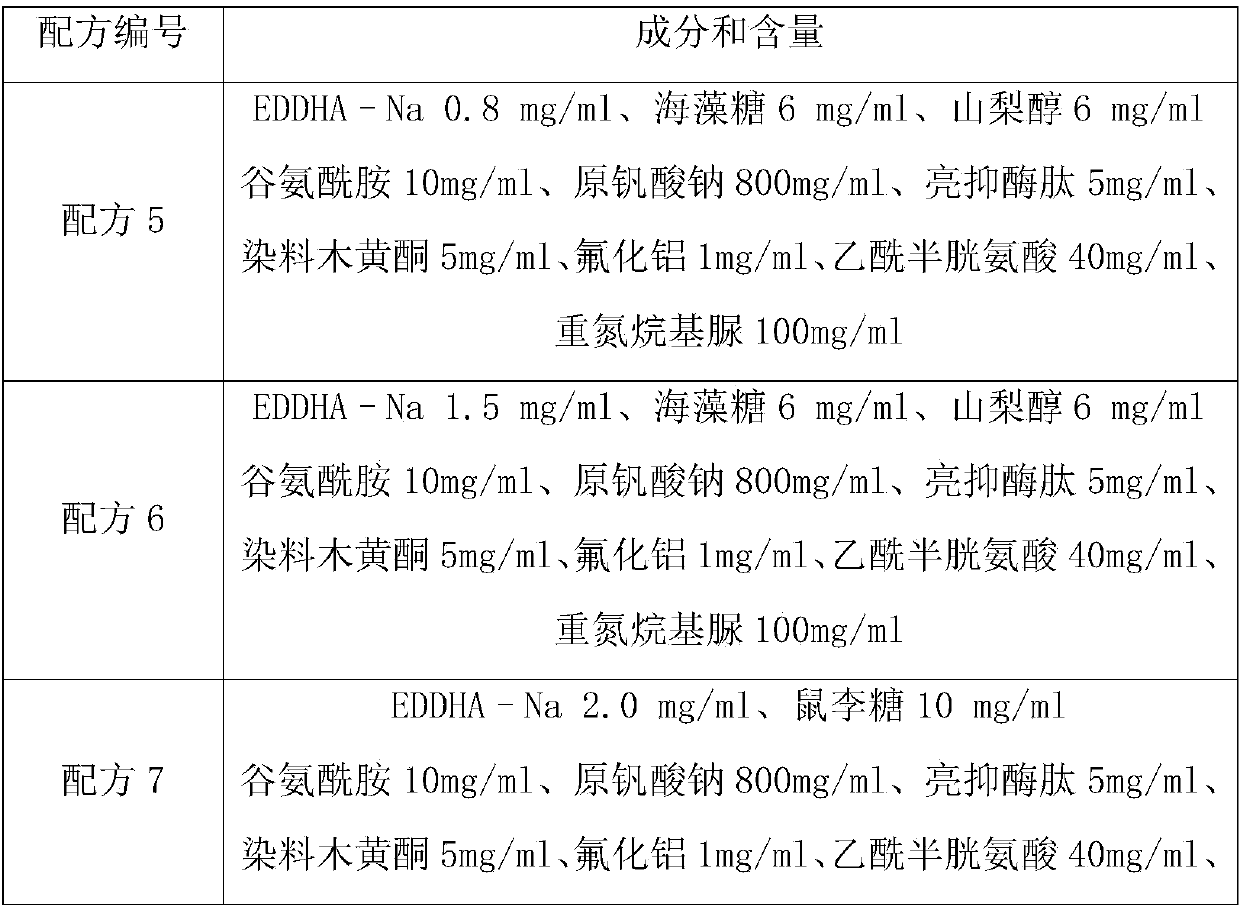

Blood cfDNA extracting kit

InactiveCN109750087AAdd storage tubePrevents contamination of target cfDNAMicrobiological testing/measurementGenisteinDiazolidinyl urea

Owner:NINGBO AJCORE BIOSCIENCES INC

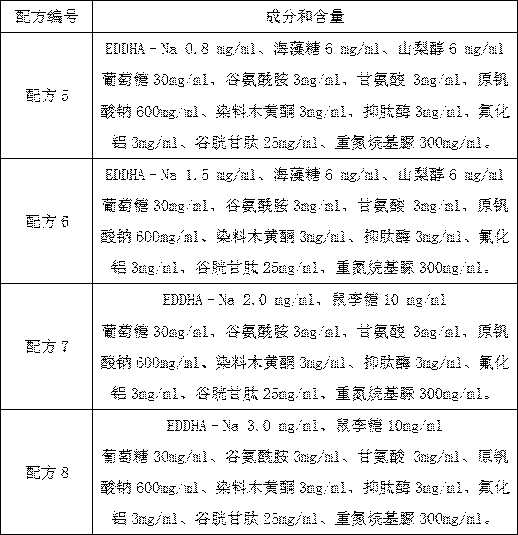

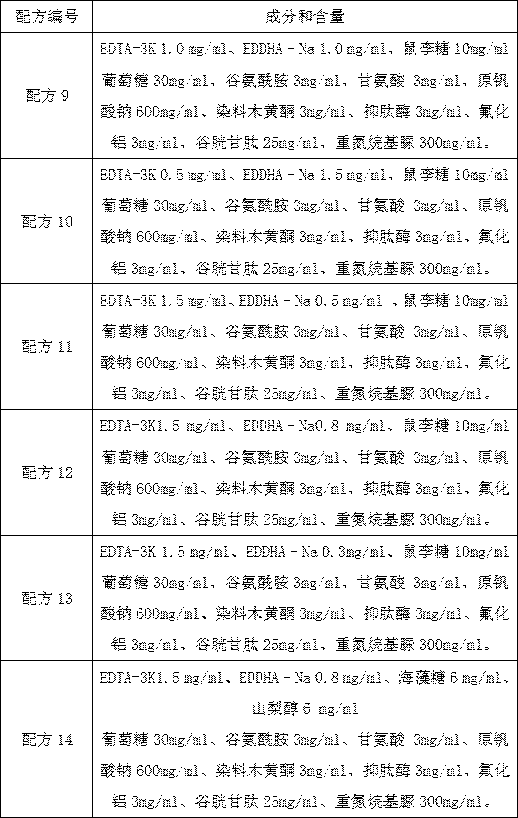

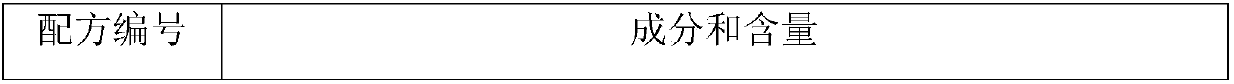

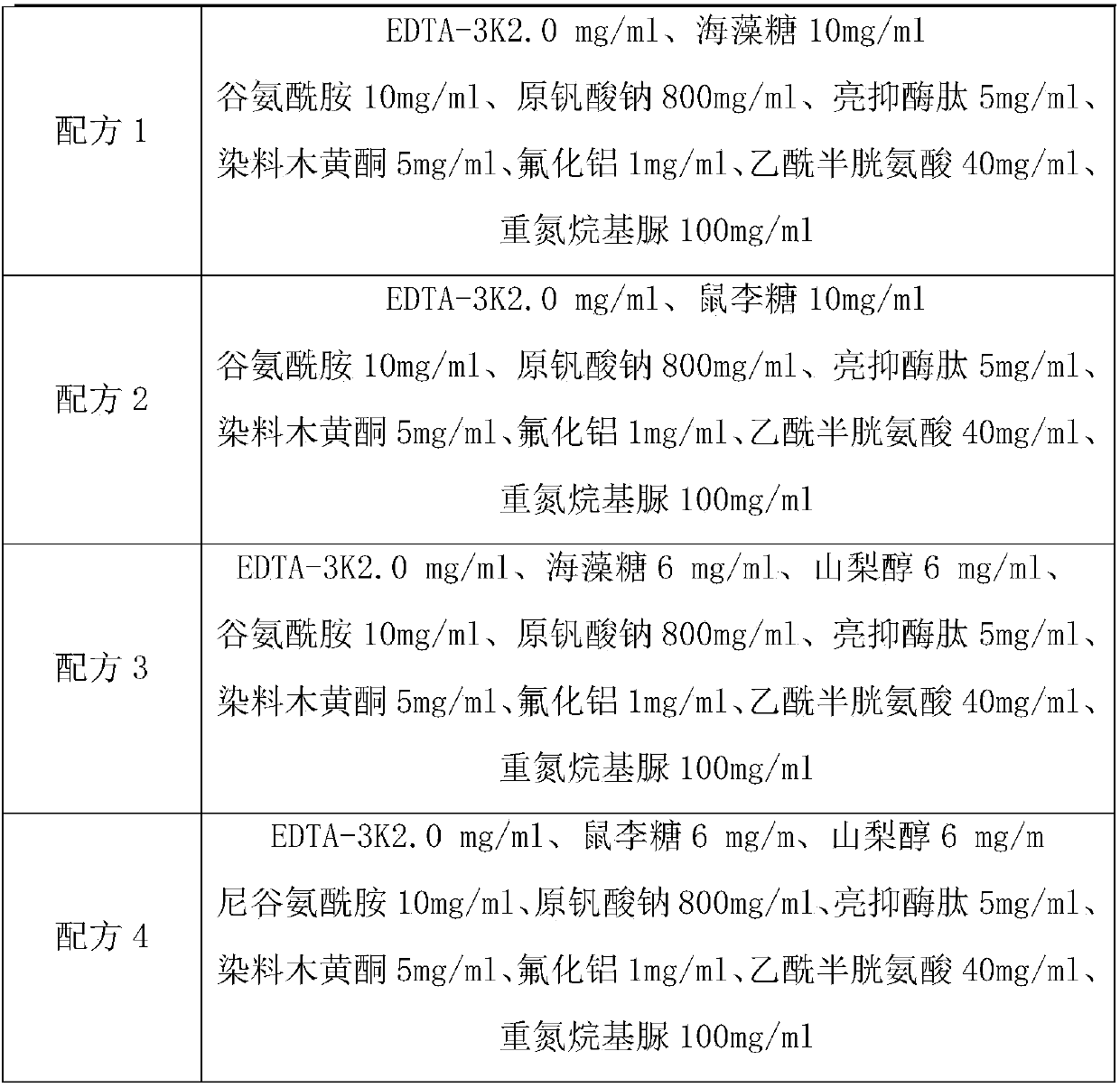

Free nucleic acid preservative and blood collection and preservation device

ActiveCN109593824AReduce crackingAvoid dilutionBioreactor/fermenter combinationsBiological substance pretreatmentsBlood collectionLeupeptin

The invention relates to a free nucleic acid preservative and a blood collection and preservation device. The free nucleic acid preservative is prepared from the following ingredients: 10-50mg / ml of glutamine, 200-1,000mg / ml of sodium orthovanadate, 1-5mg / ml of leupeptin, 1-5mg / ml of genistein, 1-5mg / ml of aluminum fluoride, 10-40mg / ml of acetylcysteine, 100-500mg / ml of diazolidinyl urea, 1-3mg / mlof an anticoagulant and 5-20mg / ml of a membrane protective agent. The free nucleic acid preservative has the advantages of effectively retarding the rupture of blood cells, preventing a target cfDNA(cell free deoxyribonucleic acid) from being diluted and polluted by DNAs in the blood cells, preventing the target cfDNA from being degraded by nucleases and prolonging the preservation time of a blood sample containing the target cfDNA.

Owner:NINGBO AJCORE BIOSCIENCES INC

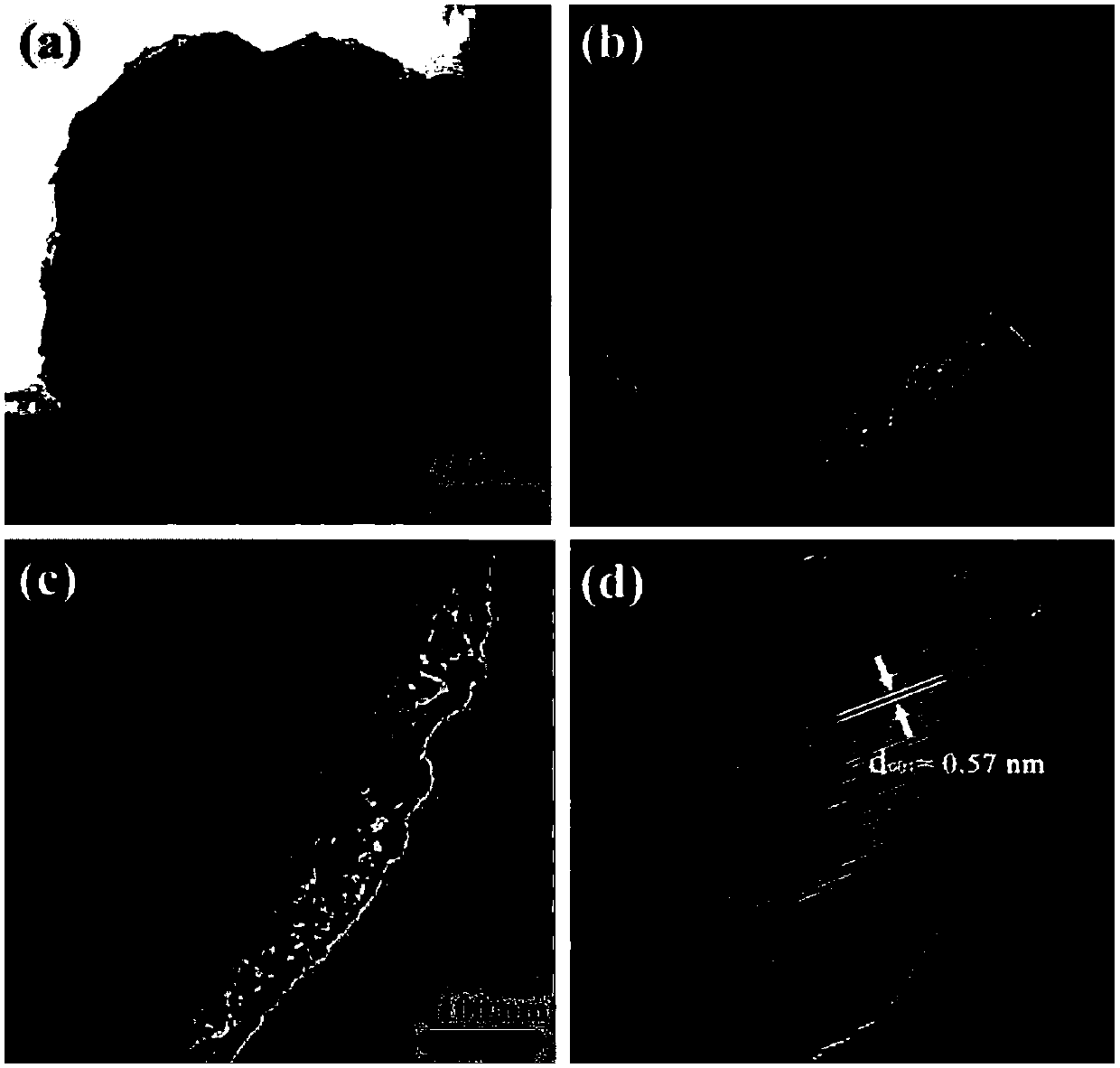

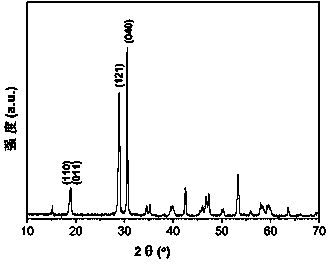

A kind of method for synthesizing manganese vanadate nanometer material

ActiveCN104528830BAchieve low temperature controllable preparationHigh crystallinityMaterial nanotechnologyCell electrodesSynthesis methodsActive agent

The invention discloses a manganese vanadate nano-micro material and a synthetic method and application thereof, belonging to the field of inorganic non-metallic materials. The composition of the nano-micro manganese vanadate material is Mn6.87(OH)3(VO4)3.6(V2O7)0.2, and the material is in the form of nanoparticle, microrod or microtube. The synthetic method comprises the following steps: preparing a mixed solution from sodium orthovanadate and manganese salt according to a mol ratio of V to Mn of 1-3: 1; adjusting the pH value of the mixed solution to be 7 to 8, carrying out stirring for 10 min, then transferring the mixed solution into a reaction vessel and carrying out a reaction at a temperature of 160 to 260 DEG C for 1 to 24 h so as to obtain the solution of a crude product; and cooling the solution of the crude product to room temperature and carrying out cooling and drying so as to obtain the manganese vanadate Mn6.87(OH)3(VO4)3.6(V2O7)0.2 nano-micro material. The invention has the following beneficial effects: the nano-micro material is synthesized by using a one-step hydrothermal method and a wet method, low-temperature controllable preparation of manganese vanadate is realized, and energy consumption is low; no surfactant or organic template is needed in the process of synthesis, so the synthetic method is friendly to the environment and the produced nano-micro material is pure and has excellent crystallization property; the nano-micro material has uniform morphology and size; and the synthetic method is simple, can be realized under controllable conditions, is suitable for batch production and lays a good foundation for application and research.

Owner:SHIJIAZHUANG UNIVERSITY

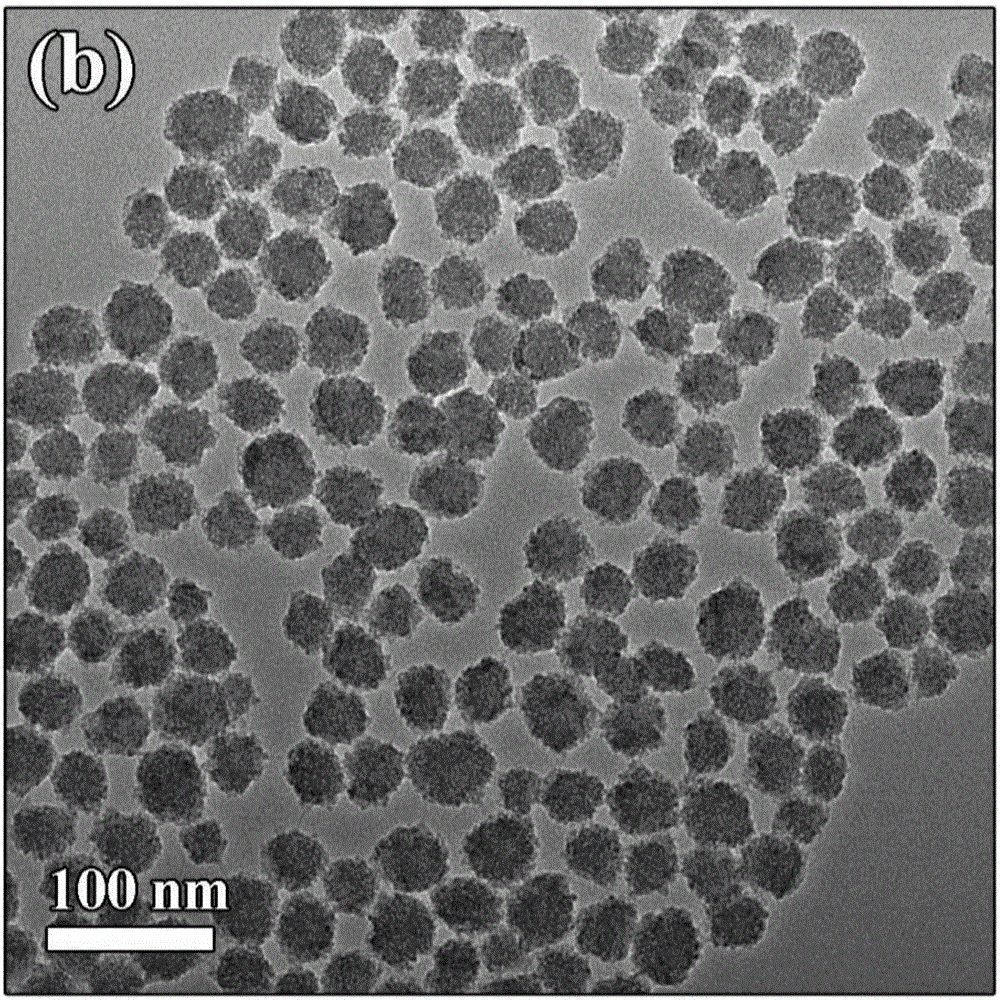

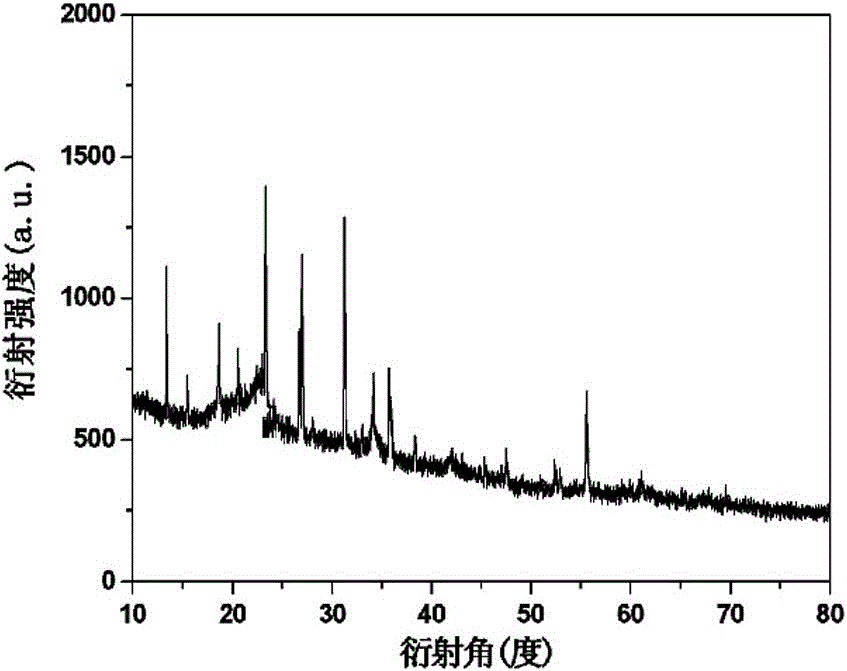

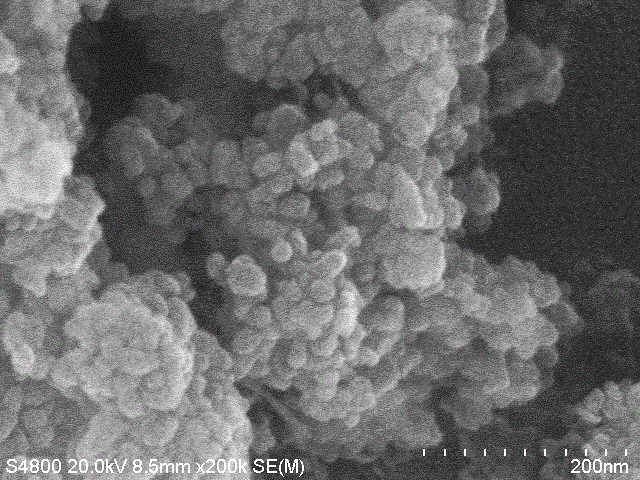

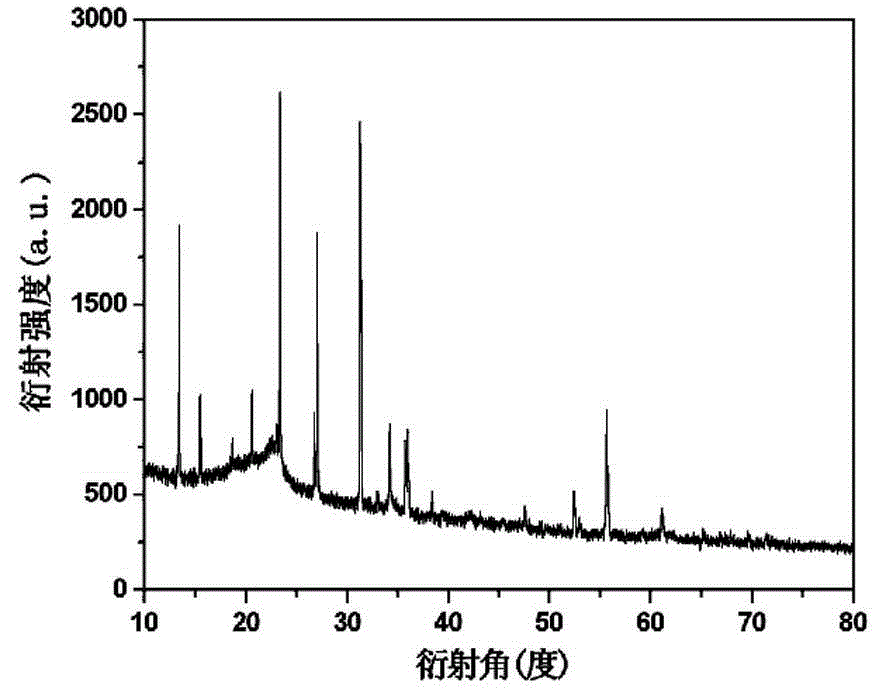

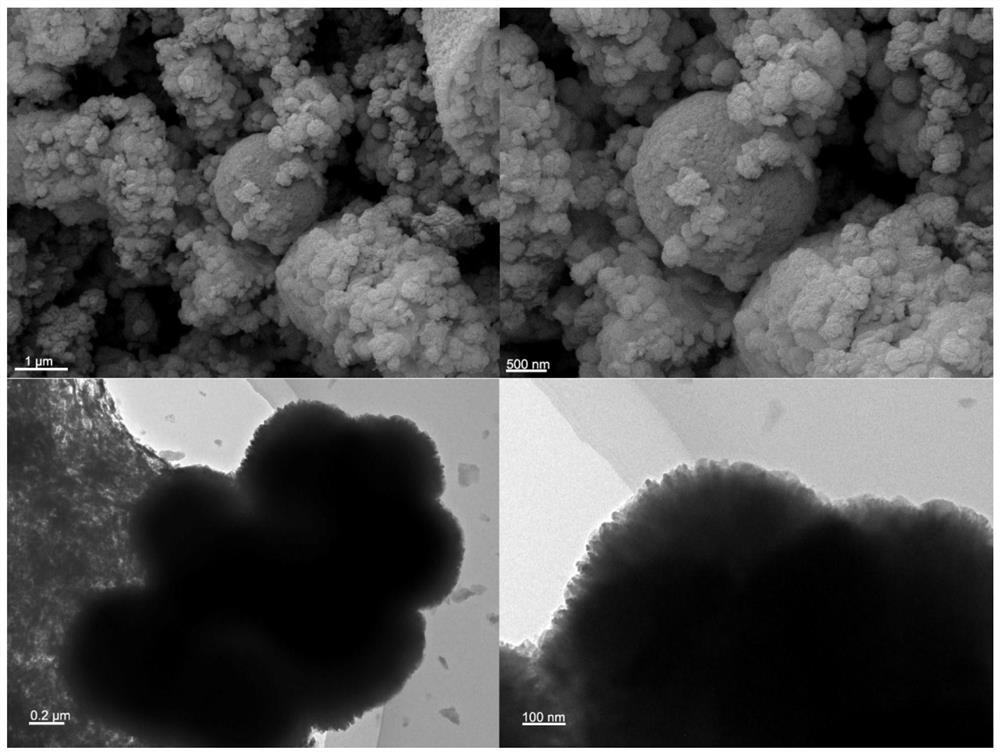

Manganese vanadate nano-micro material, and synthetic method and application thereof

ActiveCN104528830AAchieve low temperature controllable preparationHigh crystallinityMaterial nanotechnologyCell electrodesActive agentManganese

The invention discloses a manganese vanadate nano-micro material and a synthetic method and application thereof, belonging to the field of inorganic non-metallic materials. The composition of the nano-micro manganese vanadate material is Mn6.87(OH)3(VO4)3.6(V2O7)0.2, and the material is in the form of nanoparticle, microrod or microtube. The synthetic method comprises the following steps: preparing a mixed solution from sodium orthovanadate and manganese salt according to a mol ratio of V to Mn of 1-3: 1; adjusting the pH value of the mixed solution to be 7 to 8, carrying out stirring for 10 min, then transferring the mixed solution into a reaction vessel and carrying out a reaction at a temperature of 160 to 260 DEG C for 1 to 24 h so as to obtain the solution of a crude product; and cooling the solution of the crude product to room temperature and carrying out cooling and drying so as to obtain the manganese vanadate Mn6.87(OH)3(VO4)3.6(V2O7)0.2 nano-micro material. The invention has the following beneficial effects: the nano-micro material is synthesized by using a one-step hydrothermal method and a wet method, low-temperature controllable preparation of manganese vanadate is realized, and energy consumption is low; no surfactant or organic template is needed in the process of synthesis, so the synthetic method is friendly to the environment and the produced nano-micro material is pure and has excellent crystallization property; the nano-micro material has uniform morphology and size; and the synthetic method is simple, can be realized under controllable conditions, is suitable for batch production and lays a good foundation for application and research.

Owner:SHIJIAZHUANG UNIVERSITY

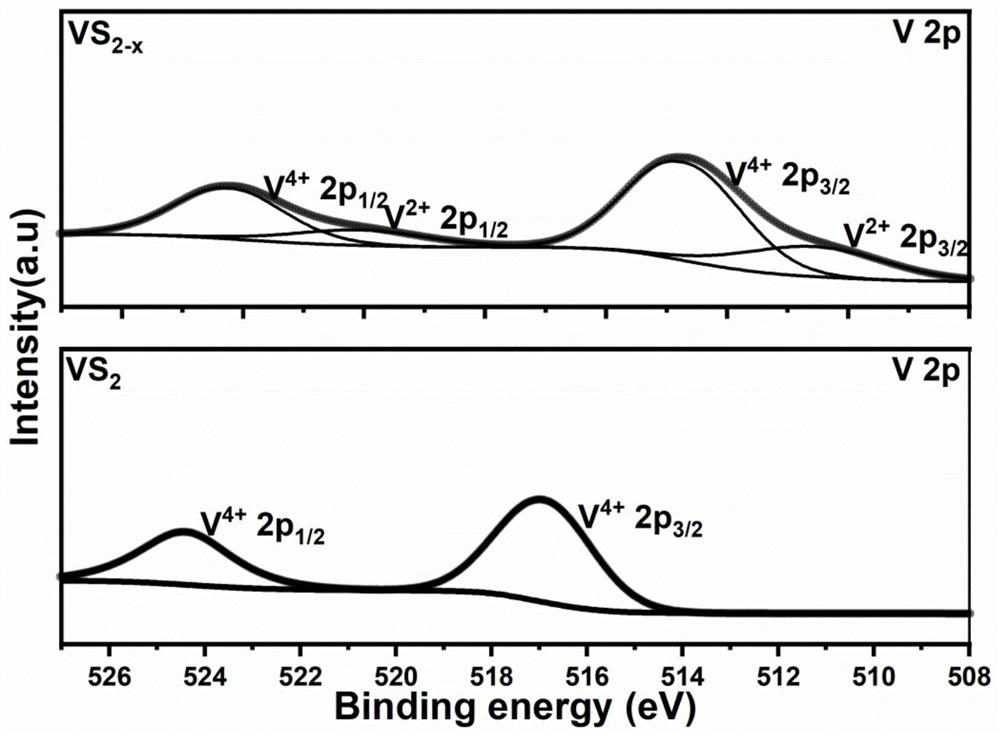

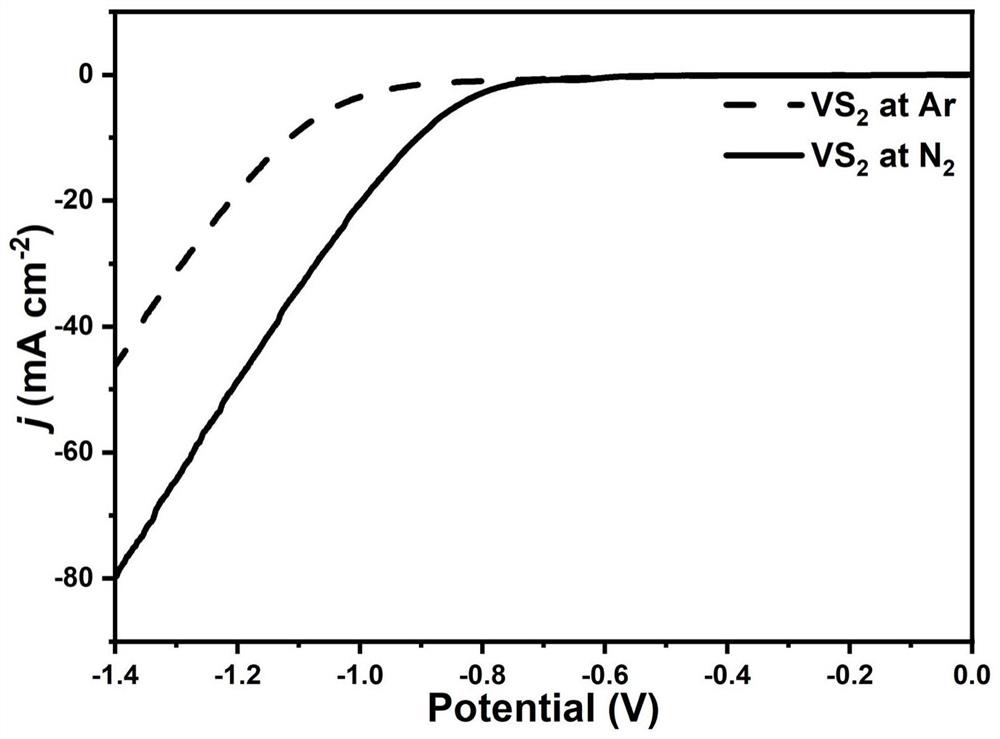

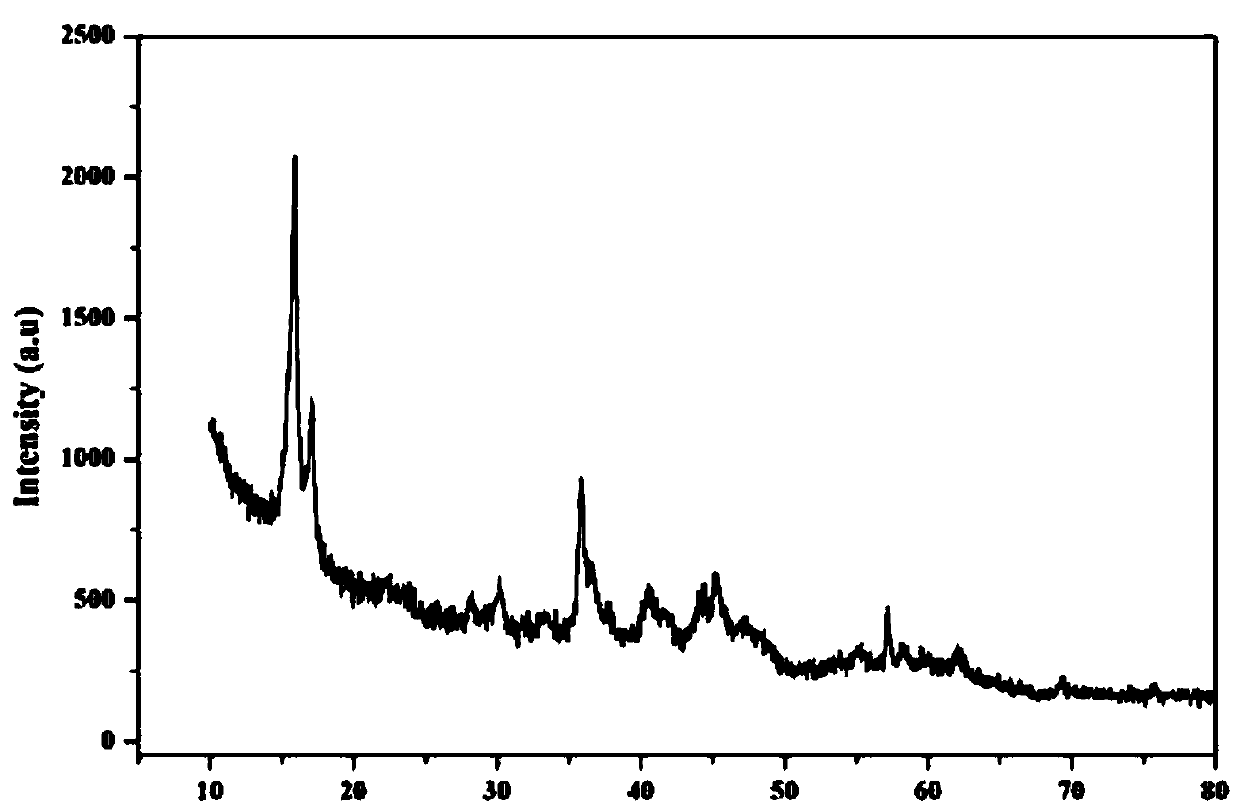

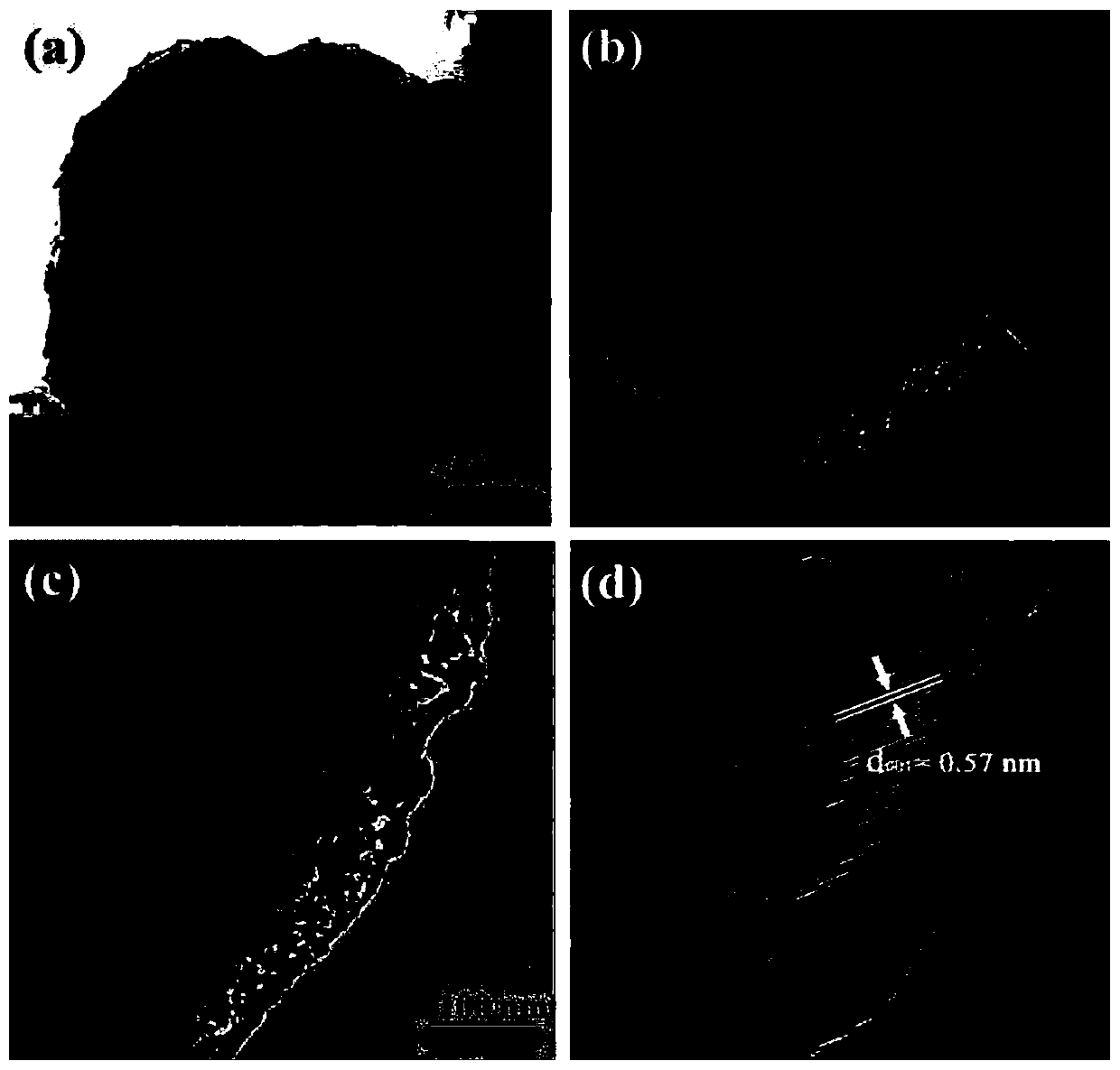

Preparation method of electro-catalytic material VS2 for ENRR

PendingCN113912114ACatalytically activeShorten the timeVanadium compoundsElectrodesVanadium disulfideThio-

A preparation method of an electro-catalytic material VS2 for ENRR belongs to the field of electro-catalytic nitrogen fixation. The method comprises the following steps: mechanically mixing a precursor, performing microwave hydrothermal treatment on a precursor solution, and performing suction filtration, washing and vacuum drying on solid obtained by the hydrothermal treatment to obtain the VS2. The method is mainly used for preparing the VS2 electro-catalysis nitrogen fixation material, and the problem that the performance of VS2 prepared through a common hydrothermal method is poor when the VS2 is used for ENRR is solved. In addition, compared with vanadium disulfide VS2-x obtained by taking sodium orthovanadate as a vanadium source and thioacetamide as a sulfur source in a hydrothermal mode, pure vanadium disulfide VS2 with +4-valence V is obtained by taking ammonium metavanadate as the vanadium source and thioacetamide in a hydrothermal mode, and the corresponding ENRR performance of the vanadium disulfide VS2 is more excellent.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of stain-resistant container bag

InactiveCN108067408AGood mechanical propertiesSmall mechanical propertiesAntifouling/underwater paintsPaints with biocidesSodium orthovanadateMechanical property

The invention relates to a preparation method of a stain-resistant container bag. The preparation method of the stain-resistant container bag comprises the following operation steps that (1) a woven container bag is placed into a modifying solution and sufficiently soaked for 2-3 h, wherein the modifying solution is prepared from, by weight, 3-7 parts of sodium orthovanadate, 6-9 parts of hexamethonium bromide, 11-16 parts of sodium allysulfonate, and 280-300 parts of water; and (2) the container bag treated in the step (1) is placed in an anti-fouling solution, soaked for 2-3 h and then takenout and dried, and thus the stain-resistant container bag is prepared. According to the preparation method of the stain-resistant container bag, operation is easy, the cost is low, and the operationprocess is safe and environmentally friendly; the prepared container bag has excellent mechanical properties, high strength and extremely excellent stain resistance, contained substances are not proneto being left on the surface of the stain-resistant container bag, and the cleaning frequency of the container bag is effectively reduced.

Owner:ANHUI YIBANG NEW MATERIAL TECH CO LTD

Common jasmin orange seed sowing and seedling raising method

InactiveCN107567965AImprove germination rateImprove seedling efficiencyBiocidePlant growth regulatorsLight treatmentEconomic benefits

The invention discloses a common jasmin orange seed sowing and seedling raising method. The common jasmin orange seed sowing and seedling raising method comprises the following operating steps that 1,double-embryo seeds are screened out and are put in a sodium orthovanadate solution with the mass fraction of 3% to be soaked for 25 minutes, and then the double-embryo seeds are mixed with single-embryo seeds; 2, the mixed seeds are put in germination accelerating liquid to be fully soaked for 2-3 hours; 3, nutritional grease is uniformly poured into a culture dish, and after the nutritional grease cakes, the seeds processed in the step 2 are uniformly scattered on the nutritional grease; 4, the culture dish is put in a culture box, the temperature in the box is kept at 27-31 DEG C, and light treatment is performed for 11-13 hours every day. The common jasmin orange seed sowing and seedling raising method is simple in operation and low in cost, the germination rate of common jasmin orange seeds can be effectively improved, young seedlings are excellent in growth vigor, the survival rate of the young seedlings is high, the common jasmin orange sowing and seedling raising efficiency isgreatly improved, and economic benefit is increased.

Owner:安徽徽思远生态农业发展有限公司

Method for recycling waste lithium vanadium phosphate

ActiveCN108773847AWide range of usesAchieve reuseVanadium compoundsLithium carbonates/bicarbonatesPhosphateSlurry

The invention discloses a method for recycling waste lithium vanadium phosphate. The method comprises the following steps: step one, oxidizing waste lithium vanadium phosphate in a furnace filled withair at 300-600 DEG C for 0.5-3h, and then adding water according to the solid-to-liquid ratio of 1:10-1:3, thus obtaining first slurry; step two, adding calcium salt into the first slurry obtained inthe step one, and then filtering to obtain a solution containing a lithium compound, and filter residues containing vanadium and calcium phosphate; step three, adding water into the filter residues containing vanadium and calcium phosphate according to the solid-to-liquid ratio of 1:7-1:2; and step four, adding sodium carbonate or sodium hydroxide into the second slurry obtained in the step three, enabling the pH value of the solution to be increased to 12.6-14.0, then filtering to obtain sodium orthovanadate solution and calcium phosphate filter residues, and concentrating and crystallizingthe sodium orthovanadate solution to obtain sodium orthovanadate crystals. The recycling method is relatively simple, lithium vanadium phosphate powder in the positive electrode material of a lithiumvanadium phosphate battery can be recycled to obtain the solution containing the lithium compound and the sodium orthovanadate crystals with relatively high purity, and the environment pollution caused by waste lithium vanadium phosphate powder can be prevented.

Owner:湖南金凯循环科技有限公司

A kind of preparation method of supercapacitor electrode material vanadium sulfide nanoflower

ActiveCN108046320BAvoid stackingLarge specific surface areaHybrid capacitor electrodesVanadium compoundsCapacitanceSulfide

The invention discloses a preparation method of supercapacitor electrode material vanadium sulfide nanoflower. The method comprises the following steps that 1, sodium orthovanadate dodecahydrate and thioacetamide are prepared into a precursor solution, wherein the mass ratio of sodium orthovanadate dodecahydrate to thioacetamide is 1: (1.2-3.5), and the mass concentration of sodium orthovanadate dodecahydrate is 0.02-0.05 g / mL; 2, the precursor solution is subjected to a hydrothermal reaction, a product obtained after the reaction is completed is washed and dried, and the vanadium sulfide nanoflower is obtained. The prepared vanadium sulfide nanoflower is of a three-dimensional structure, stacking of flake vanadium sulfide is well avoided, the specific surface area of vanadium sulfide is increased, the vanadium sulfide nanoflower is used as an electrode material of a supercapacitor, higher specific capacity can be obtained, the circulation service life is prolonged, and high energy density and power density are achieved; the maximum specific capacity of the prepared vanadium sulfide nanoflower can reach 500.4 F g<-1>, after circulation is conducted 500 times or above, the specificcapacity still reaches 459.4 F g<-1>, and the capacitance retention rate is 91.9%.

Owner:CHONGQING UNIV

Preparation method of low-slagging sludge biomass solid fuel

InactiveCN108893172APhenomenon that is not easy to slaggingHigh calorific valueBiofuelsSolid fuelsSludgeSolid fuel

The invention discloses a preparation method of low-slagging sludge biomass solid fuel, comprising the steps of (1) adding a modifying liquid into sludge to made the sludge into slurry having the water content by mass of 91-95% so as to obtain modified sludge; (2) crushing dried crop straws to average length of 1-2 cm so as to obtain crushed straws, mixing well, by weight, 89-95 parts of modifiedsludge, 33-40 parts of crushed straws, 0.1-0.3 part of sodium orthovanadate and 0.1-0.2 part of an igniting agent, and adding the mixture into a filter press to manufacture the low-slagging sludge biomass solid fuel. The preparation method of the low-slagging sludge biomass solid fuel is simple to perform, and has low cost; the fuel made herein rarely slags during combustion, and the combustion effect is significant.

Owner:合肥市晶谷农业科技开发有限公司

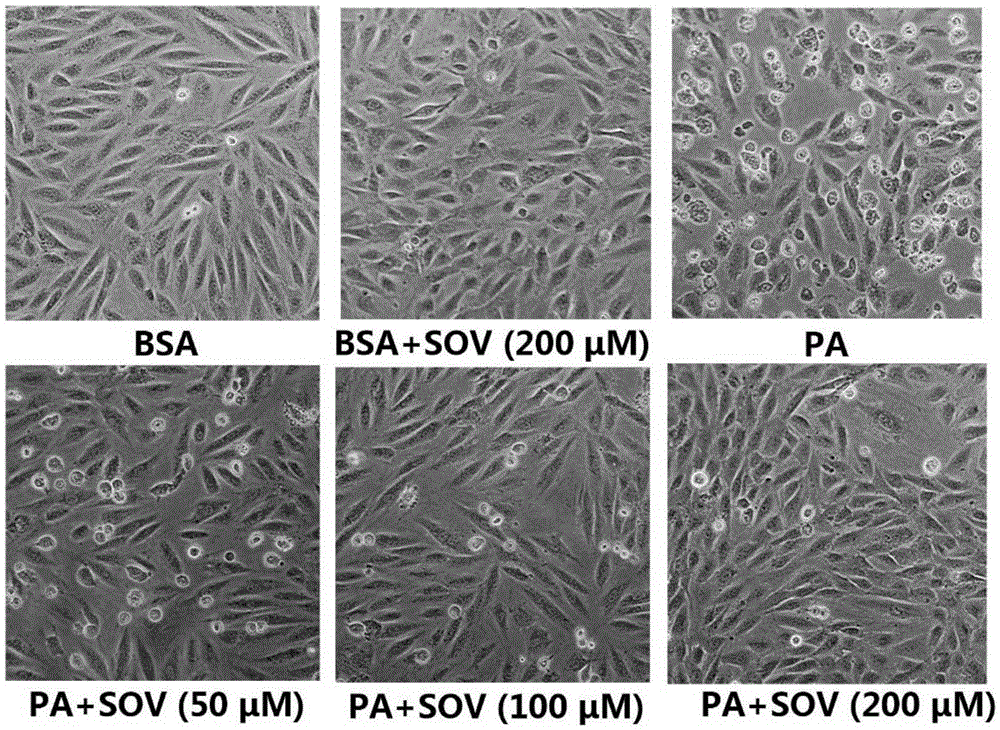

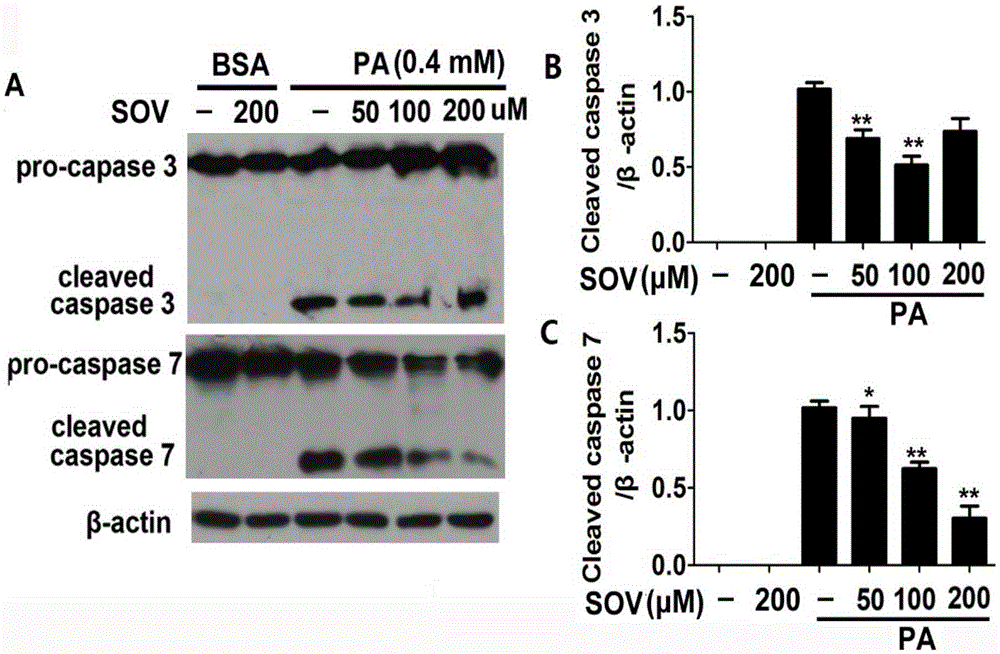

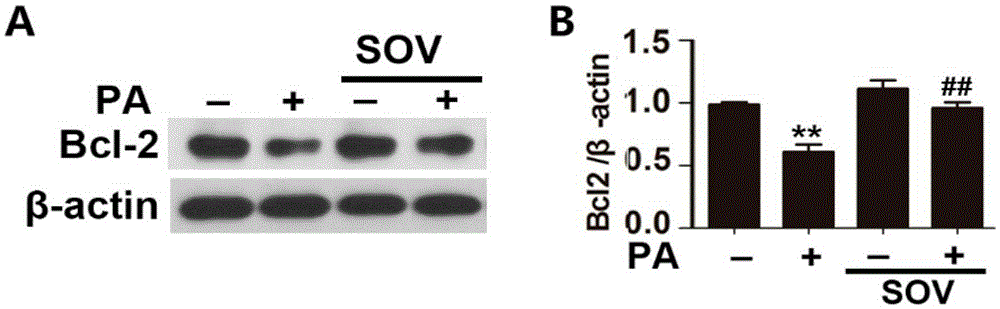

Application of sodium orthovanadate in preparation of medicine for resisting myocardial apoptosis

InactiveCN105250328AInhibit apoptosisBroad scientific researchHeavy metal active ingredientsCardiovascular disorderDiseasePyknosis

The invention discloses application of sodium orthovanadate in preparation of medicine for resisting myocardial apoptosis caused by excessive lipid accumulation. Experiments prove that the sodium orthovanadate can effectively inhibit the myocardial apoptosis induced by long-chain saturated fatty acid palmitic acid, and it is specifically shown that the sodium orthovanadate inhibits the apoptosis induced by the palmitic acid from executing cutting of a caspase precursor, promotes protein expression of anti-apoptosis protein Bcl-2 and obviously reduces the apotosis rate and pyknosis of nucleus chromatin. On the basis, it is expected that application is supplied to SOV in aspect of preparing the medicine for treating the myocardial apoptosis induced by excessive lipid accumulation along with diseases such as obesity and diabetes in clinical research, and it is indicated that the wide scientific research and clinical development prospects are achieved.

Owner:SHANDONG UNIV

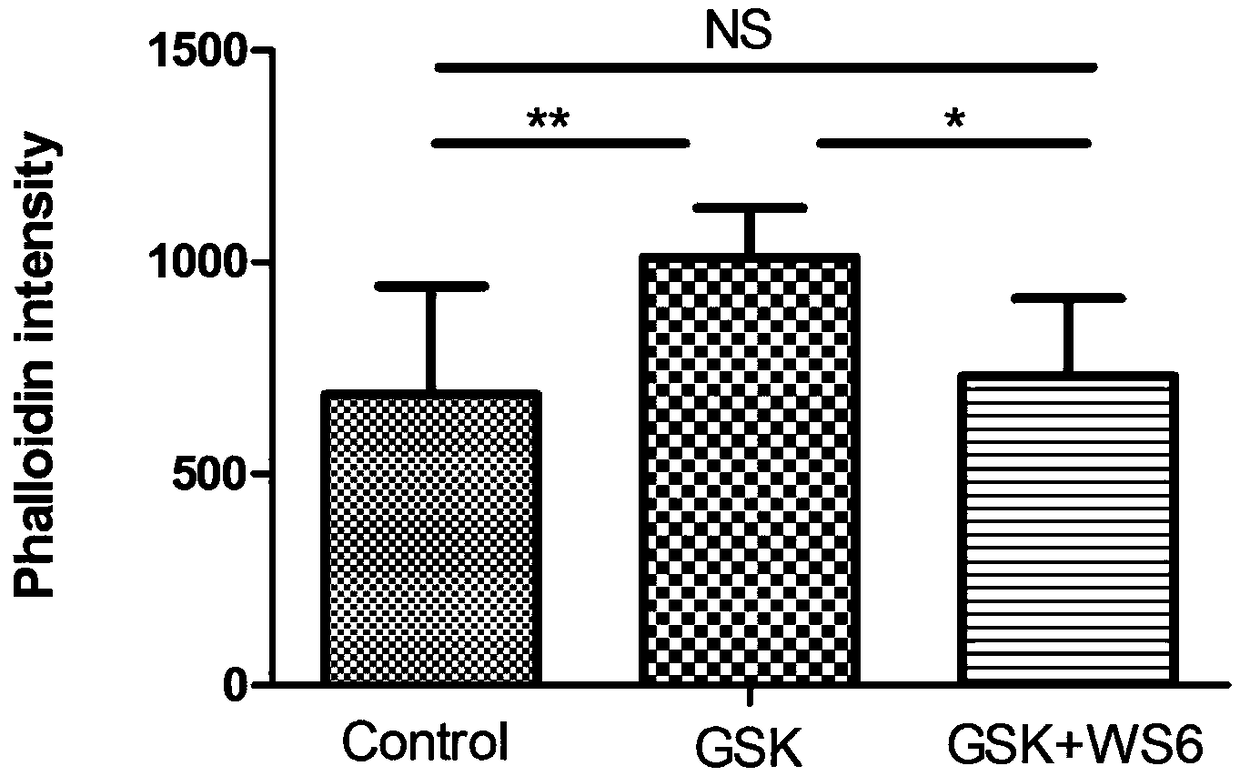

Influence of WS6 on actin formation of trabecular meshwork cells

ActiveCN108836971AInhibition formationLower eye pressureSenses disorderInorganic active ingredientsCytotoxicityAgonist

The invention discloses influence of WS6 on actin formation of trabecular meshwork cells. WS6 refers to anti-diabetic medicine glibenclamide, sodium orthovanadate and an active compound capable of promoting pancreatic beta cell proliferation. WS6 has cytotoxicity on the trabecular meshwork cells and inhibits actin formation of the trabecular meshwork cells. The influence of WS6 has the beneficialeffect that the fact that WS6 can remarkably inhibit actin formation, caused by TRPV4 agonist GSK101, of the trabecular meshwork cells is revealed. Intraocular pressure can be reduced, and the influence of WS6 has potential treatment significance in glaucoma caused by increase of intraocular pressure.

Owner:QINGDAO UNIV

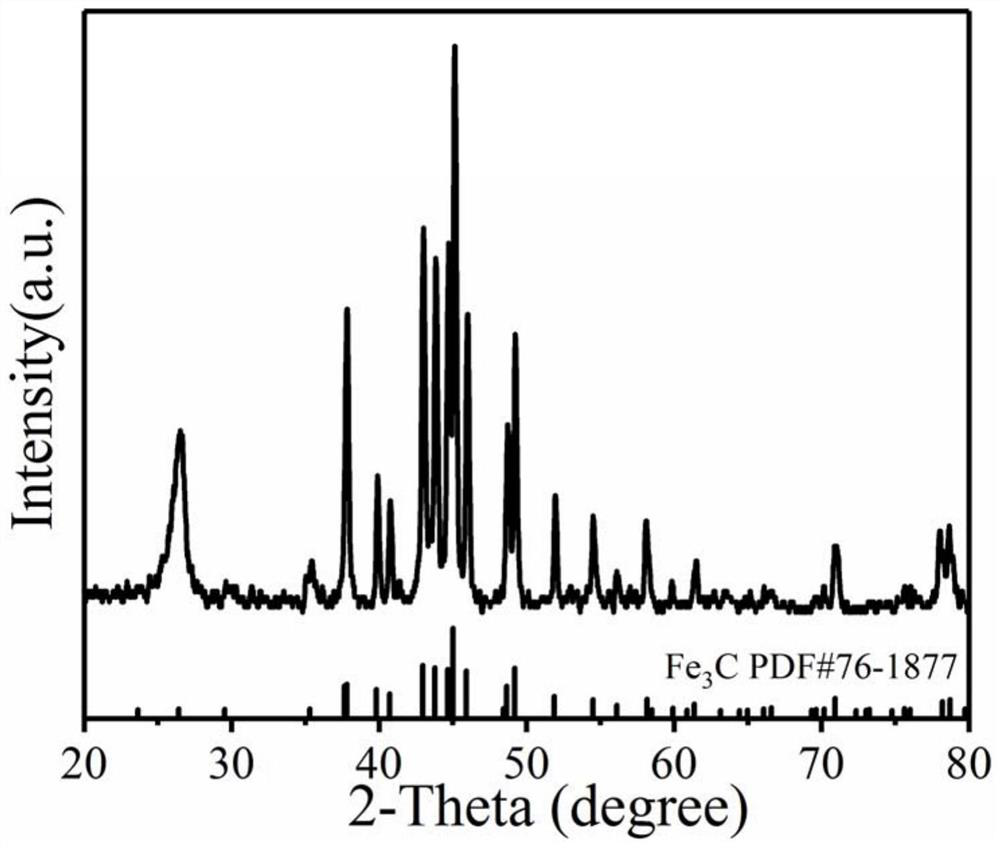

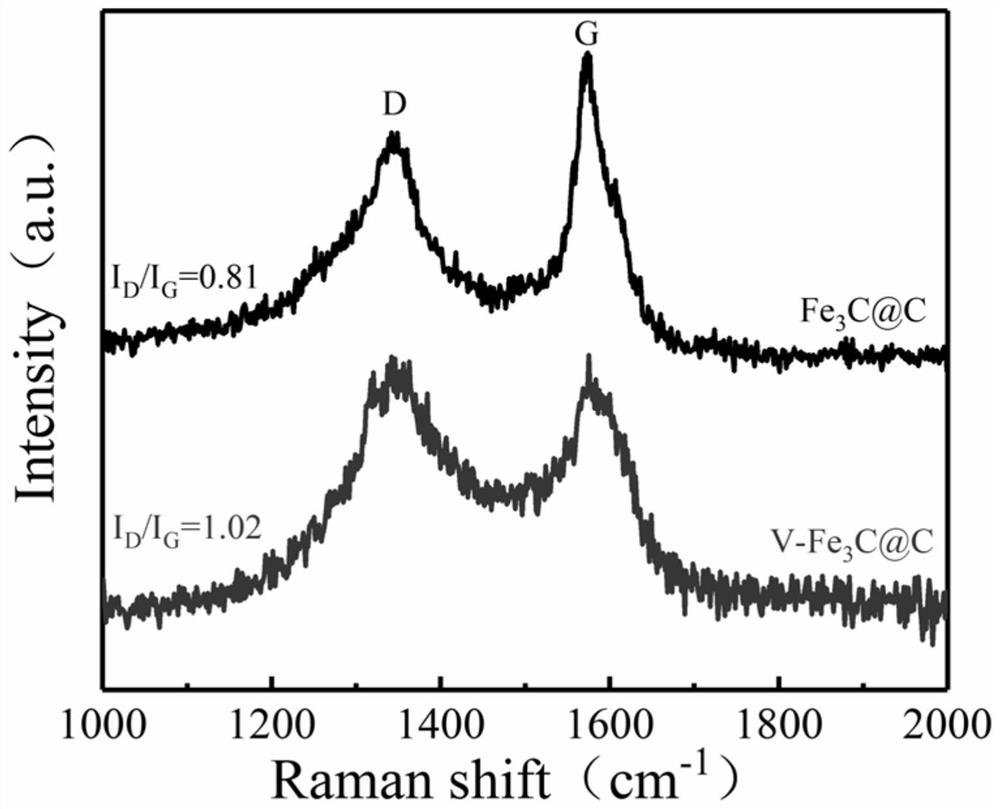

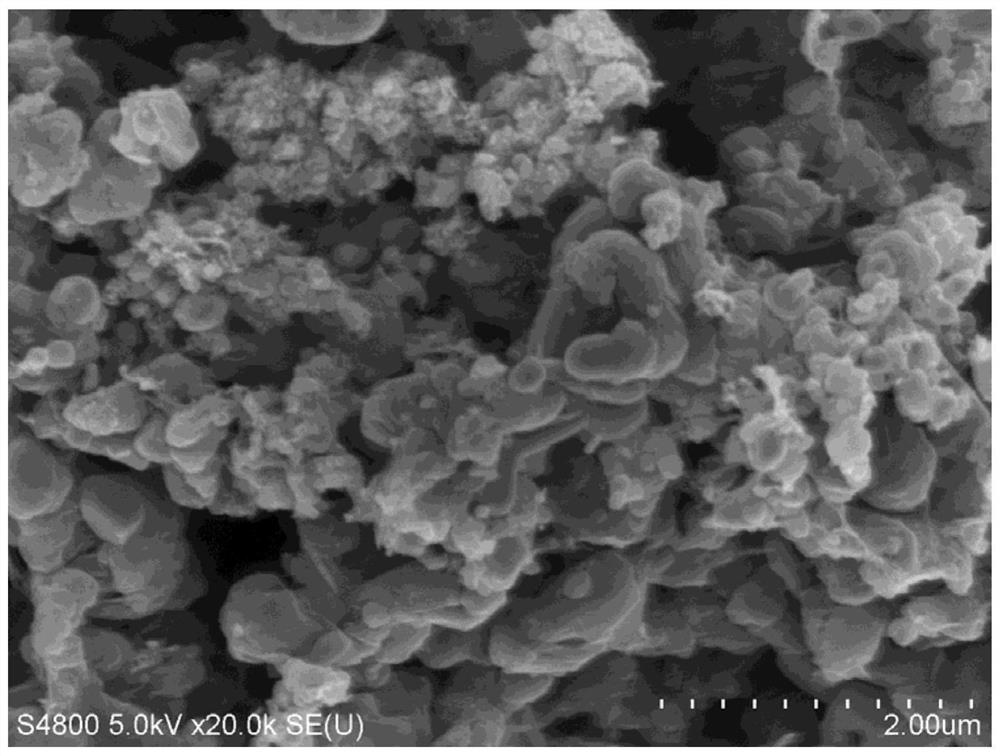

A kind of vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, preparation method and application thereof

ActiveCN113224321BImprove electronic conductivityHigh activityCell electrodesElectrodesPtru catalystMaterials science

The invention provides a vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, a preparation method and application thereof, and belongs to the technical field of electrochemical catalysis. The preparation method comprises the following steps: mixing sodium orthovanadate, hexahydrate trichloride Ferric, dicyandiamide and sodium chloride are mixed uniformly and then heat-insulated at 700~950℃ under a protective atmosphere. The mass ratio of sodium orthovanadate, ferric chloride hexahydrate and dicyandiamide is (0.01~0.06) : (0.2~0.7): (2~4.5) to obtain a mixture; the mixture is cooled in a protective atmosphere, washed and dried in sequence to obtain a vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst. The process of the invention is simple, the production cost is low, and the conditions are easy to control, and the electrocatalyst prepared by the method can be used for HER, OER and ORR, and exhibits excellent catalytic activity.

Owner:SHAANXI UNIV OF SCI & TECH

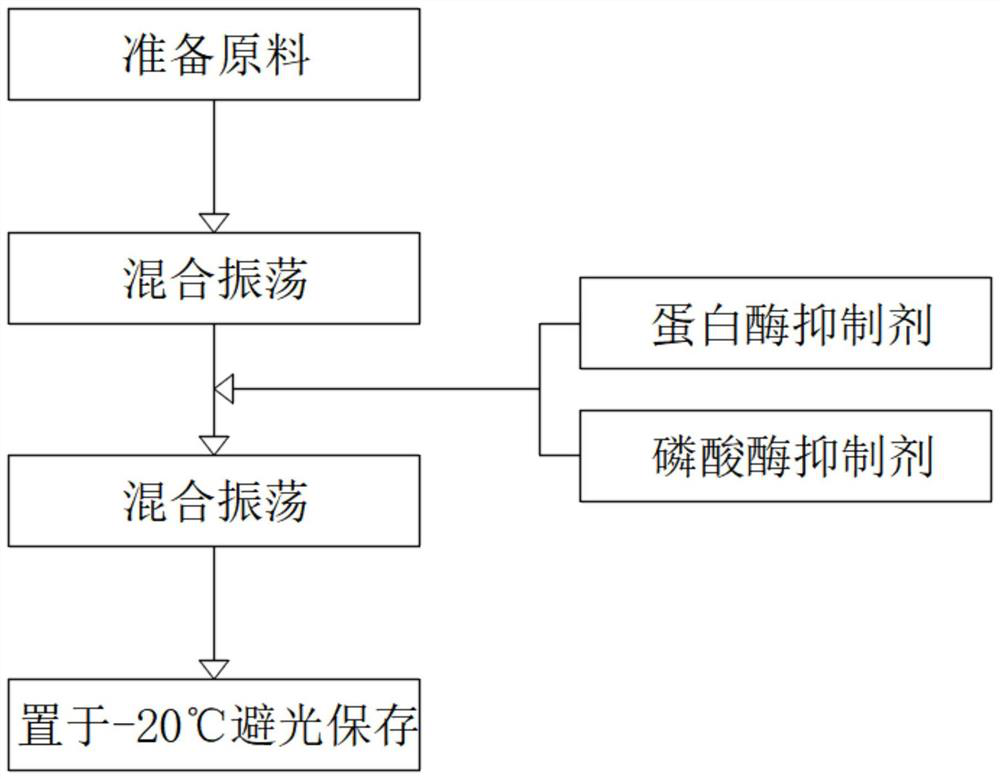

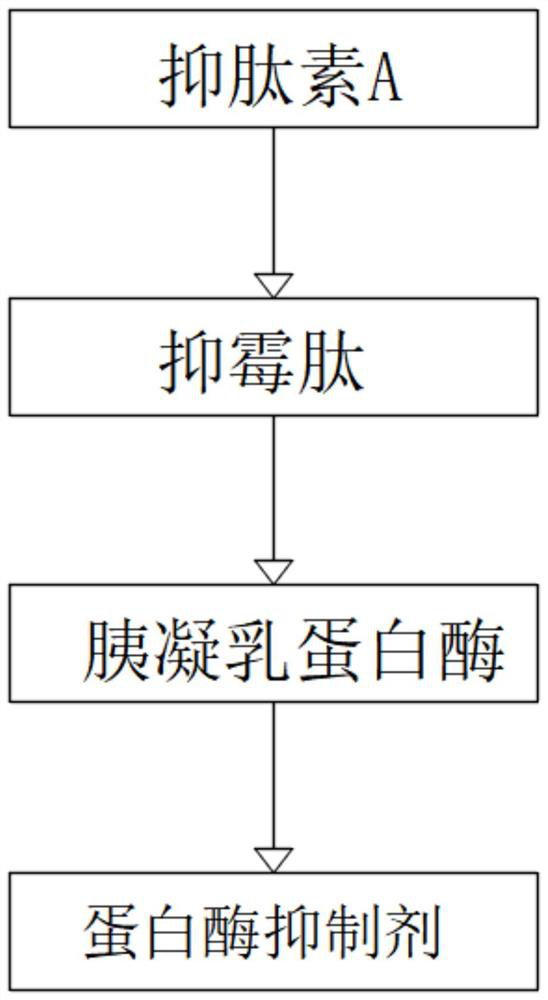

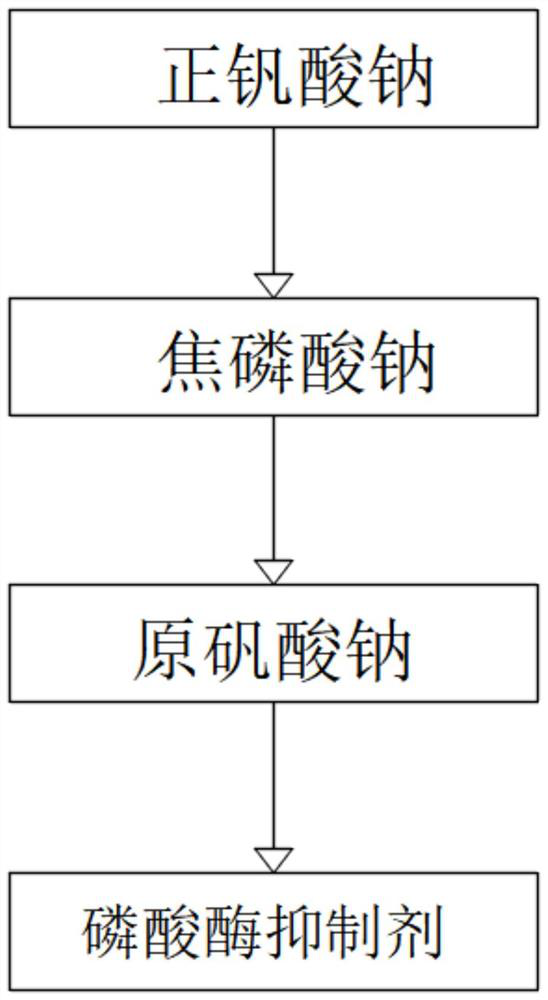

Magnetic bead method nucleic acid extraction reagent formula capable of effectively improving virus nucleic acid recovery efficiency

PendingCN114214317AImprove recycling efficiencyEnhancing Hydrophobic Residue StretchMicrobiological testing/measurementDNA preparationPhenyl EthersPolyethylene glycol

The invention discloses a magnetic bead method nucleic acid extraction reagent formula capable of effectively improving virus nucleic acid recovery efficiency. Comprising urea, thiourea, thiothreitol, ethylenediamine tetraacetic acid, cholamidopropyl, tromethamine, ethyl phenyl polyethylene glycol, polyethylene glycol octyl phenyl ether, phenylmethylsulfonyl fluoride, sodium chloride, sodium fluoride, guanidine hydrochloride, guanidine isothiocyanate, protease K, sodium deoxycholate, distilled water, a protease inhibitor, a phosphatase inhibitor and sodium orthovanadate. The preparation method mainly comprises the following steps: adding guanidine hydrochloride into urea to achieve a solubilizing effect on amino acid, adding protease K to cut carboxyl-terminal peptide bonds of aliphatic amino acid and aromatic amino acid, adding a protease inhibitor to effectively inhibit various asparaginic acid proteases, and adding a phosphatase inhibitor to inhibit various asparaginic acid proteases. Alkaline phosphatase and tyrosine phosphatase can be inhibited, the recovery efficiency of viral nucleic acid can be effectively improved, the working efficiency is improved, and the method is convenient and practical.

Owner:南京维特康检测技术有限公司

Method for cleanly preparing vanadium oxides

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

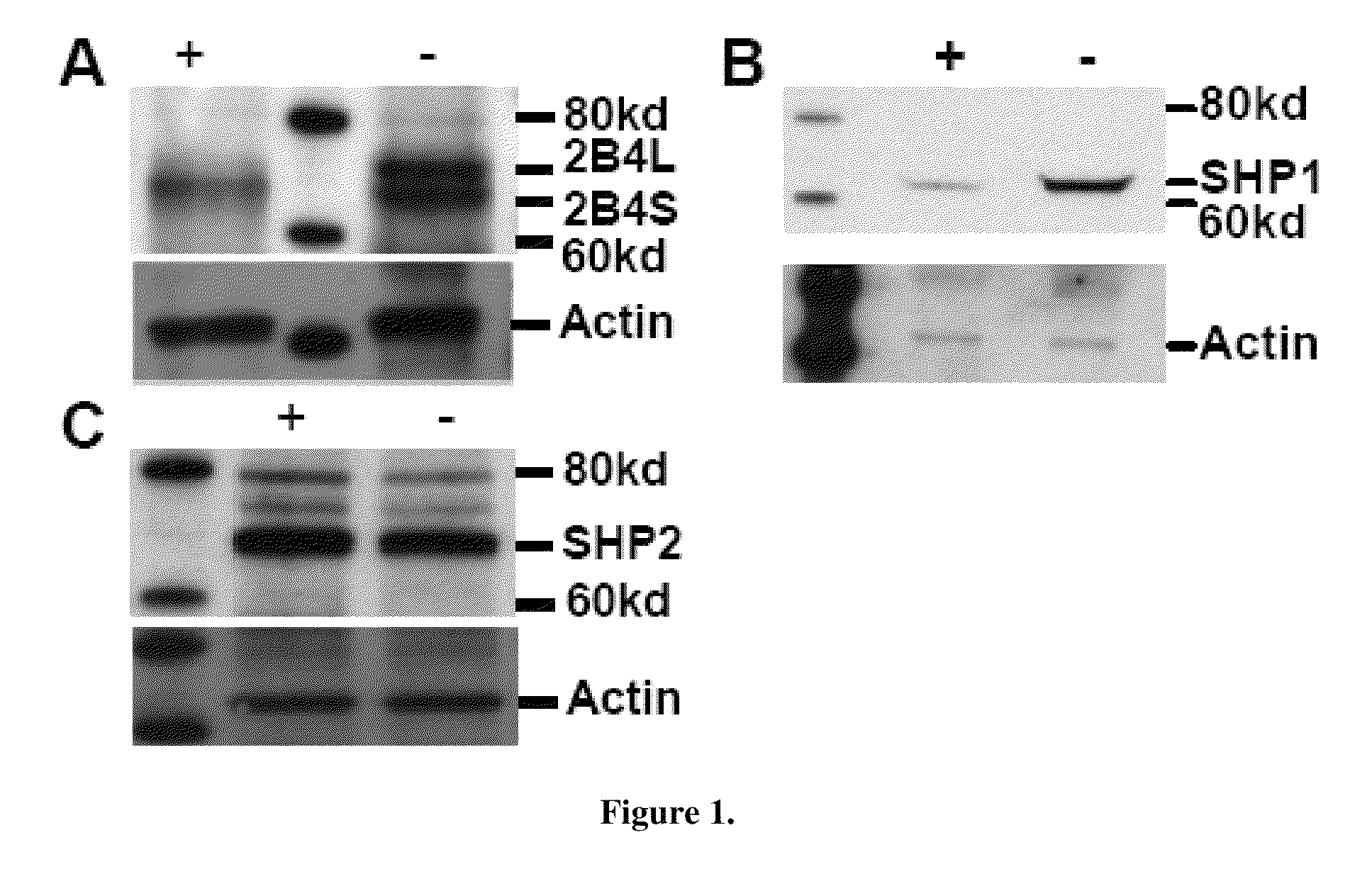

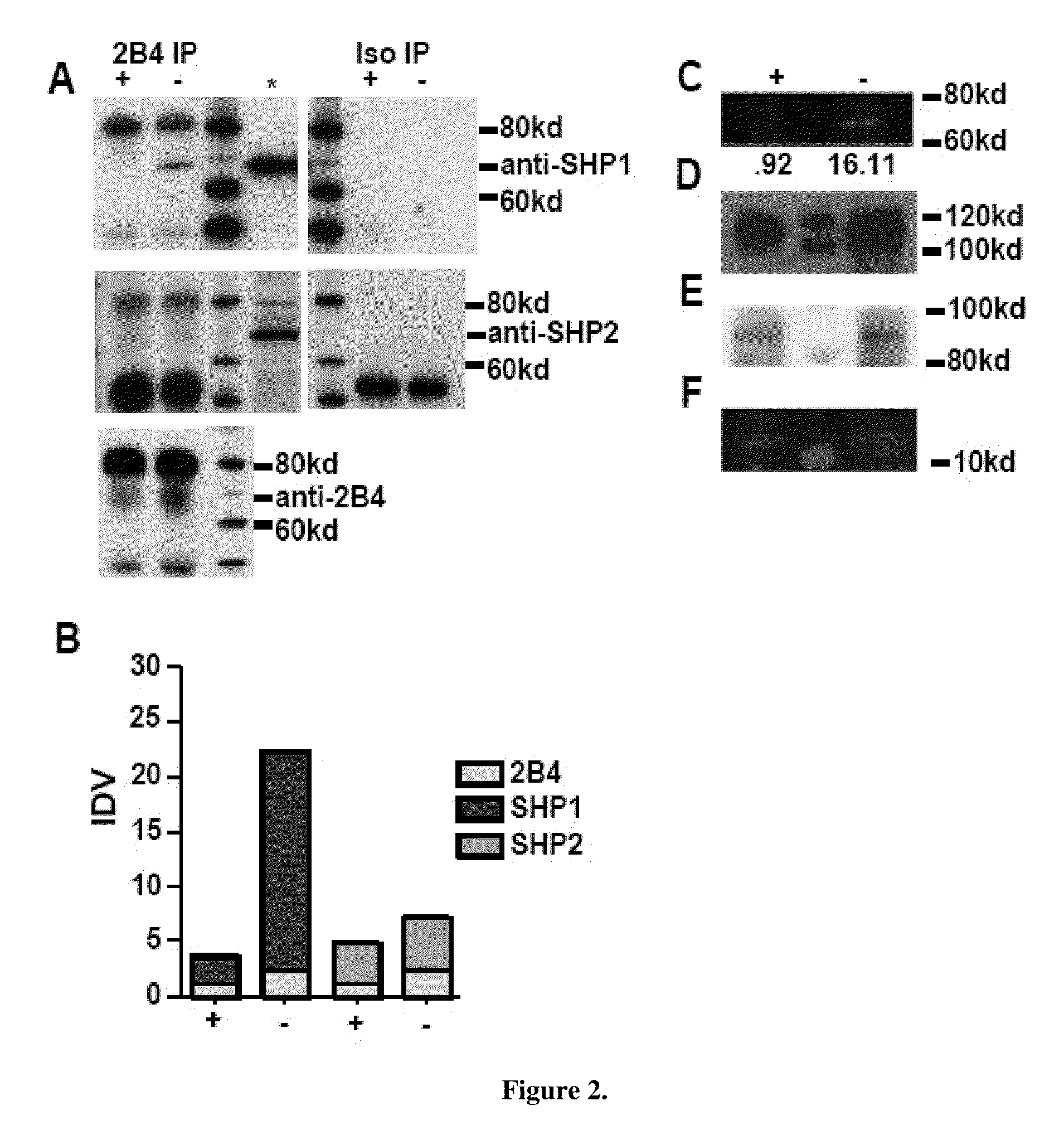

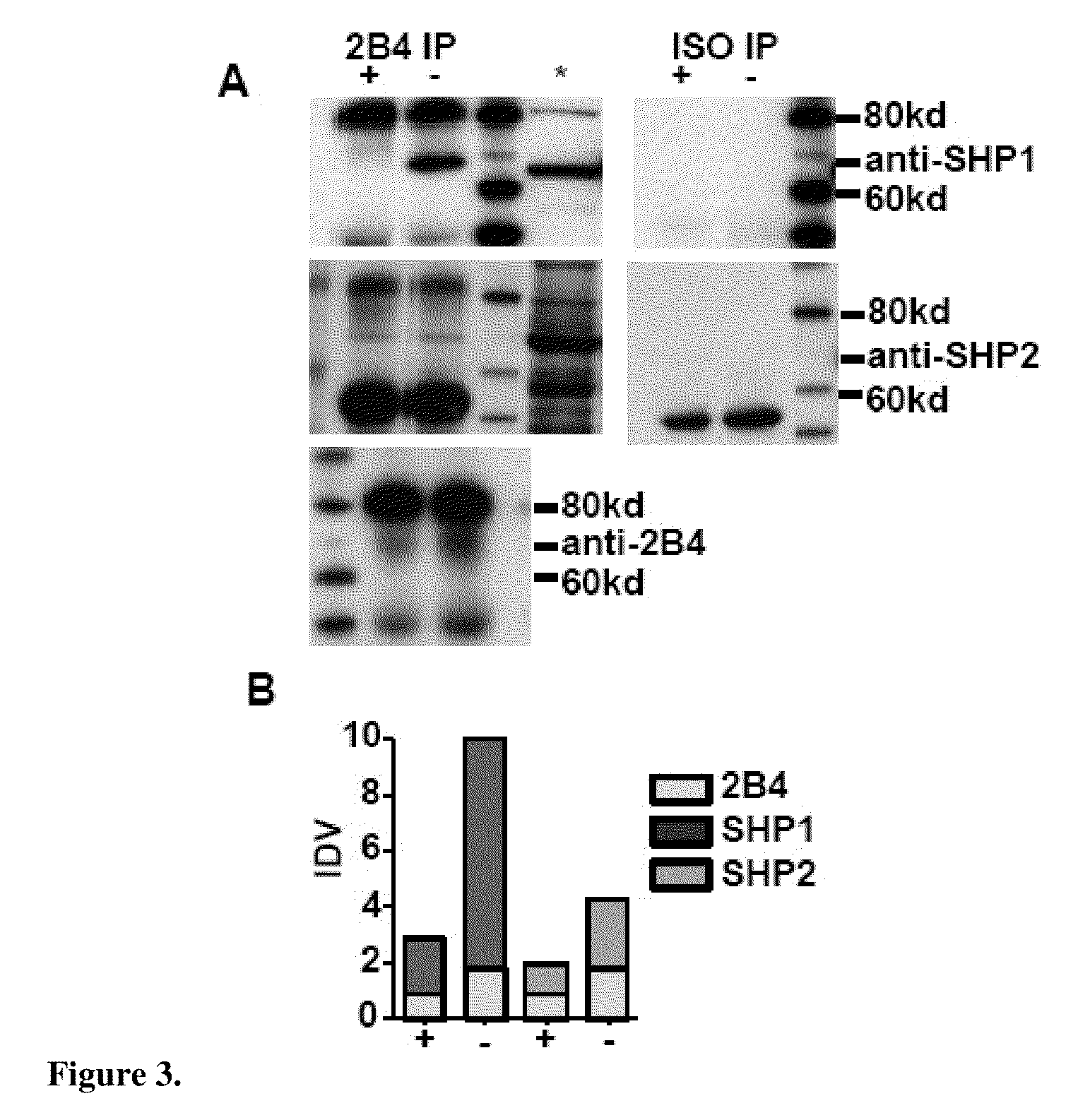

Method of activating NK cells

InactiveUS8399510B2BiocideTissue culturePhosphatase inhibitorNatural Killer Cell Inhibitory Receptors

Owner:UNIV OF SOUTH FLORIDA

Preparation method of black wear-resistant micro-arc oxidation ceramic layer of magnesium alloy

ActiveCN108004581BImprove corrosion resistanceImprove stabilityAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides a preparation method for a black abrasion-resistant micro-arc oxidization ceramic layer of a magnesium alloy. The magnesium alloy is dipped into electrolyte to be subjected to micro-arc oxidization so that the black abrasion-resistant micro-arc oxidization ceramic layer can be prepared; the electrolyte comprises 5-20 g / L of sodium silicate, 5-15 g / L of potassium fluoride, 1-60 g / L of potassium hydroxide, 5-25 g / L of triethanolamine, 2-6 g / L of ammonium meta-vanadate, 2-6 g / L of sodium orthovanadate, 2-10 g / L of nanometer SiC and 2-5 g / L of nanometer graphite. The black abrasion-resistant ceramic layer of the magnesium alloy can reach the level 9 according to 350 h of a neutral salt spray test, the Vickers hardness HV can reach 553-605, the friction coefficient is 0.08-0.14, the abrasion rate is 0.006-0.009 mg / min, the beneficial effects that stability is good, color is uniform and color fading is not prone to occurrence are all achieved, and the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is very suitable for preparing an optical collimator and other systems. The preparation method for the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is simple in technological process, convenient to operate, small in pollution and remarkable in industrial value.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for recovering sodium and/or potassium and separating vanadium from sodium orthovanadate and/or potassium orthovanadate

InactiveCN105821222AHigh recovery rateLow costProcess efficiency improvementPotassium ionsSodium orthovanadate

The invention provides a method for recovering sodium and / or potassium and separating vanadium from sodium orthovanadate and / or potassium orthovanadate. The method includes the steps that a sodium orthovanadate solution and / or a potassium orthovanadate solution and CO2 react under the conditions that the temperature is 50-150 DEG C and the pressure is 1.0-3.0 MPa, then solid-liquid separation is carried out to obtain carbonate and / or bicarbonate and a vanadium-containing solution, and positive ions in the carbonate and the bicarbonate are sodium ions and / or potassium ions. By means of the method, the vanadium recovery rate is high (higher than 98%), and the technological process is short, easy to operate, simple and good in safety; in the separation process, sodium and / or potassium in the sodium orthovanadate and / or the potassium orthovanadate are / is converted into crystals or alkaline solutions so as to be recycled.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com