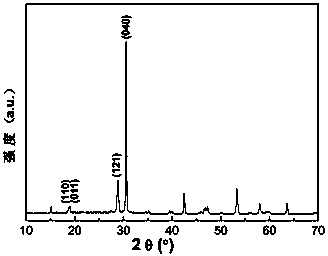

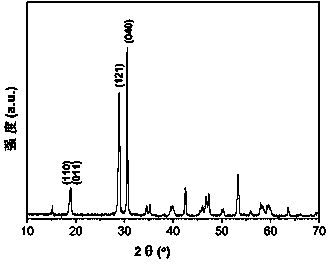

Method for synthesis of (010) preferred orientation bismuth vanadate powder by glycerol preparation hydrothermal process

A preferred orientation and glycerol technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as poor catalytic performance, achieve low cost, excellent performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

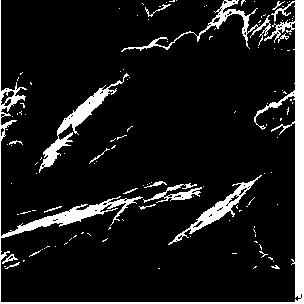

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode 1: In this implementation mode, the method steps of synthesizing (010) preferentially oriented bismuth vanadate powder by using the hydrothermal process modulated by glycerin are as follows:

[0025] 1. Use analytically pure nitric acid and deionized water to prepare a nitric acid solution with a concentration of 1mol / L, which is designated as solution A;

[0026] ②. Use analytically pure glycerol and deionized water to prepare a glycerol solution with a concentration of 0.5 mol / L to 10 mol / L, which is recorded as solution B;

[0027] ③. Mix solution A and solution B in steps ① and ② according to the volume ratio of 1:120-240 to obtain solution C;

[0028] ④. Weigh 48.5% to 50.5% of bismuth nitrate pentahydrate and 49.5% to 51.5% of sodium orthovanadate dodecahydrate respectively according to molar percentage;

[0029] 5. Dissolving the bismuth nitrate pentahydrate taken in step 4. in the solution C obtained in step 3. to prepare a bismuth ...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step ④, 50% of bismuth nitrate pentahydrate and 50% of sodium orthovanadate dodecahydrate are weighed by molar percentage. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step ②, analytically pure glycerol and deionized water are used to prepare a glycerol solution with a concentration of 1mol / L-8mol / L. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com