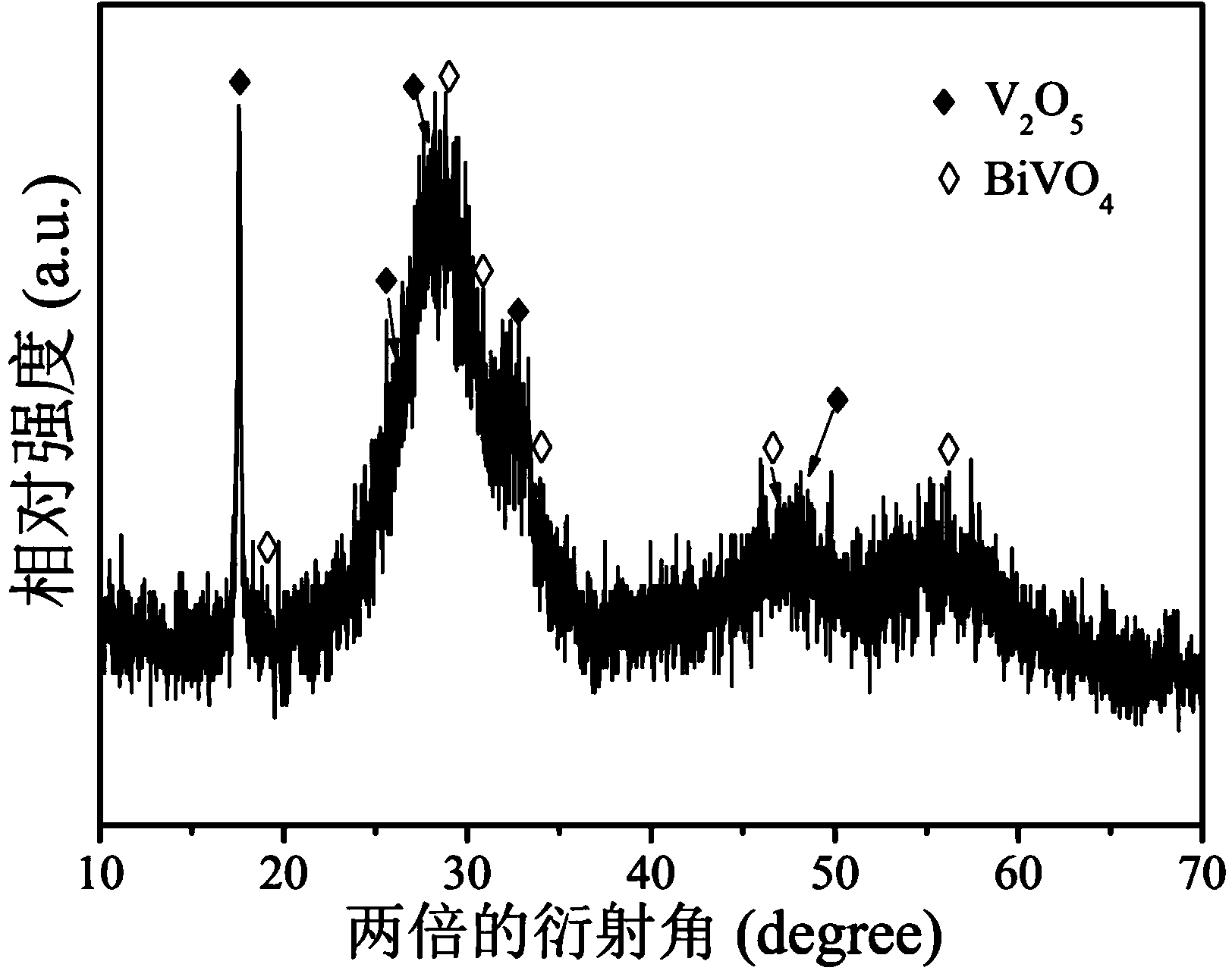

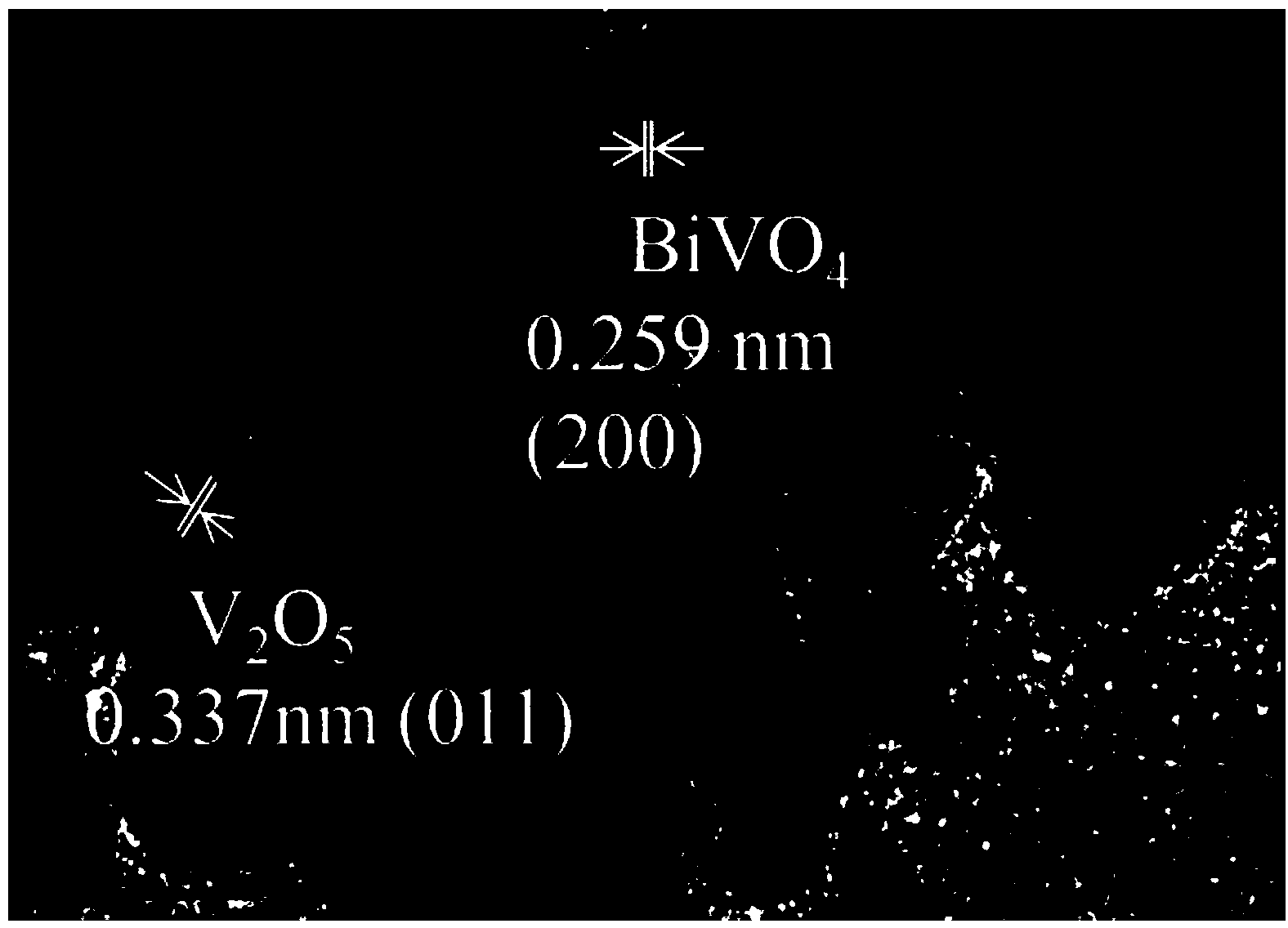

Preparation method of V2O5/BiVO4 (vanadium pentoxide/bismuth vanadium oxide) nanorod composite photocatalyst

A technology of composite light and nanorods, applied in the field of environmental pollution control, can solve the problems of poor adsorption capacity and low photocatalysis, and achieve the effects of strong photoresponse, high catalytic activity, good application value and prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 2.88mmol of sodium oleate and add it to 48mL of deionized water, then add 0.96mmol of Bi(NO 3 ) 3 ·5H 2 O was added to the sodium oleate solution while vigorously stirring for about 15 minutes. Then 0.96mmol Na 3 VO 4 12H 2 O was added to 48 mL of deionized water to form Na 3 VO 4 solution. Na 3 VO 4 The solution was added to the above solution, and after being vigorously stirred for 30 min, it was transferred to a 120 mL reaction kettle, and hydrothermally reacted at 100° C. for 12 h. Then the obtained sample was cooled to room temperature, the supernatant was extracted with acetone, the extracted sample was washed with cyclohexane and ethanol, and finally dried in a vacuum oven at 50°C for 8 hours, and the obtained light yellow sample was V 2 o 5 / BiVO 4 Nanorod composite photocatalysts.

Embodiment 2

[0037] According to the preparation method of the present invention of Example 1, the quality of sodium oleate is increased to 3.6mmol, dissolved in 60ml of deionized water, Bi(NO 3 ) 3 ·5H 2 O and Na 3 VO 4 12H 2 The quality of O is increased to 1.2mmol, and 1.2mmol Na 3 VO 4 12H 2 O was dissolved in 60ml of deionized water to prepare V 2 o 5 / BiVO 4 Nanorod composite photocatalysts.

Embodiment 3

[0039] According to the preparation method of the present invention in Example 1, the hydrothermal reaction temperature was changed to 80° C., and the reaction was carried out for 12 hours, followed by extraction, washing, separation and drying. get V 2 o 5 / BiVO 4 Nanorod composite photocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com