Ag2CO3 and Bi4O5I2g-C3N4 composite catalyst as well as synthesis method and application of Ag2CO3 and Bi4O5I2g-C3N4 composite catalyst

A technology of composite catalyst and synthesis method, which is applied in the field of composite catalyst preparation, can solve problems such as difficulty in obtaining, high material price, and secondary pollution, and achieve the effects of improving stability, improving stability, and overcoming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

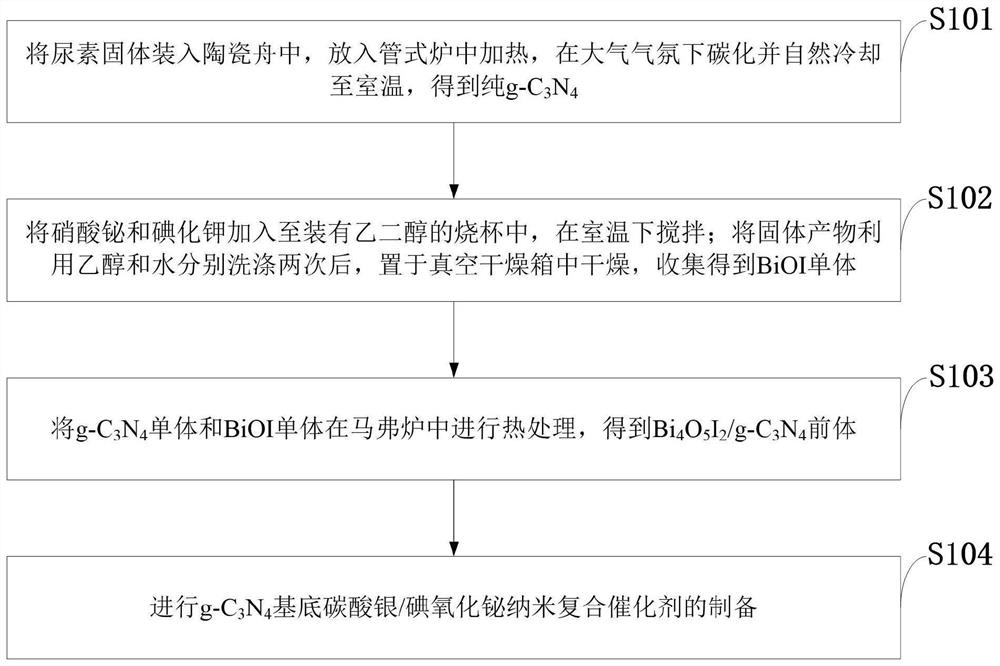

[0047] like figure 1 As shown, the Ag provided by the embodiment of the present invention 2 CO 3 @Bi 4 O 5 I 2 g-C 3 N 4 The synthetic method of composite catalyst comprises the following steps:

[0048] S101, the urea solid is loaded into a ceramic boat, heated in a tube furnace, carbonized under atmospheric atmosphere and naturally cooled to room temperature to obtain pure g-C 3 N 4 ;

[0049] S102, adding bismuth nitrate and potassium iodide into a beaker containing ethylene glycol, and stirring at room temperature; after the solid product is washed twice with ethanol and water, respectively, it is placed in a vacuum drying oven to dry, and the BiOI monomer is collected and obtained;

[0050] S103, put g-C 3 N 4 The monomer and BiOI monomer are heat treated in a muffle furnace to obtain Bi 4 O 5 I 2 / g-C 3 N 4 precursor;

[0051] S104, perform g-C 3 N 4 Preparation of substrate silver carbonate / bismuth oxyiodide nanocomposite catalyst.

Embodiment 1

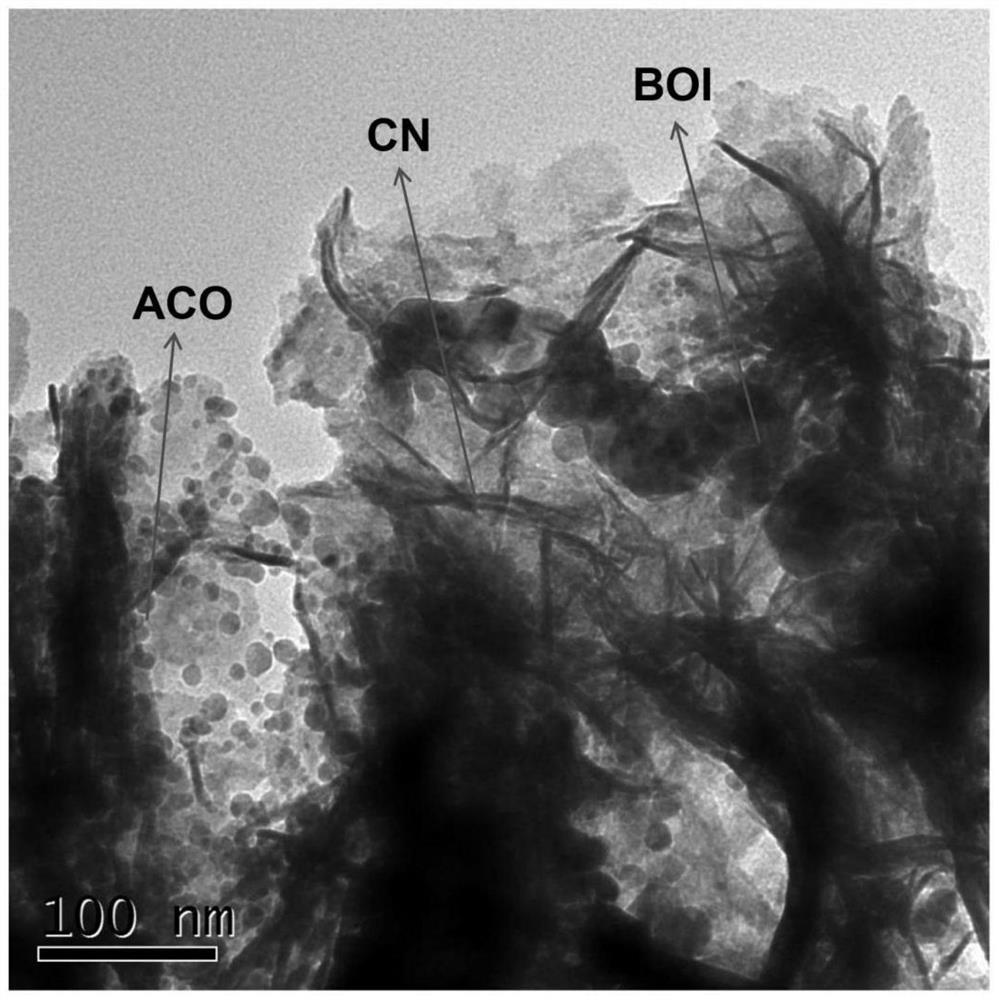

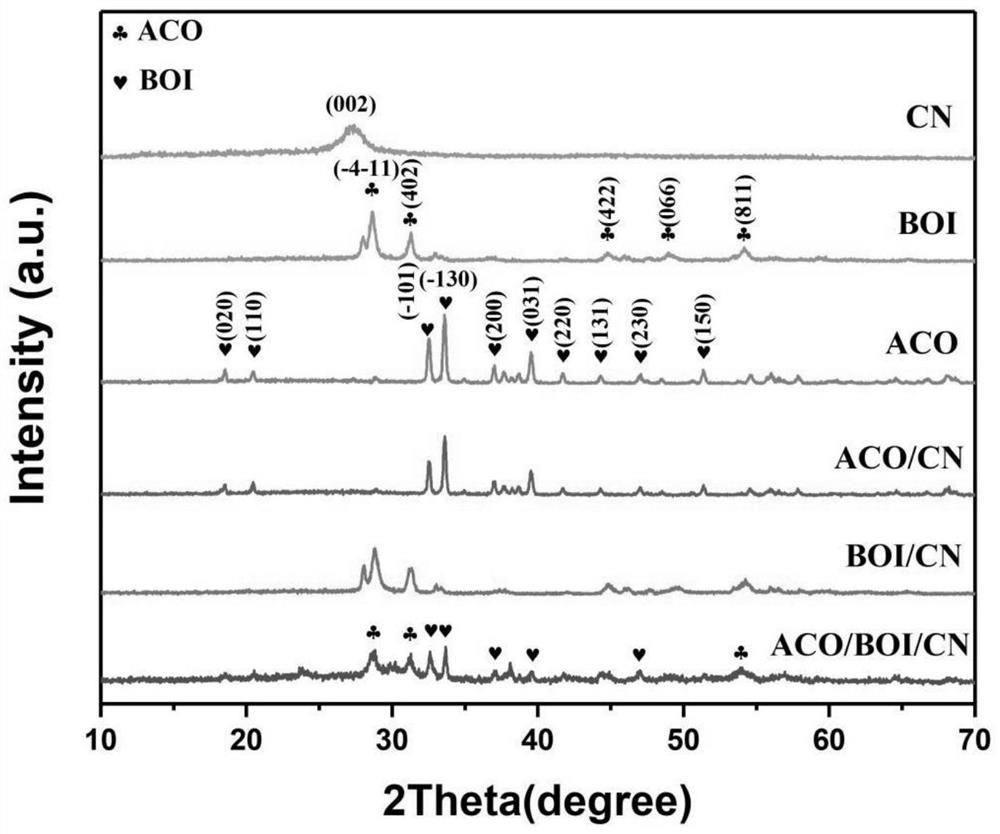

[0065] A double ladder type g-C 3 N 4 Substrate silver carbonate / bismuth oxyiodide (Ag 2 CO 3 @Bi 4 O 5 I 2 / g-C 3 N 4 ) nanocomposite catalyst, this g-C 3 N 4 Substrate silver carbonate / bismuth oxyiodide stepped nanocomposite photocatalyst based on g-C 3 N 4 basal body, then in g-C 3 N 4 Loading silver carbonate and bismuth oxyiodide on the substrate has the following steps:

[0066] (1), 30g urea solid is loaded into the ceramic boat, put into the tube furnace, heated to 550 ℃ with the speed of 5 ℃ / min, carbonized 5h under atmospheric atmosphere and naturally cooled to room temperature, obtains pure g-C 3 N 4 , named g-C 3 N 4 .

[0067] (2), 6 mmol of bismuth nitrate (Bi(NO 3 ) 3 .5H 20), the potassium iodide (KI) of 6mmol joins in the beaker that 60mL ethylene glycol is housed, stirs 60-70min at room temperature, the solid product is washed twice with ethanol and water respectively, then is placed in the vacuum drying oven 70 ℃ of drying 12h, the BiOI ...

Embodiment 2

[0083] g-C 3 N 4 Substrate silver carbonate / bismuth oxyiodide nanocomposite catalyst (Ag 2 CO 3 @Bi 4 O 5 I 2 / g-C 3 N 4 The photocatalytic performance of ) was evaluated by the catalytic degradation of tetracycline under visible light, including the following processes:

[0084] Weigh the g-C obtained in Example 1 3 N 4Substrate silver carbonate / bismuth oxyiodide nanocomposite catalyst (Ag 2 CO 3 @Bi 4 O 5 I 2 / g-C 3 N 4 ) and g-C 3 N 4 , g-C prepared in Comparative Example 1 3 N 4 Substrate silver carbonate composite (Ag 2 CO 3 @g-C 3 N 4 ), the g-C obtained in Comparative Example 2 3 N 4 Substrate bismuth oxyiodide composite (Bi 4 O 5 I 2 / g-C 3 N 4 ), the silver carbonate (Ag) prepared in the comparative example 3 2 CO 3 ), the bismuth oxyiodide (Bi 4 O 5 I 2 ) 0.02g each, put them into 100mL of 10mg / L tetracycline solution respectively, and stirred for 30min under dark conditions to achieve adsorption and desorption equilibrium, under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com