Gan-cdznte composite structural components with znte transition layer, application and preparation method thereof

A composite structure and transition layer technology, which is applied in the manufacture of electrical components, semiconductor devices, and final products, can solve the problems of low lattice mismatch and optical detection devices that have not yet been seen, so as to improve production efficiency and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

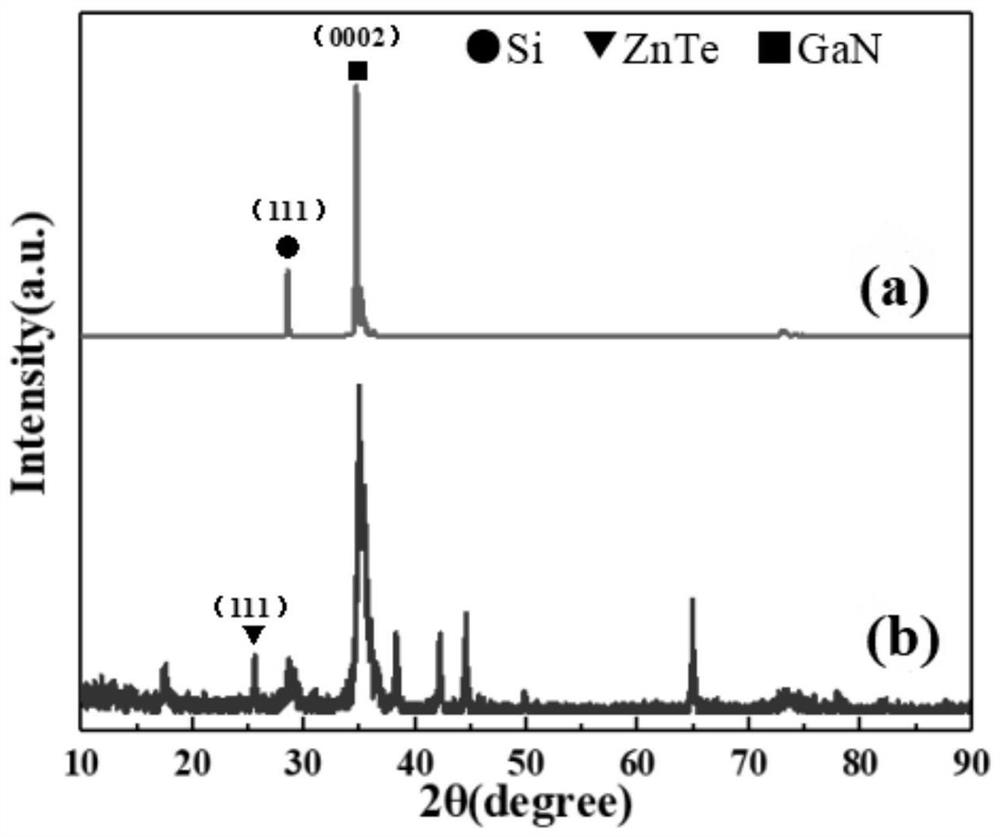

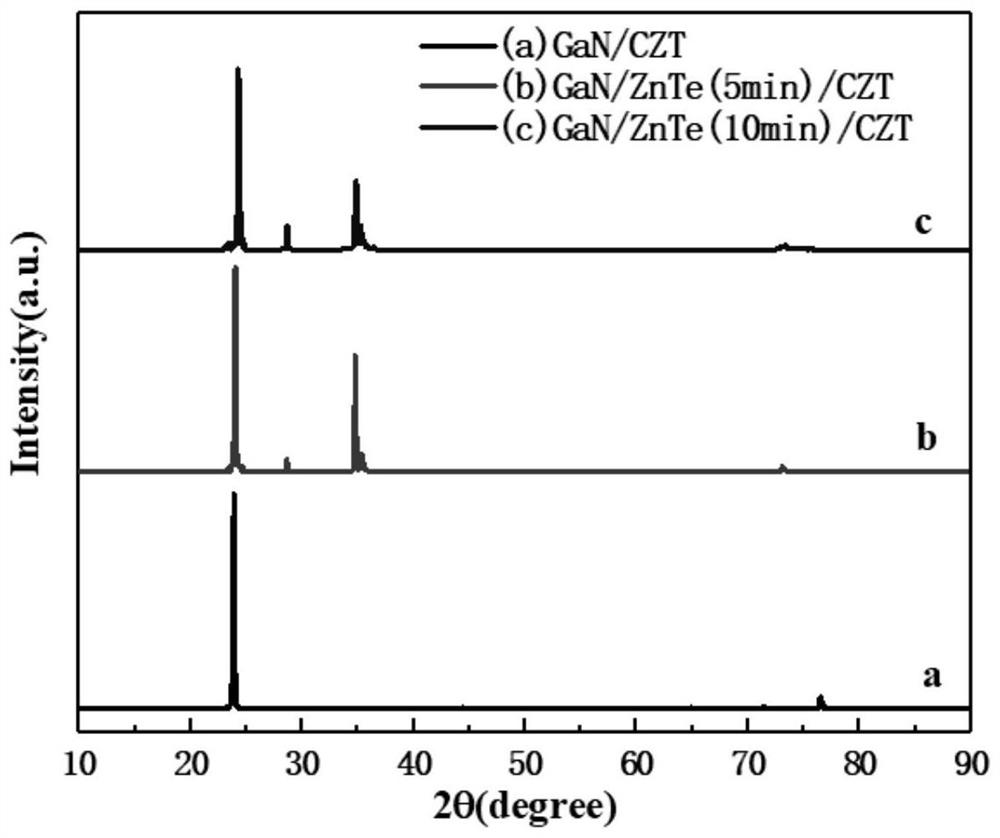

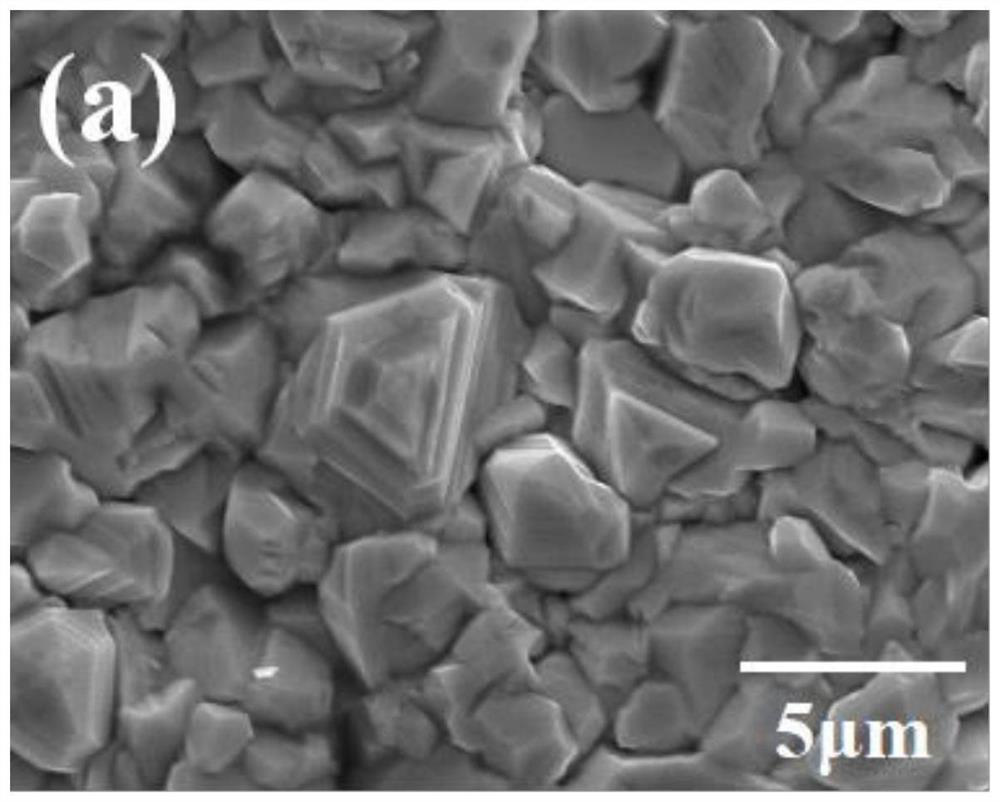

[0032]In this embodiment, a GaN-CdZnTe composite structural assembly with a ZnTe transition layer, first prepares a ZnTe transition layer on a GaN substrate to form a GaN-ZnTe composite substrate, and then forms a GaN-ZnTe composite substrate on the ZnTe transition layer of the GaN-ZnTe composite substrate The CdZnTe thin film is continuously grown on the surface to obtain a GaN-ZnTe-CdZnTe composite structural component combined with a CdZnTe transition layer and a GaN substrate. The deposited thickness of the ZnTe transition layer is 200nm. The thickness of the above-mentioned CdZnTe film is 20 μm, and the thickness of the GaN substrate is 500 nm.

[0033] In this embodiment, the preparation method of the GaN-CdZnTe composite structural component with a ZnTe transition layer in this embodiment, the steps are as follows:

[0034] a. Substrate pretreatment:

[0035] The GaN substrate with a thickness of 500nm was ultrasonically cleaned with acetone, alcohol, and deionized wa...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

[0055] In this embodiment, the preparation method of the GaN-CdZnTe composite structural component with a ZnTe transition layer of the present invention, the steps are as follows:

[0056] a. Substrate pretreatment:

[0057] The GaN substrate with a thickness of 500nm was ultrasonically cleaned with acetone, alcohol, and deionized water for 15 minutes respectively, and impurities and organic matter on the surface of the GaN substrate were washed away, dried with nitrogen, and then placed in a magnetron sputtering reaction chamber as Substrate spare;

[0058] b. Sputtering process of ZnTe transition layer:

[0059] Open the magnetron sputtering chamber, put the GaN substrate pretreated in step a into the chamber; turn on the mechanical pump, and when the vacuum degree of the chamber is lower than 5Pa, open the front valve, close the pre-pumping valve, and open the molecular Pump and high valv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com