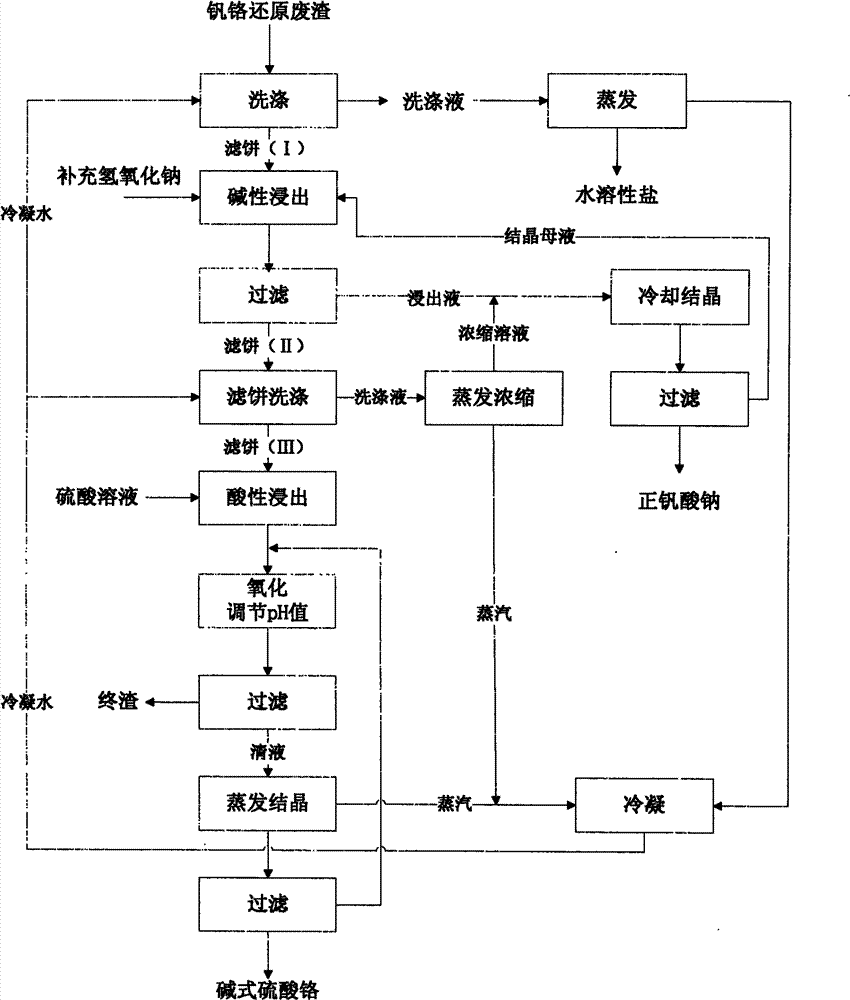

Method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue

A technology for separation and recovery of waste slag, applied in the direction of improving process efficiency, etc., can solve the problems of long process, low efficiency of vanadium and chromium separation, affecting industrial production, etc., and achieve the effect of facilitating industrial production and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] With 1000g vanadium chromium reduction waste residue (dry basis, SO 42- content of 24%, V content of 3.8%, and Cr content of 12%), the three-stage countercurrent washing method is used to wash and filter under the condition that the liquid-solid ratio is 1:1, to obtain filter cake (I) and washing liquid, and vanadium after washing In the chromium reduction waste residue, the sulfate radical concentration is reduced to 1.0%; the filter cake (I) and the concentration are 5% NaOH liquid at a liquid-solid ratio of 10: 1, the oxidizing agent is sodium peroxide, and the temperature is reacted for 6h under the condition of 20°C , The vanadium leaching rate is 98%, and the chromium leaching rate is less than 0.5%. After the leaching, the slurry is separated by filtration to obtain the filter cake (II) and the leachate, the filter cake (II) is washed to obtain the filter cake (III), the washing liquid of the filter cake (II) is evaporated and concentrated, and then combined with...

Embodiment 2

[0041] With 1000g vanadium chromium reduction waste residue (dry basis, SO 4 2- content of 24%, V content of 3.8%, and Cr content of 12%), the three-stage countercurrent washing method is used to wash and filter under the condition that the liquid-solid ratio is 4:1, to obtain filter cake (I) and washing liquid, and vanadium after washing In the chromium reduction waste residue, the sulfate radical concentration is reduced to 0.4%; the filter cake (I) and the concentration are 30% NaOH liquid at a liquid-solid ratio of 5: 1, the oxidant is oxygen, and the temperature is reacted for 3h under the condition of 70°C, and the vanadium The leaching rate is 98.5%, and the chromium leaching rate is less than 0.5%. After the leaching, the slurry is separated by filtration to obtain the filter cake (II) and the leachate, the filter cake (II) is washed to obtain the filter cake (III), the washing liquid of the filter cake (II) is evaporated and concentrated, and then combined with the l...

Embodiment 3

[0043] With 1000g vanadium chromium reduction waste residue (dry basis, SO 4 2- Content 24%, V content 3.8%, Cr content 12%) adopt the method for three-stage countercurrent washing to wash and filter under the condition that liquid-solid ratio is 8: 1, obtain filter cake (I) and washing liquid, vanadium after washing In the chromium reduction waste residue, the sulfate radical concentration is reduced to 0.05%; the filter cake (I) and the concentration are 50% NaOH liquid at a liquid-solid ratio of 2: 1, the oxidizing agent is air, and the temperature is reacted for 0.5h under the condition of 90° C. The vanadium leaching rate is 99.5%, and the chromium leaching rate is less than 0.8%. After the leaching, the slurry is separated by filtration to obtain the filter cake (II) and the leachate, the filter cake (II) is washed to obtain the filter cake (III), the washing liquid of the filter cake (II) is evaporated and concentrated, and then combined with the leachate and cooled C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com