Patents

Literature

50results about How to "Significant technical and economic advantages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

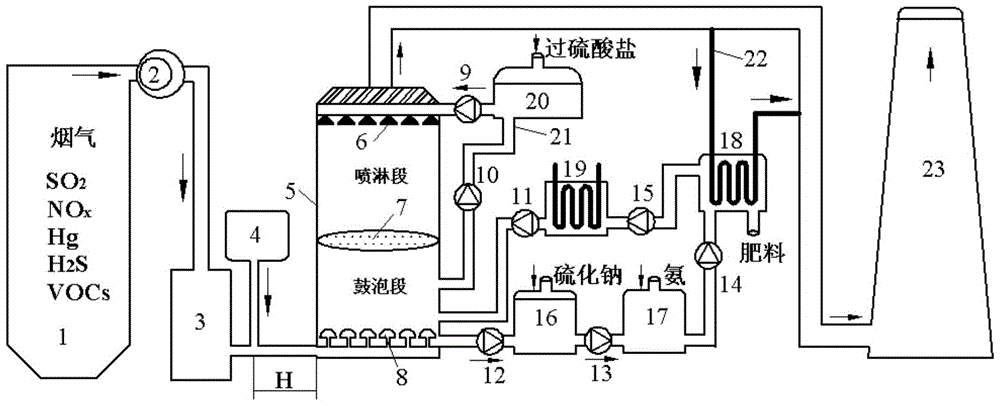

Method and system for purifying flue gas by inducing free radicals by virtue of ozone and hydrogen peroxide

InactiveCN103990365ATo achieve the purpose of removalLow investment costDispersed particle separationEnergy inputPollutionHydrogen peroxide

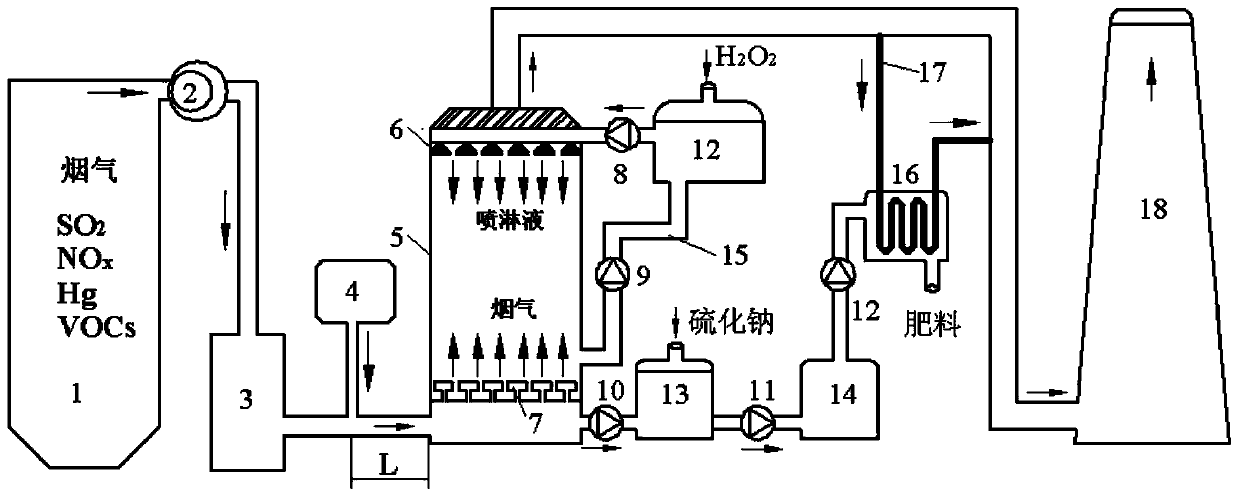

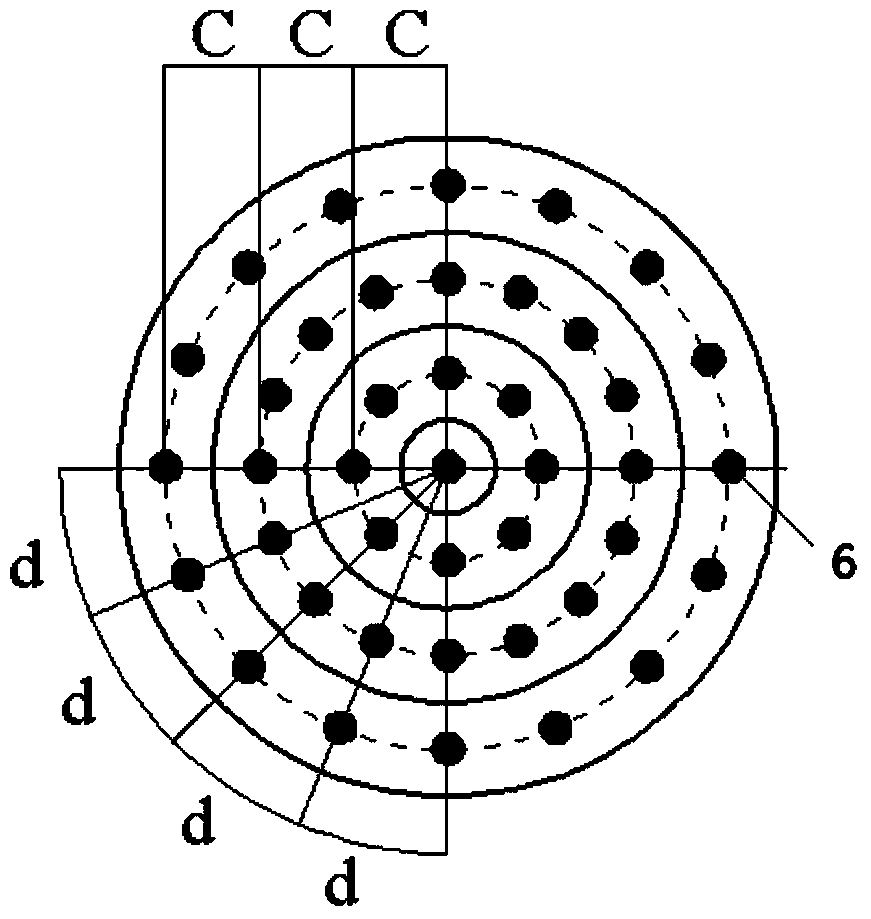

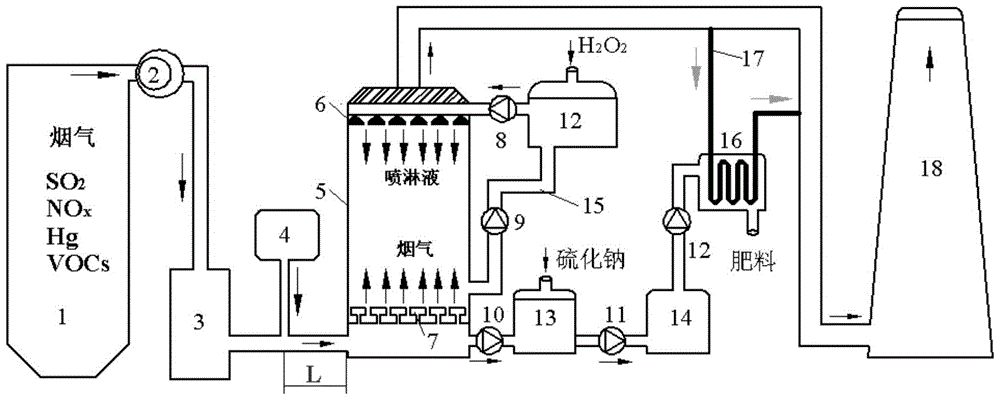

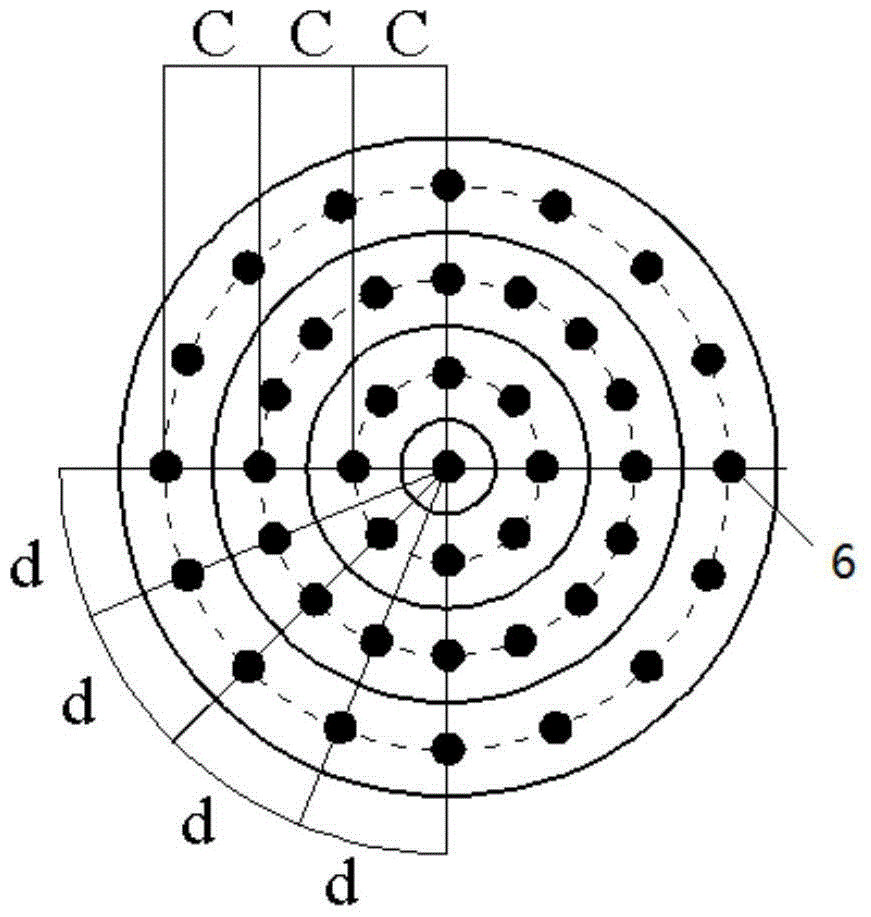

The invention discloses a method and a system for purifying flue gas by inducing free radicals by virtue of ozone and hydrogen peroxide. The system is characterized in that a flue of a boiler is connected with one end of a flue gas heat exchanger, wherein the other end of the flue gas heat exchanger is connected to the bottom of a spraying washer; an injection hole of an ozone injection system is formed in a pipeline located between the flue gas heat exchanger and the spraying washer; a solution circulating by-pass system is connected with the top end and lower part of the spraying washer, respectively; the bottom of the spraying washer is sequentially connected with a mercury separation system, an ammonification neutralizing system and a product concentrating and crystallizing system; the top of the spraying washer is connected with a chimney through the pipeline and a flue gas waste heat system. According to the method, hydroxyl free radicals with strong oxidizing property are generated in an induction manner after the ozone in the flue gas is contacted with the hydrogen peroxide in spraying liquid; four main pollutants in the flue gas can be simultaneously removed, equipment is simple and reliable, and no secondary pollution is generated in a removal process. The method and the system are novel and have wide application prospects.

Owner:JIANGSU UNIV

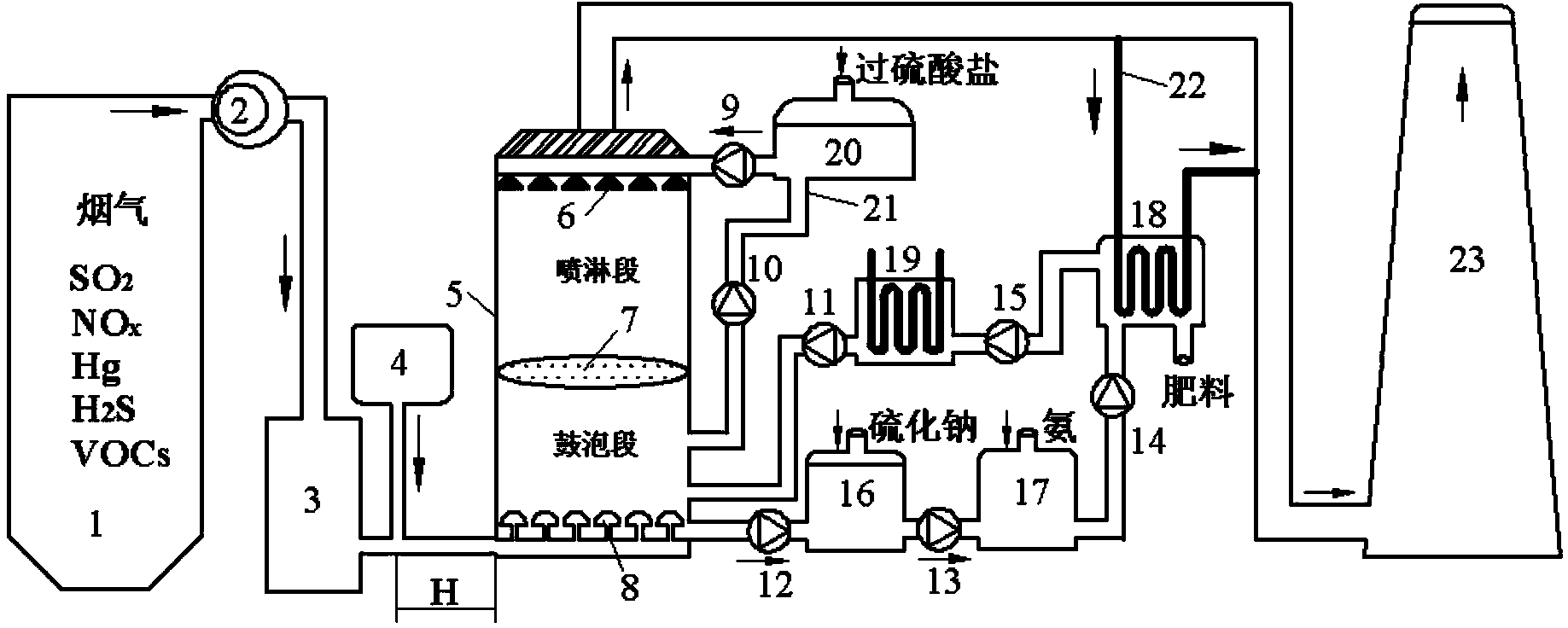

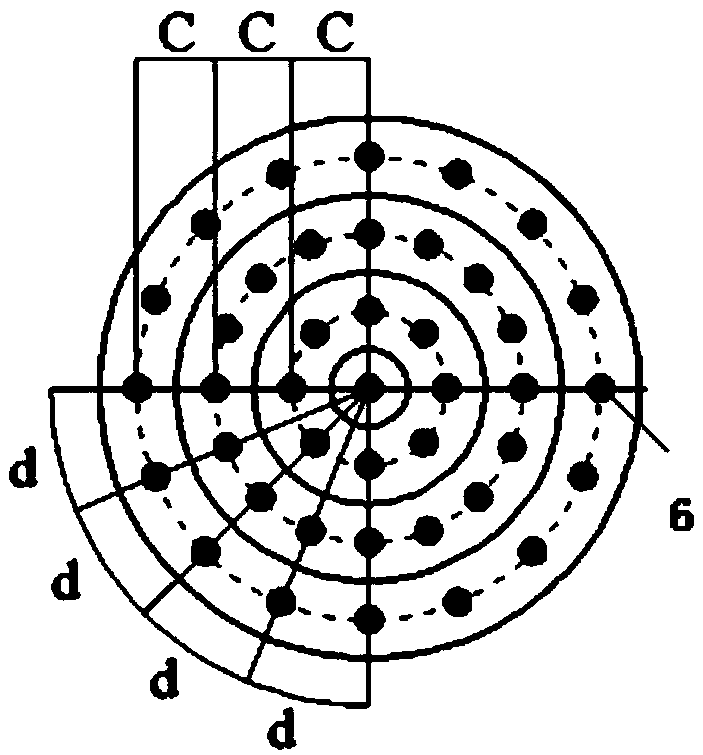

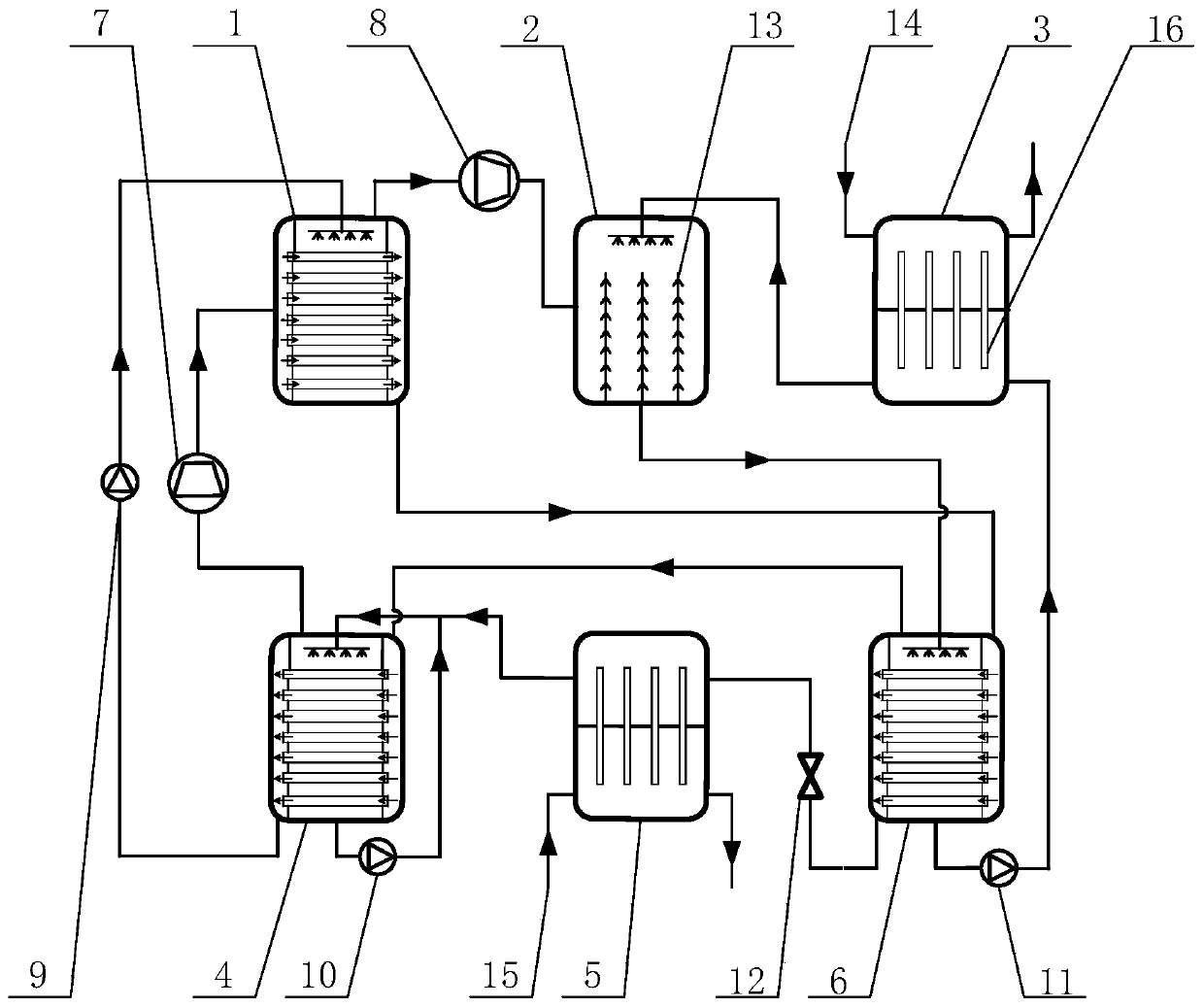

Method for purifying flue gas through activating persulfate by ozone, and apparatus thereof

ActiveCN104043325ATo achieve the purpose of removalNo secondary pollutionDispersed particle separationAir quality improvementSulfate radicalsAmmonium nitrate

The invention discloses a method for purifying flue gas through activating persulfate by ozone, and an apparatus thereof. Ozone in the flue gas contacts with persulfate in a solution in a bubbling-spray two stage reactor to generate sulfate radicals and hydroxy groups having strong oxidizability in order to oxidize and remove SO2, NOx, mercury, H2S and VOCs in the flue gas; and a reaction product solution enters a mercury separation tower to remove mercury, a mercury removed sulfuric acid and nitric acid solution enters an ammonia feeding tower, an ammonium sulfate and ammonium nitrate solution generated through the above reaction enters a product crystallization tower, and a flue gas waste heat utilizing device is used to evaporate and crystal recyclable agricultural fertilizers ammonium sulfate and ammonium nitrate. In the invention, ozone is adopted to induce persulfate to generate the sulfate radicals and hydroxy groups having extremely strong oxidizability, and the oxidbillities of the sulfate radicals and the hydroxy groups are second to that of fluorine, and are far higher than that of single ozone or persulfate, so the five pollutants can be efficiently simultaneously removed.

Owner:JIANGSU UNIV

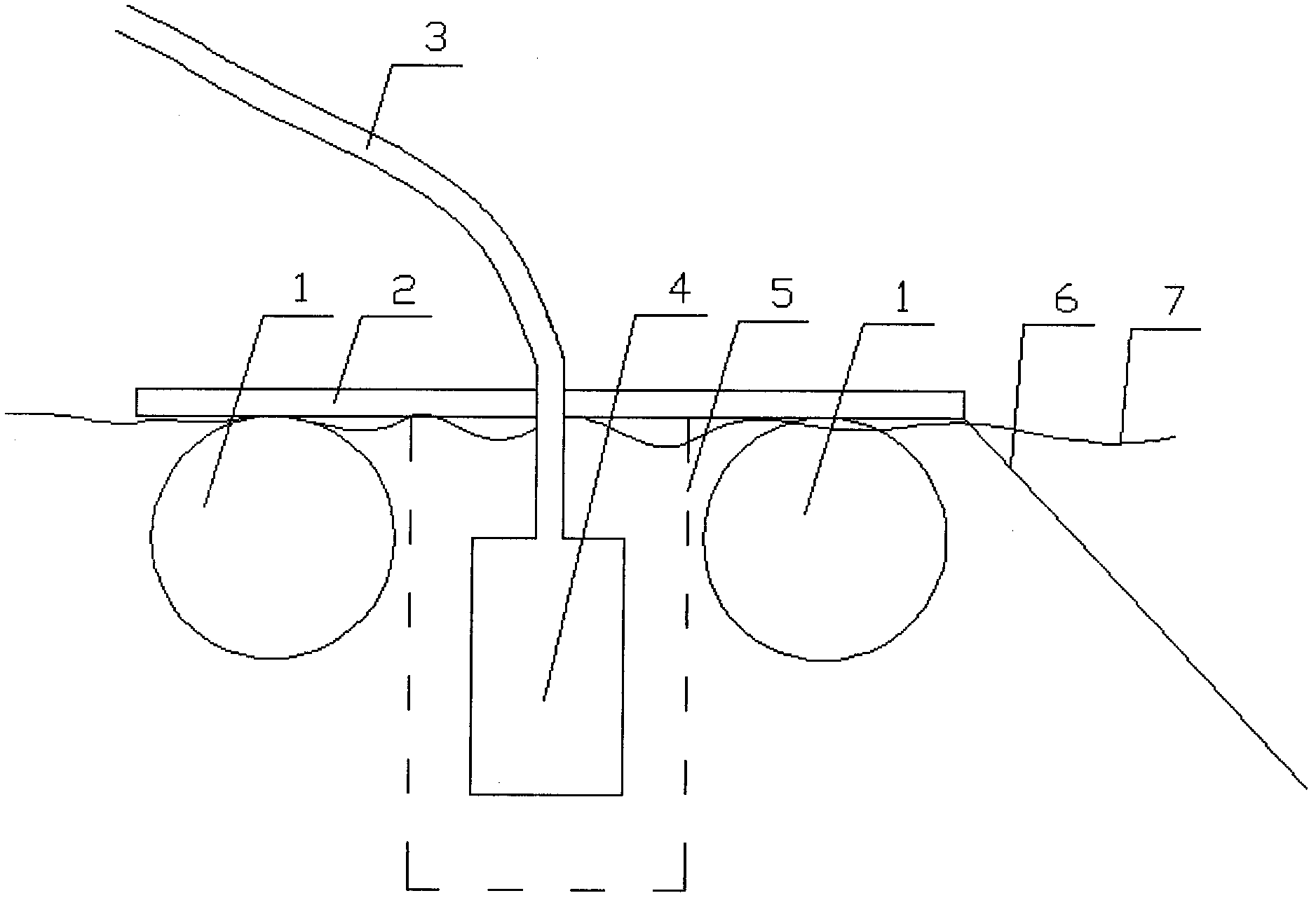

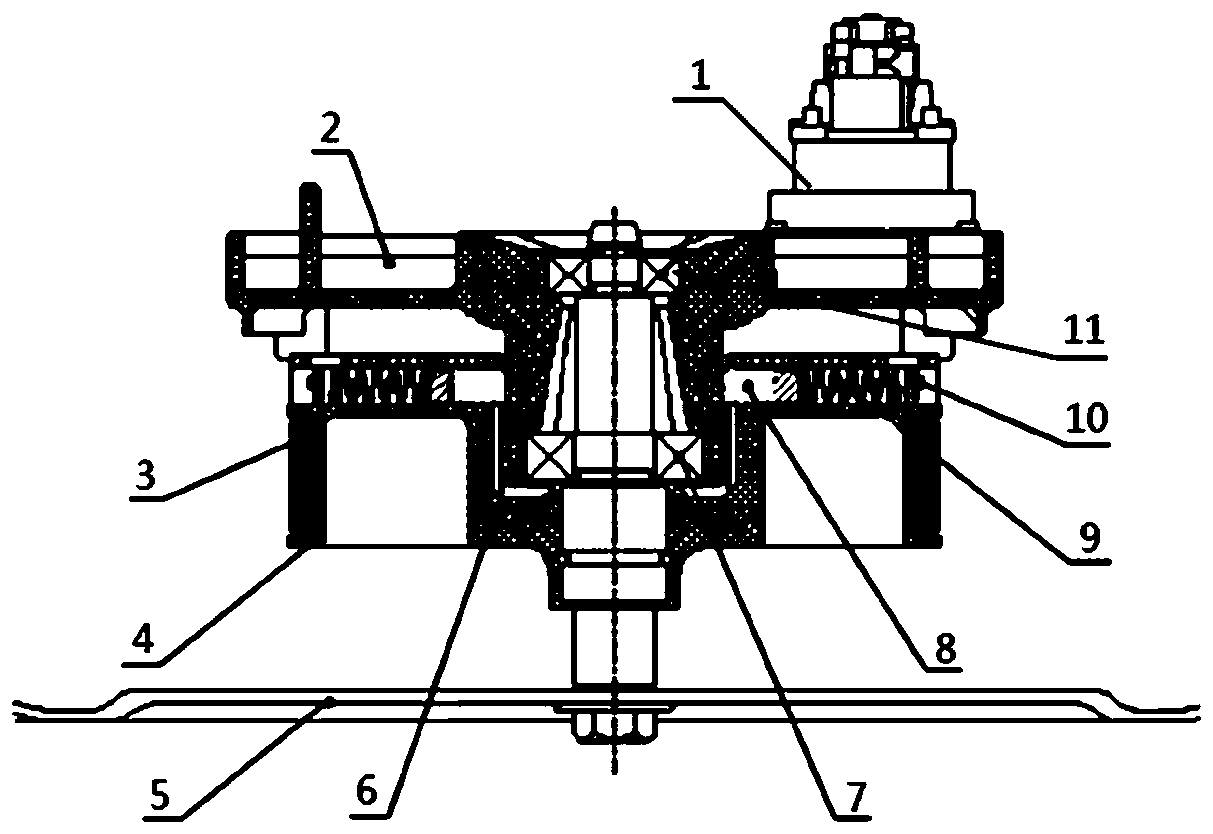

Buoy-type water getting device

InactiveCN102493528AEasy to useSolve the problem of not getting waterDrinking water installationPipeflowDevice form

A surface water ground source heat pump central air-conditioner which takes surface water, such as large rivers, rivers, lakes, sea and the like as cold and heat sources uses a fixed water getting device, but the surface water ground source heat pump central air-conditioner can not get water sometime in the places with larger water level fall. The buoy-type water getting device disclosed by the invention uses one or more of hollow buoys to provide enough buoyancy for the whole water getting device; the hollow buoys, a water taking water pump and the filter cover of the water taking water pump are fixed by one bracket, so that the buoys and the whole water getting device form a whole; and the outlet of the water taking water pump is connected with a water getting pipeline on the shore by a hose. The whole water getting device still floats on the water surface and changes along with the height change of the water surface, the water getting water pump is still dipped in water, a water getting hole is still positioned under the water surface for certain height, and water can be gotten at any time. The buoy-type water getting device has the advantages of simple structure and obvious technical and economic advantages and is convenient to construct.

Owner:CHONGQING SIKESEN ENVIRONMENTAL PROTECTION TECH

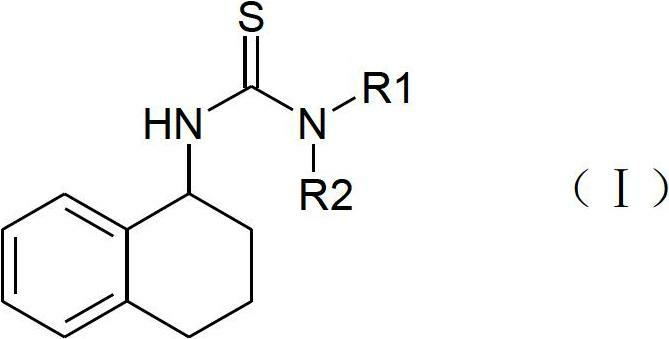

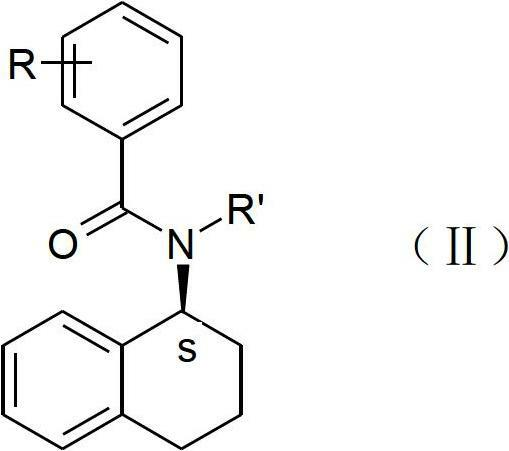

Resolving and racemization method for 1-amino-1,2,3,4-tetrahydronaphthalene

InactiveCN102675123AAvoid reduction reactionAvoid high pressure hydrogenationAmino compound purification/separationPreparation by N-O/N-N bondsTetralinDocument preparation

The invention provides a resolving and racemization method for 1-amino-1,2,3,4-tetrahydronaphthalene. The method comprises the following steps of: reducing 3,4-dihydro-1-(2H)-naphthalene ketoxime into DL-1-amino-1,2,3,4-tetrahydronaphthalene; and resolving DL-1-amino-1,2,3,4-tetrahydronaphthalene into optically pure (S)-1-amino-1,2,3,4-tetrahydronaphthalene and (R)-1-amino-1,2,3,4-tetrahydronaphthalene by using an acidic resolving agent, or oxidizing chiral secondary amine into corresponding imine or derivatives thereof, reducing into DL-secondary amine and continuously resolving to obtain a single optical product. The enantiomeric excess (ee) value of the obtained product is more than 99.5 percent; and the yield of one-time resolving exceeds 30 percent, and the total yield of the route reaches 46 to 54 percent. Compared with the methods reported by various documents and patents at present, the method has obvious technological and economical advantages.

Owner:SHANGHAI LANGTZE BIOMEDICAL TECH

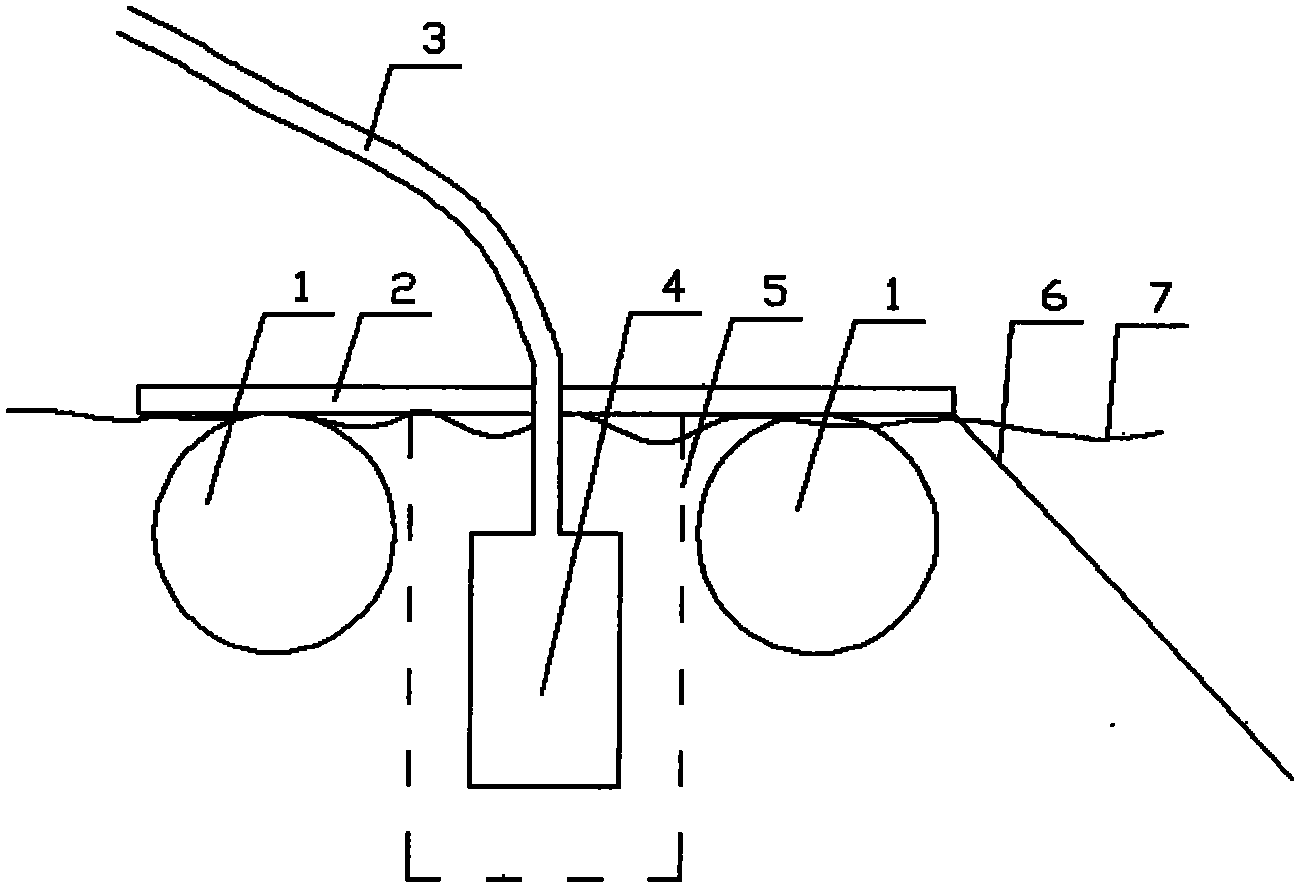

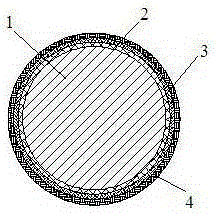

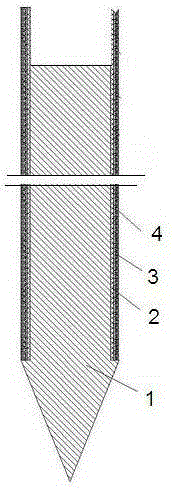

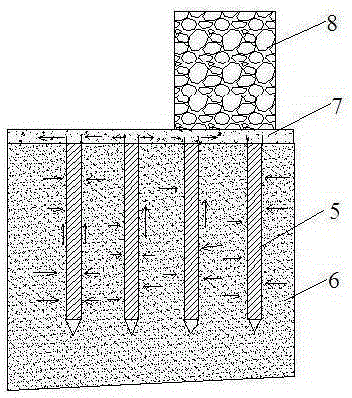

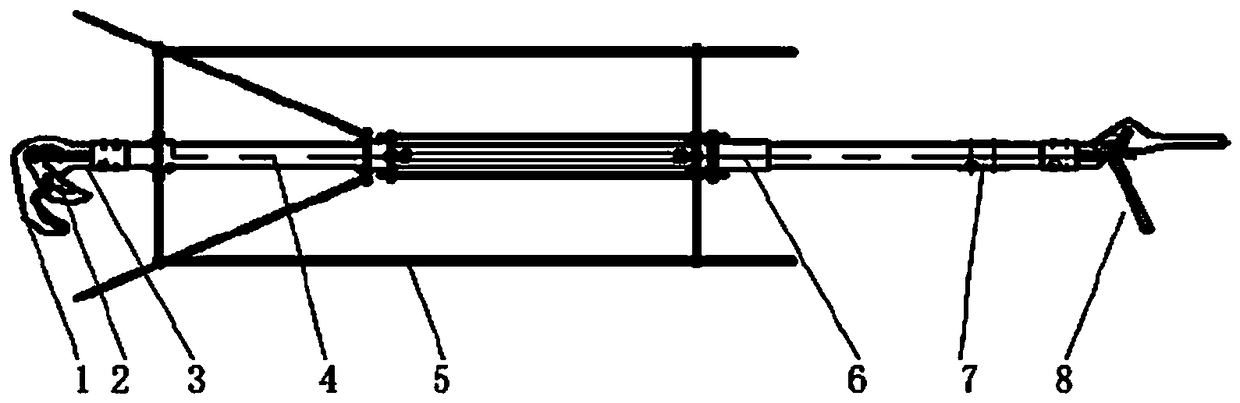

Strengthening soft clay foundation for draining pine piles and construction method of strengthening soft clay foundation

ActiveCN105220680AIncreased undrained shear strengthImprove bearing capacityBulkheads/pilesSoil preservationGeotextileSoft clay

The invention discloses a strengthening soft clay foundation for draining pine piles and a construction method of the strengthening soft clay foundation. A plurality of rows of draining pine piles are pressed into the soft clay foundation. Pine piles are used as core materials of the draining pine piles. Geofabric or geotextile is used for wrapping and serves as a draining structural layer. A horizontal draining sand cushion is arranged on the surface of the soft clay foundation. According to the strengthening soft clay foundation for the draining pine piles and the construction method of the strengthening soft clay foundation, the draining pine piles integrate the draining function and the strengthening function, are particularly suitable for strengthening processing of soft clay foundations of small and medium-sized hydraulic structures and are also suitable for primary strengthening processing of super-soft dredger fill and peat soil foundations, and the draining pine piles can be pulled out to be repeatedly used according to processing timeliness.

Owner:EAST CHINA UNIV OF TECH

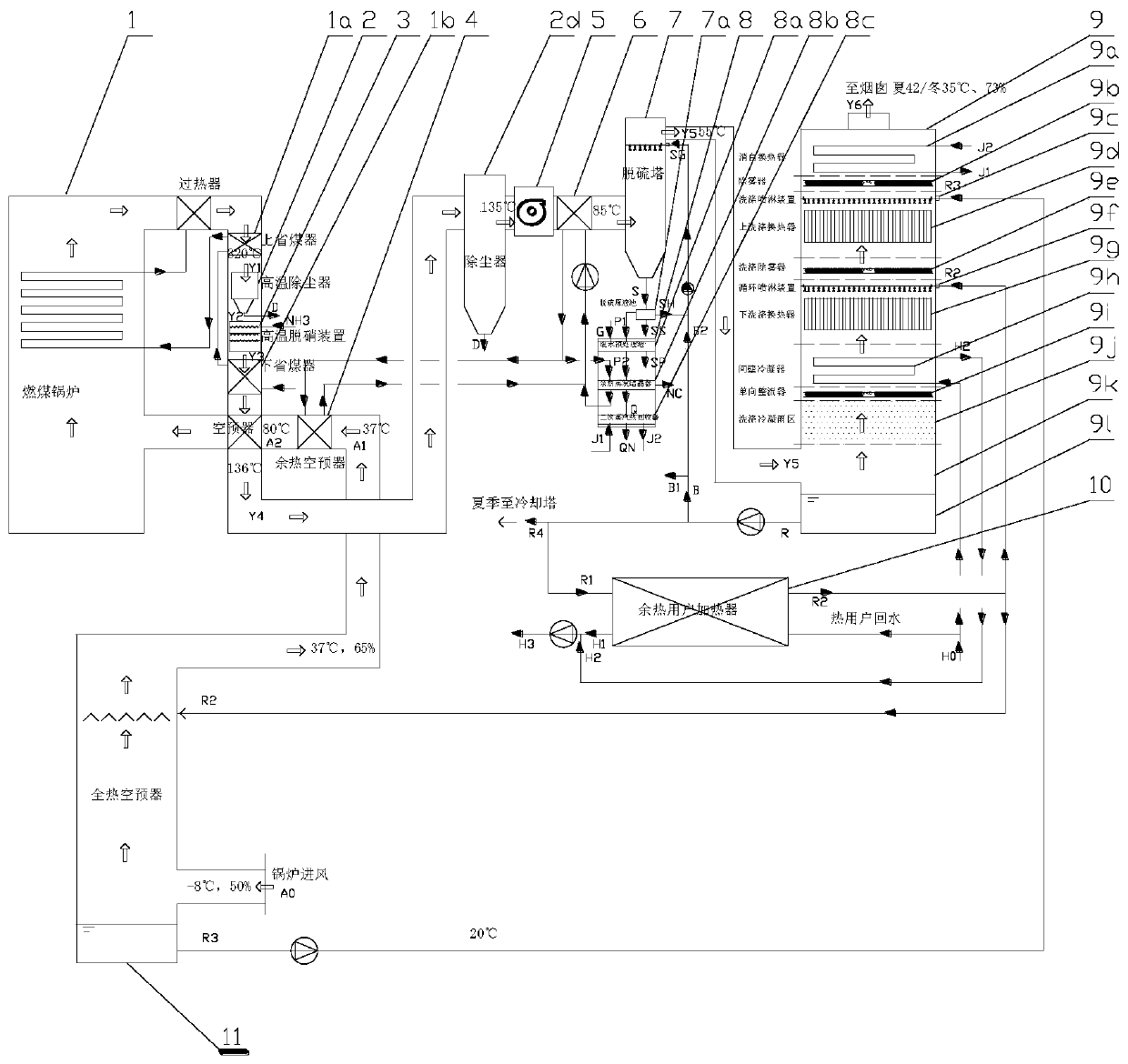

Waste heat driving based boiler smoke exhaust total component treatment and resource recycling mode

PendingCN110131742ARecycling benefits are obviousRealize pollution controlCombination devicesGas treatmentFlue gasSmoke

The invention discloses a waste heat driving based boiler smoke exhaust total component treatment and resource recycling mode, and belongs to the technical fields of flue gas treatment and circular economy. For solving the problems that flue gas of a boiler carries much vapour and a waste heat resource of the vapour, plume carries more particulate pollutants, especially a large amount of penetrable particulate matters and acidic gases in the current situation, the condensed water, the acidic gases such as a large amount of sulfur dioxide in the flue gas plume, filtratable particulate matters,coagulable particulate matters capable of penetrating the particulate matters, soluble particulate matters and the like are recycled by adopting a cascade condensation water film decontamination modewhile a high-temperature dust collector is adopted to recycle flue dust, condensation water is used for taking and carrying, comprehensive recovery of water resources and conversion into building materials, industrial raw materials and the like are finally realized through a waste heat evaporation and desalination crystallization device and the like, the waste heat is recycled to be used for driving a flue gas resource development process, and is used for heat supply, heating process water or combustion-supporting air and the like, the comprehensive resource utilization of hot, wet and hazardous wastes is realized, and near zero cost operation is realized and even generation of economic benefit of energy saving and resource saving are achieved.

Owner:TSINGHUA UNIV +1

Glass fibre / magnesium alloy composite material and preparation thereof

InactiveCN101487107AGood electromagnetic shielding performanceSignificant technical and economic advantagesPre treatmentFibrous composites

The invention relates to a glass fiber and magnesium alloy composite and a preparation method thereof, which belong to the technical field of the composite and the preparation thereof, the composite is characterized in that the surface of the glass fiber is covered with magnesium alloy, the length of the glass fiber is 100 mm to 20000 mm, the mass ratio of the glass fiber and the magnesium alloy is 0.01 to 5, the glass fiber takes a shape of a bunch or knitting. The preparation method is as follows: the glass fiber after pretreatment is put into the magnesium alloy melt with temperature of 600 DEG C to 900 DEG C for 0.5 second to 60 seconds, so the glass fiber impregnated with the magnesium alloy is obtained; and the glass fiber and magnesium alloy composite can be obtained after the glass fiber impregnated with the magnesium alloy is cooled to room temperature, or the glass fiber and magnesium alloy composites profile can be obtained by press-processing the glass fiber impregnated with the magnesium alloy after cooling to 100 DEG C to 500 DEG C. The composite compound the continuous glass fiber and the magnesium alloy so that the plating magnesium alloy glass fiber composite and the glass fiber strengthening magnesium alloy composite profiles are obtained, thus opening up the new application of the glass fiber and the magnesium alloy.

Owner:CHONGQING UNIV

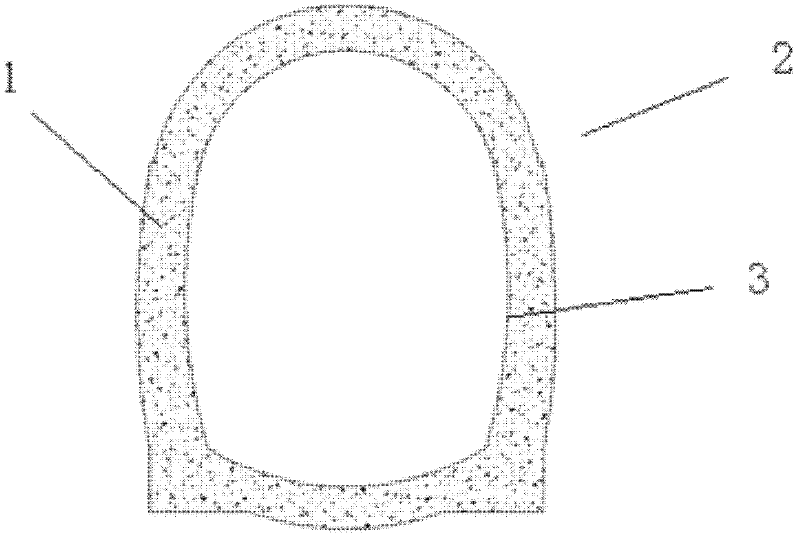

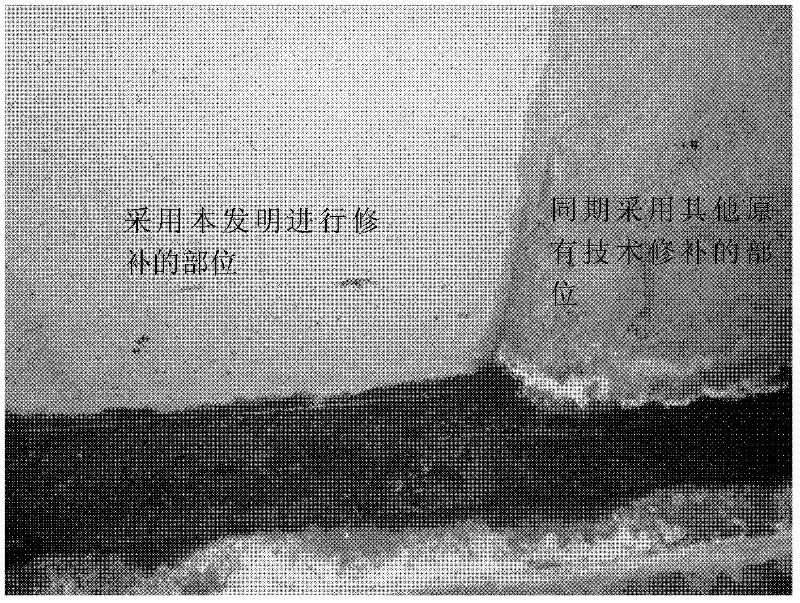

Method for repairing sulphate attack disease of tunnel lining concrete structure

The invention discloses a method for repairing the sulphate attack disease of a tunnel lining concrete structure, comprising the following steps of: firstly, effectively cleaning a disease region, isolating and dredging erosive ions, reinforcing original rib materials; secondly, repairing by adopting an erosion-resistant repairing material and processing a surface coating, and ensuring the whole repair construction quality; and finally, achieving effective repair of the diseased tunnel structure. According to the method, the sulphate attack resistance of the tunnel lining concrete structure with the salt attack disease can be remarkably improved, and the service life of the original tunnel structure is effectively prolonged; and the method has the characteristics of technical and economic advantages and strong maneuverability.

Owner:CENT SOUTH UNIV

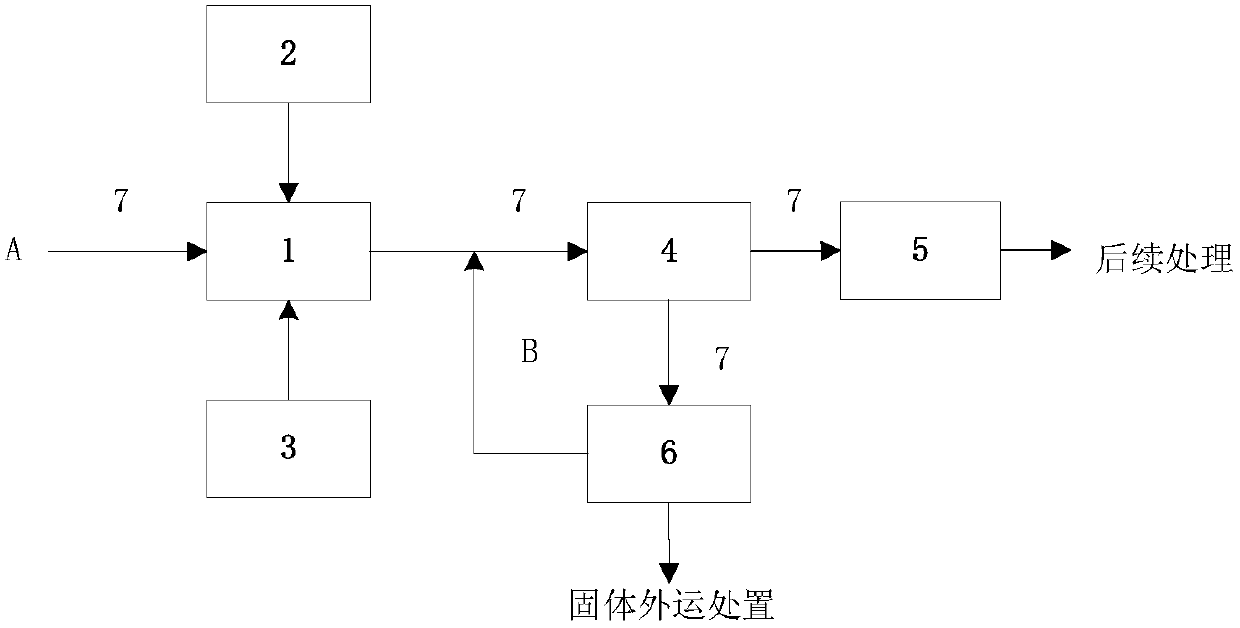

Treatment process device and method for resin-adsorbed regenerated high-concentration organic waste liquid

ActiveCN107935094AHigh removal rateLow running costSludge treatment by de-watering/drying/thickeningWater contaminantsHigh concentrationSludge

The invention relates to a treatment process device and method for a resin-adsorbed regenerated high-concentration organic waste liquid, and belongs to the field of water treatment. The device includes a catalytic condensation reaction unit, a mud-water separation and concentration unit, an adsorption unit and a solid dewatering unit; the catalytic condensation reaction unit, the mud-water separation and concentration unit and the adsorption unit are connected through a pipeline in turn, and a by-path of the mud-water separation and concentration unit is provided with the solid dewatering unit. The method comprises the steps: adding a catalyst to the resin-adsorbed regenerated high-concentration organic waste liquid, stirring, carrying out mud-water separation of the generated mud-water mixture, and carrying out adsorption treatment of a filtered clear liquid; dewatering the mud-water concentrated liquid, conveying the sludge outwards, carrying out landfill treatment, and allowing thedewatered residual liquid to flow back to a front section of the mud-water separation and concentration unit. The method has the removal rate of organic matters in the high-concentration organic wasteliquid as high as 99% or more, and has the advantages of low investment and operation cost, simple operation management and the like; discharged water can achieve the standard to be discharged by simple treatment; and compared with the prior art, the method has great technical and economic advantages.

Owner:艾西姆(辽宁)环境技术有限公司

In-situ dewatering method for sludge of sewage treatment plants

ActiveCN102863138AAvoid pollutionImprove physical and mechanical propertiesSludge treatment by de-watering/drying/thickeningSewageSewage treatment

The invention discloses an in-situ dewatering method for sludge of sewage treatment plants. The method comprises the steps of injecting sludge dewatering agents into sludge by using a high-pressure jet-grouting pile machine and mixing and stirring the agents with the sludge evenly; and treating the treated sludge by using a conventional vacuum preloading method. The method can overcome difficulties of treatment of large-area sludge stacked places, the sludge is not needed to be excavated and treated in another place, problems of secondary pollution of stink, sewage and the like produced in the excavation and transport process are solved, and the in-situ dewatering method has advantages of short treatment period, low cost and the like compared with treatment methods of burning, compost and the like.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Process for recycling excessive methyl alcohol in biodiesel production process

InactiveCN103159590ATechno-economical obviousRecycle thoroughlyOrganic compound preparationHydroxy compound preparationBiodieselAlcohol

The invention discloses a process for recycling excessive methyl alcohol in a biodiesel production process. The process comprises the following process steps of: pumping waste methyl alcohol generated by a biodiesel production line into a negative-pressure flash tower; preliminarily concentrating methyl alcohol to prepare crude methyl alcohol; pumping crude methyl alcohol to a rectifying tower; and preparing qualified fine methyl alcohol for being reused in the production. According to the process for recycling excessive methyl alcohol in the biodiesel production process disclosed by the invention, waste methyl alcohol generated by the biodiesel production line is sufficiently recycled for being reused in the production, and therefore, the process is energy-saving and efficient, and economical and remarkable in technical effect; and moreover, thorough recovery and reliable quality are ensured by the double-tower distillation, the energy using efficiency is high, the exhausted waste is clean and the environmental protection is facilitated.

Owner:SHAANXI DERONG NEW ENERGY

Portable corn picking and chopping device

A portable corn picking and chopping device is mainly composed of an inner picking roller, an outer picking roller, a roller knife combination, a cutting knife, and drum shell. The inner and outer picking rollers are multi-spiral horizontal ear-picking rollers which comprise a front part and a rear part, wherein the front part is a diversion cone and a rear part is a picking section and a haling section; the roller knife combination is mainly composed of a moving cutter, a moving cutter plate and a moving cutter shaft and is installed under the picking rollers; the drum shell is installed on abearing seat; the bearing seat is installed on the moving cutter shaft; semi-closed design is adopted, which is convenient for the feeding of straw; a straight blade flat cutter is used as the movingcutter which is installed on a moving cutter support plate and then installed on the moving cutter plate; the moving cutter plate is a welded member which is formed by a shaft wing, a disc and bending by artificial arc welding; the cutting knife is installed at the forefront of the moving cutter shaft. The invention has the advantages of simple structure, low power consumption, high chopping quality, reduced manufacturing cost, improved working efficiency and reliability.

Owner:周宝东

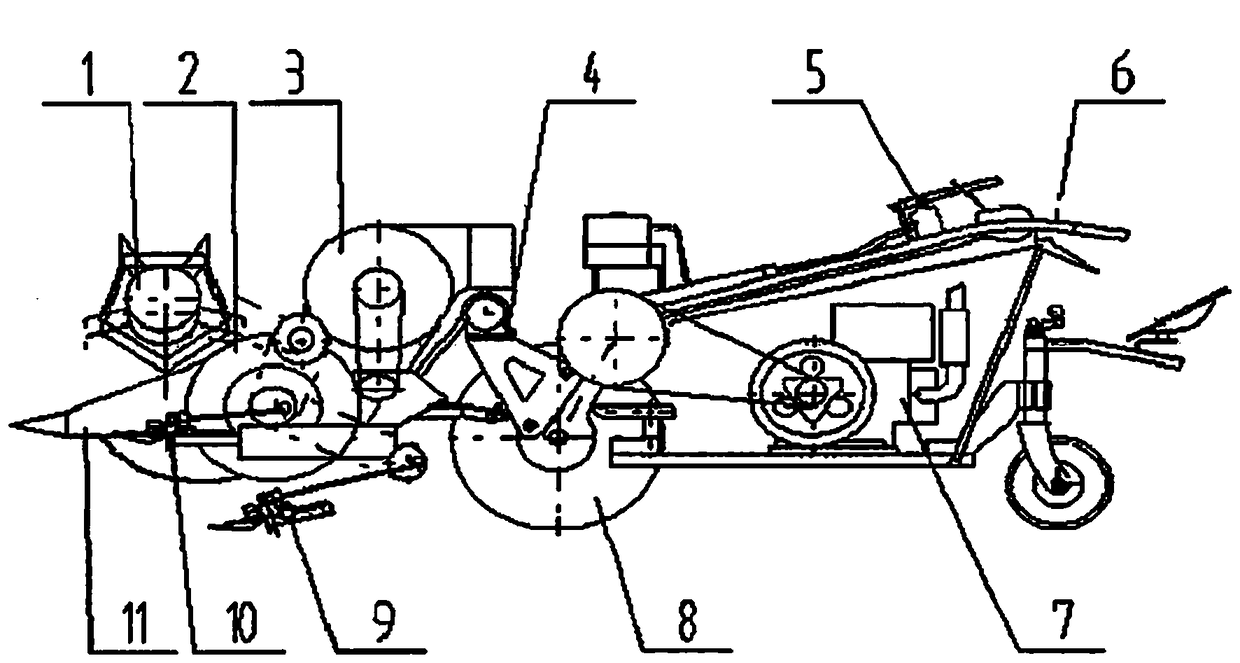

Small combine harvester for rice

A small combine harvester for rice is mainly composed of a reel wheel, a side conveyor fan, a threshing device, a hanger, a hydraulic lifting mechanism, a hand support chassis, an engine, an ultra-wide low-pressure tires, a secondary cutting mechanism, a primary mechanism, a splitter and a transfer system; the hand support chassis uses the GN-71 hand tractor chassis; the engine is a diesel engineand is arranged at the back of the whole machine; the side conveyor fan is centrifugal; the impeller structure is backward straight board type; a front end of the blade is arc shaped; the cutter is asingle moving blade reciprocating cutter; a certain number of blade protectors with fixed blades are installed on the cutter beam; the secondary cutting mechanism has the hydraulic elevating header linkage design and is close to the bottom of the header. The invention has the advantages of simple structure, reasonable arrangement, convenient installation, high work efficiency, low production cost,stable operation, and simple operation, and can well meet the rice harvesting requirements in mountainous and hilly regions.

Owner:周宝东

Novel litchi picker

InactiveCN108076824AReduce breakage rateMeet the picking requirementsPicking devicesSlant angleSpring force

A novel litchi picker is mainly composed of a shearing mechanism, a guiding mechanism and a control handle; the shearing mechanism is composed of a fixed blade, a moving blade, a pull rod and a handle; the moving blade has a convex cutting edge and at the same time, the fixed blade is grinded into 40 DEG to 50 DEG slant angle at the position fruit stems are pulled so that a certain cut-in angle isguaranteed when fruit stems are cut to reduce shearing force; a front end of the guiding mechanism is a stir rod and the bottom is stitched with a fruit receiving canvas; under the effect of the spring force before picking, the guiding mechanism is in a tensioned state; the stir rod is close to a main rod; the tightened picker can conveniently extend to litchi trees; after positioning, a push cylinder is pushed to unfold the stir rod to push branches and leaves aside, which is convenient for picking; the control handle is positioned at the rear of the picker, which is convenient for manual operation. The invention has simple structure, high work efficiency, low cost and convenient installation, and satisfies the requirements for string fruit picking of litchi, and has important significance for improving the level of agricultural machinery in China.

Owner:牛金生

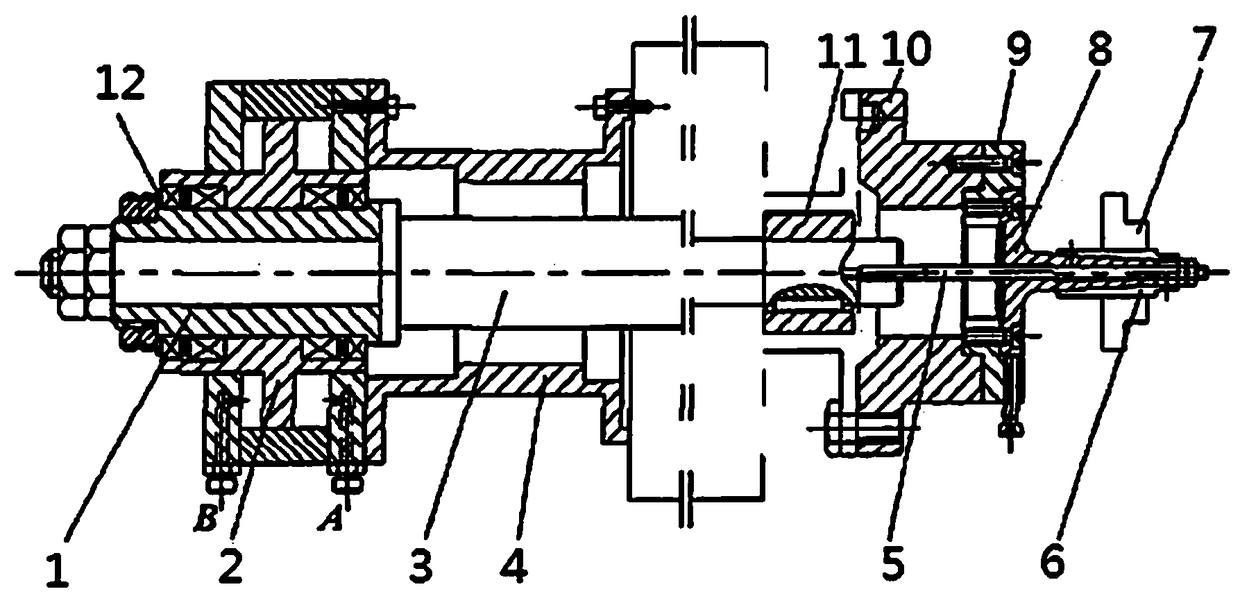

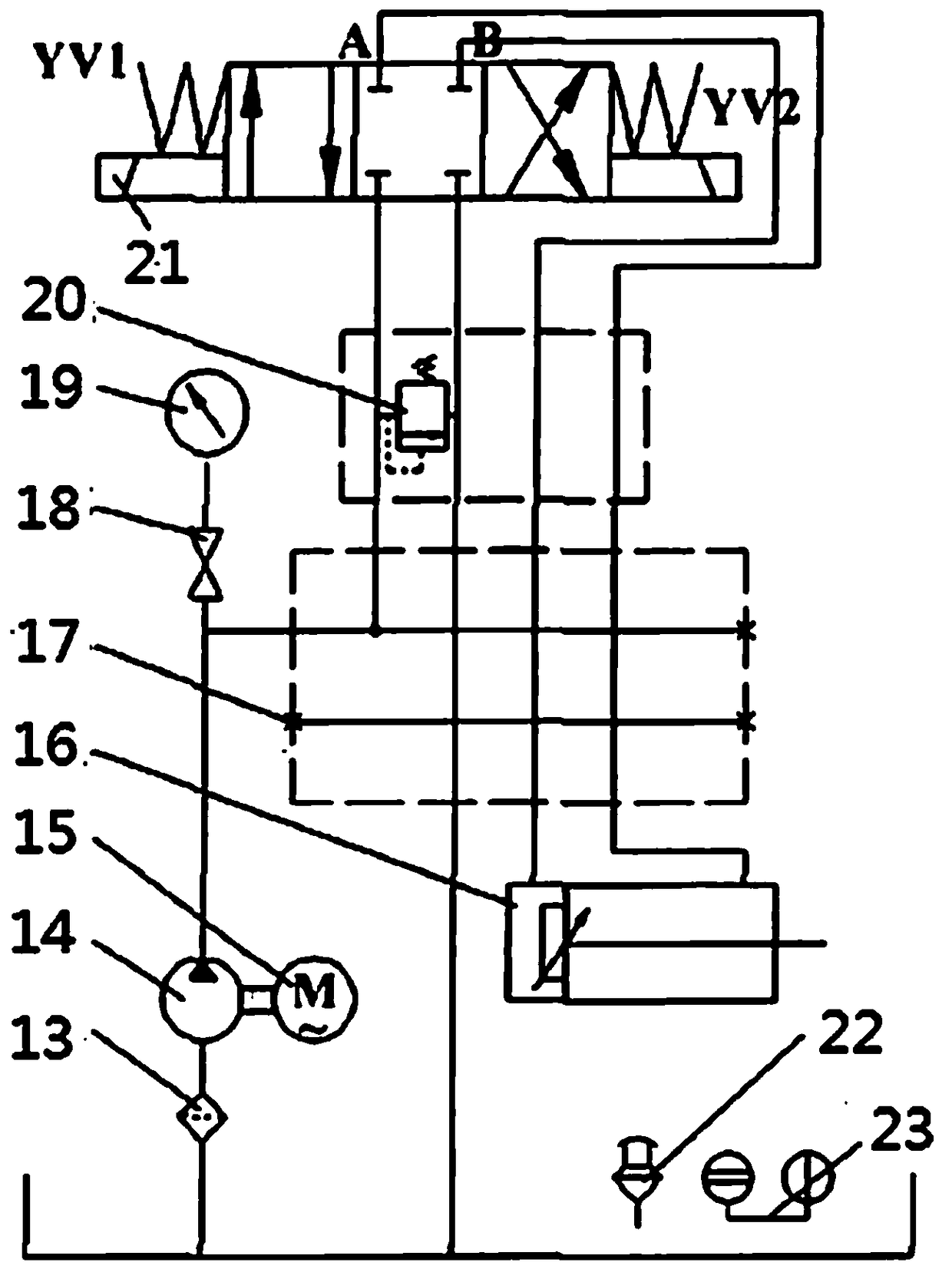

Tooth blank finish turning hydraulic tool system

InactiveCN108081001ASolve process difficultiesMeet the fine car requirementsServomotor componentsWork clamping meansEngineeringFlange

The invention discloses a tooth blank finish turning hydraulic tool system which mainly consists of a bearing sleeve, a rotary oil cylinder, a pull rod, a connecting sleeve, a connecting rod, a finishturning tire sleeve, a tooth blank, a finish turning tire seat, a flange plate, a connecting plate, a locating sleeve, a spacer bush, a corresponding hydraulic system and the like; the front end of the pull rod is connected with the connecting rod; the connecting sleeve is arranged at the tail of a spindle, and after alignment, the special rotary oil cylinder and the pull rod (which penetrates through a spindle hole) are arranged on the connecting sleeve; the connecting plate is arranged at the front end of the spindle of a lathe; finish turning tire sleeves in different sizes can be mountedon the finish turning tire seat as required so as to meet the requirement of machining the tooth blanks in various sizes; the finish turning tire seat is arranged on the flange plate in an alignment manner; and after the connecting plate is aligned, the flange plate is arranged on the connecting plate. The tooth blank finish turning hydraulic tool system is simple in structure, high in working efficiency, simple and convenient in clamping, wide in clamping range, adjustable in tensioning force and high in precision and can meet the finish turning requirements of the tooth blanks better.

Owner:吴丽娜

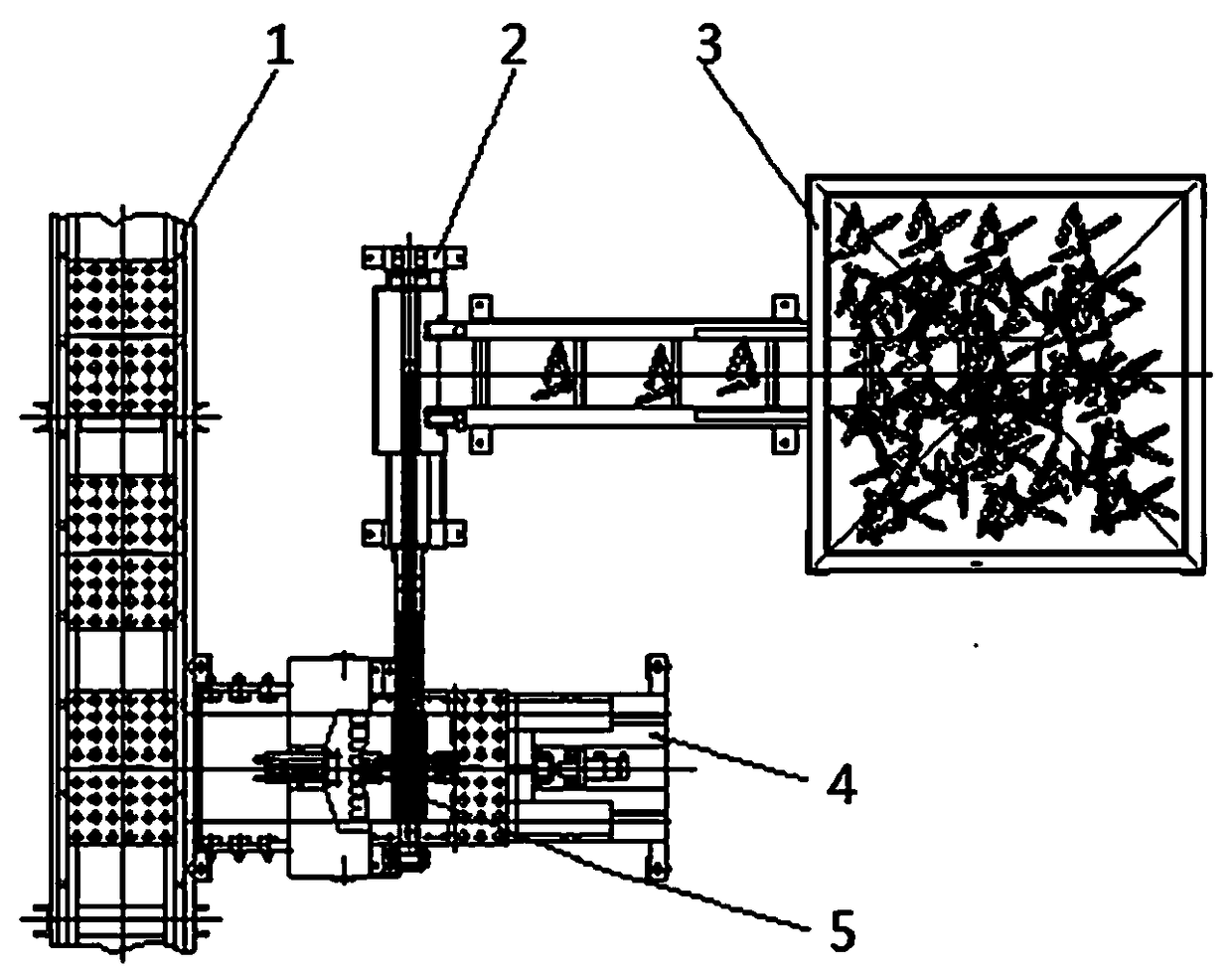

Automatic aligning and feeding system for middle-sized cartridge-case-shaped workpieces

InactiveCN108100619AMeet the use requirements of automatic arrangement and feedingSimple structureConveyor partsTransfer mechanismCounter rotating

An automatic aligning and feeding system for middle-sized cartridge-case-shaped workpieces is mainly composed of an automatic stock bin, an arrangement aligning mechanism, a fork separating and feeding (nail hanging) mechanism, a tray transferring mechanism and the like; the automatic stock bin is composed of a stock bin main body and an automatic discharging hoister; the arrangement aligning mechanism is mainly composed of a counter-rotating double-roller mechanism, a hopper and the like and used for aligning disordered cartridge cases in rows and conveying the cartridge cases to a fork separating mechanism; and the fork separating and feeding (nail hanging) mechanism is mainly composed of a fork separating plate, a movable clamping plate, a slide rail and the like, and both the fork separating plate and the movable clamping plate are driven by an air cylinder provided with a guide rod. The automatic aligning and feeding system is simple in structure, reasonable in layout, high in working efficiency, low in production cost, stable in operation and easy and convenient to operate and can well meet the automatic aligning and feeding requirements of the middle-sized cartridge-case-shaped workpieces.

Owner:吴庆宝

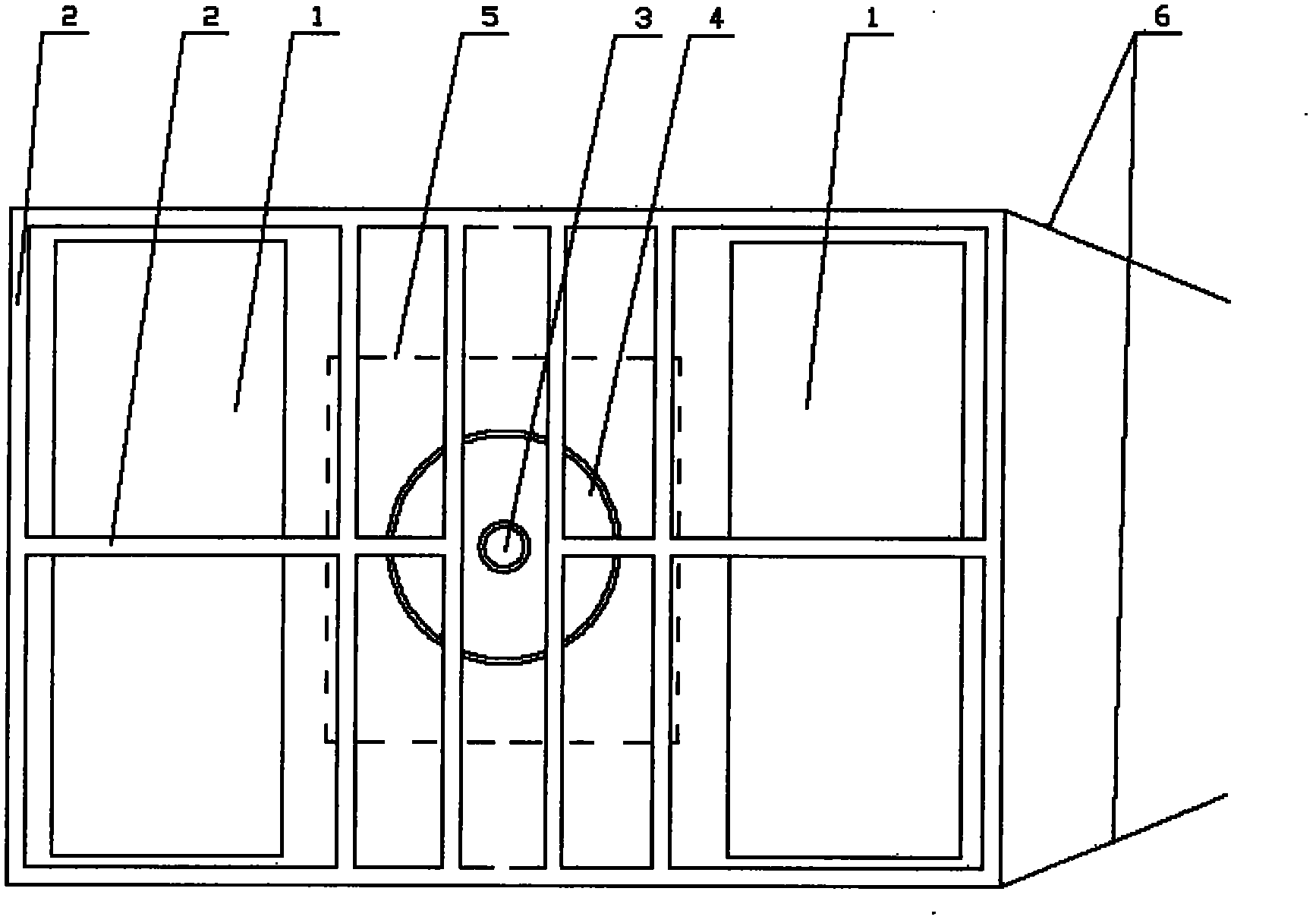

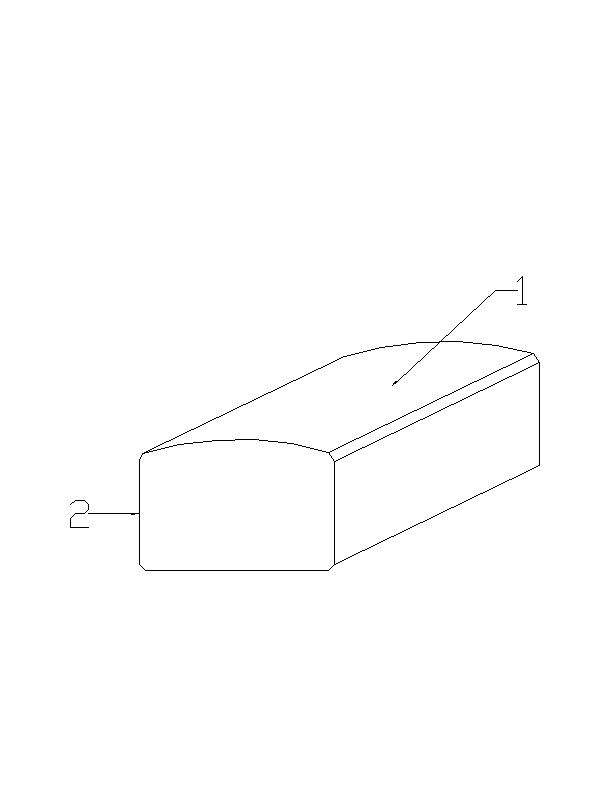

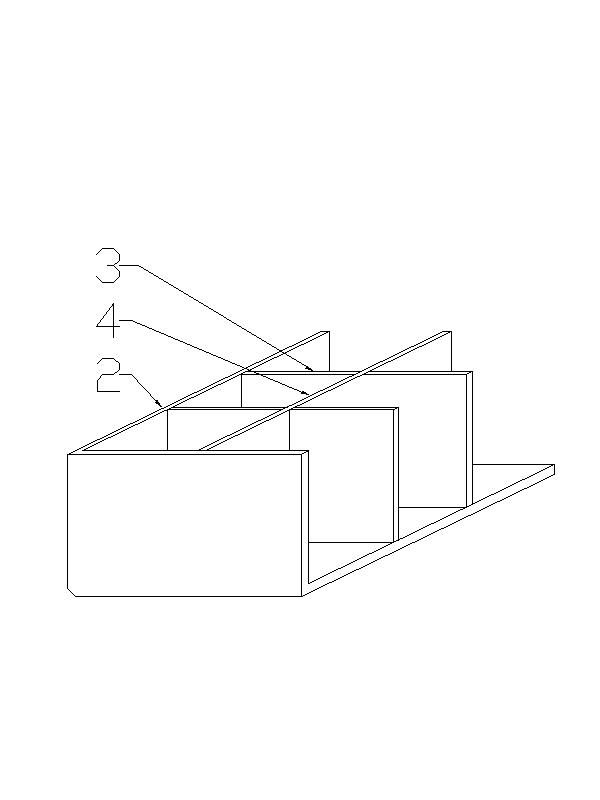

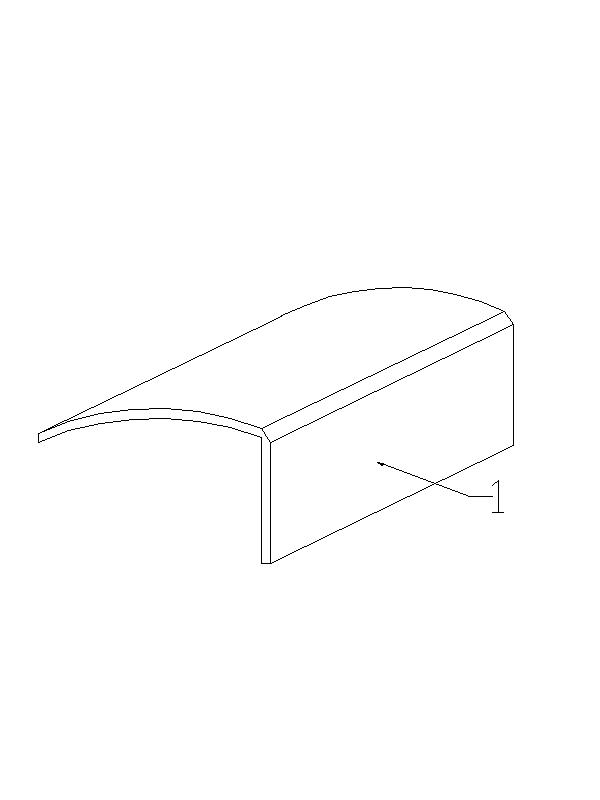

Building core and manufacture method of building core

InactiveCN102605894AHigh strengthSignificant technical and economic advantagesCeramic shaping apparatusBuilding componentsCalcium silicateWork in process

The invention provides a manufacture method of a building core. Firstly, prepared semi finished products of silicate plates are cut according to specifications; then, the cut semi finished products of silicate plates are covered on three adjacent surfaces of a prefabricated building core mold, and the other three adjacent surfaces are covered on the other mold and are carried onto a steam-curing car; the steam-curing car is pushed into a pre-curing chamber to be subjected to baking treatment and is then conveyed into a steam-curing kettle to be subjected to high-temperature and high-pressure steam curing, and finished products after the steam curing are taken out; prepared calcium silicate plates are cut into transverse separation plates conforming to the specifications; and finally, the finished products are conveyed to a construction site for assembly construction. The method provided by the invention has the main advantages that the building core is directly assembled and constructed in the construction sites, the energy consumption is low, the energy sources are saved, the air pollution is reduced, the environment protection is realized, and the like. In addition, the transportation cost can be greatly reduced, and the occupied space during the piling is small.

Owner:湖南高盛板业股份有限公司

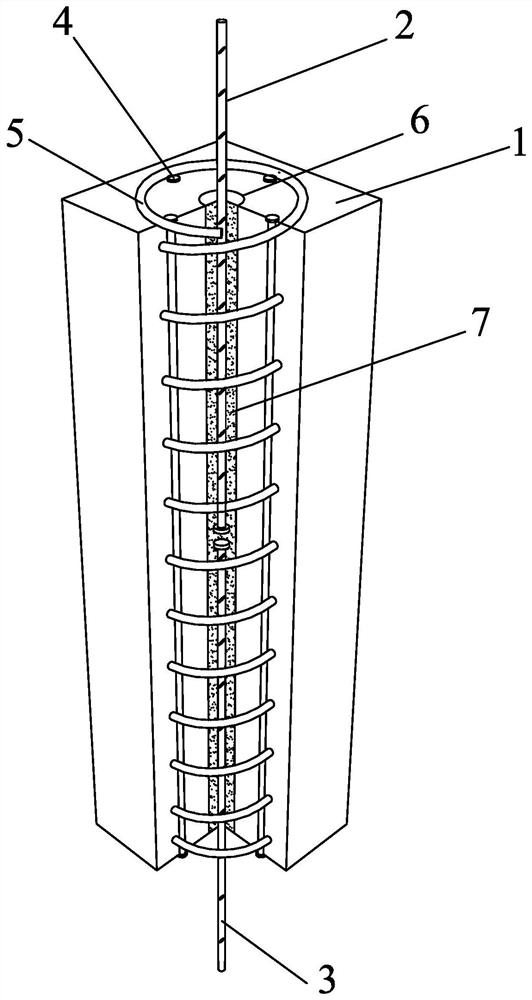

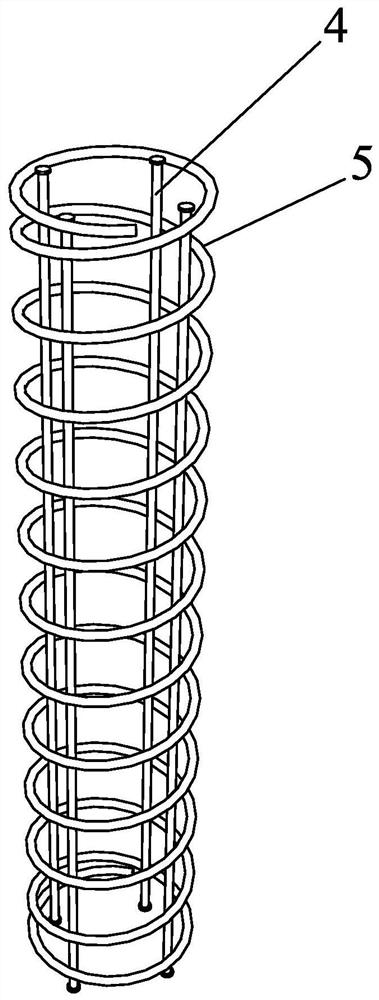

Steel bar butt joint connecting structure and method based on corrugated pipe slurry anchor

The invention discloses a steel bar butt joint connecting structure and method based on a corrugated pipe slurry anchor. The connecting structure comprises a to-be-connected steel bar, a connecting steel bar, a corrugated pipe and a steel bar cage, wherein upset head steel bars are adopted as the to-be-connected steel bar and the connecting steel bar, and the to-be-connected steel bar and the connecting steel bar are arranged in the corrugated pipe in a butt joint manner; and the steel bar cage is arranged on the periphery of the corrugated pipe, and the corrugated pipe and the steel bar cage are buried in prefabricated concrete. The connecting method of the steel bar butt joint connecting structure comprises the steps that the upset head steel bars are adopted as the to-be-connected steel bar and the connecting steel bar; during component prefabrication, the to-be-connected steel bar is inserted in the corrugated pipe, the steel bar cage is arranged on the periphery of the corrugated pipe, and the to-be-connected steel bar and the connecting steel bar are overall buried in the prefabricated concrete; and during component connection, the connecting steel bar is inserted in the corrugated pipe, a high-strength and low-shrinkage grouting material is poured in the corrugated pipe, and a steel bar butt joint connecting connector based on the corrugated pipe slurry anchor is formed after the grouting material is hardened. By means of the steel bar butt joint connecting structure and method, reliable butt joint connection of the to-be-connected steel bar and the connecting steel bar can be achieved, cost is low, and the installing efficiency is high.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING +1

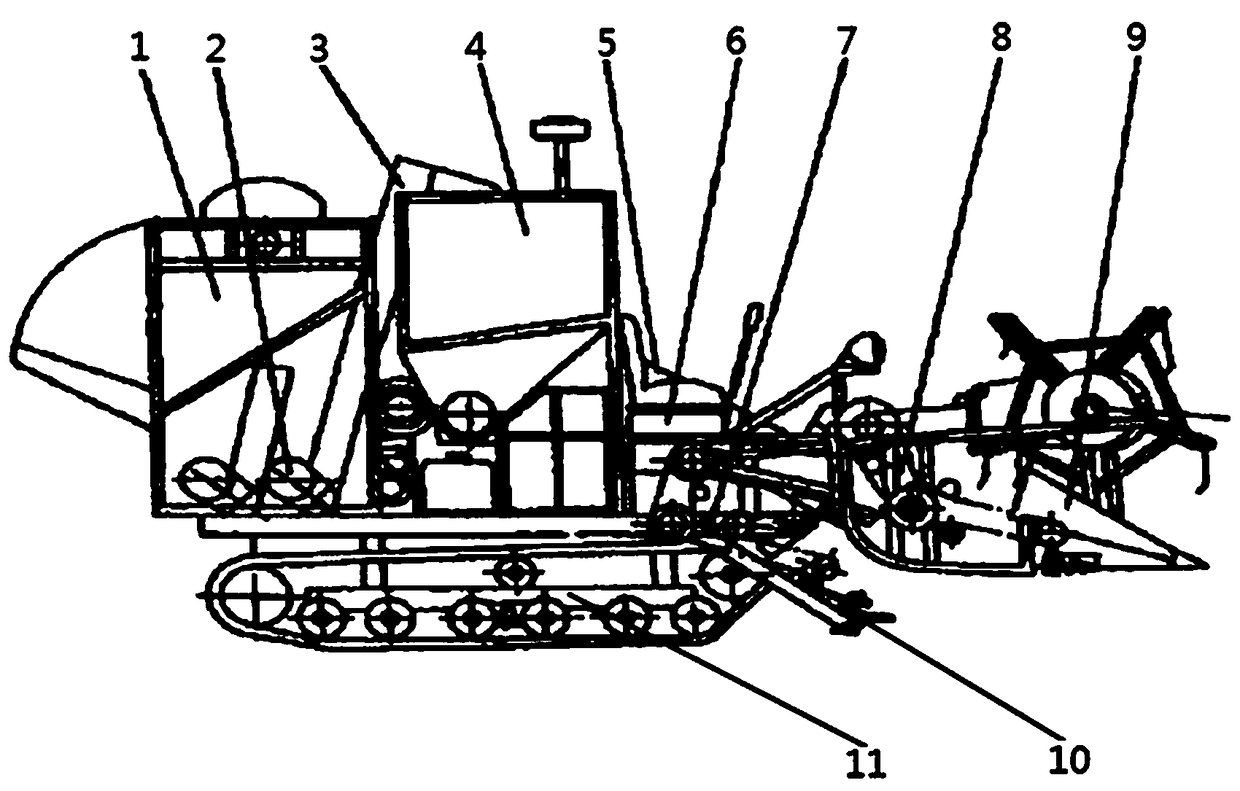

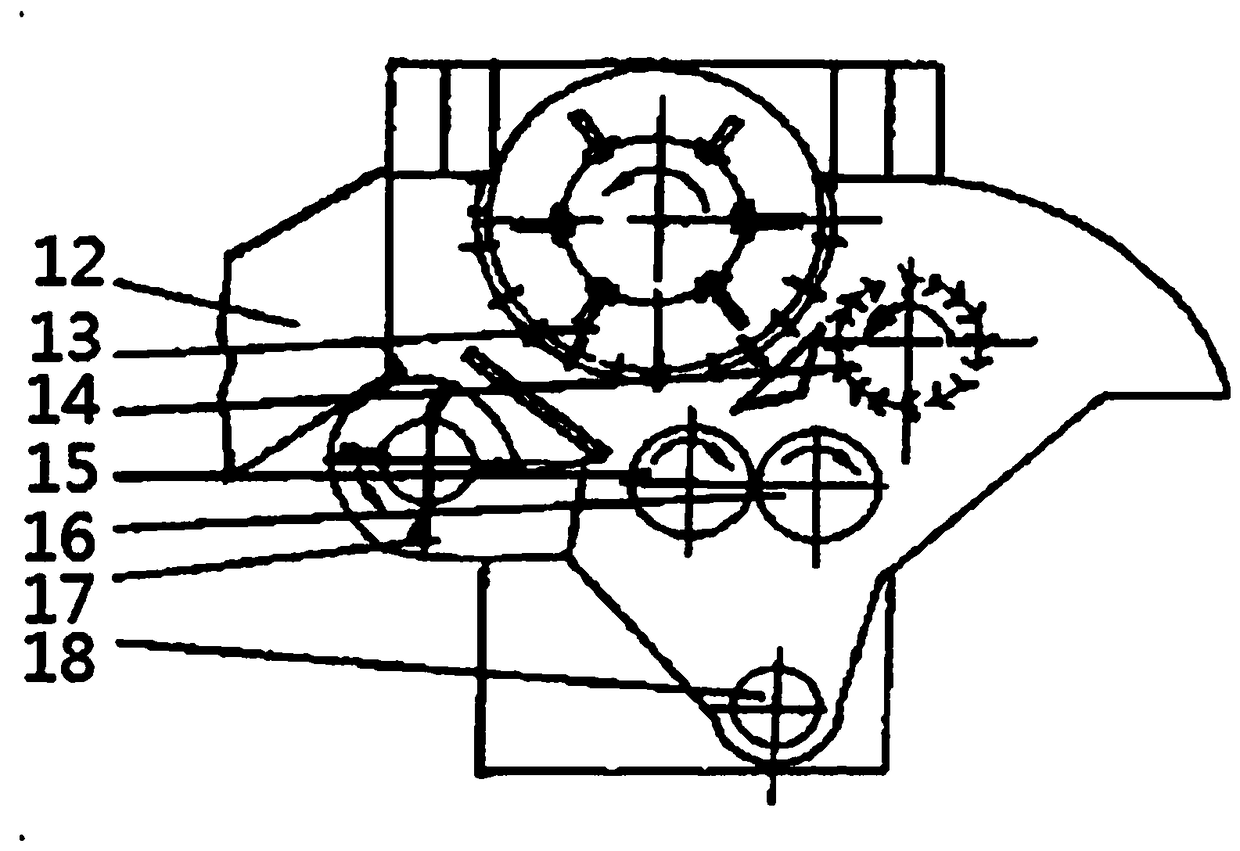

Crawler-type self-propelled combine harvester

InactiveCN108076790AMeet harvesting requirementsSimple structureMowersThreshersDrive wheelCentrifugation

A crawler-type self-propelled combine harvester is mainly composed of a threshing cleaning device, a horizontal screw conveyor, a vertical screw conveyor, a grain tank, a conveying trough, a console,a chassis, a header, a reel, a secondary cutting device and a traveling mechanism; the travelling mechanism has a front-driving crawler type structure and the driving wheels are gear tooth type; a cutter is a II-type casting cutter; the secondary cutting device is configured under the rear of the header; the vertical height of the upper cutter and the lower cutter on the header is adjustable; theradial blower fan cylinder screen cleaning device is mainly composed of a conveying trough, a concave screen, a radial blower fan, a front cylinder screen, a rear cylinder green, a centrifugation blower fan and a screw conveyer, which form a dual-screen and dual-blower fan structure; a secondary threshing device is composed of a group of miniature threshing rollers and concave screens. The invention has the advantages of simple structure, reasonable arrangement, high work efficiency, low production cost, stable operation and simple operation, and can well meet the wheat harvest requirements inthe northwest region.

Owner:周宝东

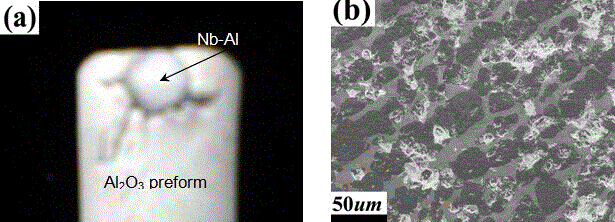

Method for improving wettability of Al2O3 porous perform and NbAl molten alloy

InactiveCN105274380AImprove wettabilitySignificant technical and economic advantagesCeramic compositeOxidation resistant

The invention provides a method for improving the wettability of an Al2O3 porous perform and NbAl molten alloy. A near-net-size product which is compact and provided with a continuous micro structure can be obtained with low cost by repairing NbAl / Al2O3 composite materials of a network interconnection structure, and therefore the respective advantages of ceramics and intermetallic compounds are brought into full play, and metal-based ceramic composite materials with high oxidation resistance, good mechanical performance and long service life are obtained. In the process that the NbAl molten alloy infiltrates into the Al2O3 porous ceramic perform, non-pressure infiltration can not be achieved due to the wettability problem of the Al2O3 porous perform and the NbAl molten alloy. A proper number of alloyed elements are added, the wettability between the Al2O3 porous ceramic perform and the NbAl molten alloy is improved fully, and therefore non-pressure infiltration between the Al2O3 porous ceramic perform and the NbAl molten alloy is realized. By means of the method for improving the wettability of the Al2O3 porous perform and the NbAl molten alloy, the use range of an industrial chain of NbAl intermetallic compounds is enlarged, the preparation cost of the NbAl / Al2O3 composite materials is reduced, and multi-aspect technical and economic advantages are achieved.

Owner:陈焕铭 +5

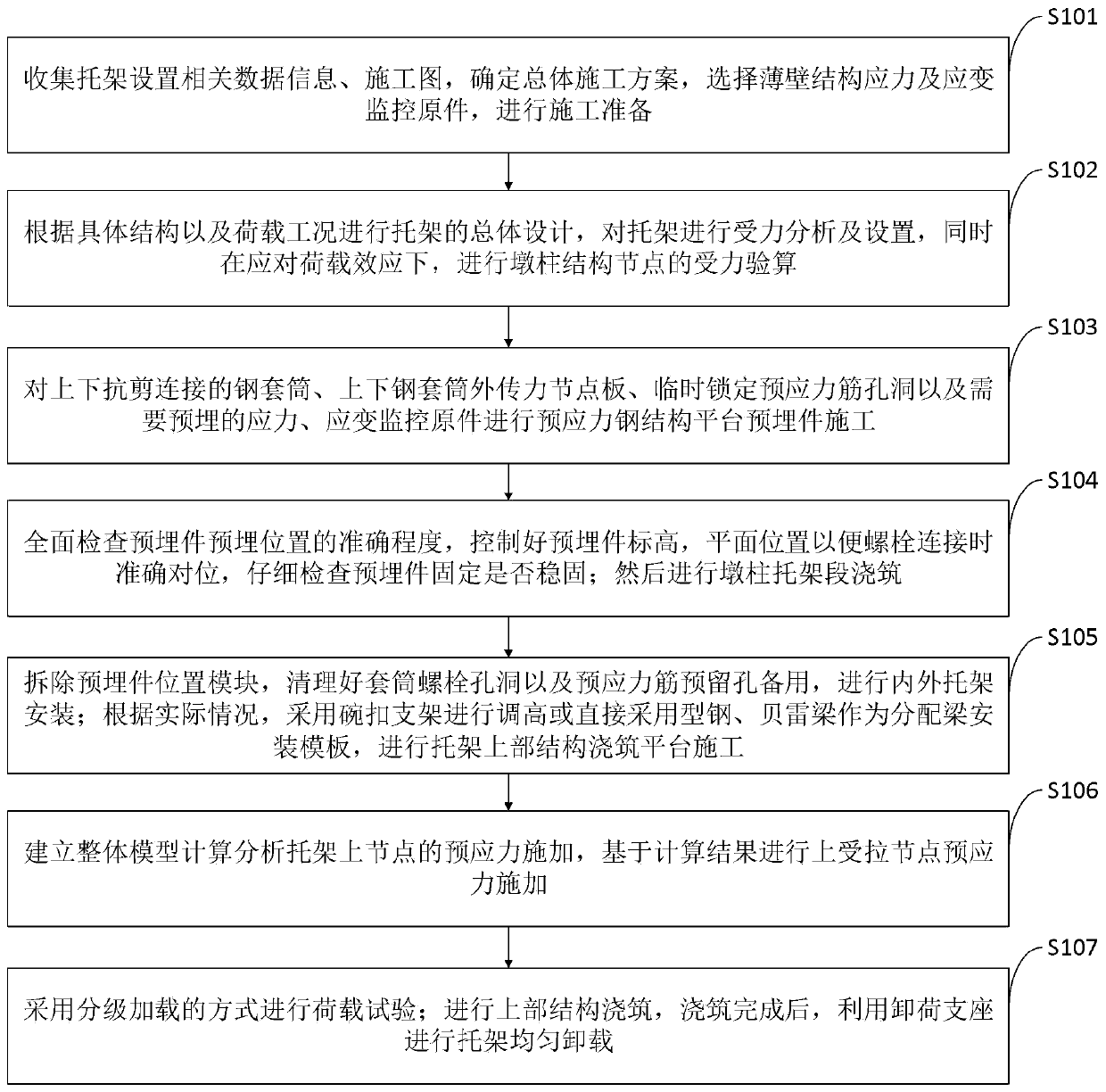

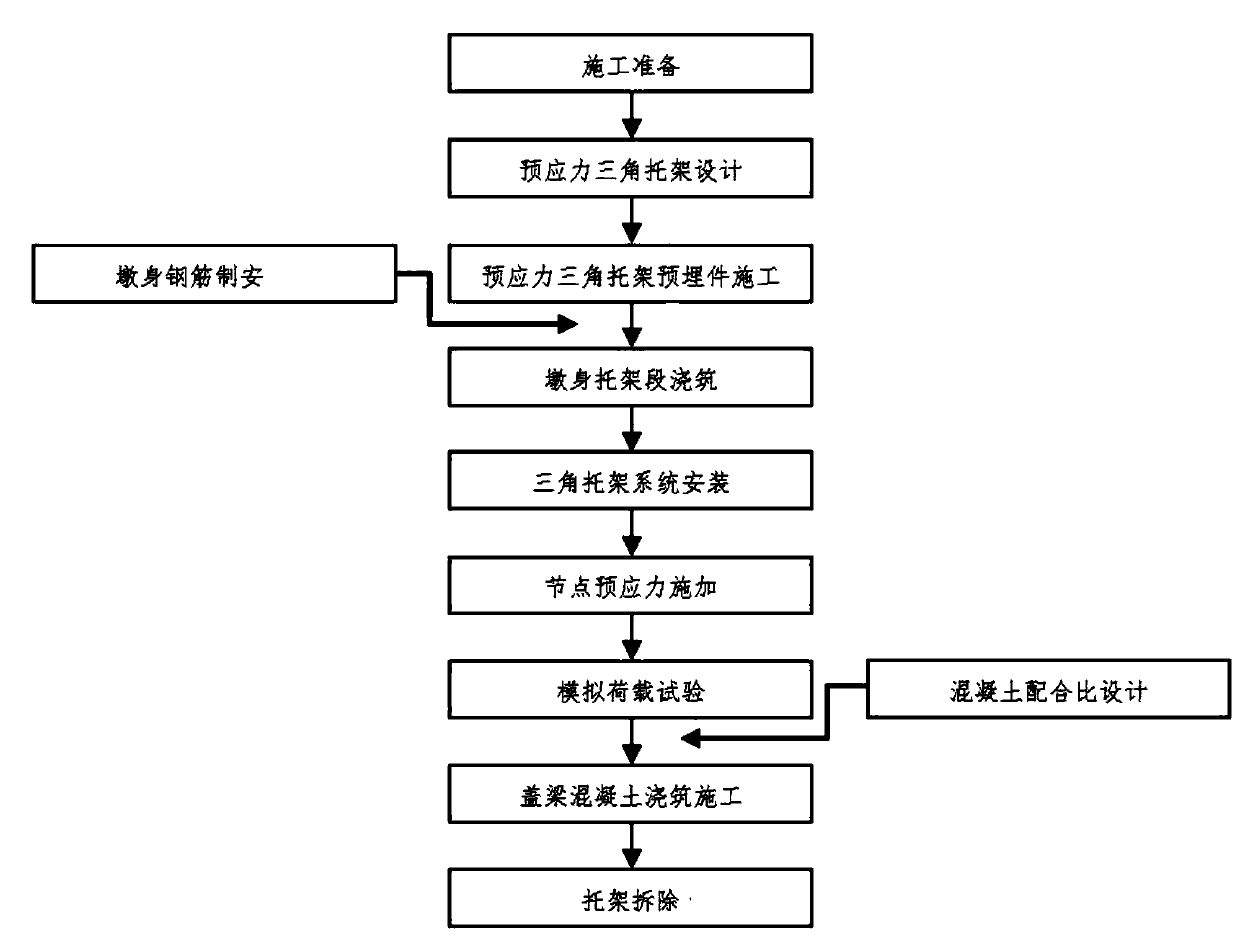

Prestressed steel structure front-pulling and rear-locking cast-in-place platform construction method

PendingCN110700102AImprove the forceImprove the state of stressBridge erection/assemblyPre stressArchitectural engineering

The invention belongs to the technical field of constructional engineering construction, and discloses a prestressed steel structure front-pulling and rear-locking cast-in-place platform constructionmethod which comprises the steps that an overall construction scheme is determined, and construction preparation is conducted; stress analysis and setting are conducted on the bracket, and meanwhile stress checking calculation of pier column structure joints is conducted under the load effect; pre-stressed steel structure platform embedded part construction is conducted; pier column bracket section pouring is conducted; the inner and outer brackets are installed; according to the actual situation, a bowl buckle support is adopted for height adjustment, or profile steel and a bailey beam are directly adopted as distributive girder installation formworks, and bracket upper structure pouring platform construction is conducted; an integral model is established to calculate and analyze the prestress application of the node on the bracket, and the prestress of the upper tension node is applied based on the calculation result; a load test is carried out; and an upper structure is poured andthe bracket is detached. The construction method is well applied to a plurality of projects, successfully solves the construction problem of the bent cap bracket with large span load, and has good popularization and application values.

Owner:重庆建工建筑产业技术研究院有限公司 +2

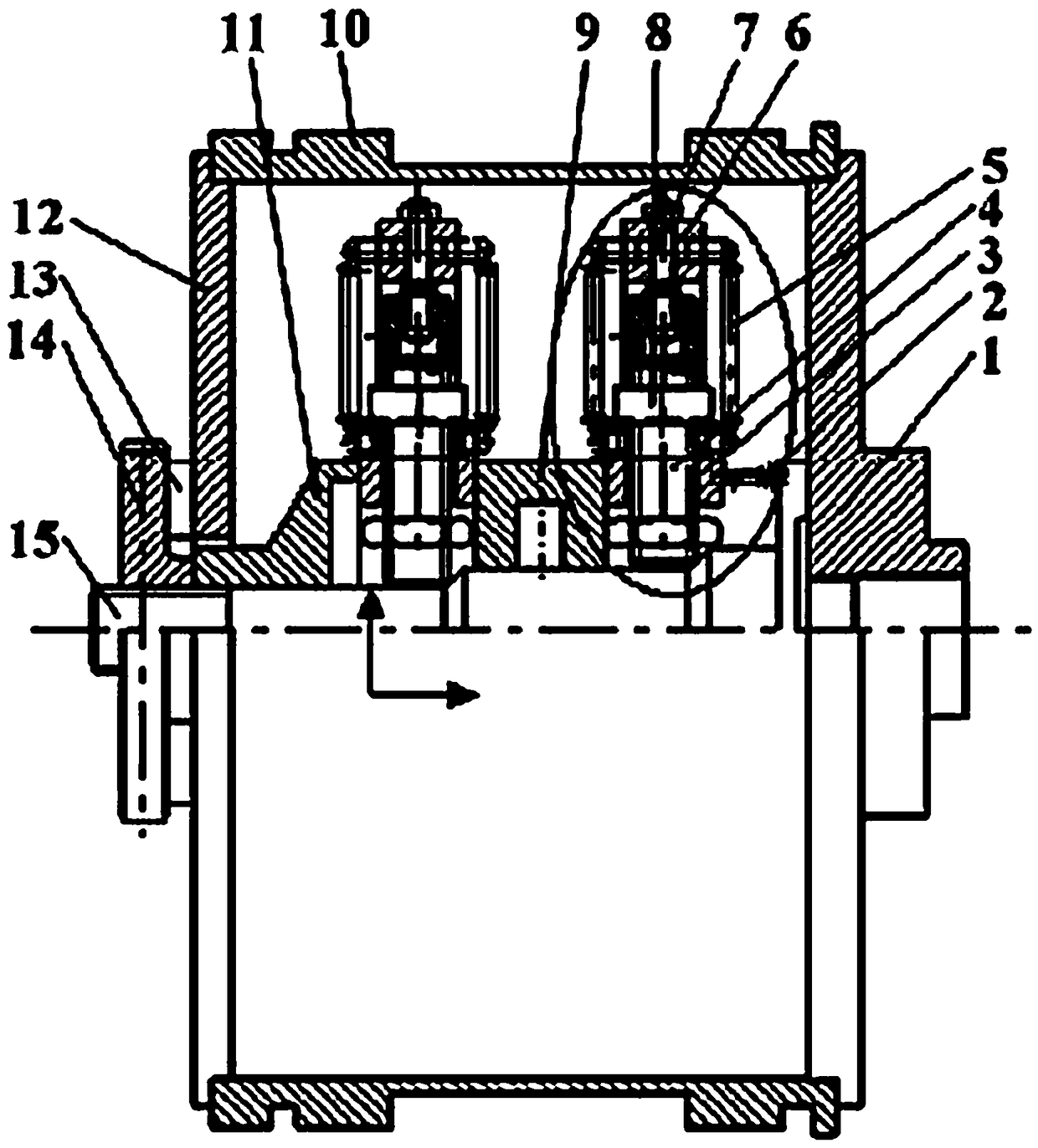

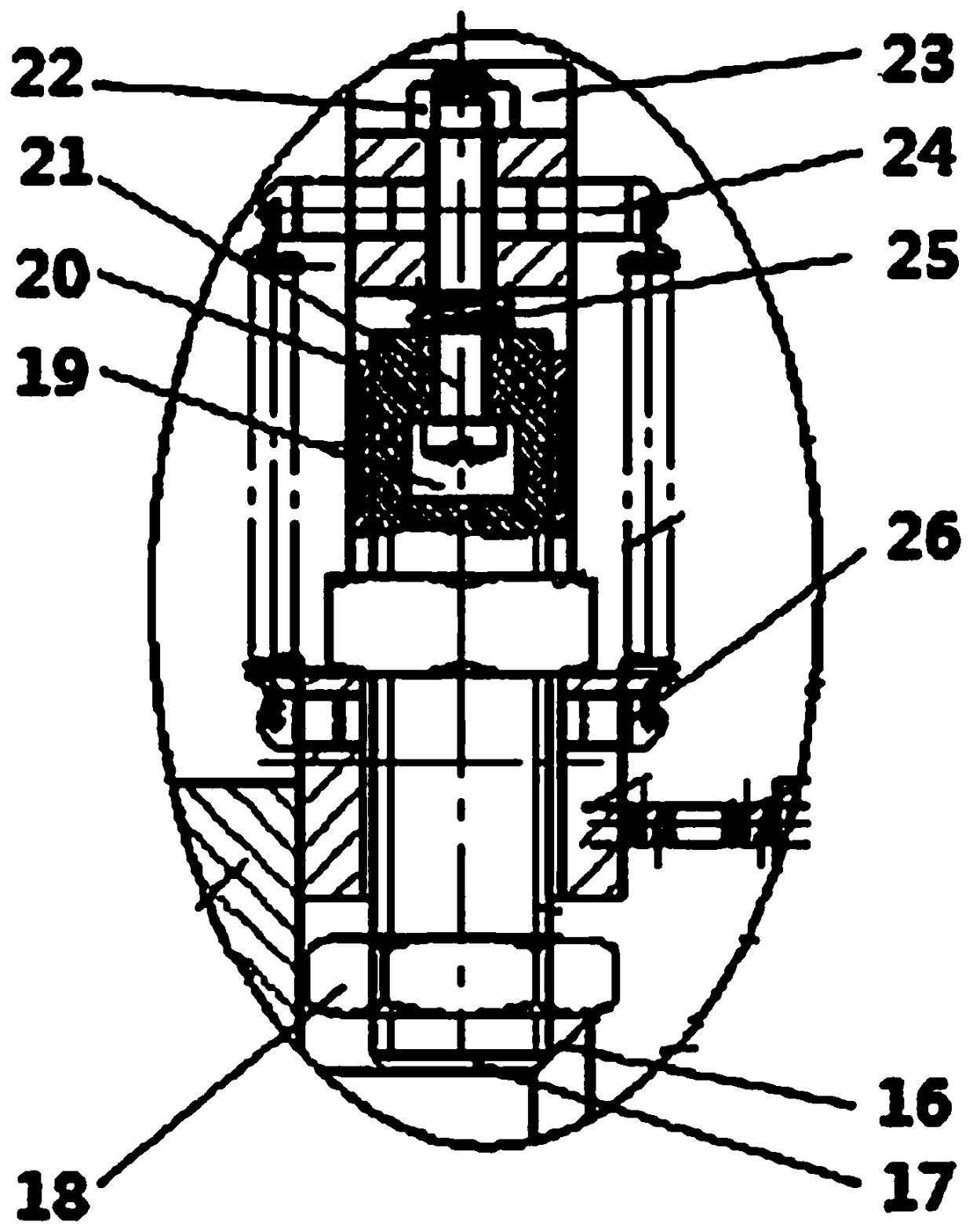

Universal flexible clamp for thin-walled parts

InactiveCN108080982AMeet processing requirementsReduce processing requirementsWork clamping meansPositioning apparatusEngineeringScrew thread

A universal flexible clamp for thin-walled parts is mainly composed of a right pressing disc, an axial spring, a supporting ring, an ejection rod, a spring, a supporting fan, a screw, a nut, a spacerring, an ejection ring, a right pressing disc, an adjusting washer, a rotary nut, a supporting shaft and the like. An internal thread is machined on a center hole of the right pressing disc. An external thread is machined at the right end of the supporting shaft, and the right end of the supporting shaft is fixedly connected with the right pressing disc in a threaded mode. The left end of the supporting shaft is sleeved with the left pressing disc. The adjusting washer is mounted between the nut and the left pressing disc. Two radial supporting mechanisms are arranged on the supporting shaft in the axial direction, located between the supporting shaft and the left pressing disc and mainly composed of an internal stop nut, a T-shaped connection groove, a supporting piece, a screw cap, a nut, an upward-pulling spring hanger, a supporting spring, a downward-pulling spring hanger, a groove and the like. The universal flexible clamp is simple in structure and low in production cost, clamping deformation of the parts is reduced, and the production efficiency and quality stability of the thin-walled parts are improved.

Owner:牛金生

Ozone/hydrogen peroxide-induced free radical flue gas purification method and system

InactiveCN103990365BLow investment costLow running costDispersed particle separationEnergy inputRecuperatorPollution

The invention discloses a method and a system for purifying flue gas by inducing free radicals by virtue of ozone and hydrogen peroxide. The system is characterized in that a flue of a boiler is connected with one end of a flue gas heat exchanger, wherein the other end of the flue gas heat exchanger is connected to the bottom of a spraying washer; an injection hole of an ozone injection system is formed in a pipeline located between the flue gas heat exchanger and the spraying washer; a solution circulating by-pass system is connected with the top end and lower part of the spraying washer, respectively; the bottom of the spraying washer is sequentially connected with a mercury separation system, an ammonification neutralizing system and a product concentrating and crystallizing system; the top of the spraying washer is connected with a chimney through the pipeline and a flue gas waste heat system. According to the method, hydroxyl free radicals with strong oxidizing property are generated in an induction manner after the ozone in the flue gas is contacted with the hydrogen peroxide in spraying liquid; four main pollutants in the flue gas can be simultaneously removed, equipment is simple and reliable, and no secondary pollution is generated in a removal process. The method and the system are novel and have wide application prospects.

Owner:JIANGSU UNIV

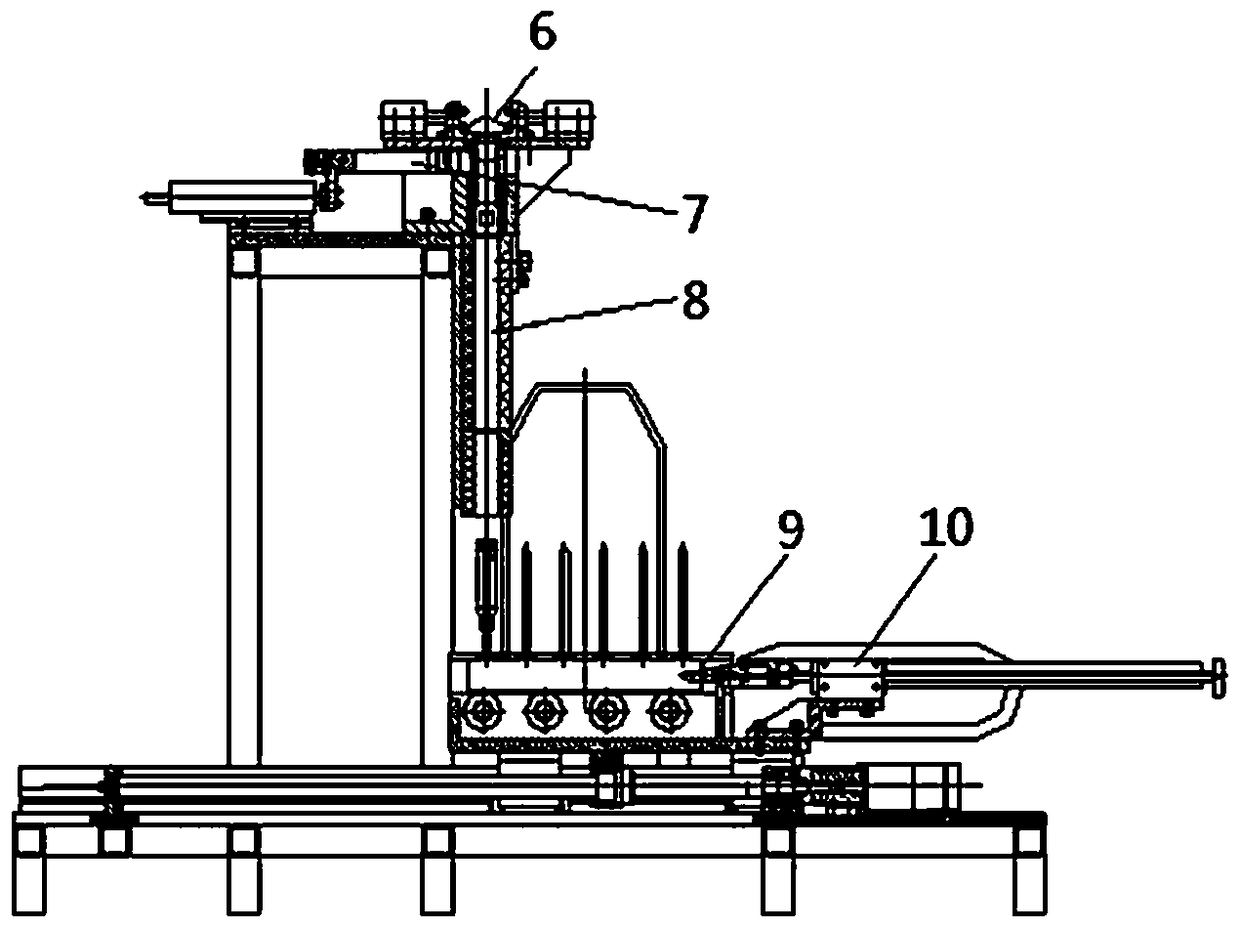

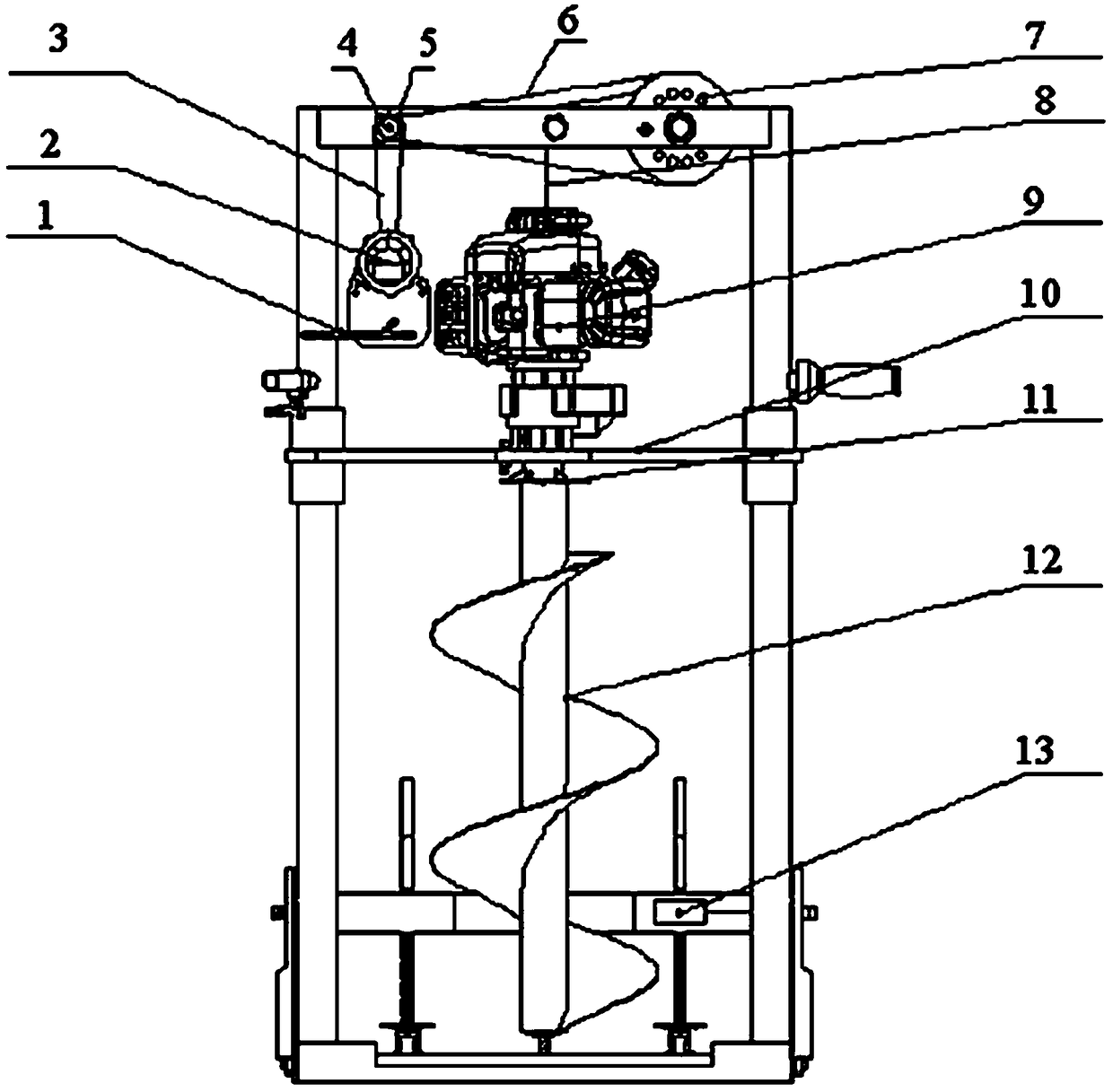

Electric power assistance system for orchard light and simple hole digging device

InactiveCN108076731ASatisfy the digging requirementsSimple structurePlantingFurrow making/coveringElectric power systemElectric power

The invention relates to an electric power assistance system for an orchard light and simple hole digging device. The electric power assistance system mainly comprises a support frame, a direct current motor, a first belt wheel, a first belt, a second belt wheel, a third belt wheel, a second belt, a fourth belt wheel, a steel wire rope, a gasoline engine, an iron frame, a plastic plate, a drill bit, a fixation frame and other components, wherein the direct current motor is arranged on the bracket of one side of a hand-operated hole digging device, the first belt wheel is sleeved on the rotation shaft of the direct current motor, and is connected to the second belt wheel through the first belt wheel, the second belt wheel is coaxial with the third belt wheel, and is connected to the fourthbelt wheel through the second belt, and the second belt wheel, the fourth belt wheel and the rotation shaft of a fixation pulley are positioned on the cross beam at the top end of the hole digging device. According to the present invention, the electric power assistance system has advantages of simple structure, high working efficiency, low cost and convenient installation, can meet the hole digging requirements of hold digging devices, and can provide important significance for the improvement of agricultural machinery levels in China.

Owner:吴丽娜

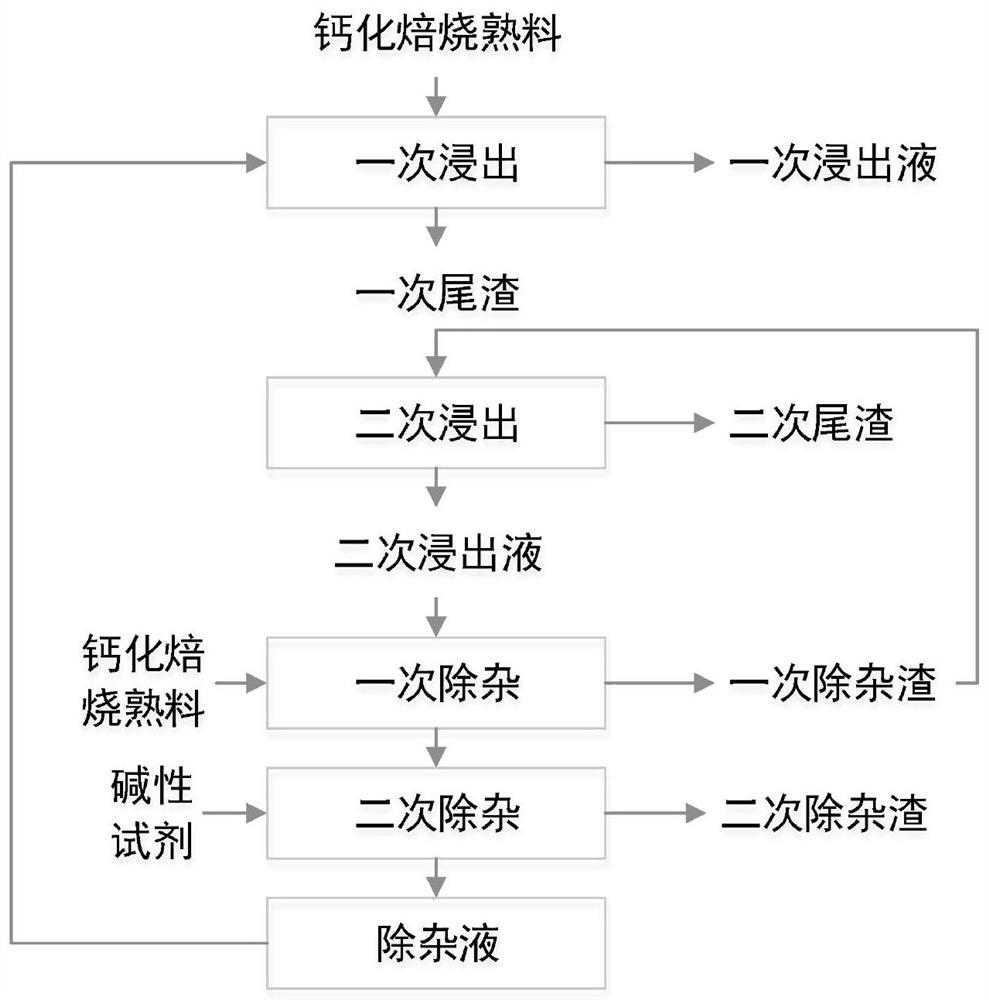

Recycling and Utilization Method of Calcified Vanadium Extraction Tailings

ActiveCN109321760BImprove the dissolution and leaching rateIncrease productivityProcess efficiency improvementPregnant leach solutionSlag

The invention relates to a recycling method of calcified vanadium extraction tailings, and belongs to the field of vanadium oxide preparation. What the present invention aims to solve is the problem that the vanadium content in the tailings for vanadium extraction by calcification is too high, resulting in waste of resources. Place in 1%-4% w / w sulfuric acid aqueous solution for acid leaching, use vanadium slag to calcify and roast the clinker to adjust the pH of the leachate to 1.0-2.0, separate the solid and liquid, collect the liquid phase, and obtain the impurity-removed leachate, use Primary leaching of calcified roasted clinker from vanadium slag. The invention can not only fully extract the vanadium in the tailing slag, avoid waste of resources, but also help to increase the vanadium concentration of the leaching solution, so as to achieve the purpose of enriching vanadium.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Thermal mass decoupling heat exchanger and thermal mass decoupling method thereof

PendingCN110500910ASignificant technical and economic advantagesImprove efficiencyIndirect heat exchangersEngineeringTemperature difference

The invention discloses a thermal mass decoupling heat exchanger and a thermal mass decoupling method thereof in the technical field of energy utilizing. The thermal mass decoupling heat exchanger isa two-stage compression thermal mass decoupling heat exchanger, and is composed of a phase transformation heat exchanger, an absorbing tower, a cooler, a heater, a desorbing device, a compressor, a circulation pump, a throttling valve, padding, a hot water pipeline, a cold water pipeline, a heat pipe and a connection pipeline. The thermal mass decoupling heat exchanger adopts a heat pipe heat exchanging manner, the heat exchanger flow path of two-stage compression and thermal mass decoupling is built, so that the irreversible loss in the heat exchanging process of the heat exchanger and a coldsource and a hot source is remarkably reduced, and efficient transmission of heat under a large temperature difference is achieved; and efficient heat exchanging of a low temperature object and a high temperature object is achieved, heat can be extracted from the low temperature object such as soil, underground water, air or industrial waste heat, high temperature water, steam or chemical media are obtained, and remarkable technological and economical advantages are achieved due to remarkable improvement of the system efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A flue gas purification method and device for ozone-activated persulfate

ActiveCN104043325BLow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsAmmonium nitrate

Owner:JIANGSU UNIV

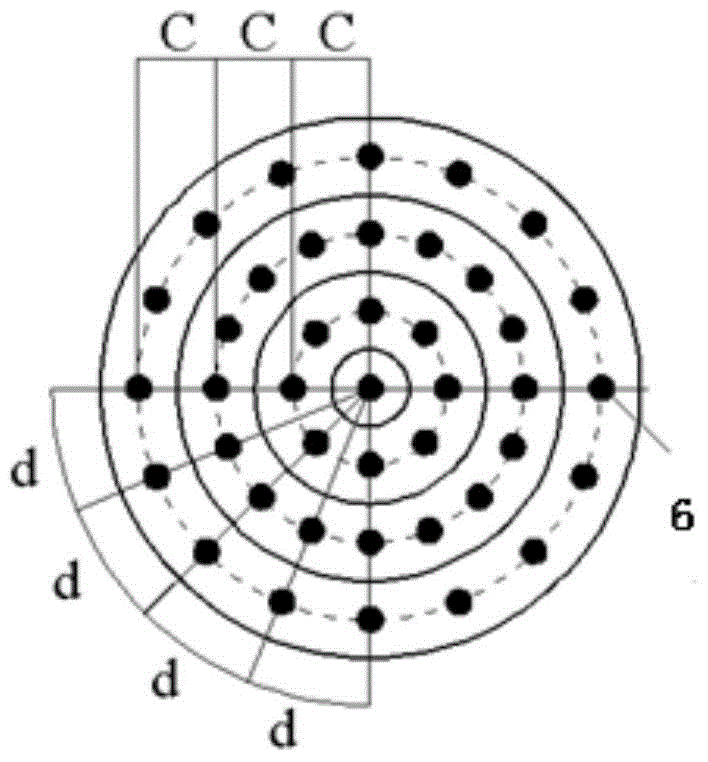

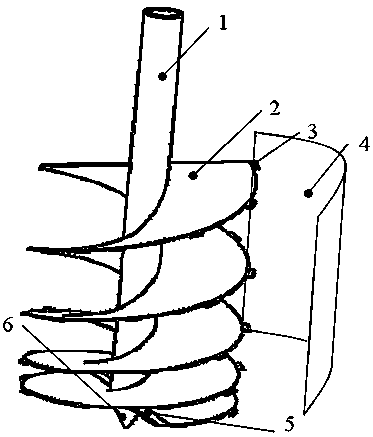

Vertical helix ditching machine spiral cutter combination

InactiveCN108076692ASatisfy ditching requirementsSimple structureTilling equipmentsHelical lineTransmitted power

A vertical helix ditching machine spiral cutter combination which is mainly composed of a main shaft, a spiral blade, a spiral soil cutting blade, a baffle, a transverse plane soil cutting blade and adrill tip; the main shaft is responsible for transmitting power output by a reduction box to the spiral blade and the main shaft is designed into a hollow shaft; the spiral blade is the most important part of the helical cutter structure and is composed of countless tangents of variable pitch spirals; the spiral cutting blade is welded on the outer edge of the spiral blade to reduce the wear of the spiral blade; the transverse plane cutting blade is fixed on the blade holder welded to the end of the spiral blade by bolting; the arc baffle is installed at a rear of the spiral cutter; the drilltip is installed at an end of the main shaft through welding; small taper screwed type drill tip is used. The invention has the advantages of simple structure, high working efficiency, low cost and convenient installation, and satisfies the requirements for the trenching of the vertical spiral trencher, and has important significance for improving the level of agricultural mechanization in China.

Owner:牛金生

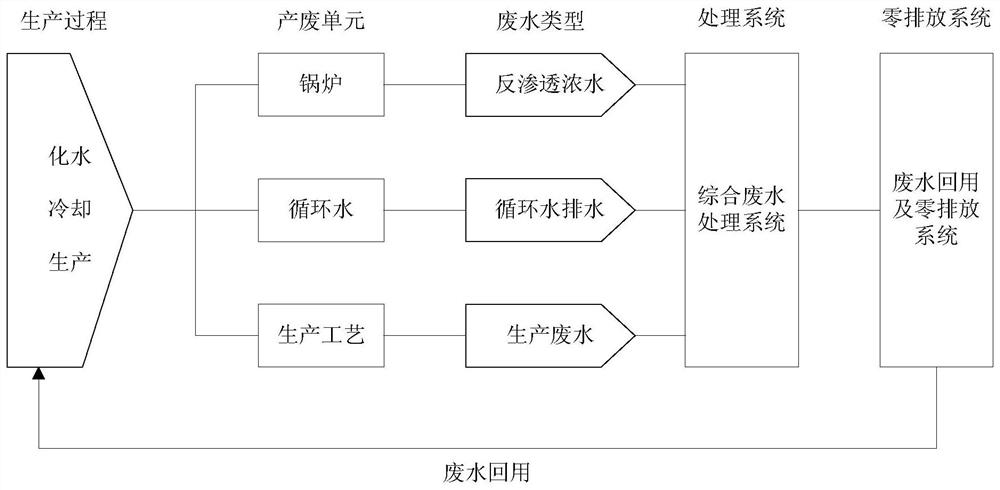

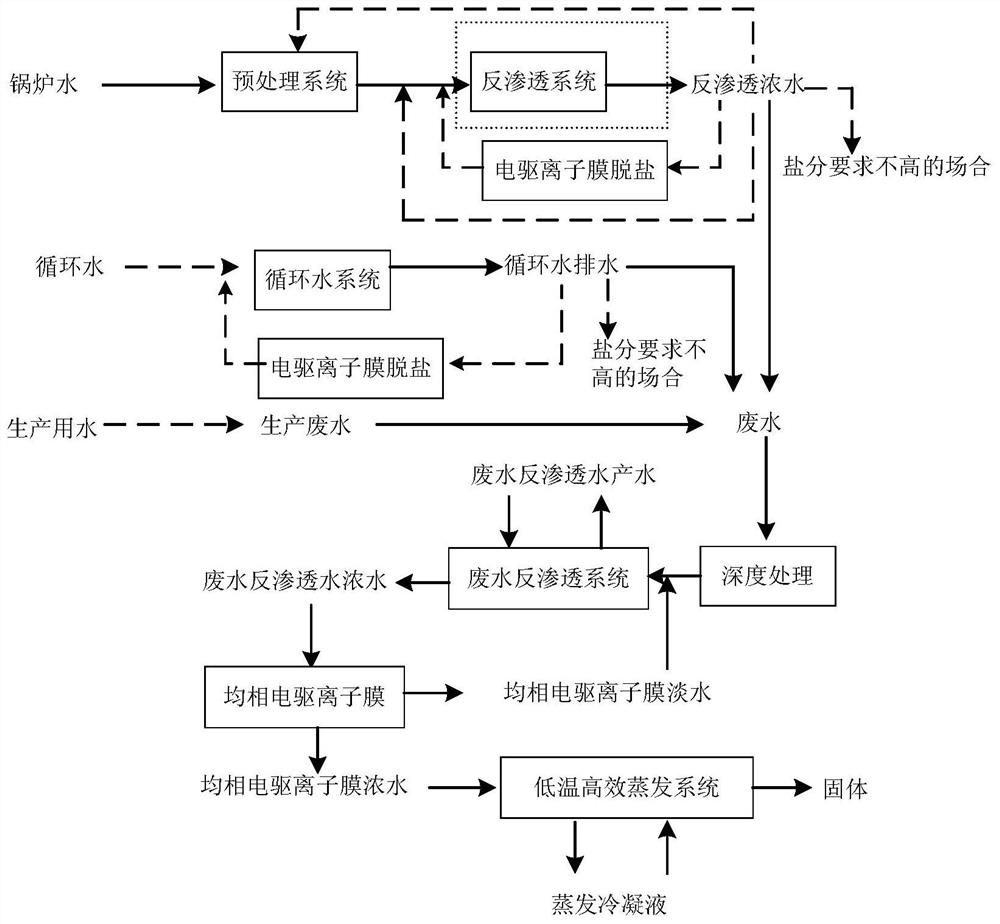

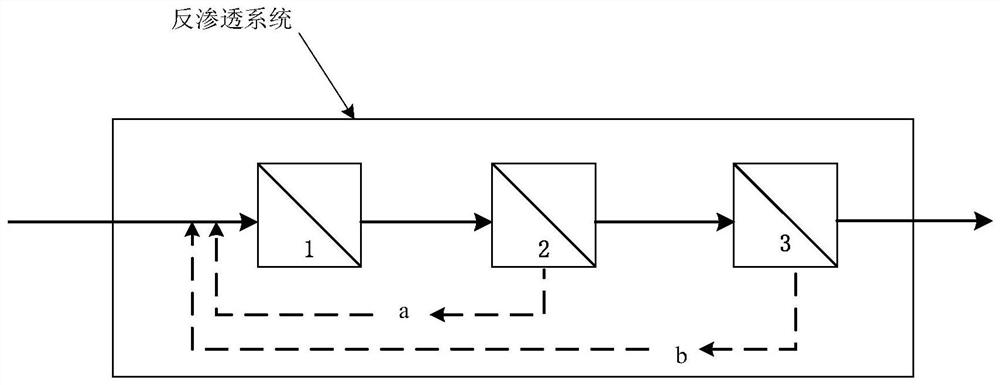

A zero-discharge process route for enterprise production wastewater based on the 3r principle

ActiveCN106746132BEmission reductionLow investment costSpecific water treatment objectivesTreatment involving filtrationWater useWater saving

The invention discloses a 3R principle-based enterprise production wastewater zero discharge process route, and belongs to the field of water treatment. According to the process route, a 3R principle is taken as a guide; firstly, a wastewater discharge amount is reduced through strengthening management to realize reduction (Reduce); secondly, water demands are analyzed to realize reuse (Reuse); thirdly, water quality is enabled to meet the requirement of reuse through simple treatment, and to realize recycle (Recycle). On the basis of implementing the 3R principle, the wastewater amount is greatly reduced; zero discharge of wastewater is realized by reasonably selecting a low-investment and low-cost zero discharge process. According to the process, water is effectively saved on the premise of not increasing investment and operation cost; the wastewater discharge amount is greatly reduced; the investment and the treatment cost of wastewater treatment and zero discharge process facilities can be effectively reduced; the 3R principle-based enterprise production wastewater zero discharge process route has extremely good economic, social and environment benefits; compared with a simple end treatment and zero discharge mode, the technical economic advantages are very remarkable.

Owner:沈阳艾柏瑞环境科技有限公司

Electric four-wheel mower blade brake mechanism

InactiveCN108076836AMeet fast braking requirementsIncrease the level of mechanizationHarvestersFriction effectKnife blades

An electric four-wheel mower blade brake mechanism mainly comprises a string excited motor, a holder, a multi-wedged belt, a cutting blade, a large pulley, a brake ring, a bearing I, a brake sheet, abrake spring, a stopping sheet and a bearing II; braking function is realized by the friction effect between the brake sheet and the brake ring; the string excited motor is fixed at one end of the holder; the large pulley is fixed at the other end of the holder through the bearing I and the bearing II; the brake ring is fixed at the same end of the large pulley of the holder; the brake sheet is intouch with the brake ring under the pressure effect of the brake spring; the brake sheet adopts the composite body of friction material and metallic iron blocks; one end in touch with the brake ringis a friction sheet and the other end is an iron block; the air out passage of the string excited motor is used for cooling the brake mechanism through the brake ring. The invention has the advantagesof simple structure, reasonable arrangement, high working efficiency, low production cost, stable operation and simple operation, and can meet the requirement of fast braking of the electric four-wheel mower blade.

Owner:周宝东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com