Building core and manufacture method of building core

A manufacturing method and construction technology, applied in the direction of building structure, construction, building components, etc., can solve the problems of large space occupation, inconvenient transportation, long production cycle, etc., so as to reduce transportation costs, reduce air pollution, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

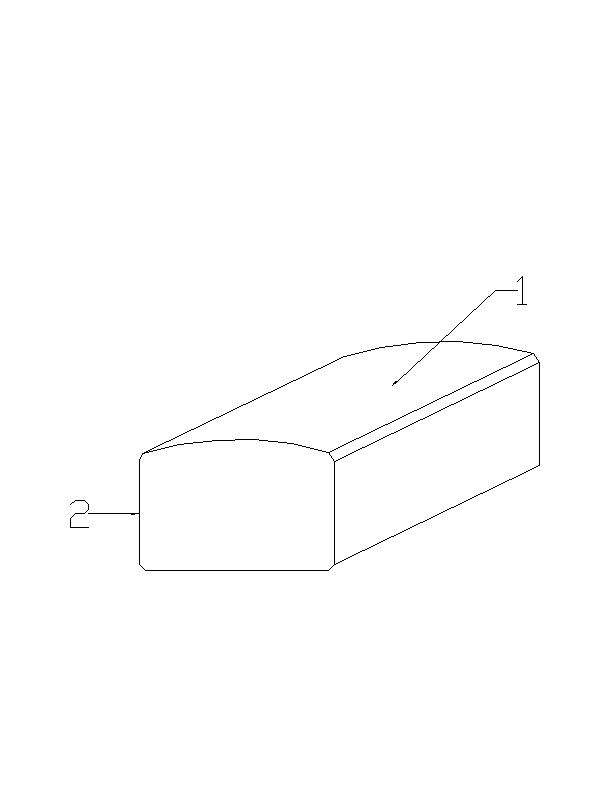

[0021] The present invention will be further described below in conjunction with all accompanying drawings, preferred embodiment of the present invention is: the manufacturing method of building core described in this embodiment comprises the following steps:

[0022] The first step: cut the prepared semi-finished silicate board according to the specifications;

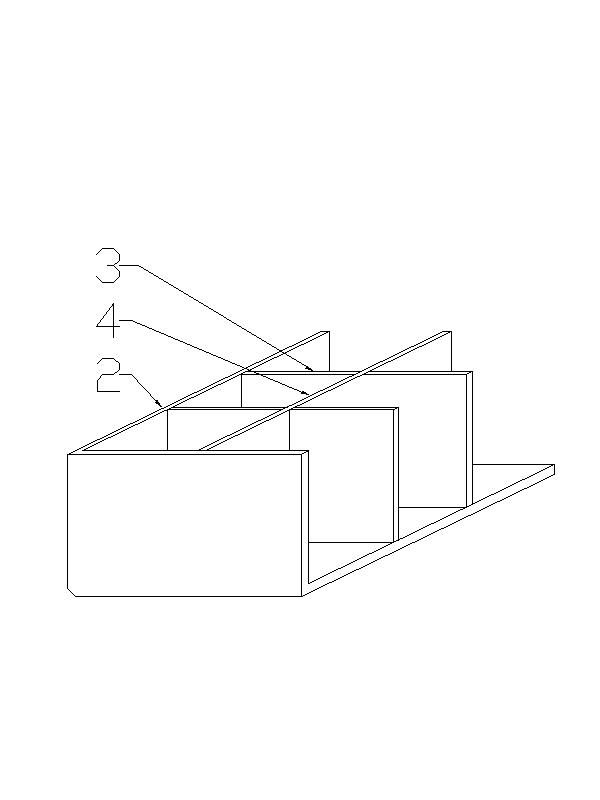

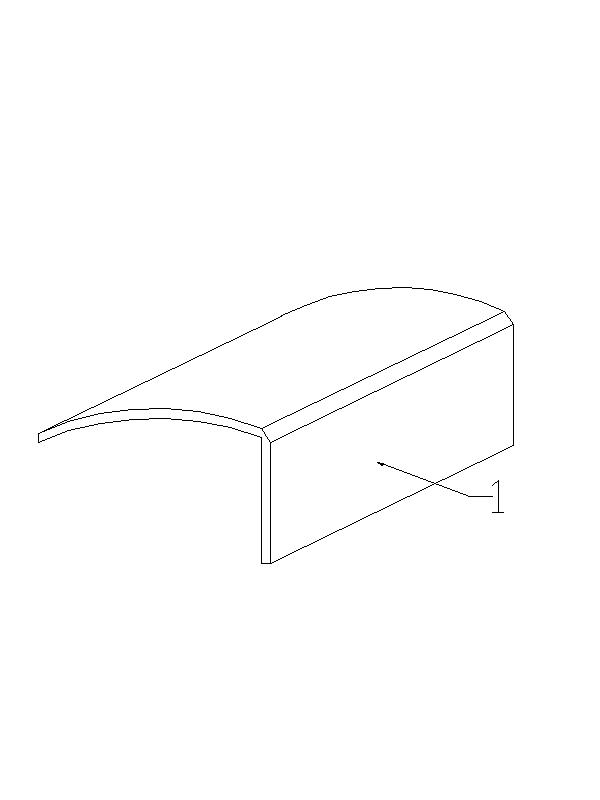

[0023] The second step: wrap the cut semi-finished silicate plate on three adjacent faces of the pre-manufactured core mold and tie it tightly, and wrap the other three adjacent faces on the other on the mold; as attached Figure 4 As shown, the mold is a rectangular main body 6 formed by welding angle steel, and one of the wide surfaces of the rectangular main body 6 is welded with an arc shaped plate 5;

[0024] The third step: move the mold that completed the second step to the steam curing car;

[0025] The fourth step: Push the steam curing car into the pre-curing room with a temperature of 40°C for drying;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com