Crawler-type self-propelled combine harvester

A combine harvester, self-propelled technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of less use of wheat combine harvesters, low level of production mechanization, labor and labor loss, etc., and achieves remarkable results. Technical and economic advantages, high work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

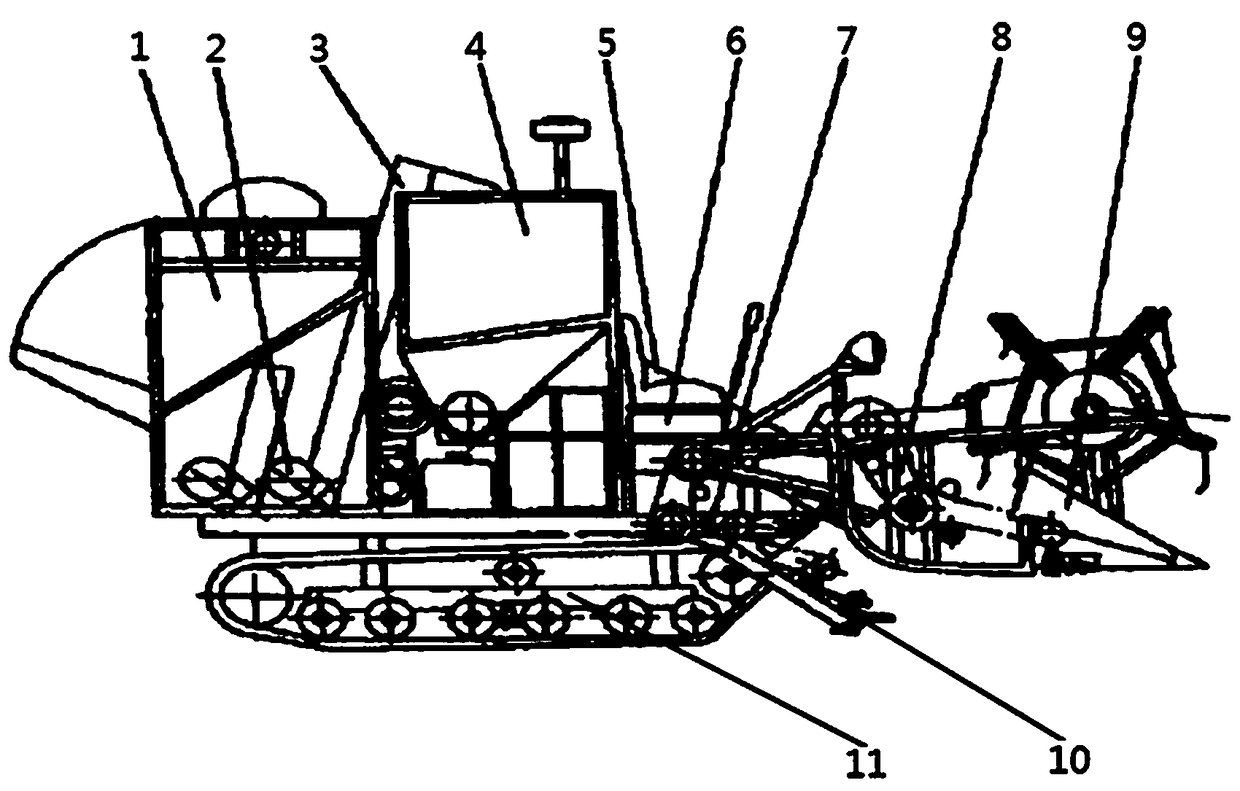

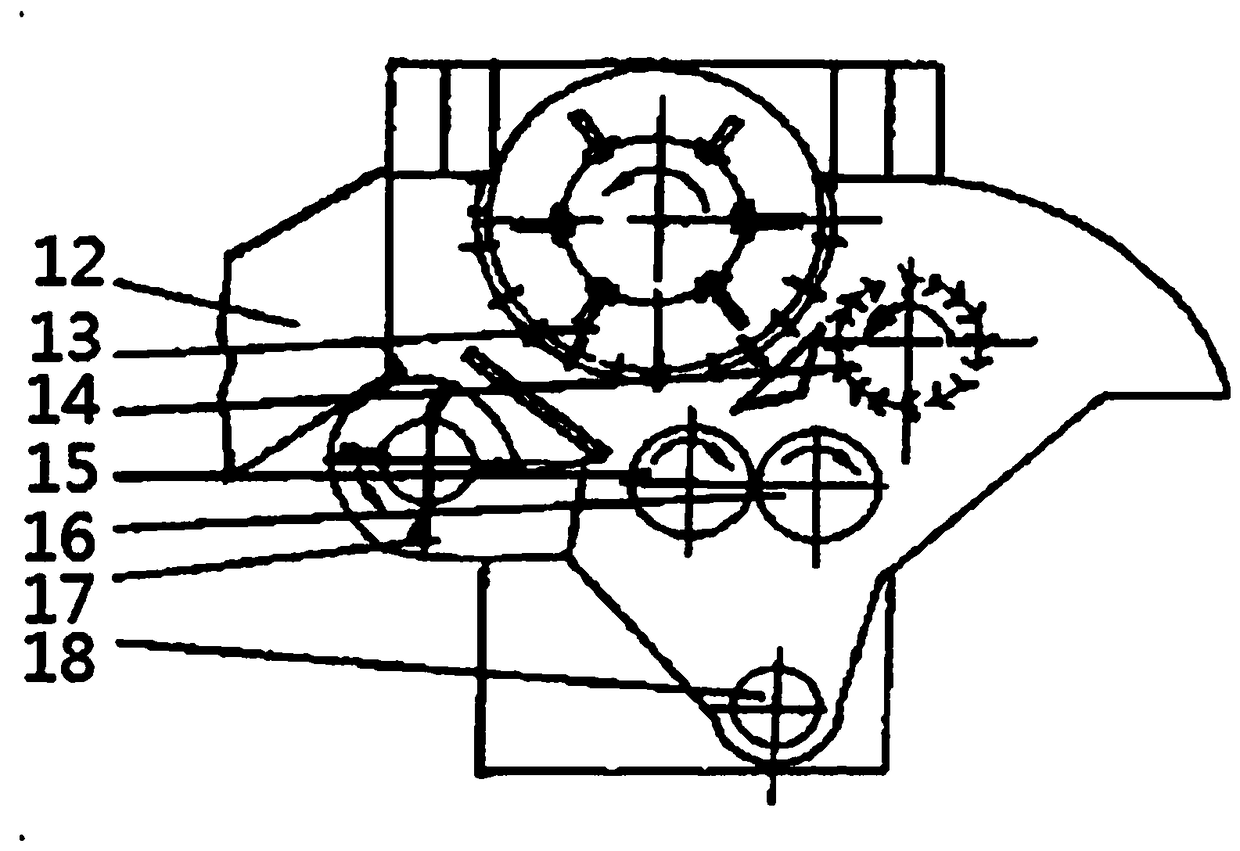

[0019] figure 1 The medium crawler self-propelled combine harvester is mainly composed of threshing and cleaning device, horizontal screw conveyor, vertical screw conveyor, grain tank, conveying trough, console, chassis, harvesting platform, reel, secondary cutting device, walking mechanism and other components; the walking mechanism is a front-drive crawler structure, the driving wheel is a toothed type, and the T angle of the track is increased to 45°, which improves the driving passability; the cutter is a type II casting cutter, which improves The rigidity and cutting quality of the cutter are improved; the secondary cutting device is arranged at the rear and lower part of the header, and the vertical height of the upper and lower cutters of the header is adjustable. The stalks left after the first cutting are thrown back field, which reduces the load of separation and cleaning of high-yield and high-stalk rice and wheat, and makes stubble cutting meet the agronomic requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com