Prestressed steel structure front-pulling and rear-locking cast-in-place platform construction method

A technology of prestressed steel and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of not being able to meet the construction load of large-span cap beams, achieve good promotion and application value, reduce pre-embedded requirements, and improve structures The effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Background

[0071] The roads and ancillary projects of the east extension section of Huanan Road in Chongqing Chemical Industry Park are located in the Changshou Chemical Industry Park in the eastern suburbs of Chongqing. The K1+242.60 medium bridge in this project, the mileage and pile number is K1+205.100, the design elevation is 268.734m, the design longitudinal slope is -2.00%, the bridge deck is 26.00m in full width, located on the curve, and the upper structure is made of post-tensioned prestressed concrete. Continuous box girder, U-shaped abutment and open-cut foundation are adopted for substructure abutment, and column pier and pile foundation are adopted for pile pier.

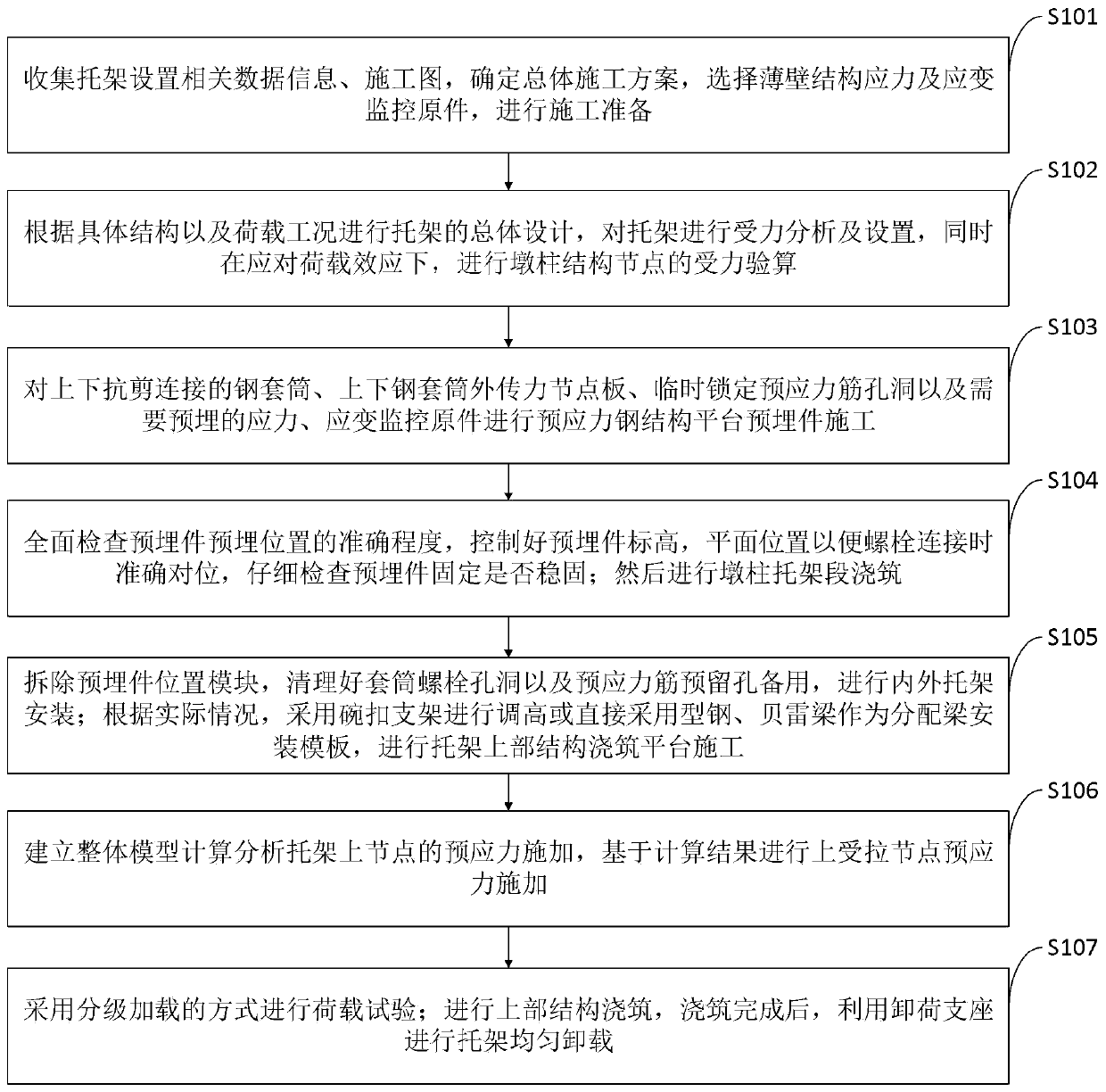

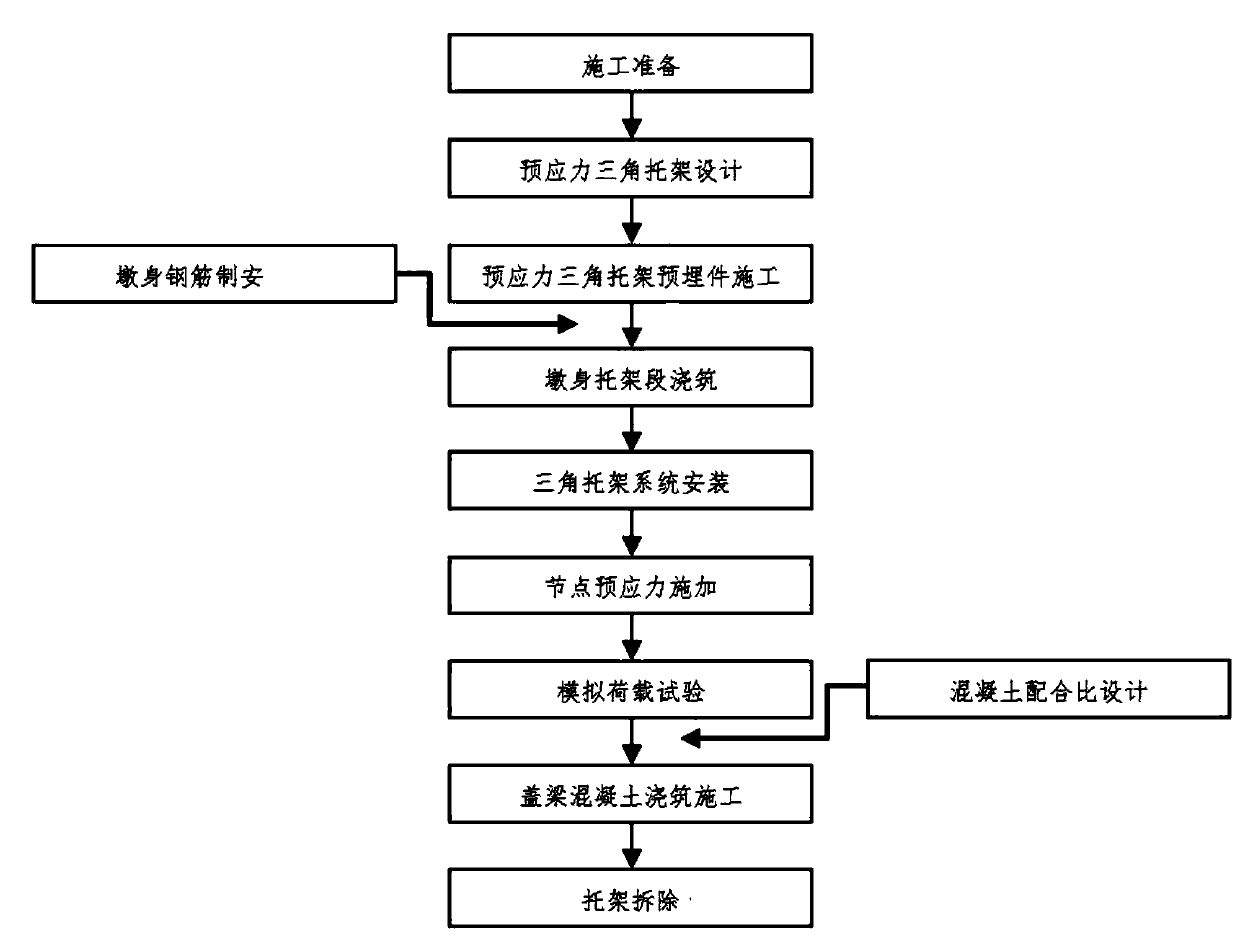

[0072] The construction technology of a large-span cap beam unsupported prestressed steel structure platform. At the node of the cap beam pier column bracket, the PVC pipe is embedded in the pier column to resist the tension of the bracket pier column node, and the vertical shear force is throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com