Universal flexible clamp for thin-walled parts

A flexible fixture and part technology, applied in metal processing machinery parts, clamping, clamping devices and other directions, can solve the problems of affecting the machining accuracy of parts, increasing waste, and increasing processing costs, and achieves high automatic centering accuracy and production costs. Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

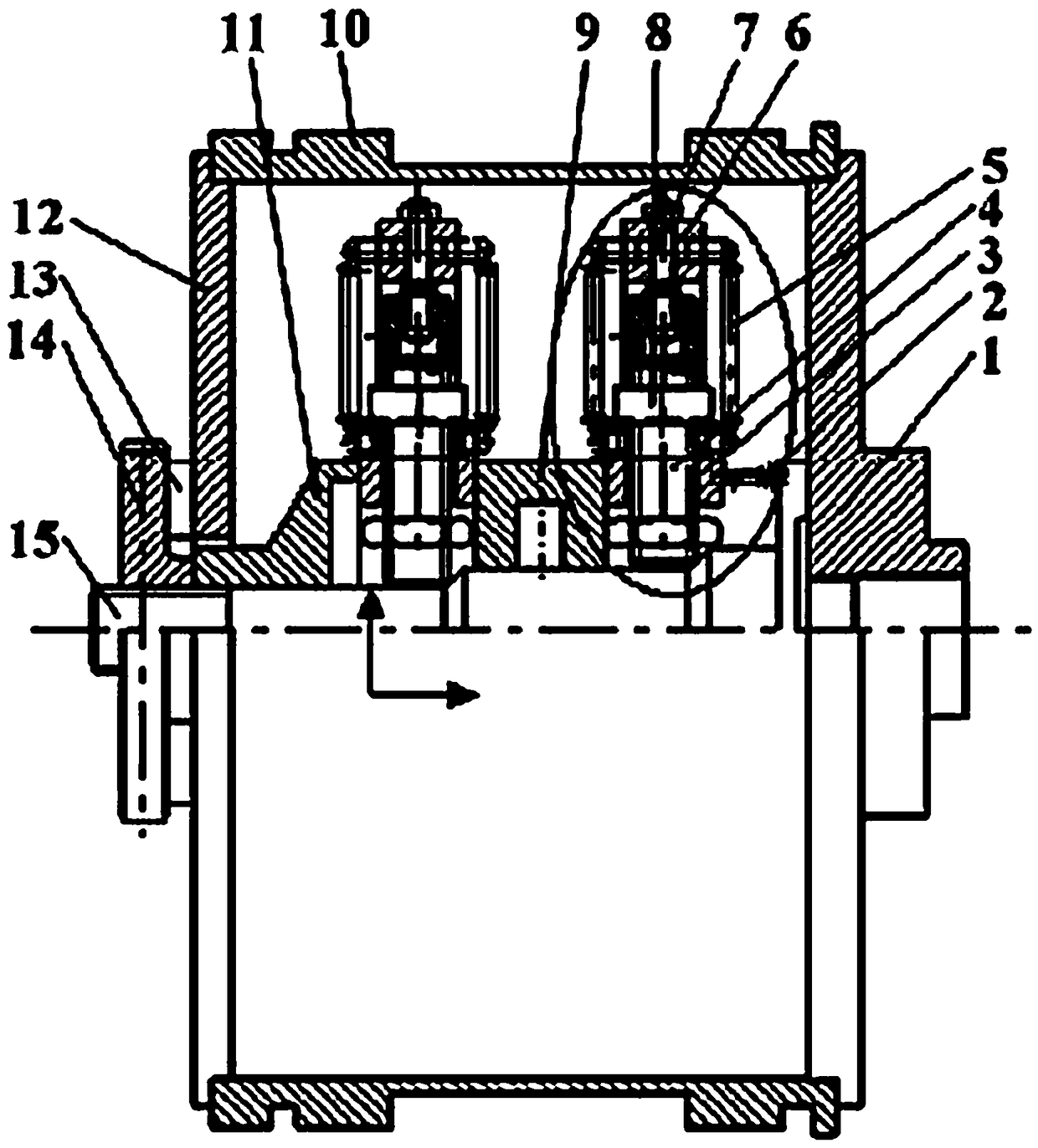

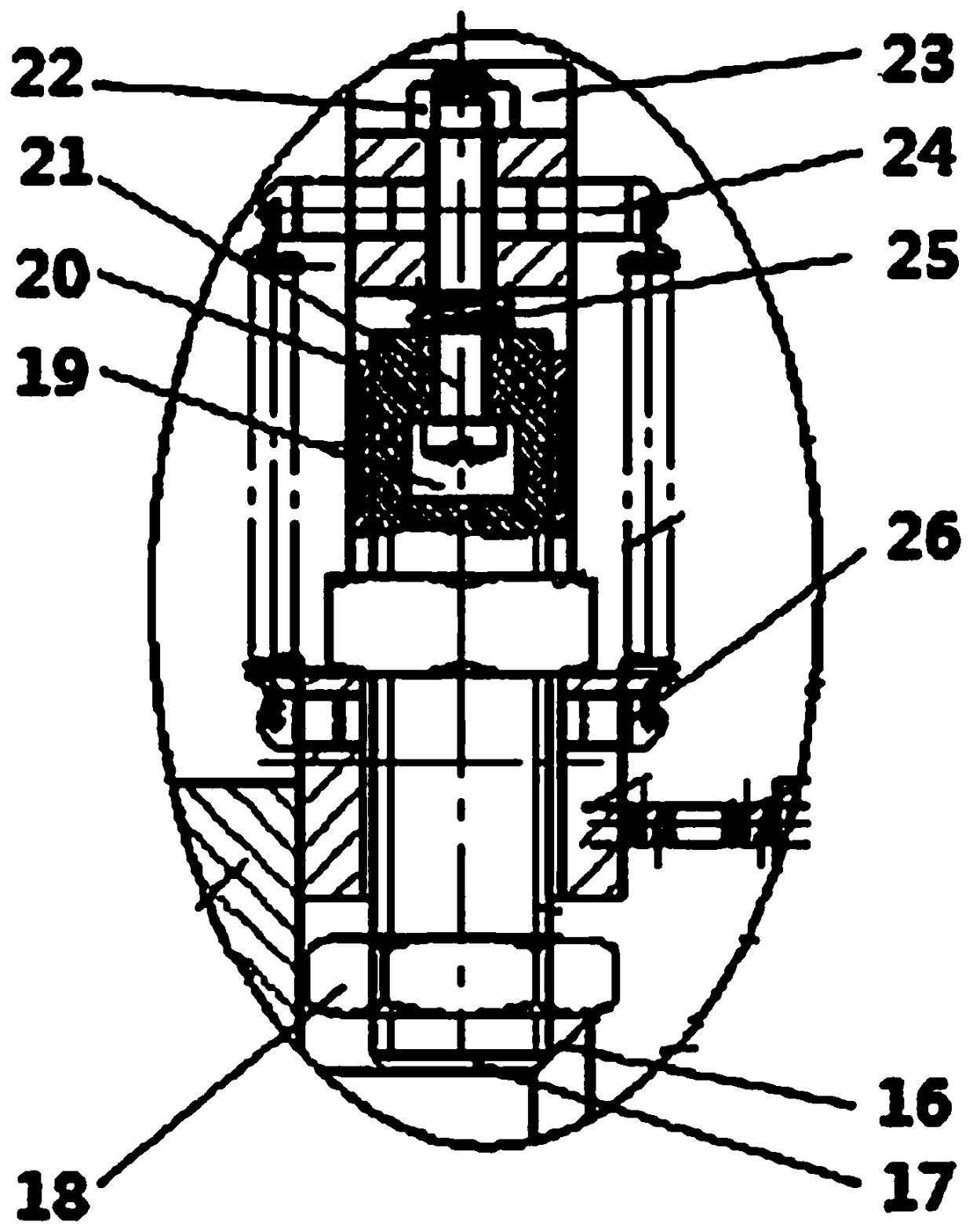

[0018] figure 1 Flexible fixtures for general thin-walled parts are mainly composed of right pressure plate, axial spring, support ring, ejector rod, spring, support fan, screw, nut, spacer ring, top ring, left pressure plate, adjusting washer, rotating nut, The support shaft and other components; the central hole of the right pressure plate is processed with internal threads; the upper end of the ejector rod is also processed with external threads to connect with the limit nut; the right end of the support shaft is processed with external threads The thread is fixedly connected with the right pressure plate through threads; the left pressure plate is sleeved at the left end of the support shaft; the left end of the support shaft is also processed with external threads and is connected with a nut through the external threads; the adjustment washer It is installed between the nut and the left pressure plate; two sets of radial support mechanisms are arranged in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com