Processing method of large-scale suspension bridge vice saddle

A suspension bridge loosening and processing method technology, which is applied in the field of suspension bridges, can solve the problems of increasing the manufacturing cost of loose cable saddles, the limited geometric size and bearing capacity of the machine tool rotary table, and increasing the cost of bridges, etc., and achieves outstanding economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

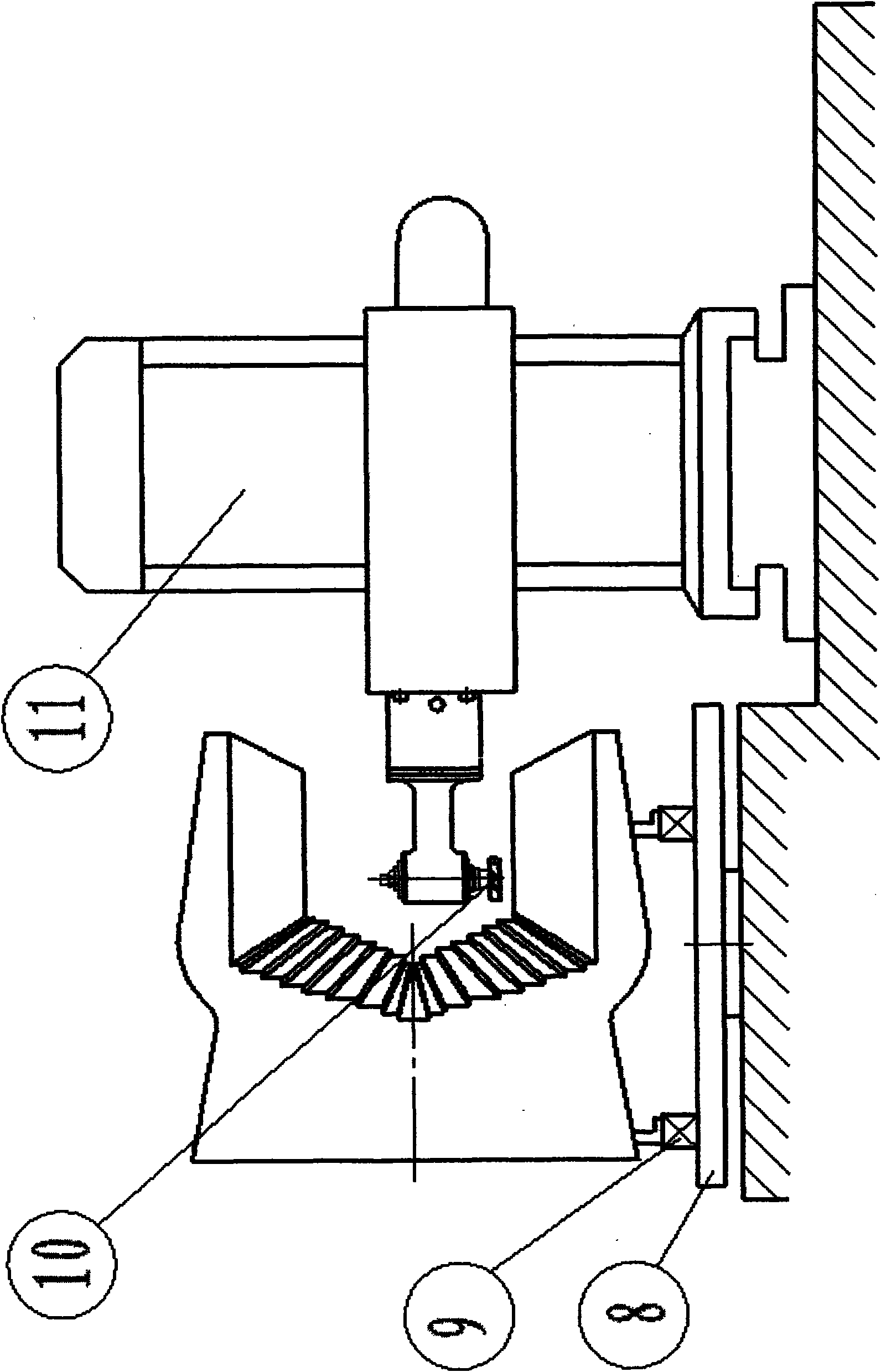

[0043] In order to facilitate understanding of the present invention, the structure of the cable saddle and its processing surface are introduced at first.

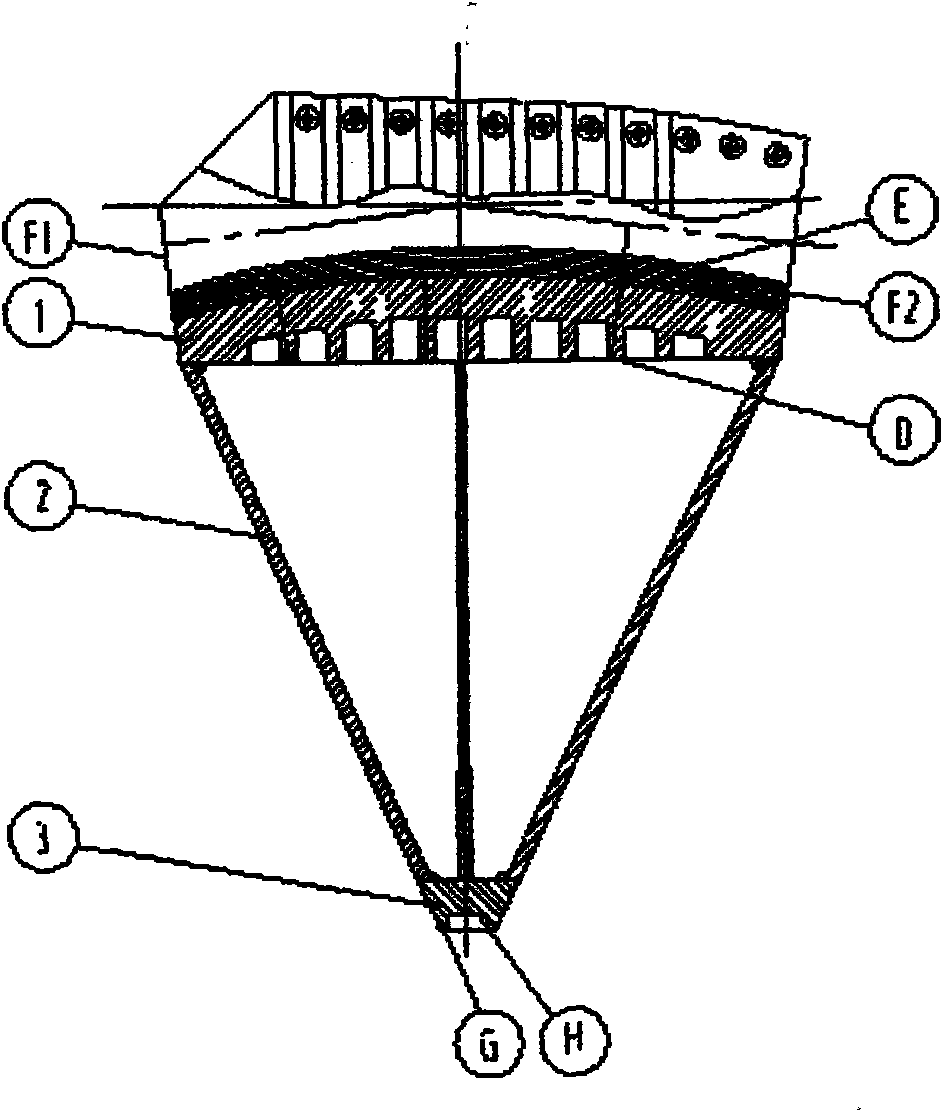

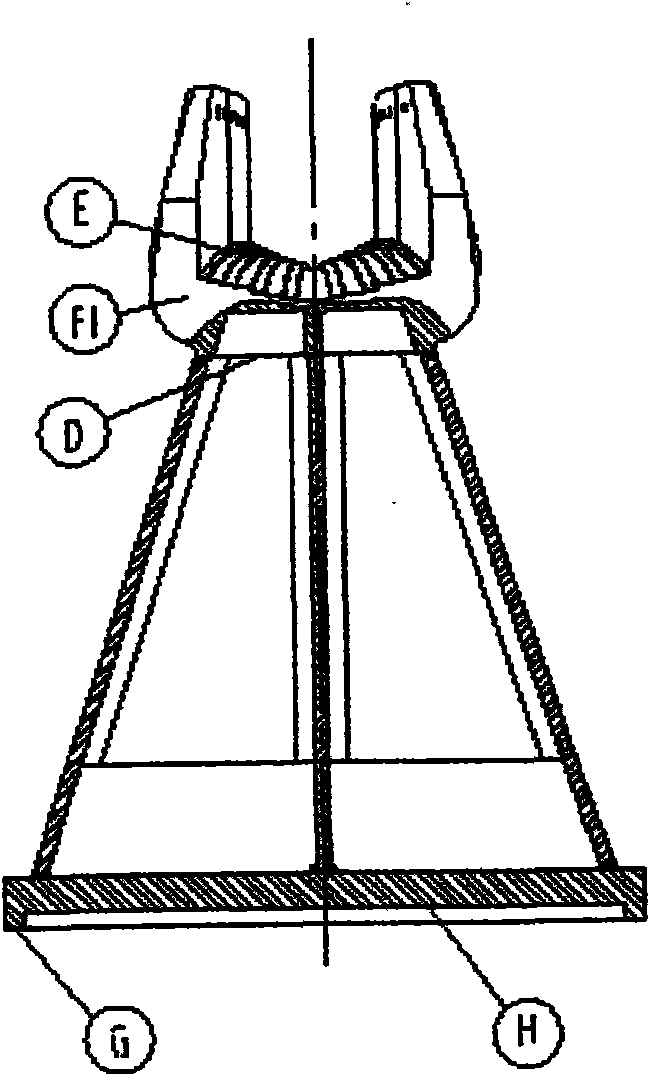

[0044] see figure 1 , figure 2 The scatter saddle is formed by combined welding of the saddle head 1 and the saddle body, and the saddle body is formed by the combined welding of the bottom block 3 and the rib plate 2.

[0045] The processing surface of the saddle head 1 has a bottom plane D, a saddle groove surface E, and two end surfaces F 1 and F 2 . The processing surface of the saddle bottom block 3 has a bottom surface G and a keyway H.

[0046] For suspension bridges with long spans (greater than 1000 meters), the geometric dimensions and weight of the loose cable saddles are large, with a height of more than 3 meters and a weight of more than 100 tons. For the overall processing of cable saddles, if large-scale machine tools are purchased and corresponding workshops are built, the investment in fixed assets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com