Method for improving sheet annular titanium alloy gear part machining precision

A technology for processing parts and titanium alloys, which is applied in the field of improving the processing accuracy of thin-sheet annular titanium alloy gear parts, and can solve the problems of small main cutting force, large back cutting force, and poor cutting performance of titanium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The object of the present invention is achieved like this, a kind of method that is used to improve the processing precision of sheet annular titanium alloy gear part, it comprises the steps:

[0027] 1) For the rough turning blank, press the parts with the pressure plate along the axis direction to rough the parts; during the processing, it is forbidden to use radial pressing methods such as three claws to prevent "three-point" deformation.

[0028] 2) Recrystallization annealing. In step 1, the machining allowance of the parts is large, a large cutting stress will be generated inside, and the material structure is also in an unstable state. Therefore, recrystallization annealing is arranged in the process plan. The heating temperature is 740-760°C, and the heat preservation 1.9 to 2.1 hours, after cooling to 150°C with the furnace, air cooling to room temperature, this process will recrystallize the deformed grains and restore the equilibrium state, the metallographic ...

Embodiment 2

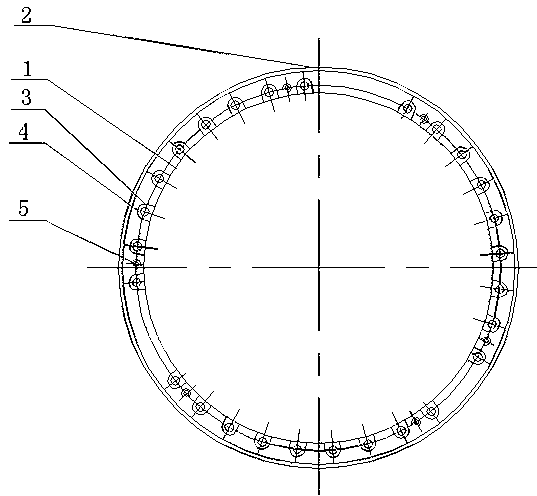

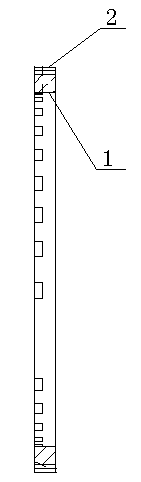

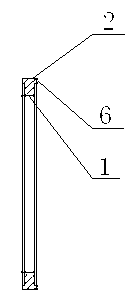

[0041] Taking the machining of grade 6 precision gear parts as an example, the material is titanium alloy TC4, the modulus is M1, and the number of teeth is 330. The part structure is as follows: figure 1 and figure 2 As shown, the diameter of the inner hole 1 is φ312H6mm, the diameter of the addendum circle 2 is φ332h8mm, the coaxiality of the addendum circle 2 relative to the inner hole 1 is required to be φ0.014mm; the thickness of the gear is 6mm, and the verticality of the two ends of the inner hole 1 It is 0.014mm, and 27 gear grooves 3 with a radius of 3mm and a depth of 3.5mm and 27 first gear holes 4 with a diameter of 3.4mm are distributed on the circumference of φ318mm, and there are 6 second gear holes 5 with a diameter of 2mm. image 3 Shown, the gear addendum garden 2 outer rings have annular process boss 6.

[0042] From the structural analysis of the part, the difference between the inner and outer radius of the ring is only 10mm, the thickness is 6mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com