Production method of low-carbon free-cutting steel

A technology of free-cutting steel and production methods, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve problems such as roll wrapping and slipping, difficult operation, head cracking, etc., to avoid pulling cracks, mechanics The effect of uniform performance and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

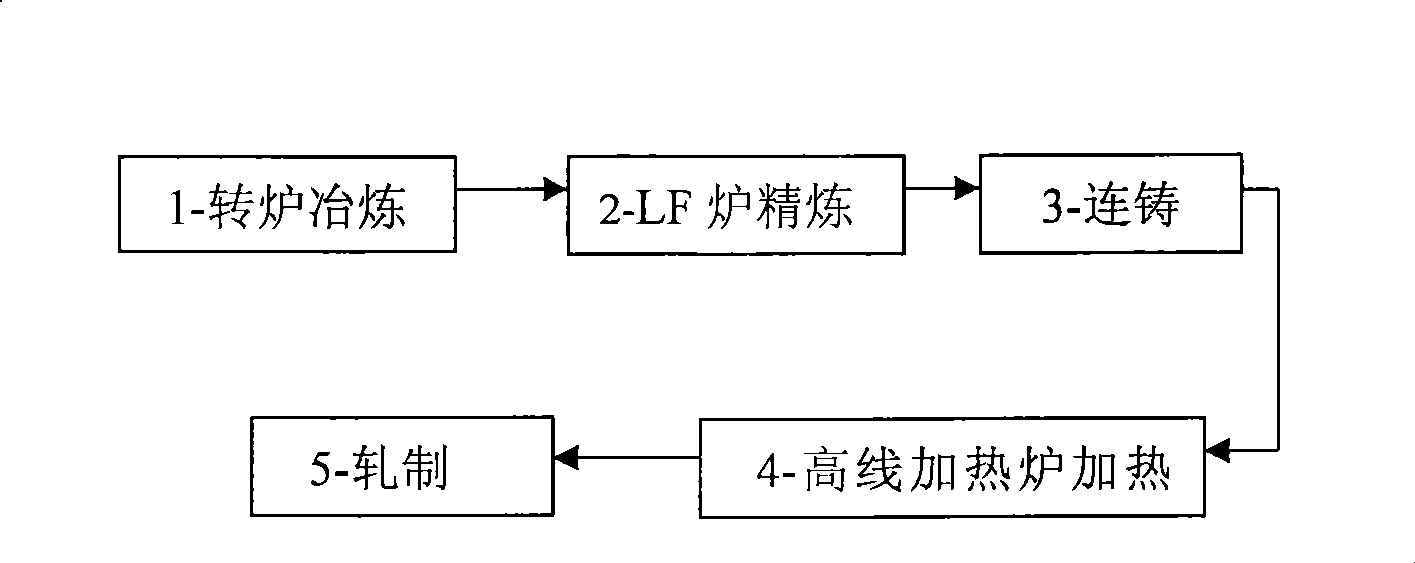

Method used

Image

Examples

Embodiment Construction

[0015] Examples of the present invention are shown in Table 1, Table 2 and Table 3. Table 1 is the low-carbon free-cutting steel production process and its detection performance of the φ8.0mm specification produced by the process of the present invention, including 3 examples; Table 2 is the lead-free environmental protection type of the φ17.0mm specification produced by the process of the present invention Low-carbon free-cutting steel wire rod and its detection performance, including 3 embodiments; Table 3 is the lead-free environment-friendly low-carbon free-cutting steel wire rod and its detection performance of the φ32.0mm specification produced by the process of the present invention, including 3 an example.

[0016] Table 1 Production process and testing performance of φ8.0mm free-cutting steel wire rod

[0017] Preface

No

one plus

temperature

℃ two plus

temperature

℃ Soaking

Duan Wen

degree ℃ open rolling

tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com