Patents

Literature

57results about How to "Reduce clamping deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

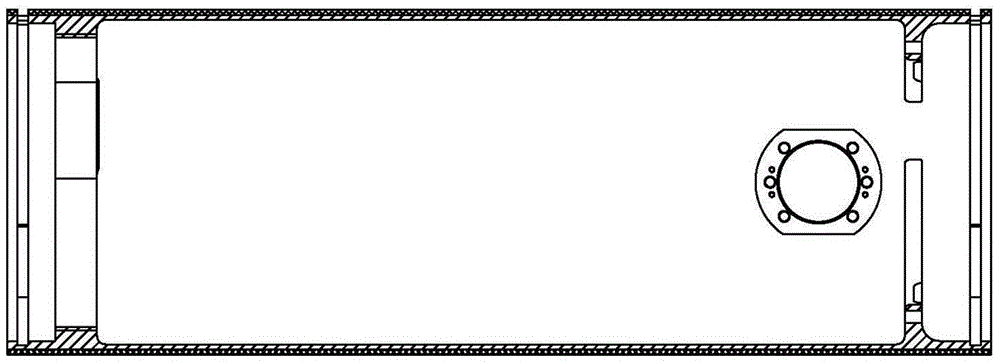

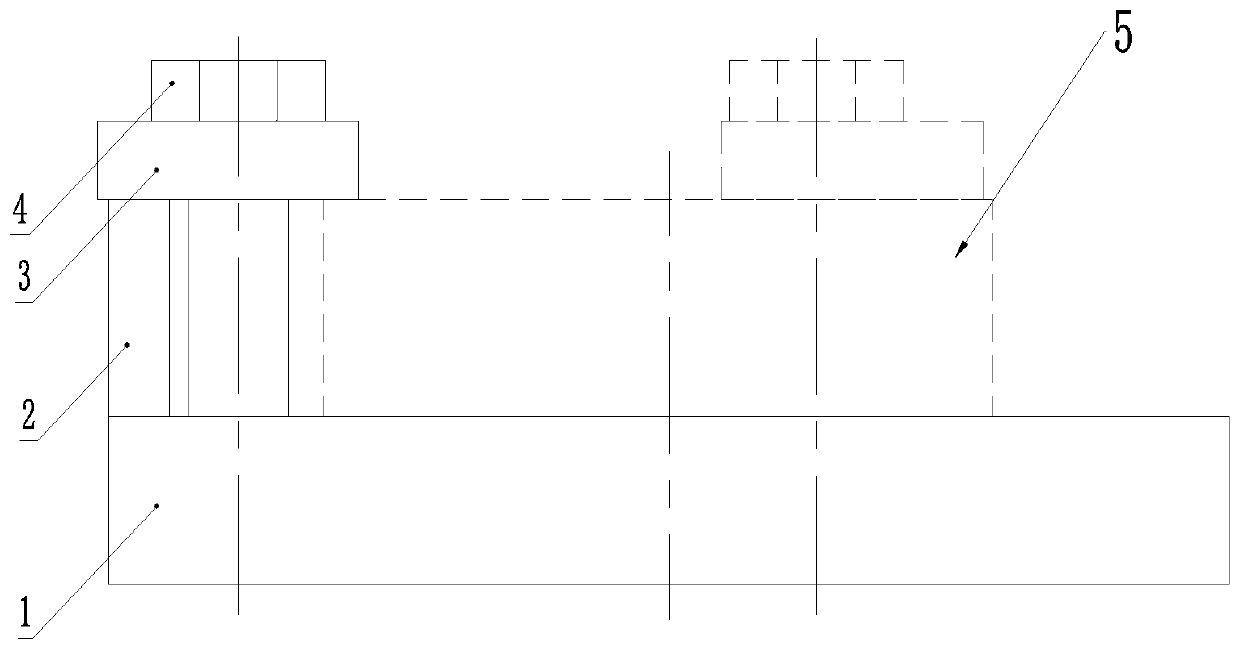

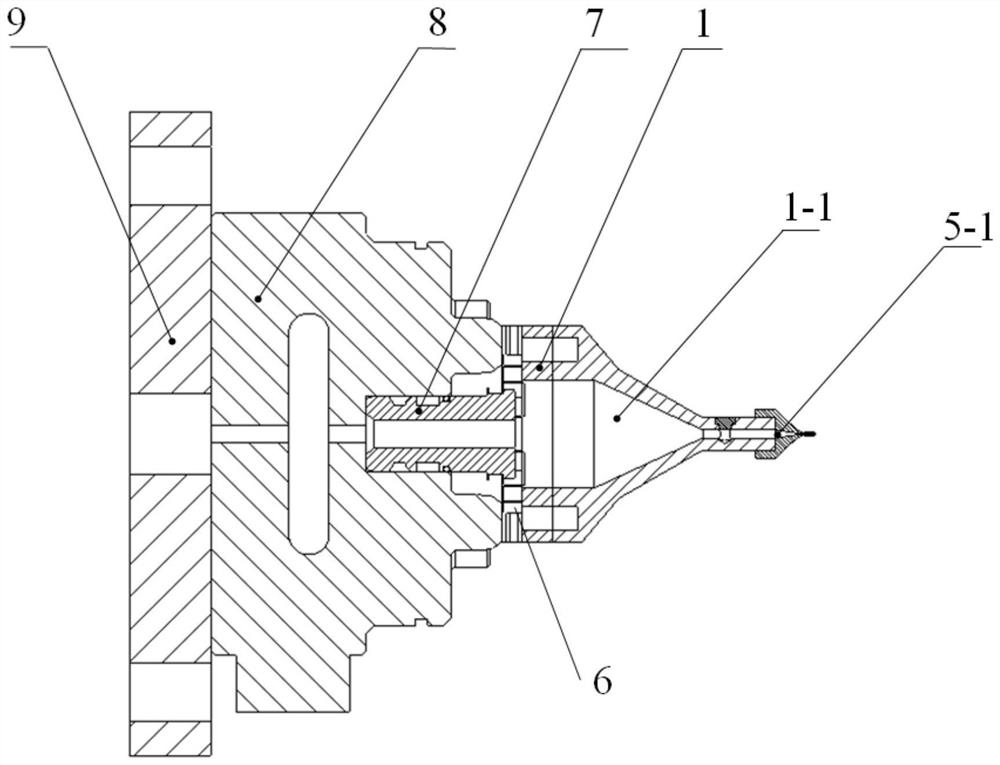

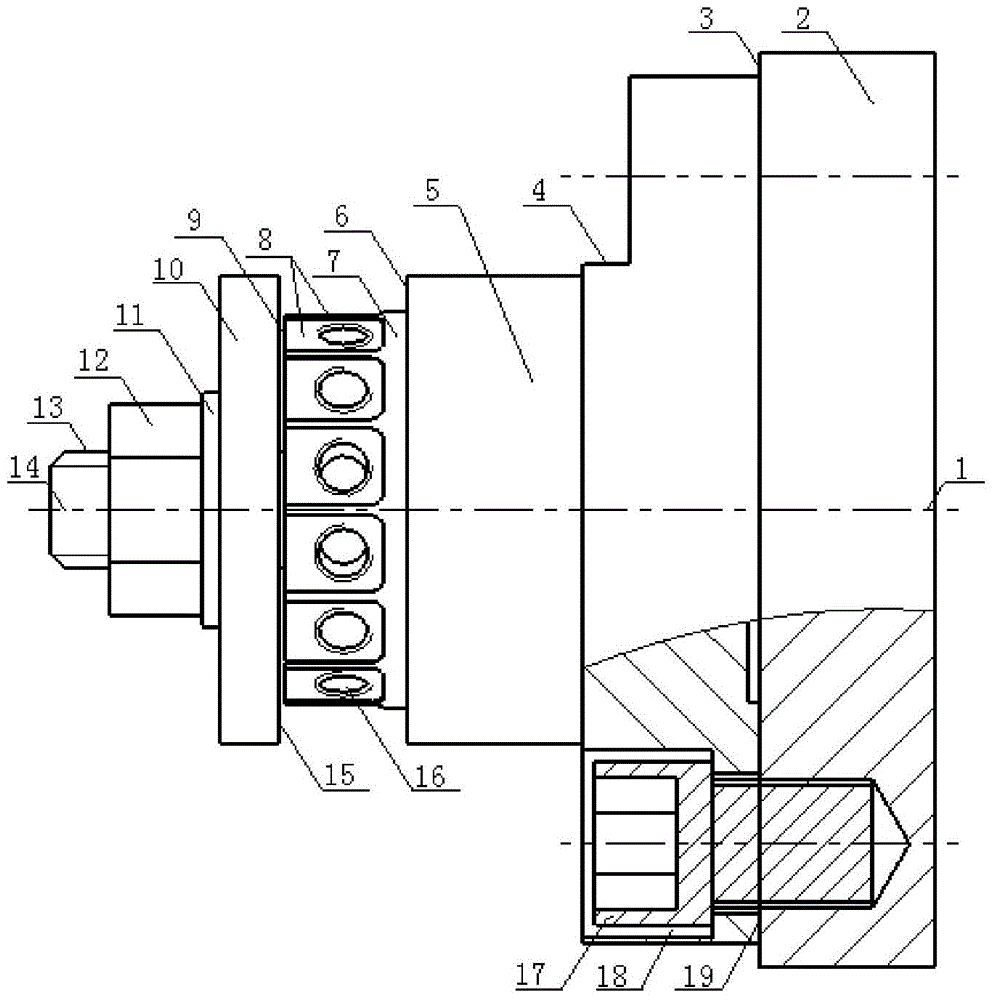

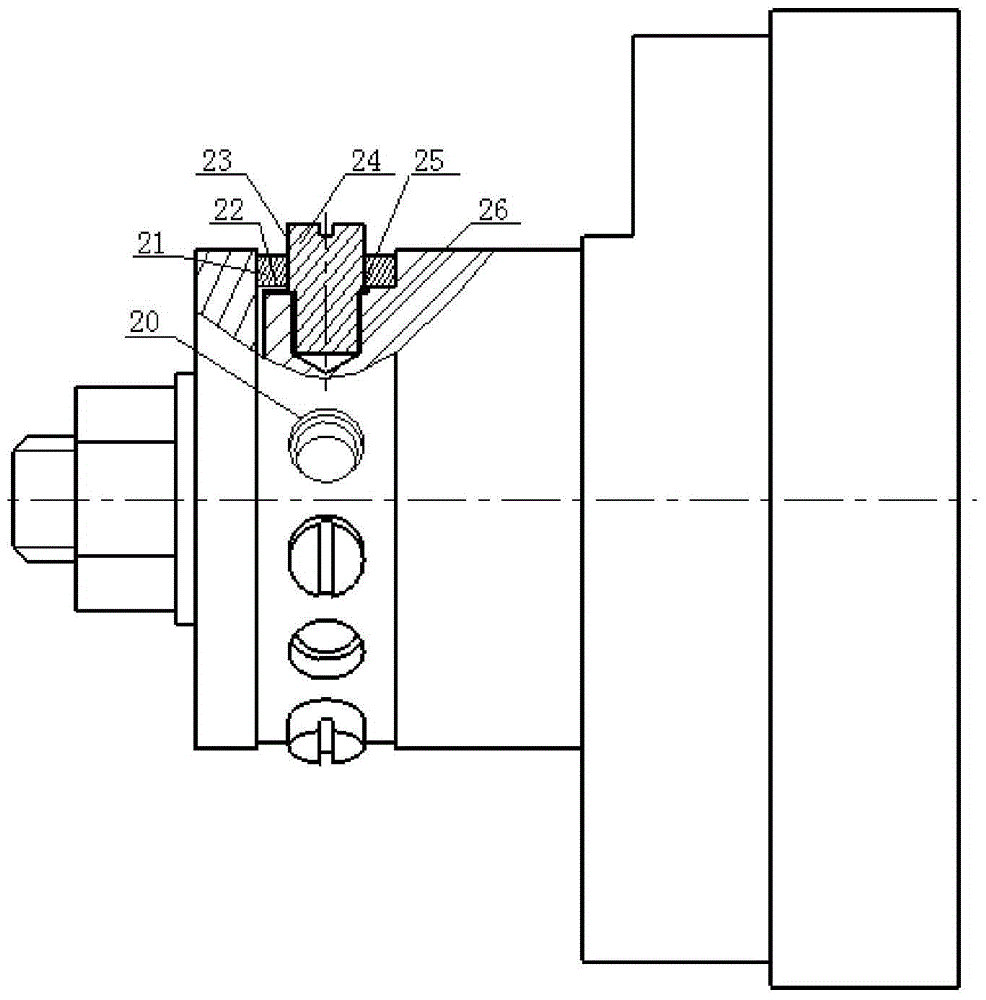

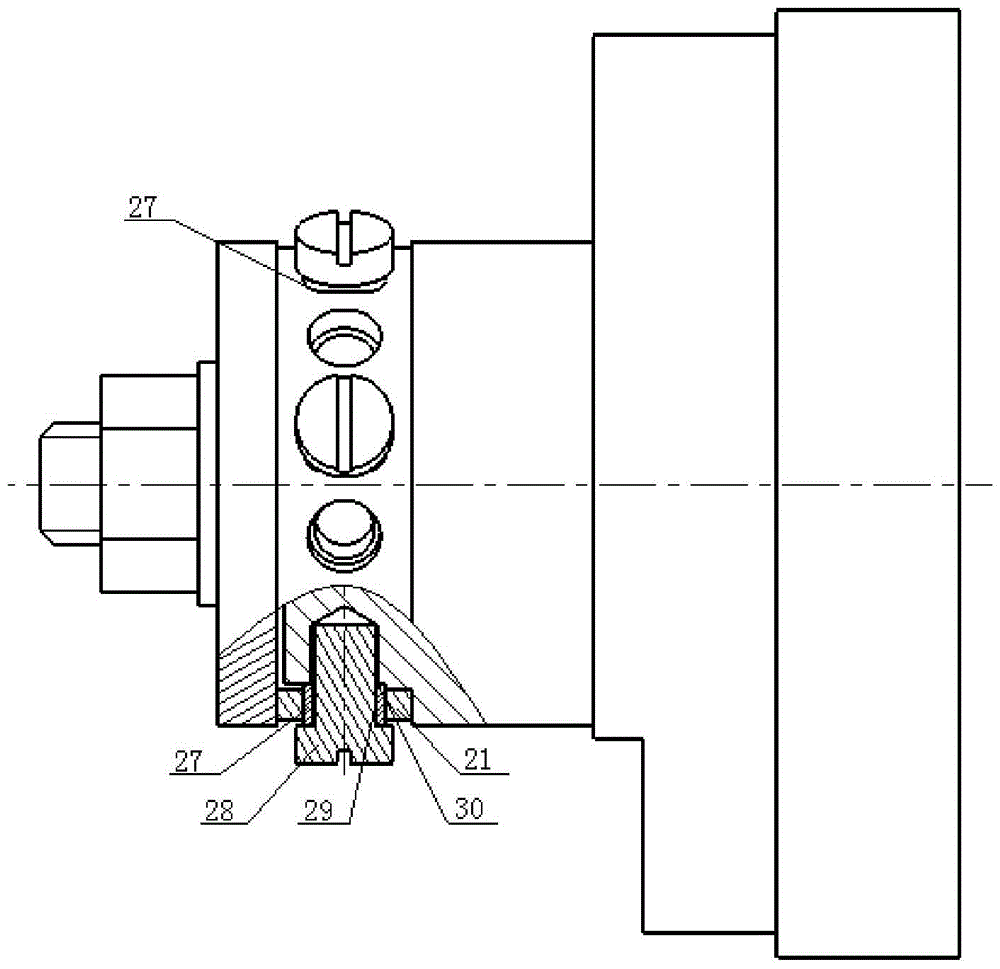

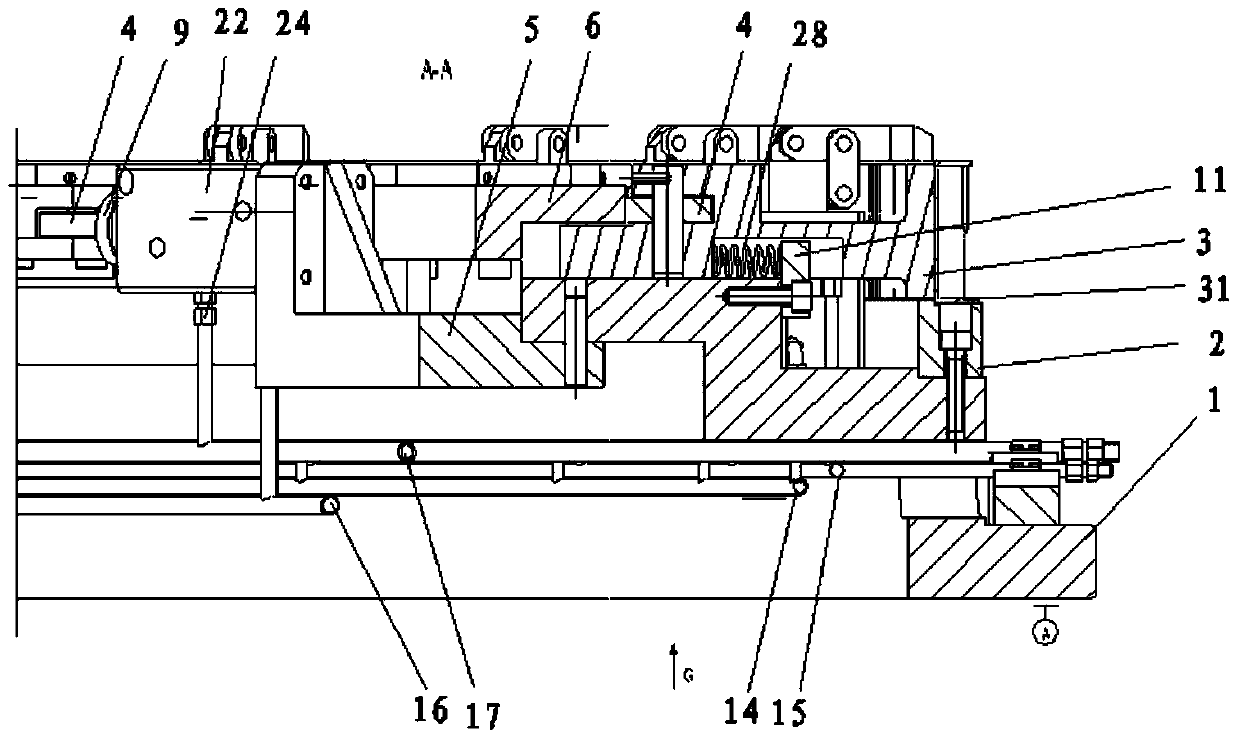

Indexing jig device for radial hole in cylindrical face

InactiveCN103465060AReduce labor intensityReduce lossPrecision positioning equipmentPositioning apparatusProduction rateUltimate tensile strength

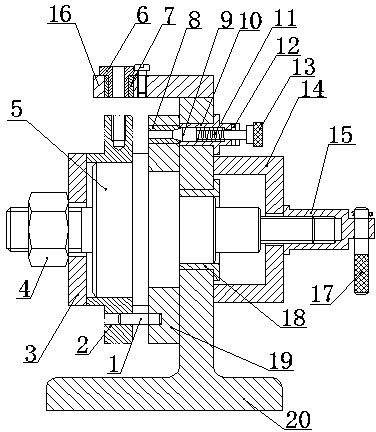

The invention relates to the technical field of circular hole machining and particularly relates to an indexing jig device for a radial hole in a cylindrical face. The indexing jig device comprises a jig body and a workpiece, wherein a locking bracket and a mandrel bushing are arranged in the jig body, a locating mandrel is arranged in the mandrel bushing and is provided with an opening pressing plate and a rotary indexing disc, and the jig body is provided with a jig bush rack. The indexing jig device has the advantages that the labor production rate is increased greatly, the labor intensity of operating workers is lowered, the wear and tear of a drill bit is reduced, the service life of a cutter is prolonged, and the clamping deformation of the workpiece is little, and the effect is very good.

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

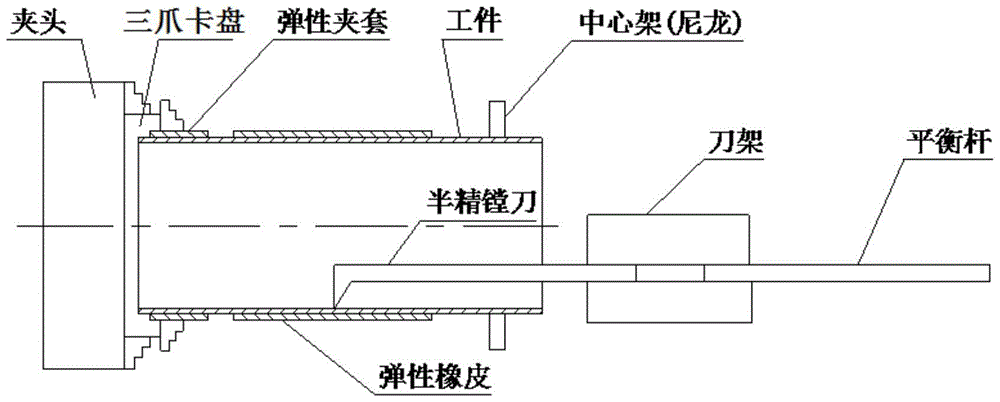

Method for machining thin-wall sleeve type part through wedge type inner supporting mechanism

InactiveCN105328409AImprove pass rateGuaranteed Wall Thickness DimensionsAircraft componentsExpansion mandrelsEngineeringMachining

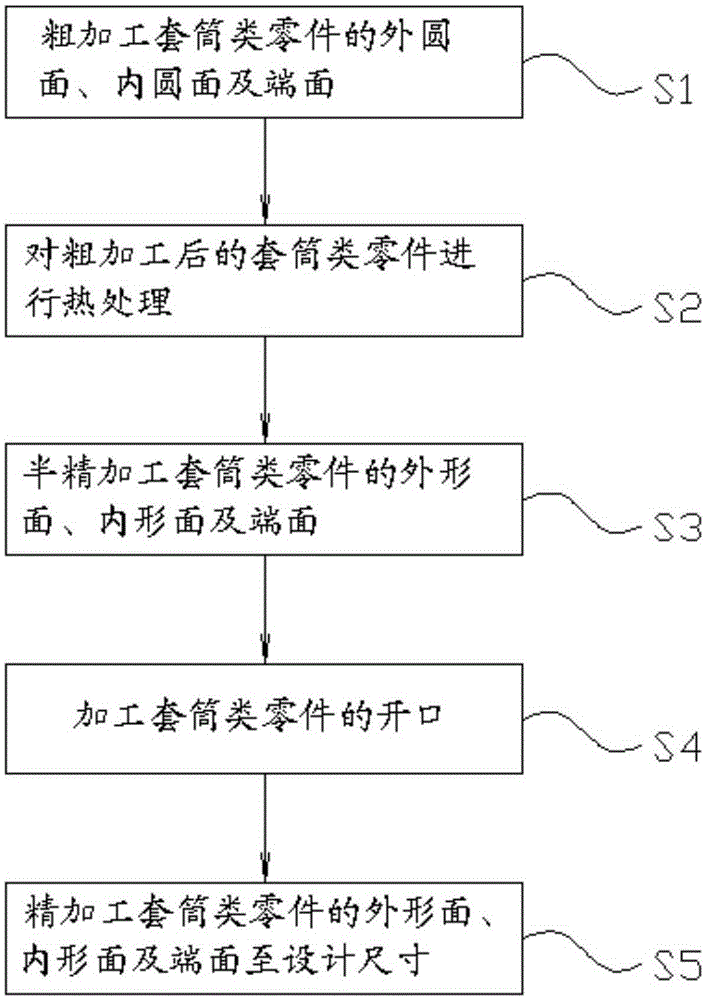

The invention relates to a method for machining a thin-wall sleeve type part through a wedge type inner supporting mechanism. The method includes the following steps that rough machining is conducted on the outer circle face, the inner circle face and the end face of the sleeve type part; heat treatment is conducted on the sleeve type part obtained after rough machining, and the roundness deformation of the sleeve type part is controlled to be within 2 mm; semi-finishing is conducted on the outer shape face, the inner shape face and the end face of the sleeve type part; an opening of the sleeve type part is machined; and finish machining is conducted on the outer shape face, the inner shape face and the end face of the sleeve type part to reach the design sizes. According to the method, the phenomena of chattering, cutter relieving, the uneven wall thickness, deformation and the like when the outer circle of the part is turned can be avoided, and the qualification rate of the part can be improved to 97% or above from 70%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

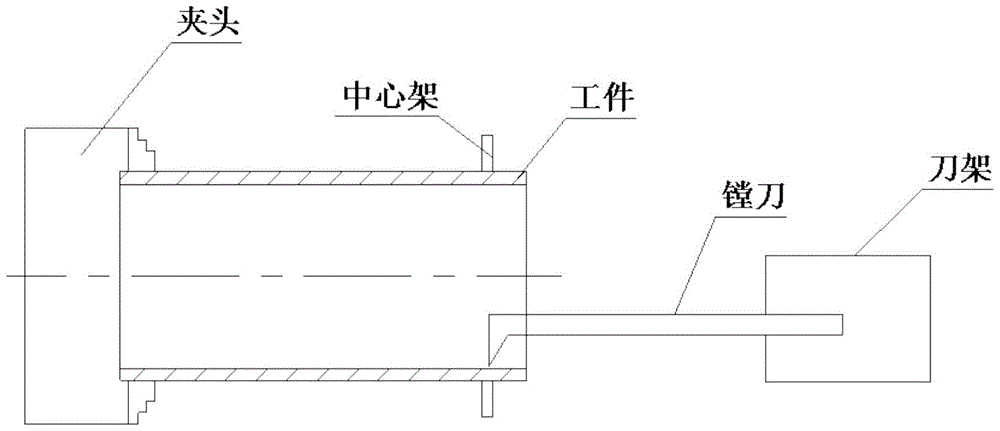

Turning method of long thin wall composite shell body formed by metal and glass fiber reinforced plastics

ActiveCN104588682AExtend your lifeImprove processing efficiencyAircraft componentsAmmunitionGlass fiberCold air

The invention discloses a turning method of a long thin wall composite shell body formed by metal and glass fiber reinforced plastics. The method comprises the steps that (1) glass fiber reinforced plastics outer circle rough turning is carried out; (2) the two end faces of the shell body are subjected to rough turning; (3) glass fiber reinforced plastics outer circle fine turning is carried out; and (4) the two end faces of the shell body, an inner hole and an annular groove are subjected to fine turning. Rough-fine machining processes are used, technology allowance is distributed reasonably, deforming amount is controlled, metal shell inner hole accuracy is controlled and is used as the machining standard of a structure piece after recombination, an end cap and a soft claw are used for clamping, clamping deforming is lowered, through a low-temperature cold air cooling mode, a cutting environment is improved, a tool and cutting parameters during cutting machining are stipulated, product tool service life is prolonged, and machining efficiency is improved. The technology method is reasonable and reliable, product deforming is small, and the machining quality of the composite shell body can be effectively guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

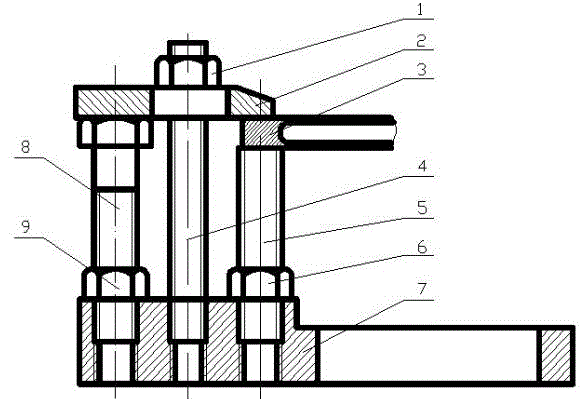

Fixture for machining annular parts and method for machining parts through fixture

InactiveCN104972333AImprove machining accuracyAvoid machining errorsWork clamping meansPositioning apparatusMachine partsEngineering

The invention provides a fixture for machining annular parts and a method for machining the parts through the fixture. The fixture comprises a supporting base provided with a boss on the top. The boss is provided with three supporting columns, and the lengths of the three supporting columns are sequentially reduced. A pressing plate is installed on the top of the supporting column II. The pressing plate is pressed on the top of the supporting column II through a pressing block installed on the supporting column I. The bottom of one end of the pressing plate and the top of the supporting column III are matched to clamp the parts to be machined. The position of the pressing plate is adjusted through cooperation of the three supporting columns, and the pressing plate and the supporting column III are matched to press the parts to be machined, so multiple fixtures can be matched to clamp some annular parts inconvenient to fix, the fixture can be adjusted to adapt to parts in different sizes, machining errors caused by elastic deformation generated due to clamping and radial fixing when the annular parts are fixed are avoided, and machining precision of the annular parts is improved.

Owner:LUOYANG BEARING SCI & TECH CO LTD

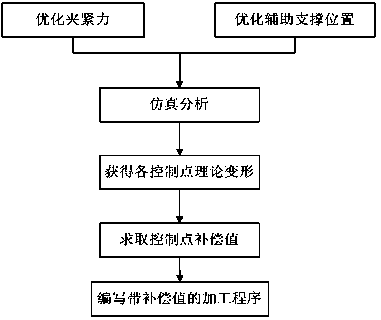

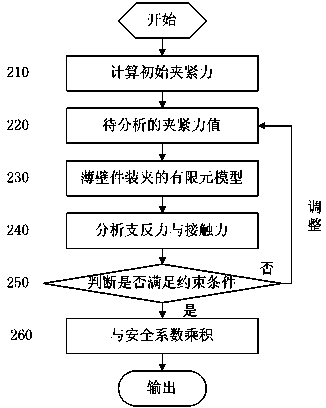

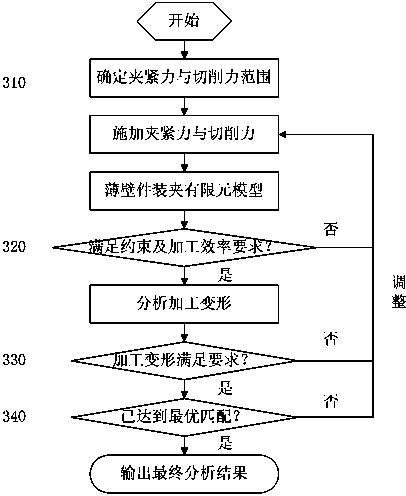

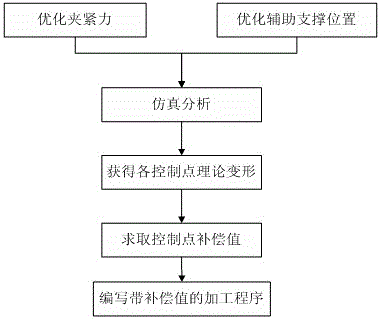

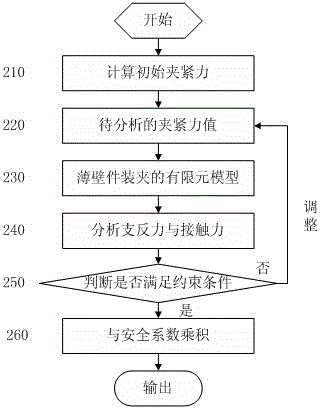

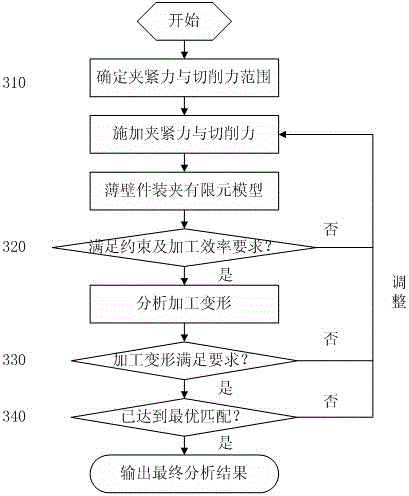

Active machining method for clamping deformation of thin-walled special-shaped workpieces

ActiveCN104111625AStable clamping deformationReduce clamping deformationProgramme controlComputer controlNumerical controlSupport point

The invention discloses an active machining method for clamping deformation of thin-walled special-shaped workpieces. Firstly, clamp force of a thin-walled machined workpiece undergoes optimal settings; secondly, force point range of the workpiece is found out; thirdly, ancillary shoring of the workpiece is carried out; and finally, compensation data is introduced into a numerical control program. In comparison with the prior art, the active machining method for clamping deformation of thin-walled special-shaped workpieces can be used to analyze a thin-walled workpiece before numerical control machining, determine magnitude of the clamp force and find clamp pint and supporting point of the workpiece. By increasing or decreasing cutter compensation, clamping of workpieces is stabilized, cutting deformation of workpieces is minimized, and precision is further raised.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Machining method for thin-wall circular ring part

InactiveCN111015112AInternal stress relief annealingImprove cutting performanceThin walledThermal deformation

The invention provides a machining method for a thin-wall circular ring part. According to the method, a procedure of eliminating internal stress annealing is added in the machining process, the cutting machining performance is improved, and stress deformation in the machining process is eliminated; and meanwhile, end face pressing is adopted when a workpiece is clamped, and clamping deformation of the workpiece and vibration in the machining process are avoided. According to the machining method, a 90-degree tool cutting edge angle tool is used for machining, generation of cutting heat and vibration in the cutting process are reduced, and therefore thermal deformation is reduced, the surface roughness and the size precision of the workpiece are improved, machining deformation of the partis well controlled, and the machining quality and the machining efficiency of products are guaranteed.

Owner:贵州凯星液力传动机械有限公司

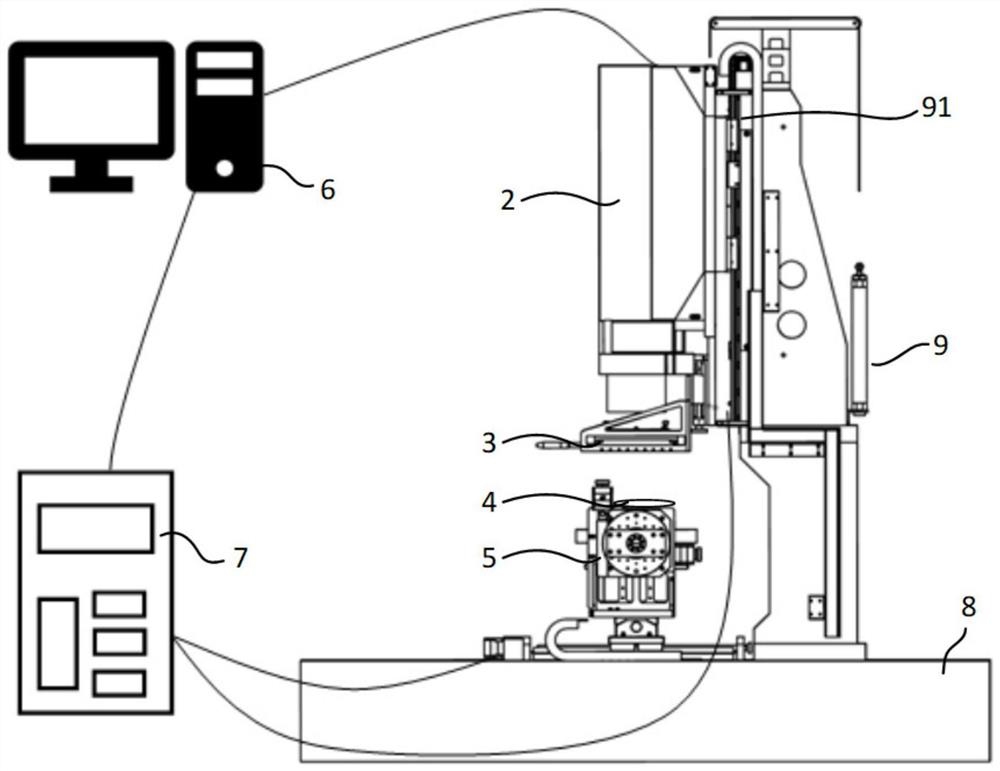

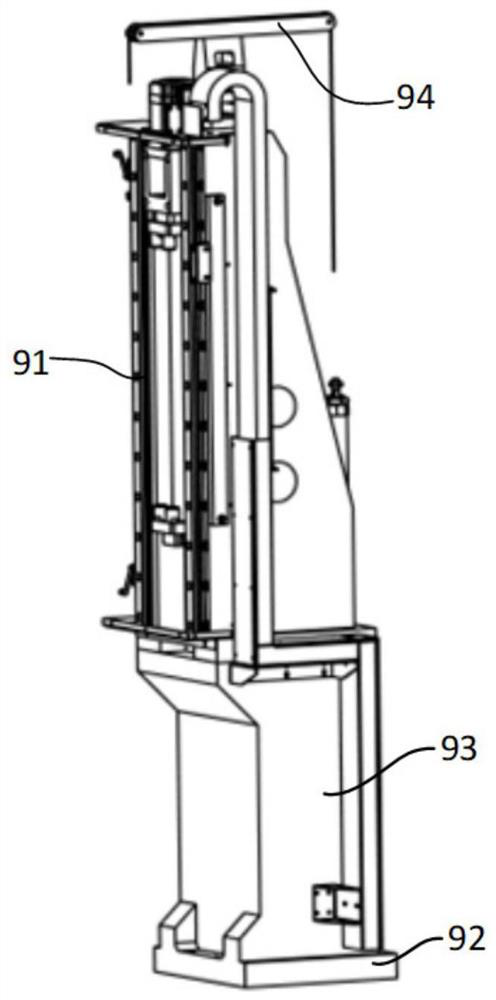

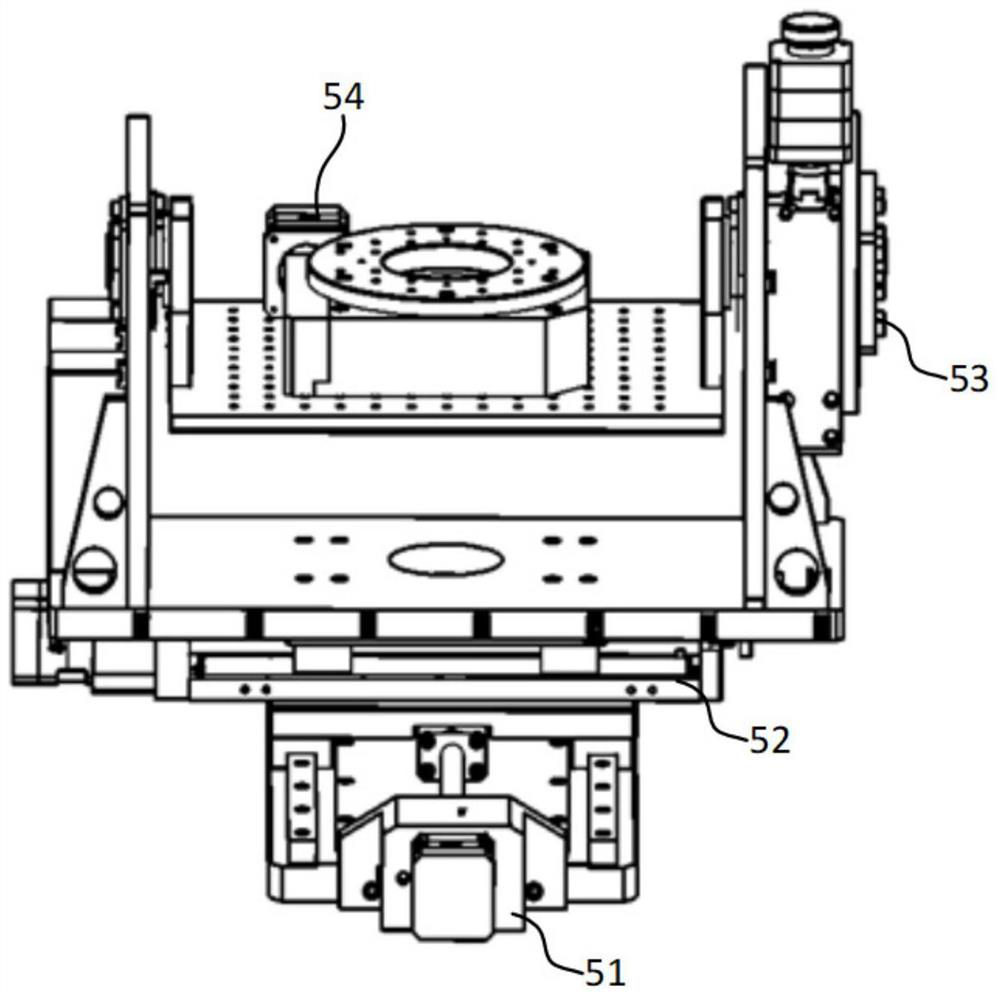

Multifunctional vertical zero overlapping scanning interferometry device

ActiveCN112504177ASave time and costSave economic costUsing optical meansAutomatic controlEngineering

The invention discloses a multifunctional vertical zero overlapping scanning interferometry device which comprises a main control unit, a drive control circuit and an air floatation vibration isolation base. A stand column and a four-dimensional motion adjusting platform are arranged on the air floatation vibration isolation base, a vertical lifting shaft is arranged on the stand column, and a laser wave surface interferometer is arranged on the vertical lifting shaft. A detachable CGH five-dimensional motion combination adjusting platform is arranged on a light output path of the laser wave surface interferometer, the CGH five-dimensional motion combination adjusting platform is located over the four-dimensional motion adjusting platform, and the control end of the CGH five-dimensional motion combination adjusting platform and the control end of the four-dimensional motion adjusting platform are connected with the main control unit through the drive control circuit. And the control end of the laser wave surface interferometer is connected with the main control unit. According to the invention, high-precision and high-efficiency measurement of a large-aperture plane, a spherical surface and a convex aspheric surface can be realized, zero measurement of the plane, the spherical surface and the aspheric surface can be flexibly carried out, and high-efficiency and high-precision detection of a large-aperture optical surface shape is realized in combination with automatic control.

Owner:NAT UNIV OF DEFENSE TECH

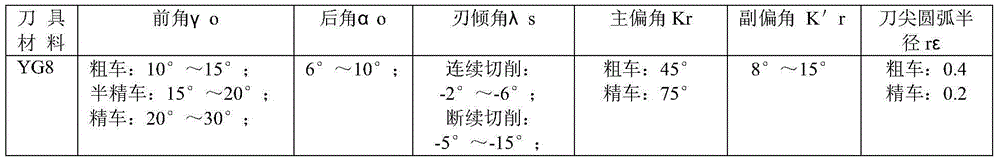

Titanium alloy casting turning and boring processing method

The invention discloses a titanium alloy casting turning and boring processing method. During turning and boring processing, firstly, cutter materials need to be selected, hard alloy cutters such as YG8, YG8W and YG-10H are used during the coarse turning, and hard alloy cutters such as YG8W and YP15 are used during fine processing; in order to well grind turning cutters and boring cutters, during the coarse processing, the cutting speed needs to be low, and the cutting depth needs to be shallow; during the fine processing, the cutting speed needs to be higher, and the cutting depth needs to be shallow, a proper cutting allowance needs to be left before the final fine processing, and the rigidity of a cutter rod is improved, so the qualified titanium alloy parts are manufactured. The method has the advantages that the temperature of cutting cutter edges is reduced, the cutter abrasion and the cutting edge tipping are reduced, the installing and clamping deformation is reduced, the surface quality of processed parts is improved, the dimension precision is ensured, the processing efficiency is effectively improved, and the production cost is reduced.

Owner:青岛齐力铸钢有限公司

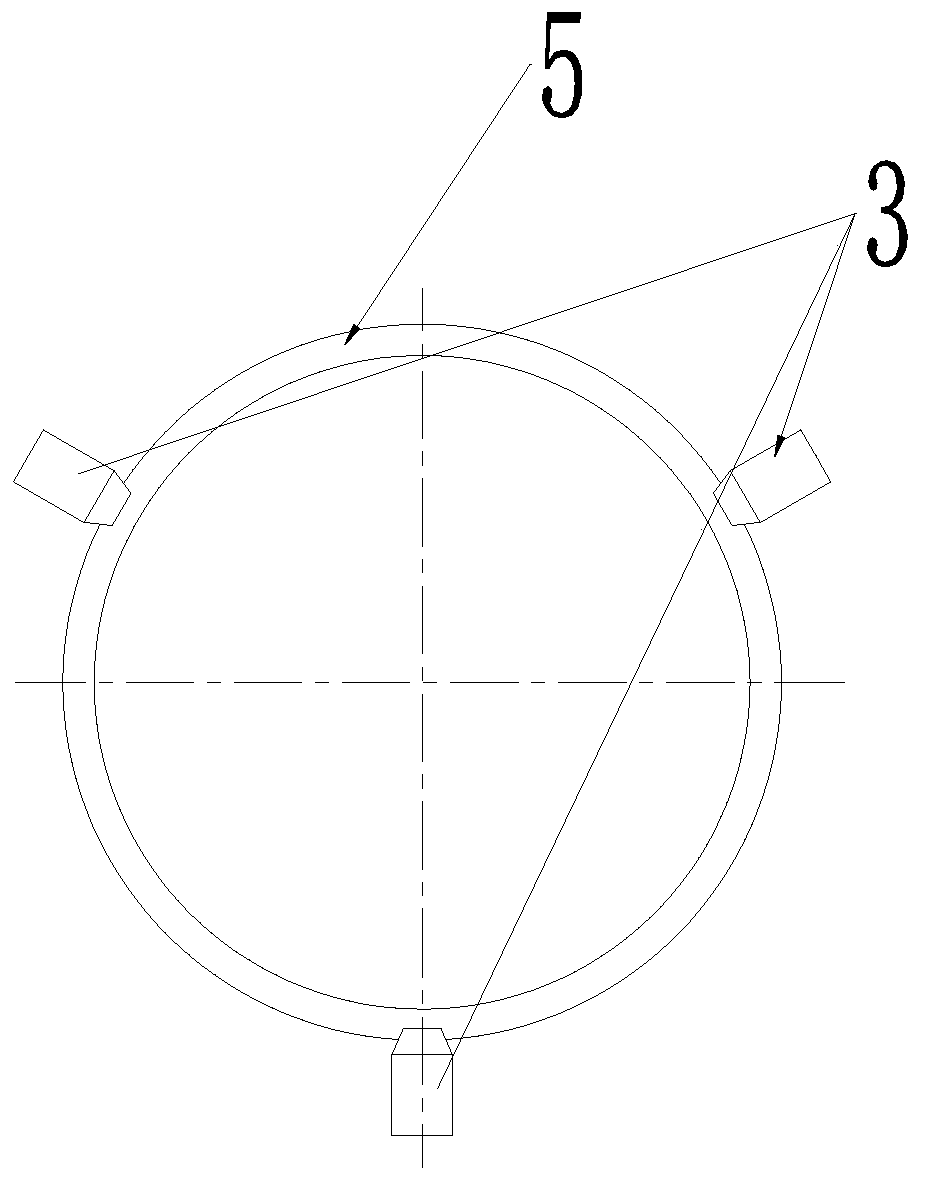

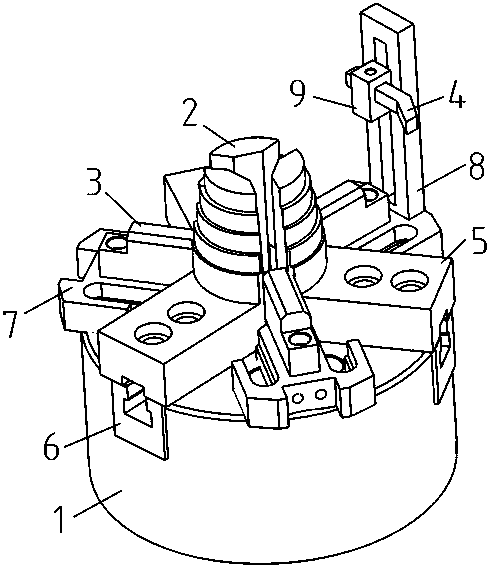

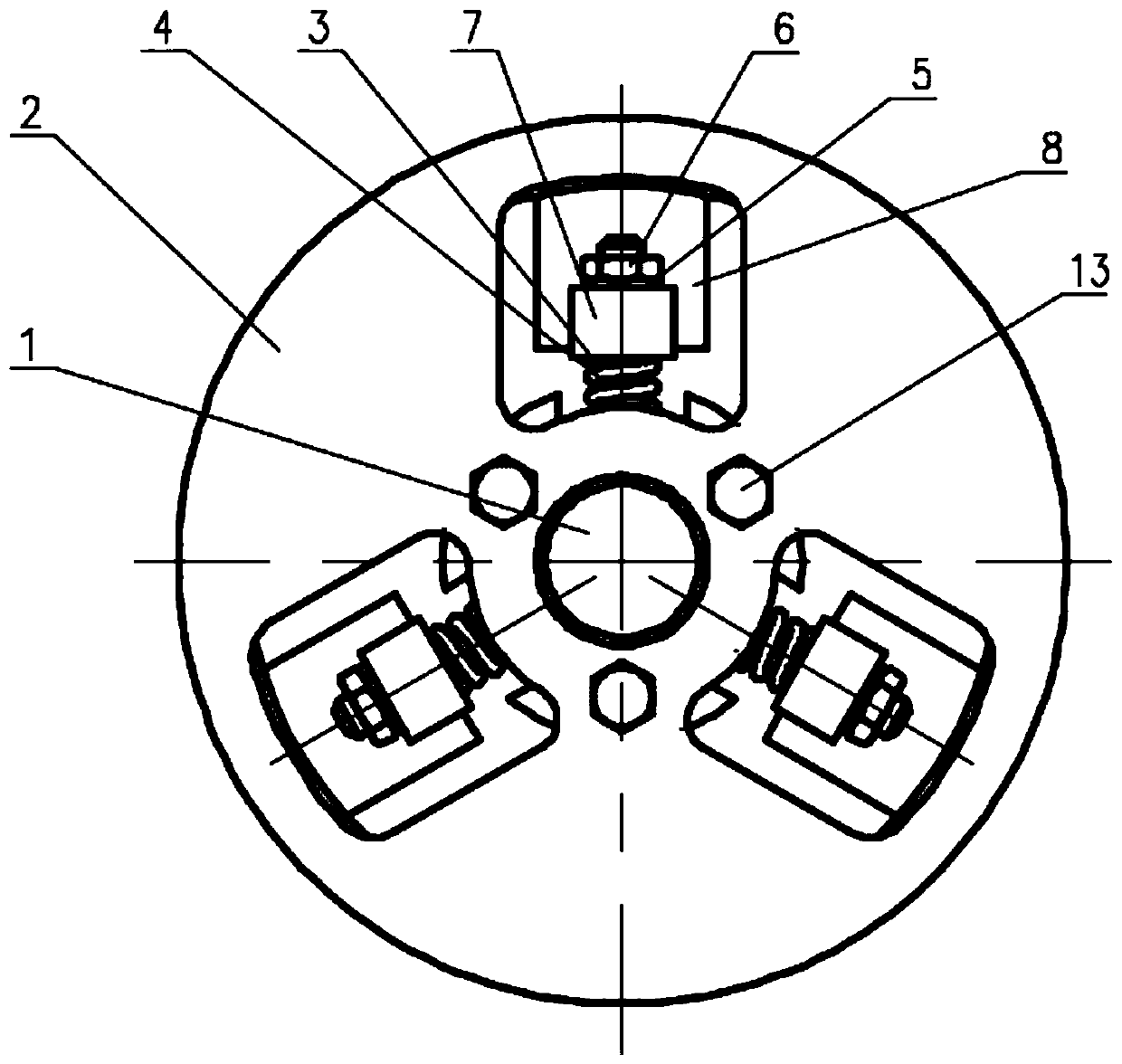

Positioning and clamping device for automobile hub outer flange processing

PendingCN108788204AReduce clamping deformationImprove machining accuracyChucksEngineeringProcessing accuracy

The invention discloses a positioning and clamping device for automobile hub outer flange processing and relates to the field of automobile hub processing. The positioning and clamping device comprises a chuck and three clamping pieces which are arranged on the top surface of the chuck in an annular shape around the axis of the chuck, and the three clamping pieces can synchronously stretch out anddraw back radially along the top surface of the chuck. The positioning and clamping device is characterized in that each clamping piece comprises a fan-shaped clamping jaw, the outer wall of each clamping jaw is provided with a plurality of steps which are arranged in the axis direction, the outer walls of different outer diameters of the clamping jaws are used for clamping the inner walls of automobile hub outer flanges in different sizes, the positioning and clamping device further comprises a positioning device arranged on the chuck, the positioning device comprises a plurality of bolstering blocks and angle positioning blocks, and the height of the bolstering blocks is adjustable so as to be flush with different step surfaces of the chuck. Clamping of the inner wall of an automobile hub outer flange can be realized, the processing accuracy can be improved, the clamping deformation of the automobile hub outer flange can be reduced, and the automobile hub outer flange of different model sizes can be conveniently processed.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

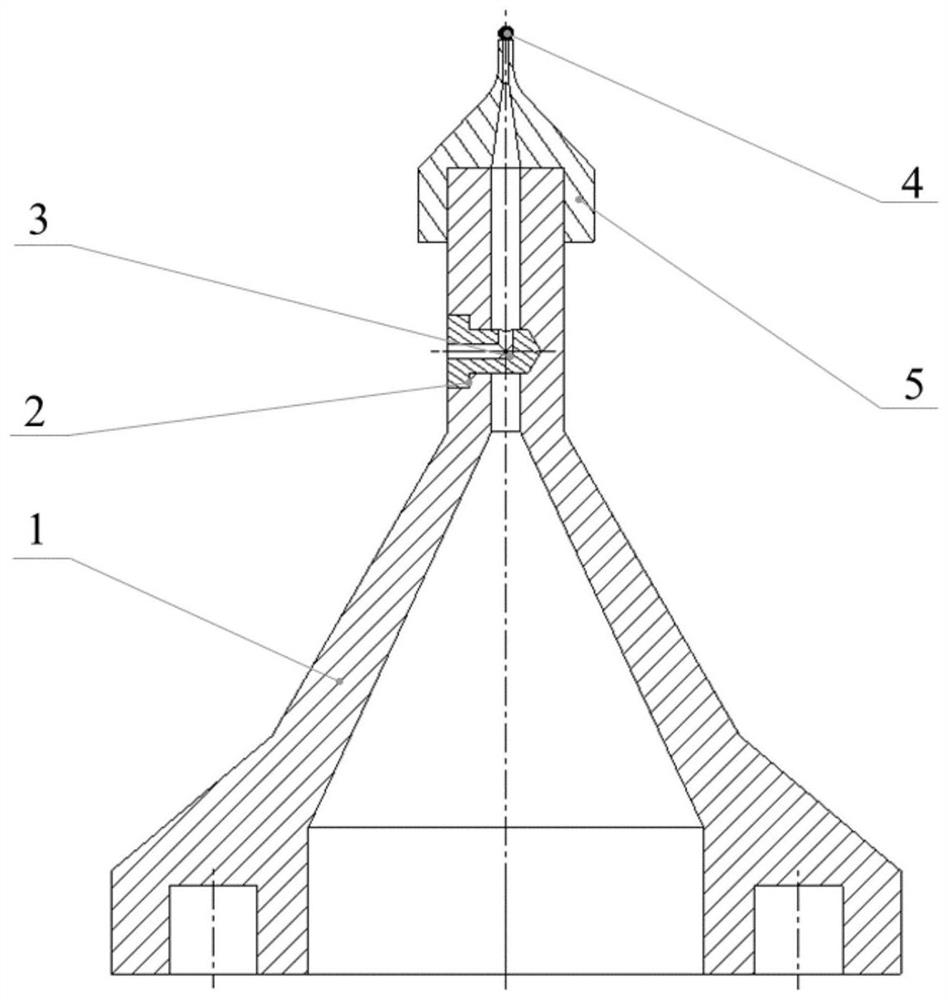

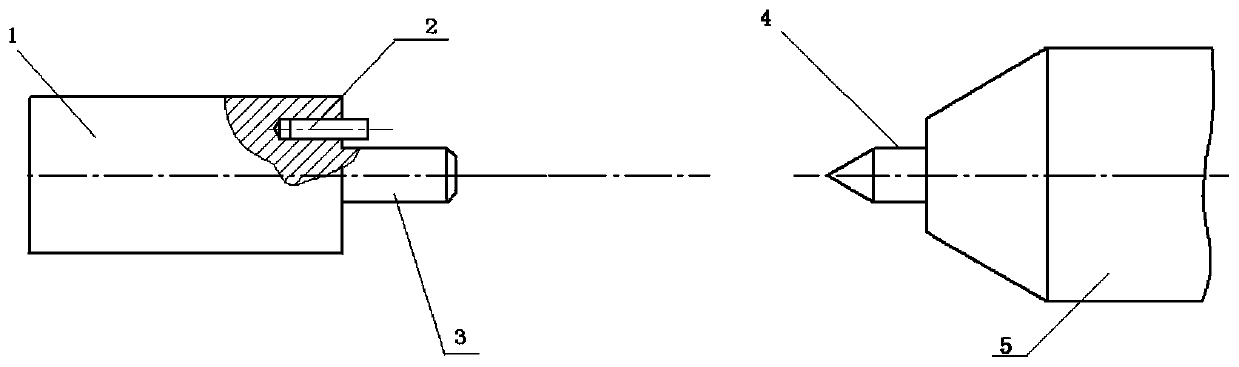

Tool used for turning seal ring V-type groove

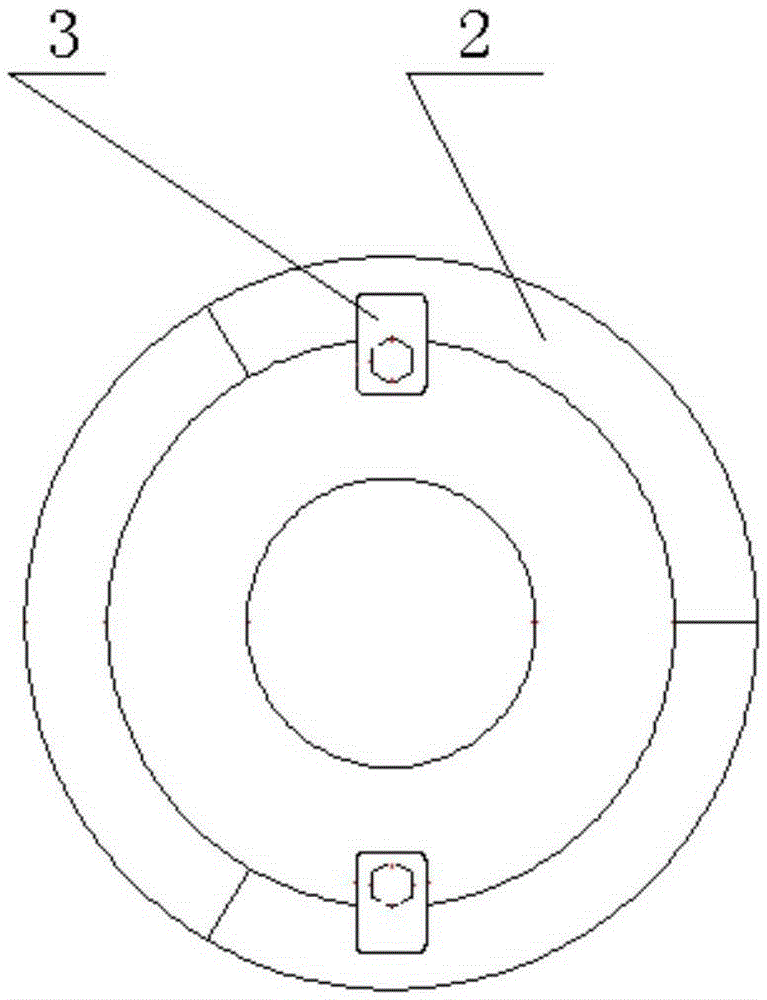

InactiveCN105196093ASimple structureLow costPositioning apparatusMetal-working holdersCircular coneEngineering

The invention discloses a tool used for turning a seal ring V-type groove. The tool mainly comprises a taper mandrel, a press plate, a locking nut and a locking screw; the left end of the taper mandrel is provided with a cylindrical face, the right end of the taper mandrel is provided with a conical surface outer circle, a center inner hole of a seal ring is provided with a conical face, a threaded hole is formed in the center of the taper mandrel, and the conical surface outer circle of the right end of the taper mandrel is sleeved with the center inner hole of the seal ring; an installing hole is formed in the center of the press plate, the press plate is installed on the taper mandrel through the locking screw, the left end face of the press plate is pressed on the right end face of the seal ring, the locking nut is installed on the locking screw, and the left end face of the locking nut is pressed on the right end face of the press plate.

Owner:ZHENJIANG SUODA COUPLING

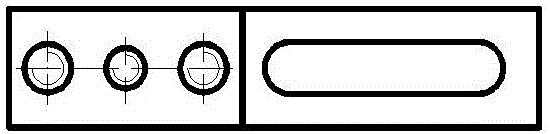

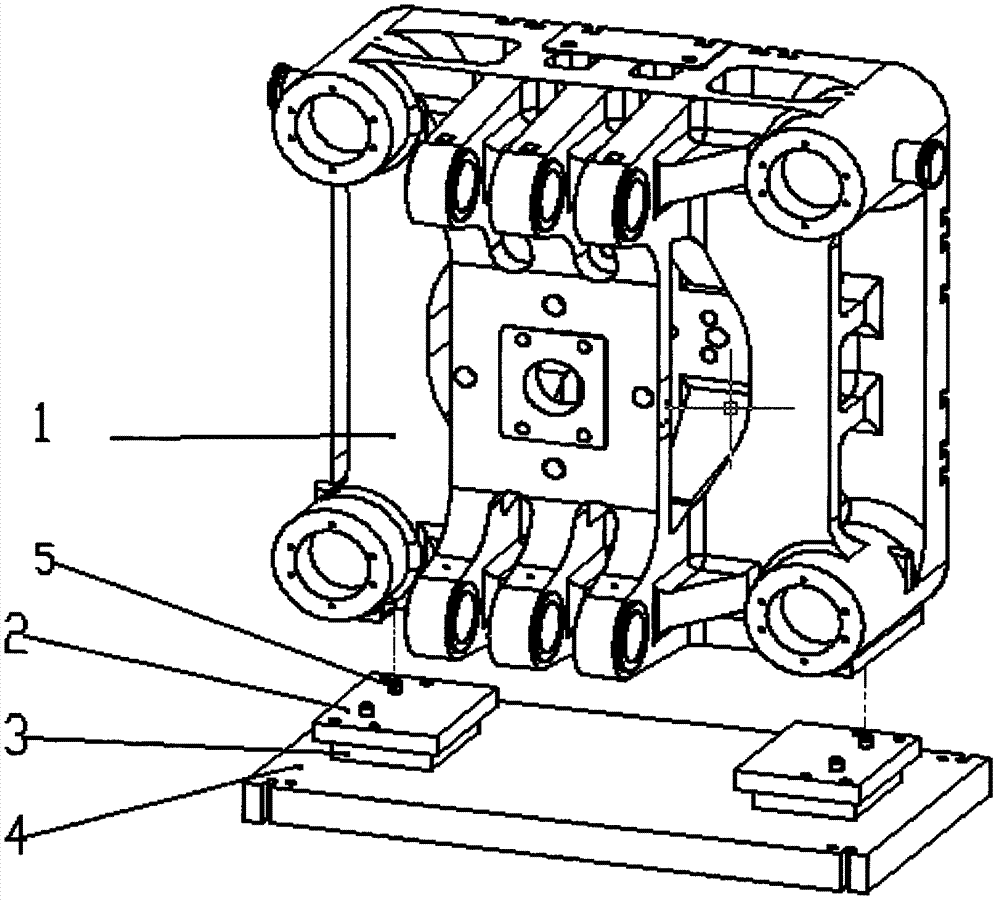

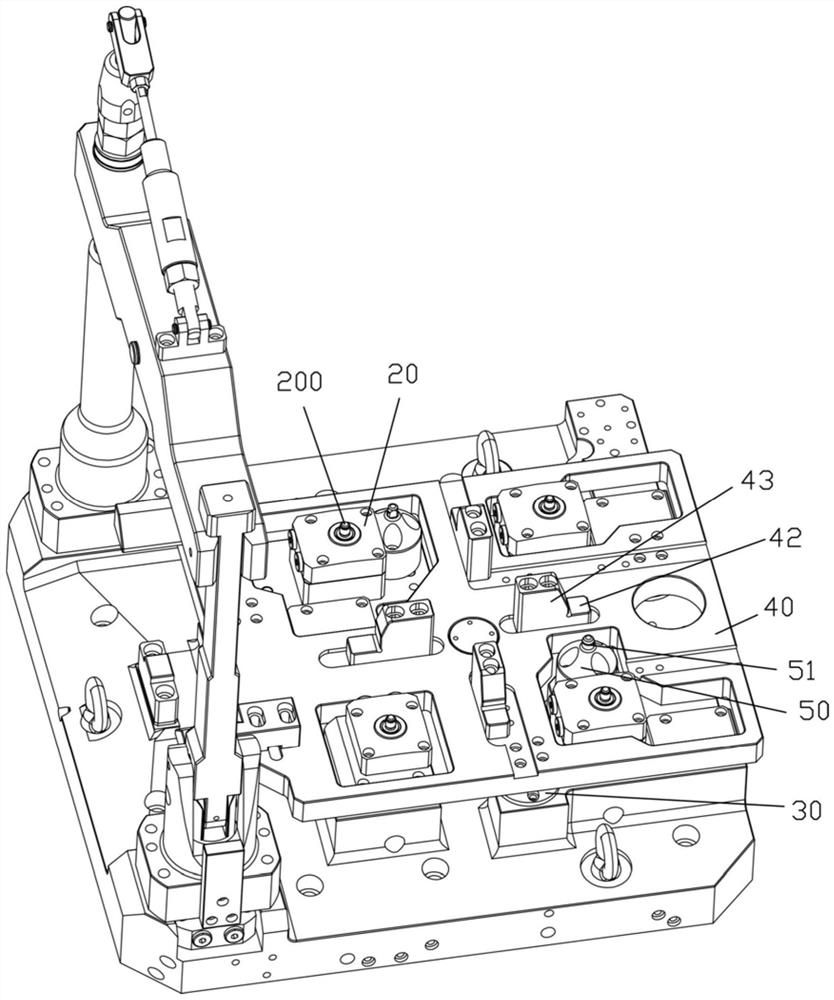

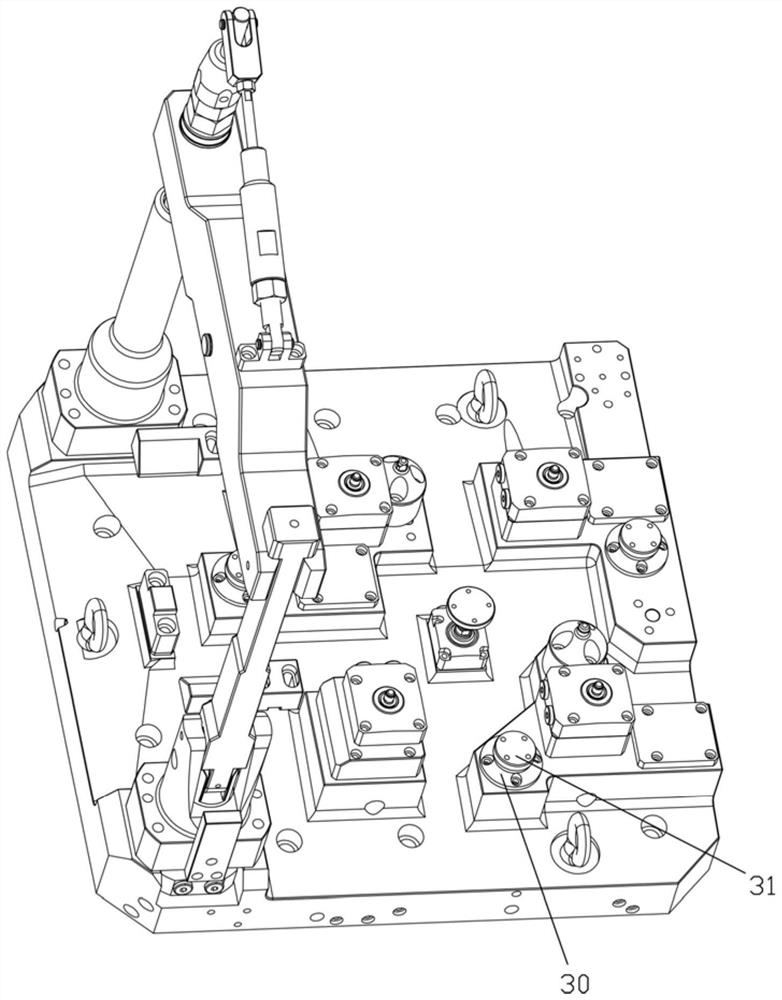

Special processing device of injection machine moulding board

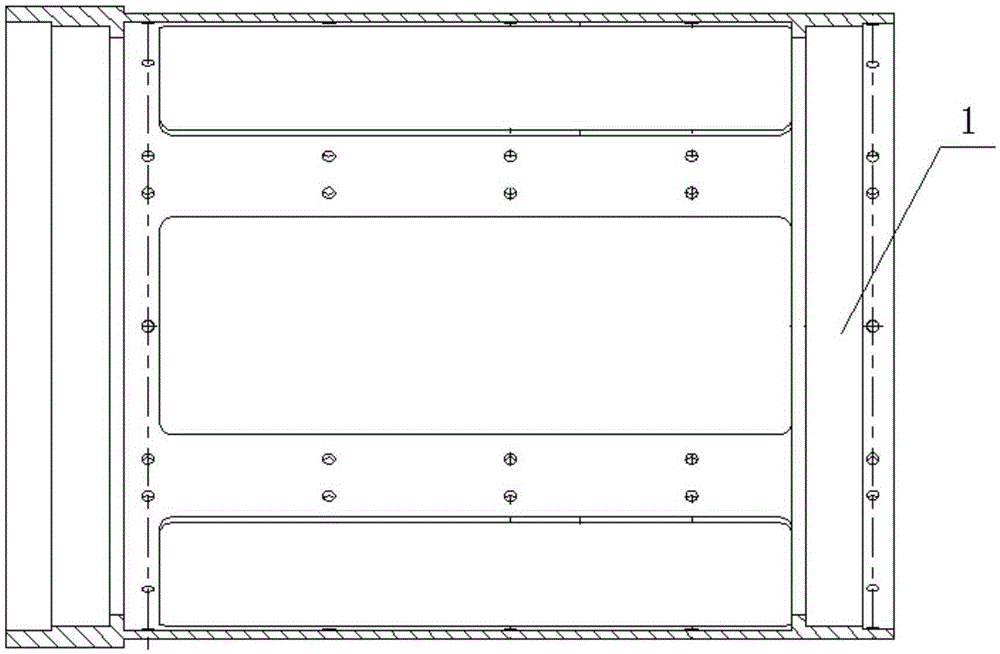

InactiveCN103111886AHigh positioning accuracyReduce clamping deformationPositioning apparatusMetal-working holdersWrenchEngineering

Provided is a special processing device of an injection machine moulding board. According to the special processing device, a top plate and a transition plate are fixedly connected. The injection machine moulding board is located through two locating pins on the top plate so that inclination or loosing of the injection machine moulding board can be prevented and locating accuracy of processing can be improved. Footing of the injection machine moulding board is tight attached to the top plate. A clamping surface is a footing surface of the injection machine moulding board, and clamping deformation of the injection machine moulding board is effectively reduced. A locking bolt hole is designed to be on the outer side of the transition plate, amplitude of swinging of a locking wrench can be increased, locking force is guaranteed, and convenience is brought to operation.

Owner:BORCH MACHINERY

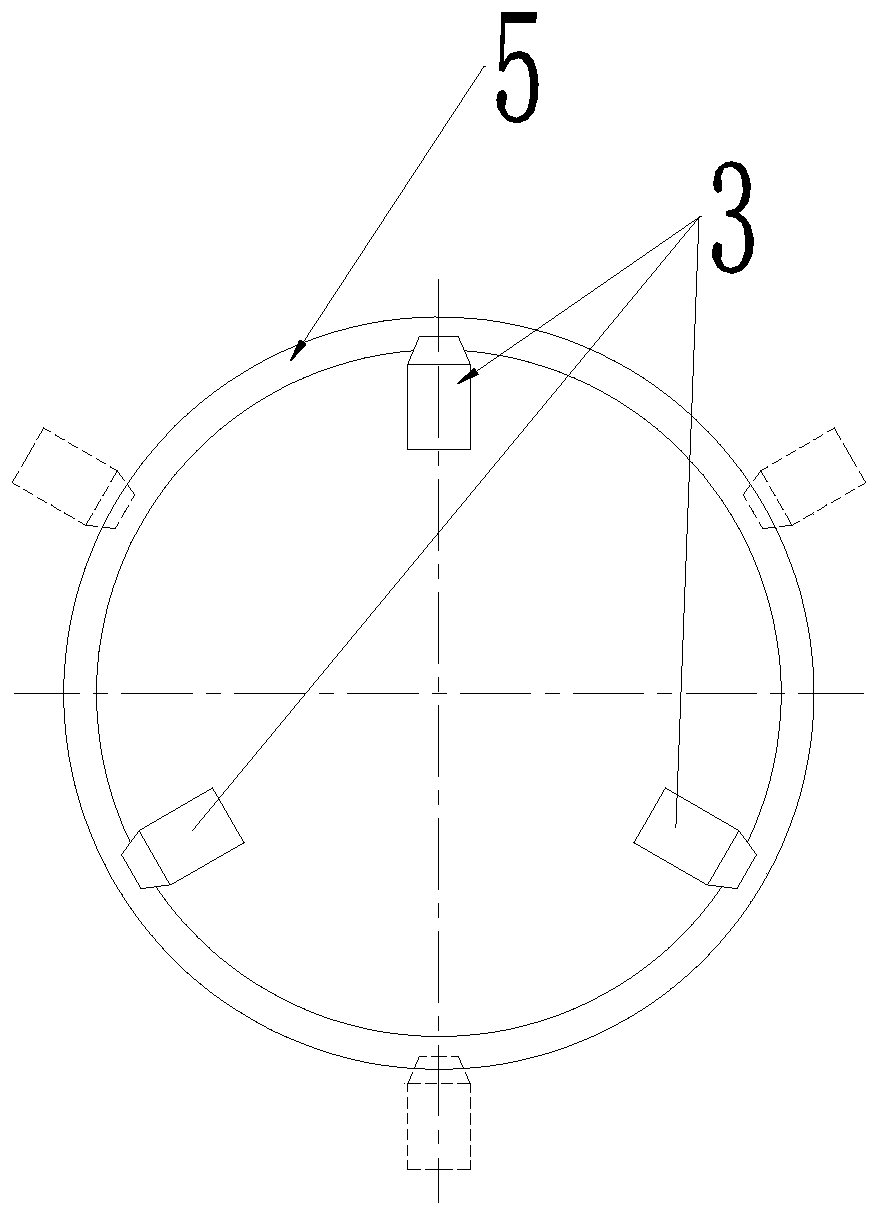

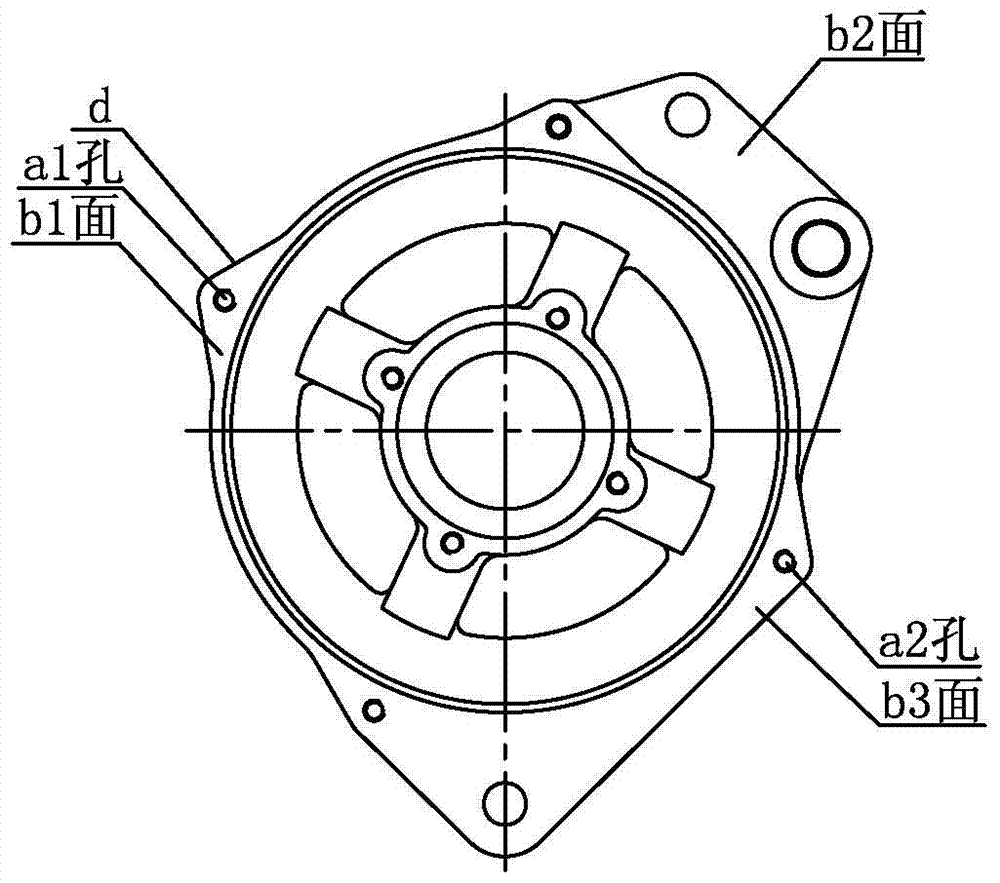

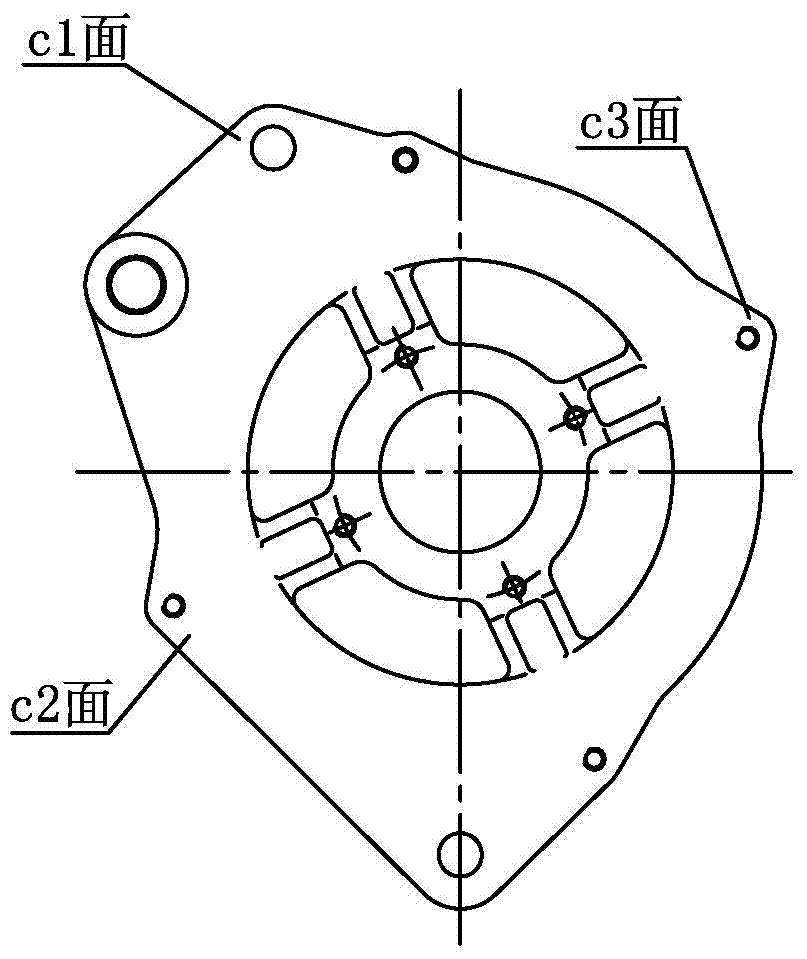

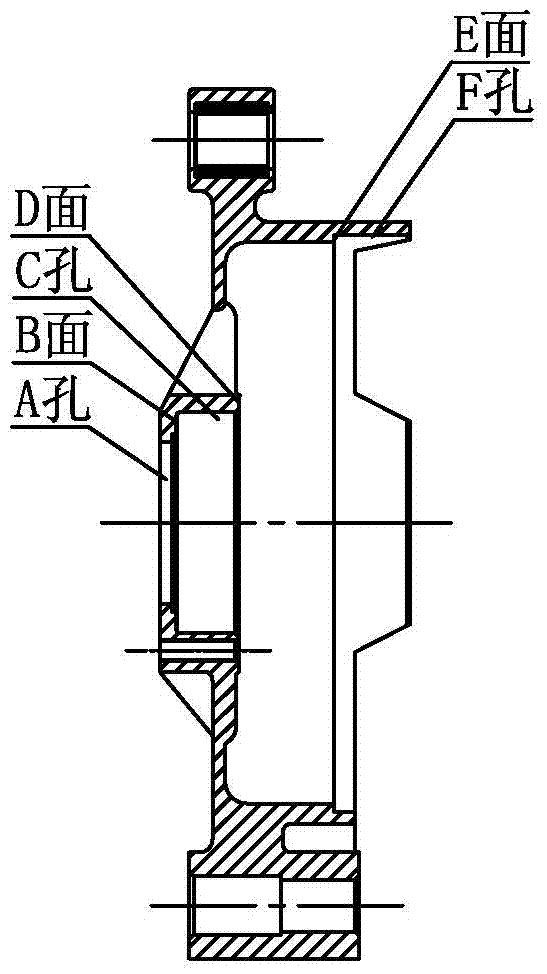

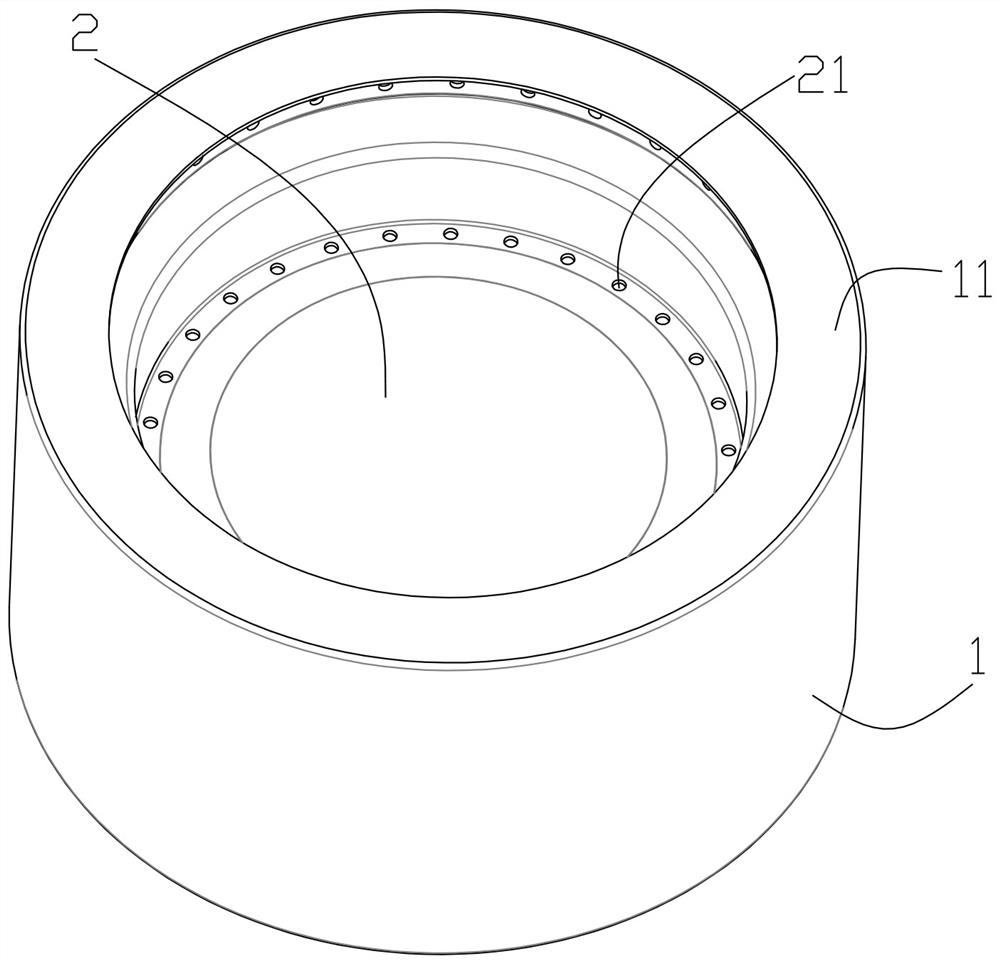

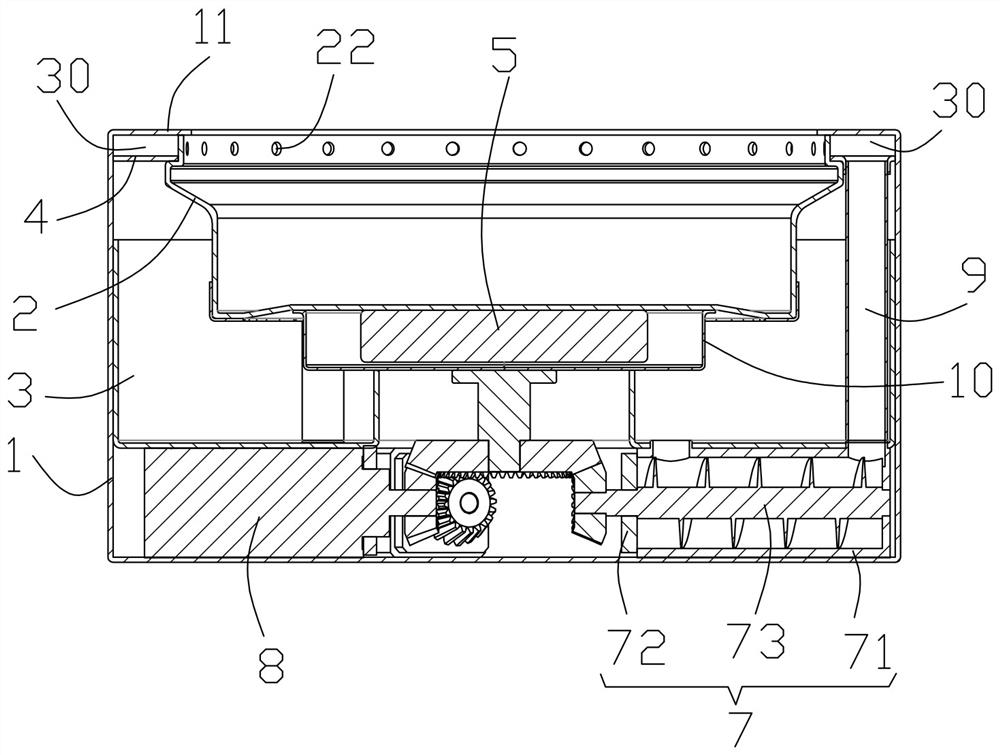

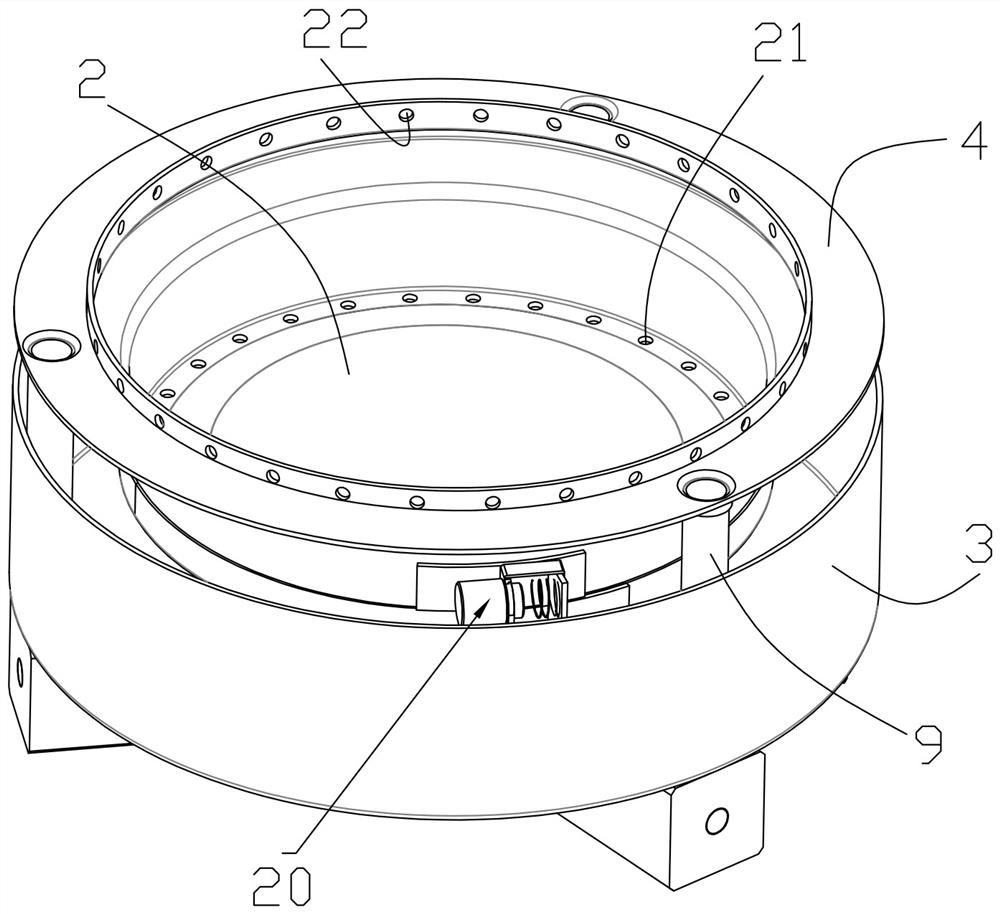

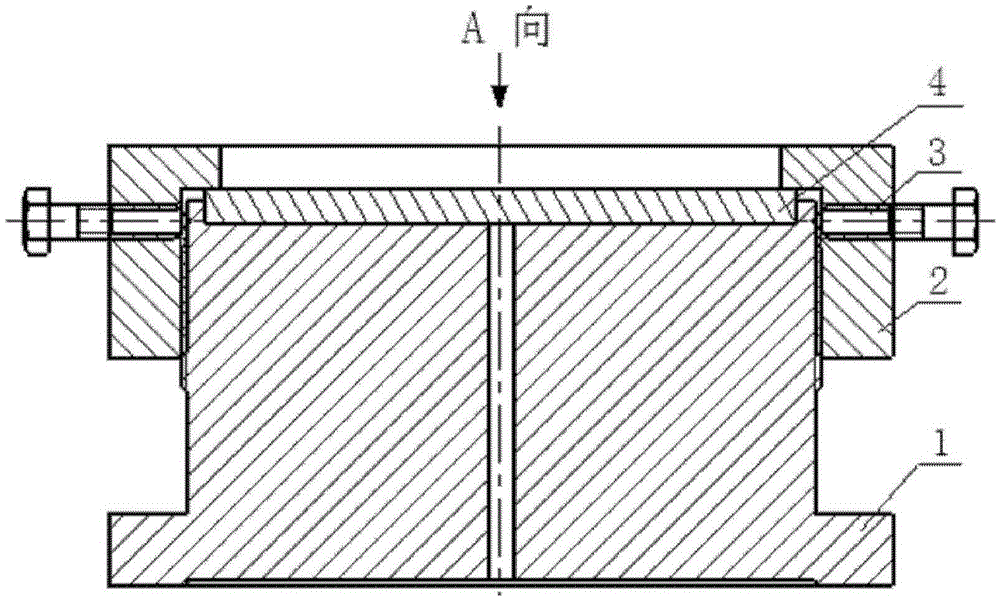

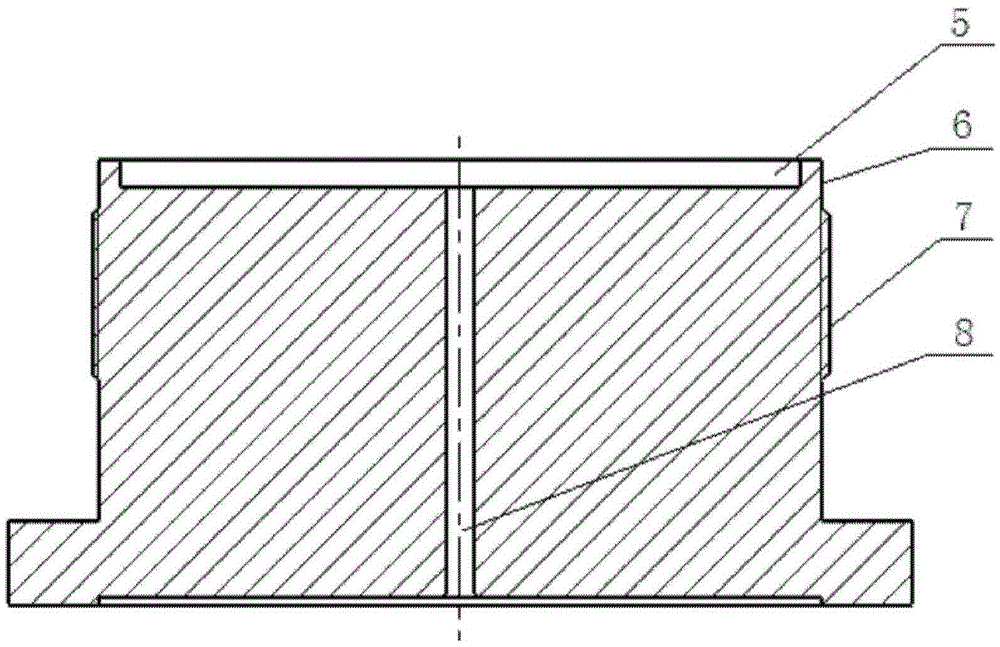

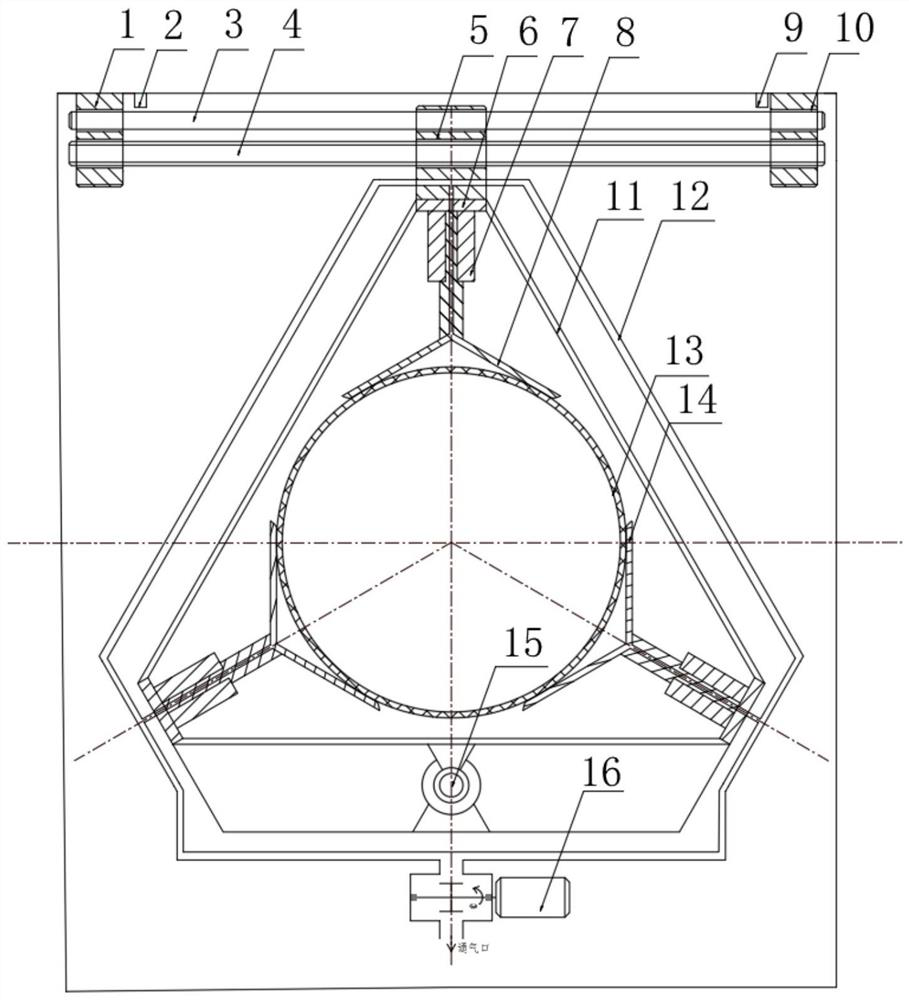

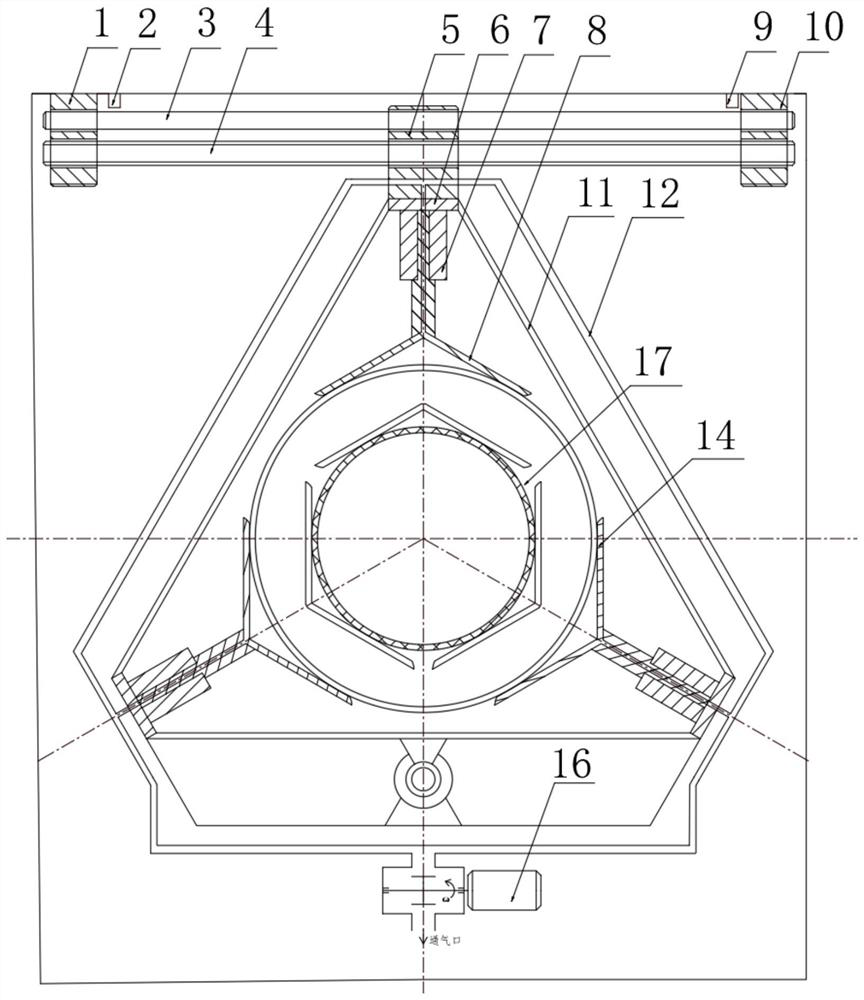

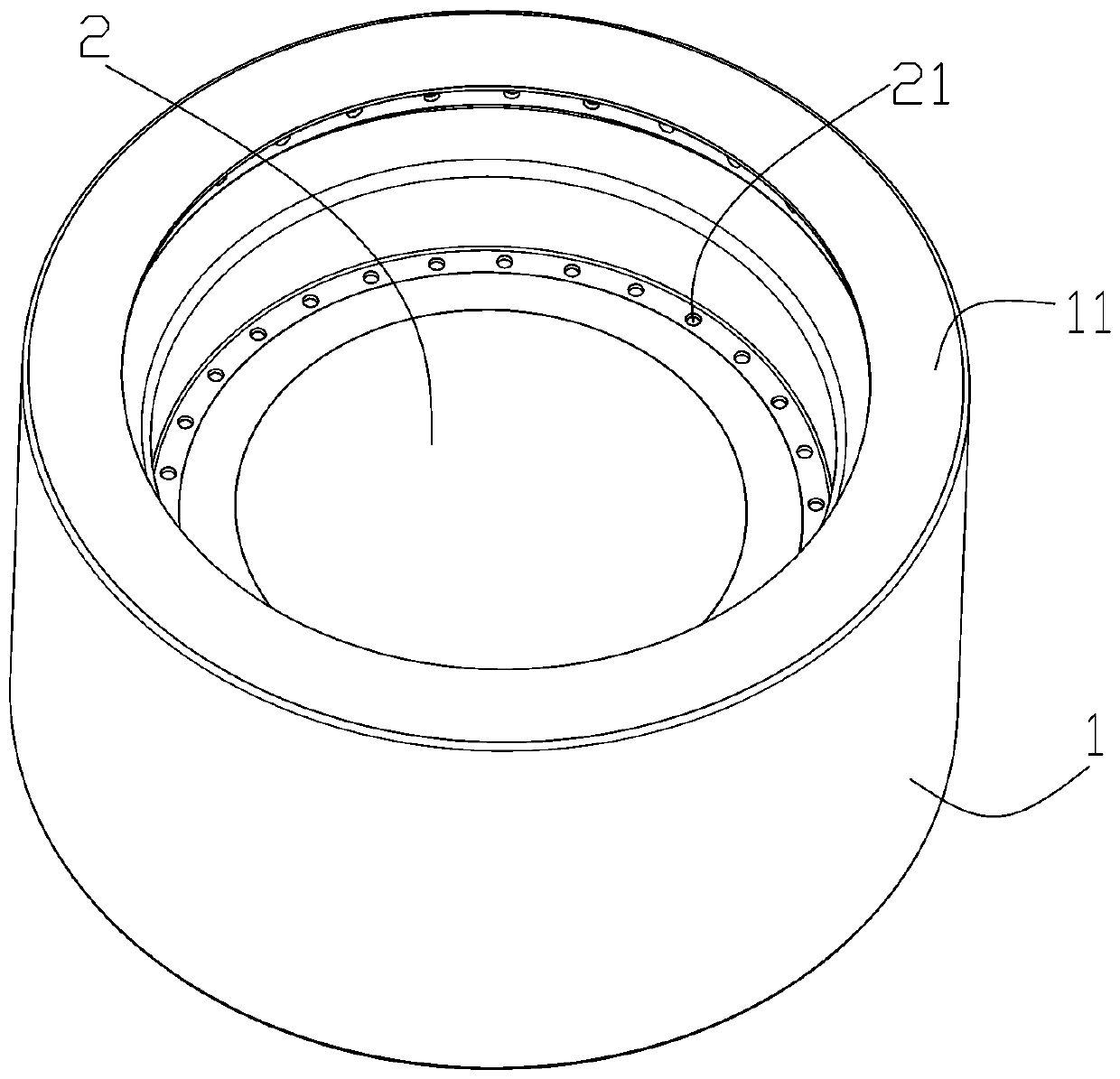

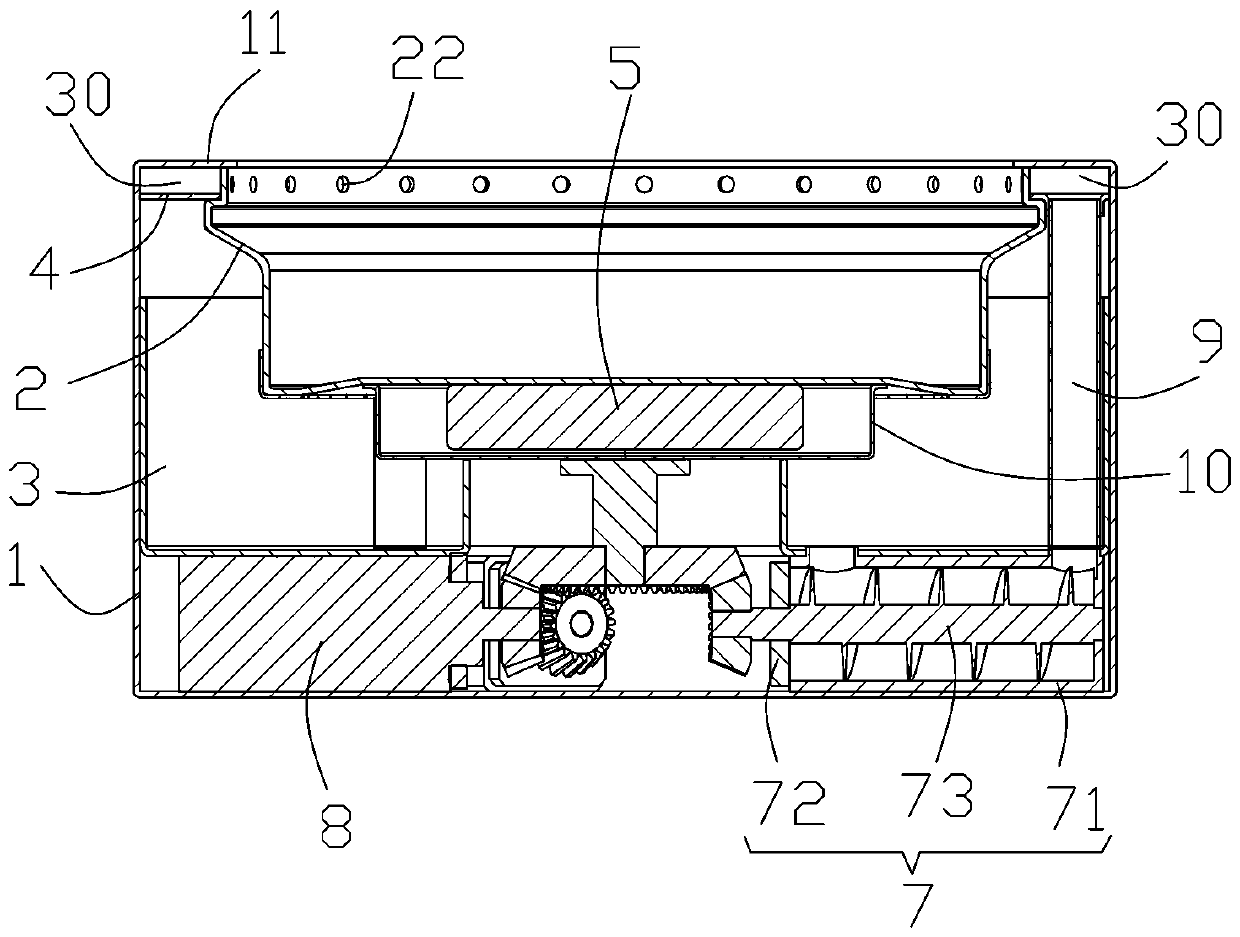

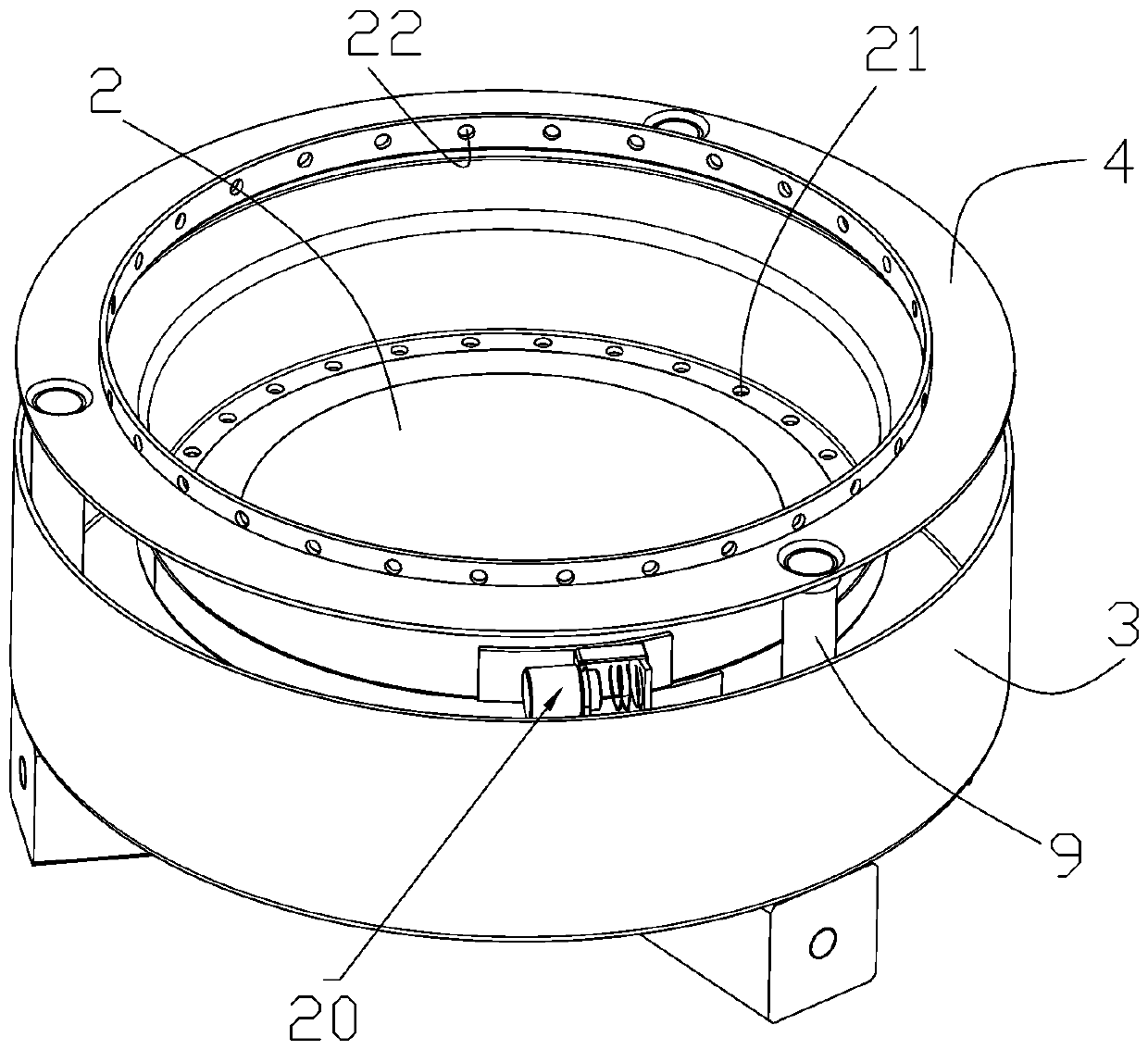

A hydraulic automatic fixture for turning motor casings

ActiveCN104907868BAvoid misalignmentImprove clamping efficiencyChucksPositioning apparatusHydraulic motorElectric machine

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

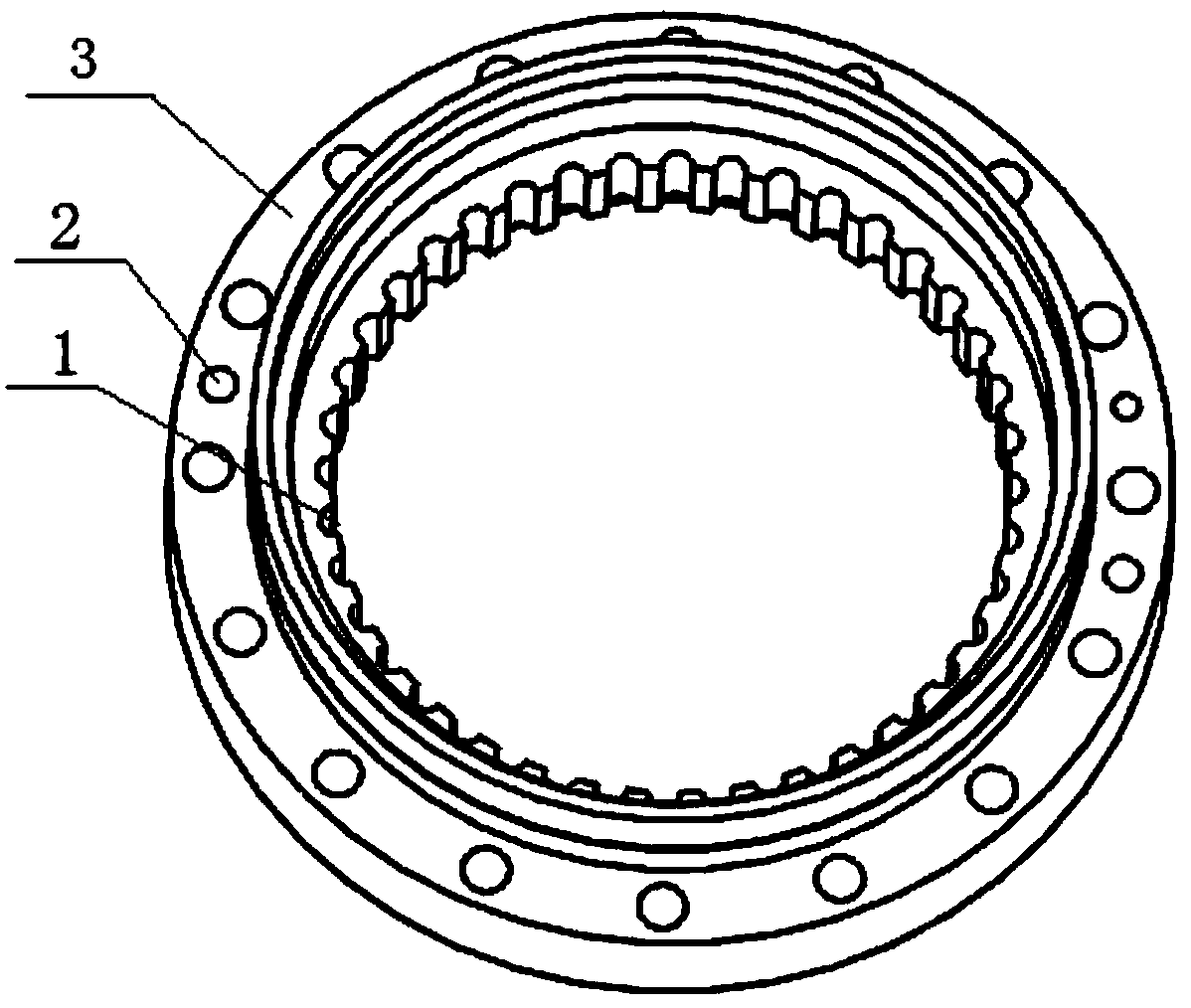

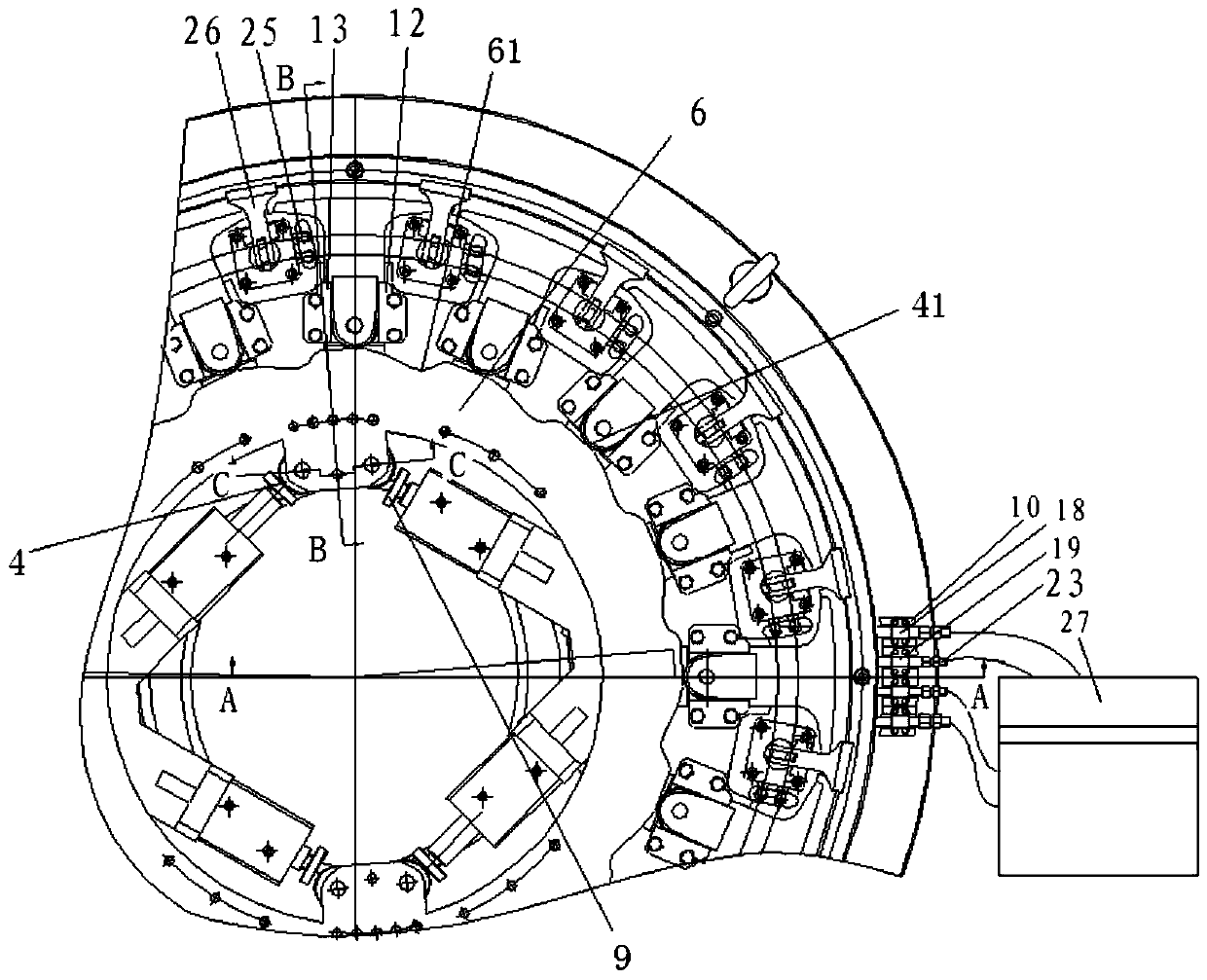

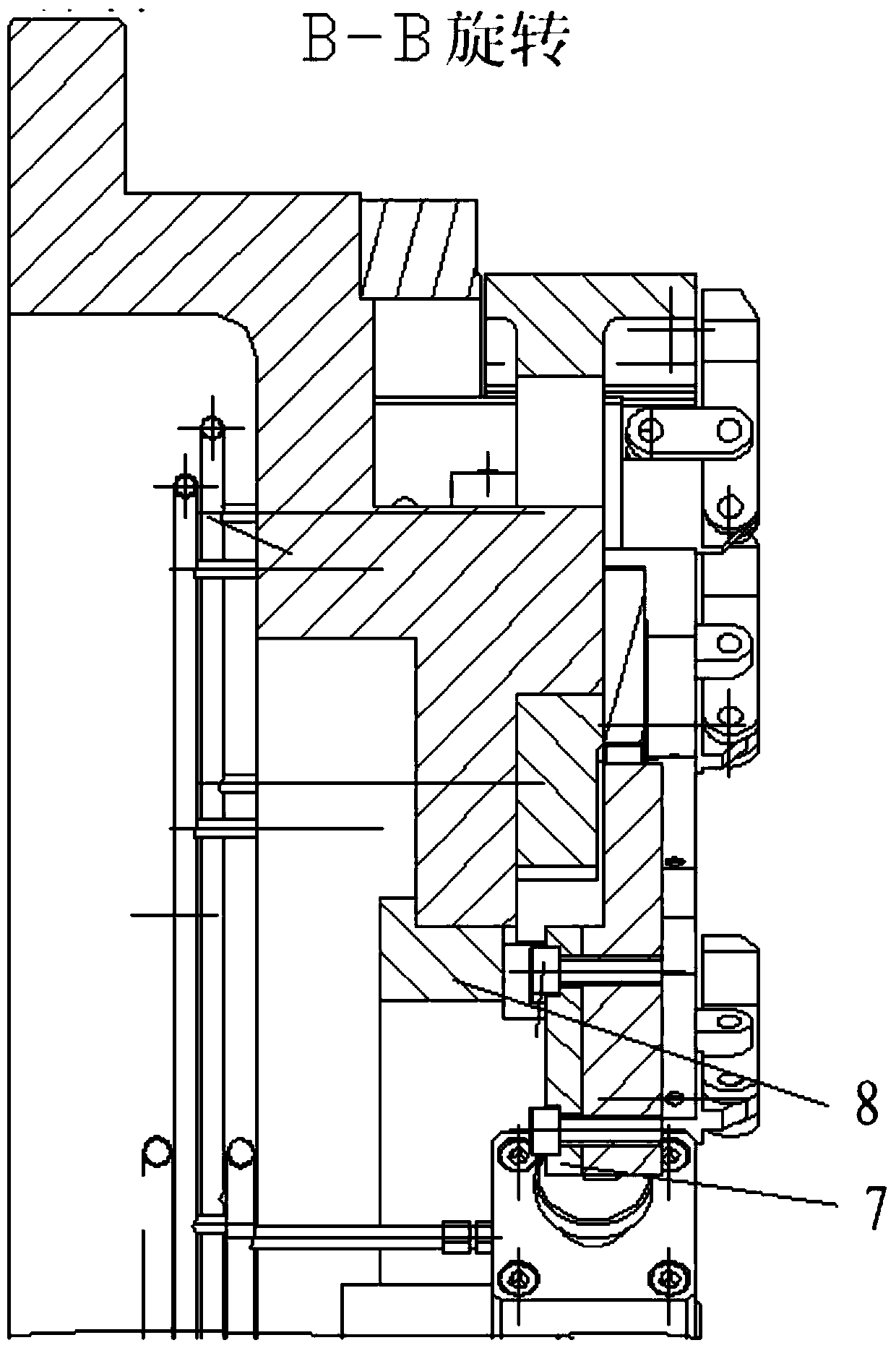

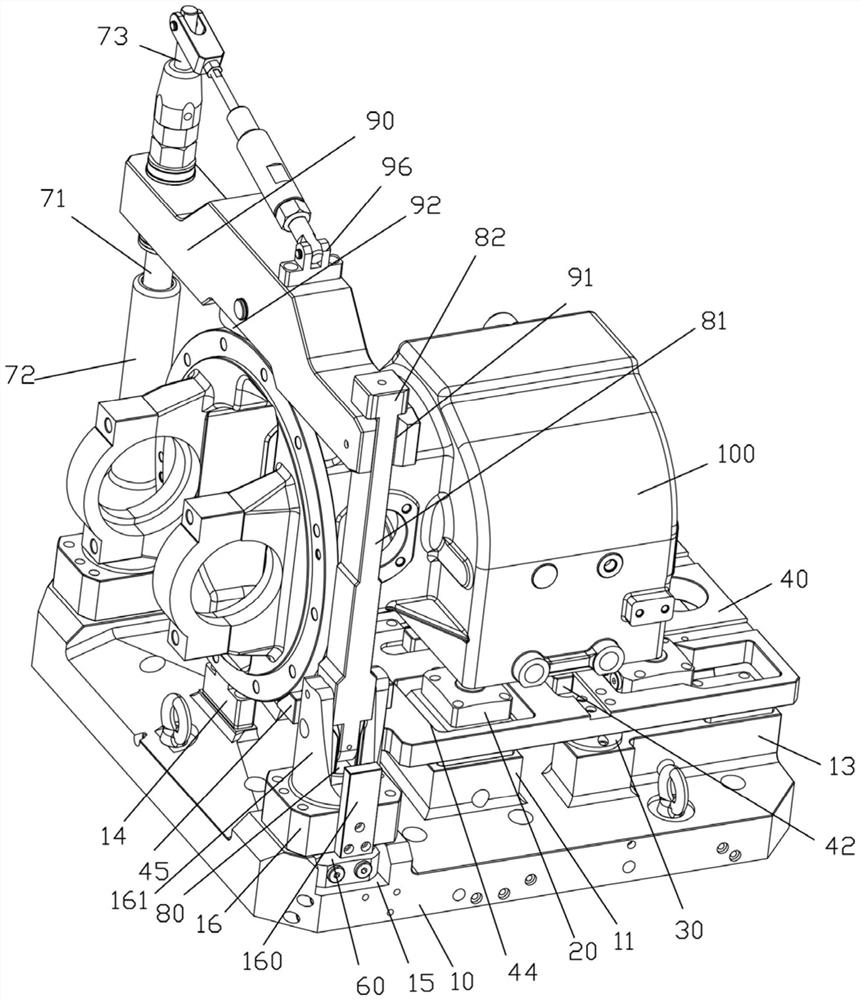

Method and device for machining internal teeth of planetary cycloidal pin gear reducer housing

InactiveCN109158708AEasy clampingReduce cumulative errorAutomatic control devicesFeeding apparatusReduction driveReducer

The invention relates to a method and device for machining internal teeth of a planetary cycloidal pin gear reducer housing. A tool is installed on a vertical machining center, a workpiece is assembled on the tool, alignment of the tool is carried out, the tool is static after the workpiece is completely machined, and the workpiece is detached for machining a new workpiece. The invention further provides the method for machining the internal teeth of the planetary cycloidal pin gear reducer housing and a flexible device. When the method and device are used for machining the internal teeth of the planetary cycloidal pin gear reducer housing, machining of all pin tooth holes can be completed through one-time clamping, machining errors and assembly errors are reduced, the manufacturing accuracy is improved, the production speed is accelerated, and products meet the high precision requirements of reducers.

Owner:天津旗领机电科技有限公司

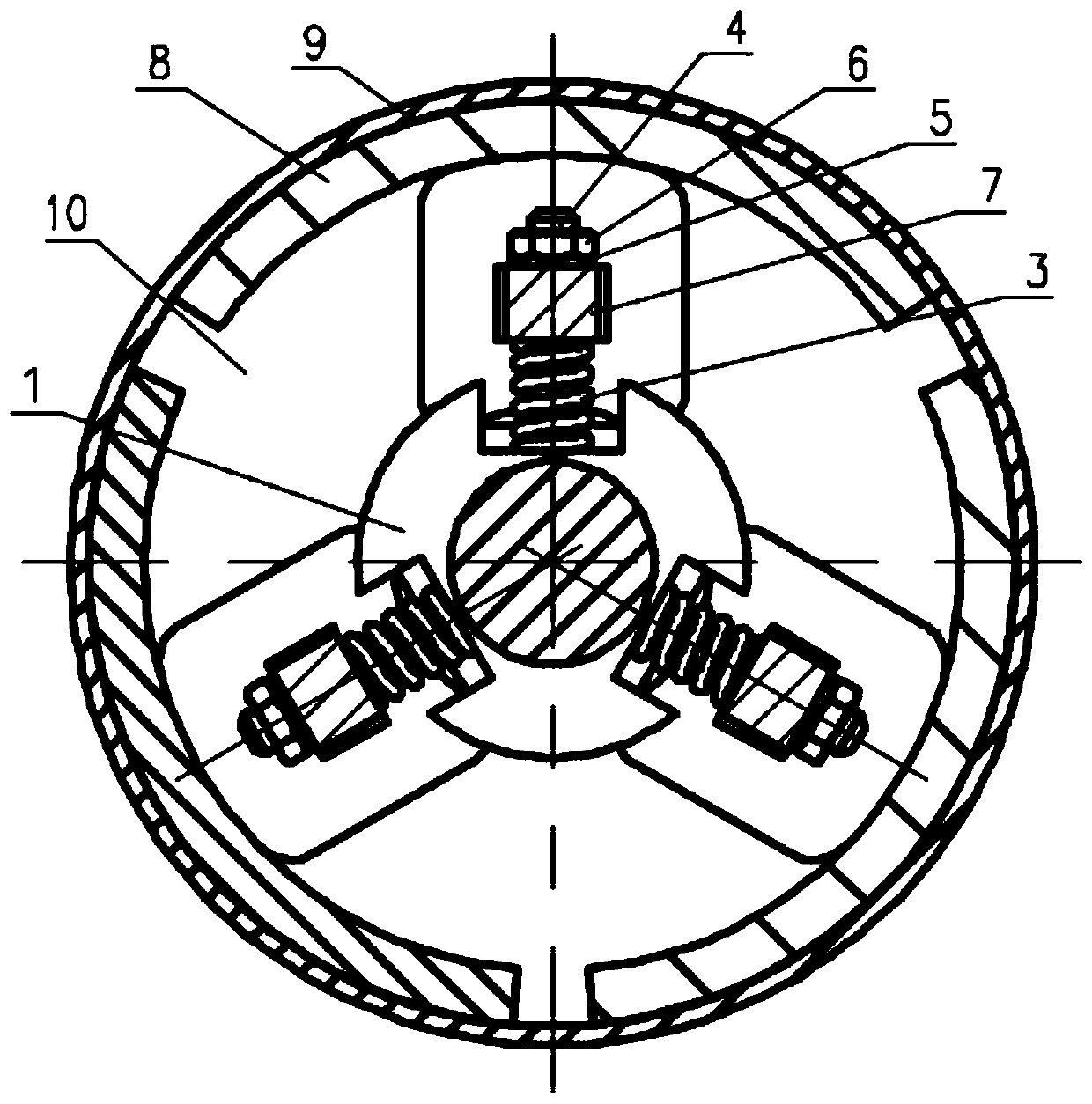

Universal flexible clamp for thin-walled parts

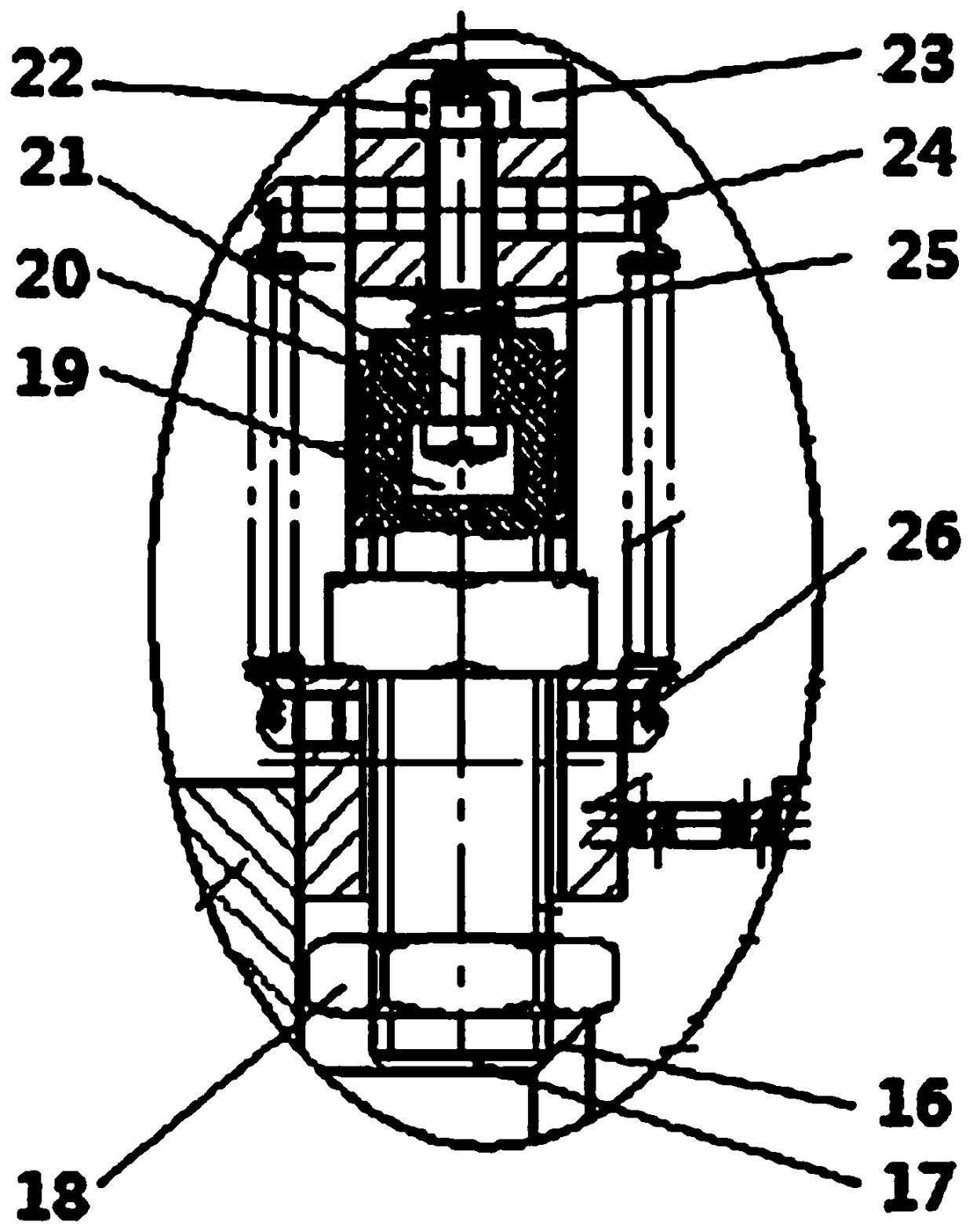

InactiveCN108080982AMeet processing requirementsReduce processing requirementsWork clamping meansPositioning apparatusEngineeringScrew thread

A universal flexible clamp for thin-walled parts is mainly composed of a right pressing disc, an axial spring, a supporting ring, an ejection rod, a spring, a supporting fan, a screw, a nut, a spacerring, an ejection ring, a right pressing disc, an adjusting washer, a rotary nut, a supporting shaft and the like. An internal thread is machined on a center hole of the right pressing disc. An external thread is machined at the right end of the supporting shaft, and the right end of the supporting shaft is fixedly connected with the right pressing disc in a threaded mode. The left end of the supporting shaft is sleeved with the left pressing disc. The adjusting washer is mounted between the nut and the left pressing disc. Two radial supporting mechanisms are arranged on the supporting shaft in the axial direction, located between the supporting shaft and the left pressing disc and mainly composed of an internal stop nut, a T-shaped connection groove, a supporting piece, a screw cap, a nut, an upward-pulling spring hanger, a supporting spring, a downward-pulling spring hanger, a groove and the like. The universal flexible clamp is simple in structure and low in production cost, clamping deformation of the parts is reduced, and the production efficiency and quality stability of the thin-walled parts are improved.

Owner:牛金生

An Active Processing Method for Clamping and Deformation of Thin-walled Special-shaped Parts

ActiveCN104111625BStable clamping deformationReduce clamping deformationProgramme controlComputer controlEngineeringSupport point

The invention discloses an active processing method for clamping deformation of thin-walled special-shaped parts. First, the clamping force of the thin-walled workpiece is optimally set, and then the range of the force point of the workpiece is found out, and then the workpiece is supported auxiliaryally, and finally the compensation is performed. The data is imported into the CNC program. Compared with the prior art, the active machining method for clamping and deformation of thin-walled special-shaped parts can be analyzed before numerical control machining of thin-walled parts to determine the magnitude of the clamping force, identify the clamping point and the support point of the workpiece, Using increasing and decreasing tool compensation, the clamping of the workpiece is stabilized, the cutting deformation of the workpiece is reduced, and the accuracy is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of processing method of aluminum alloy thin-wall cylindrical parts

Owner:贵州凯星液力传动机械有限公司

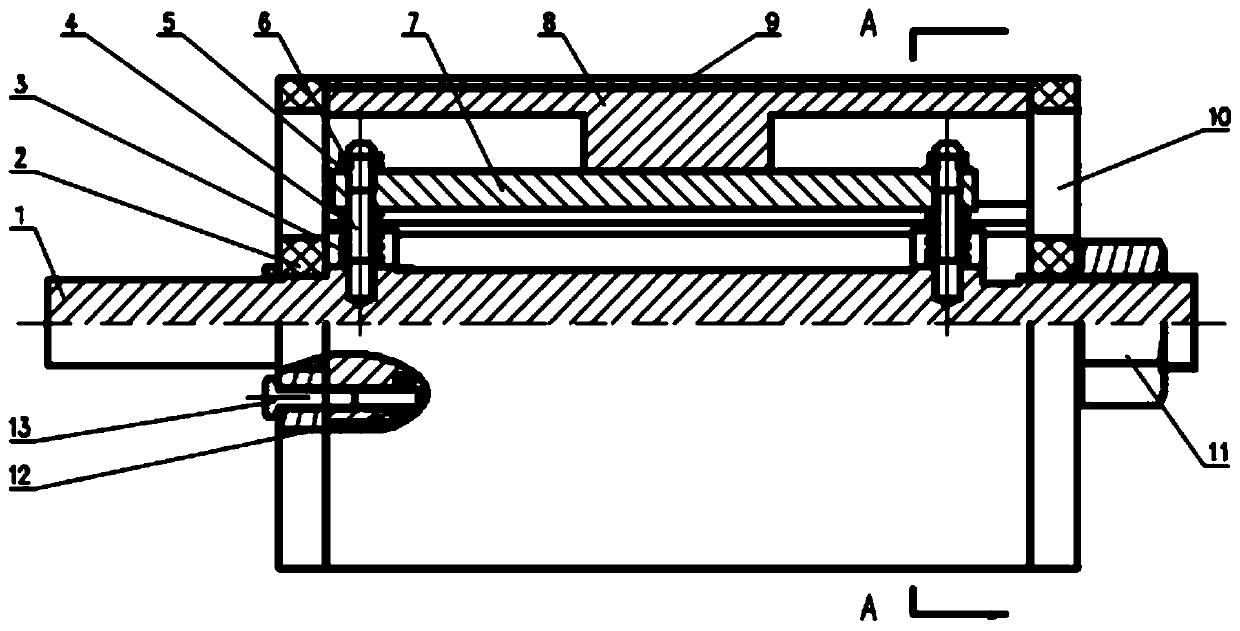

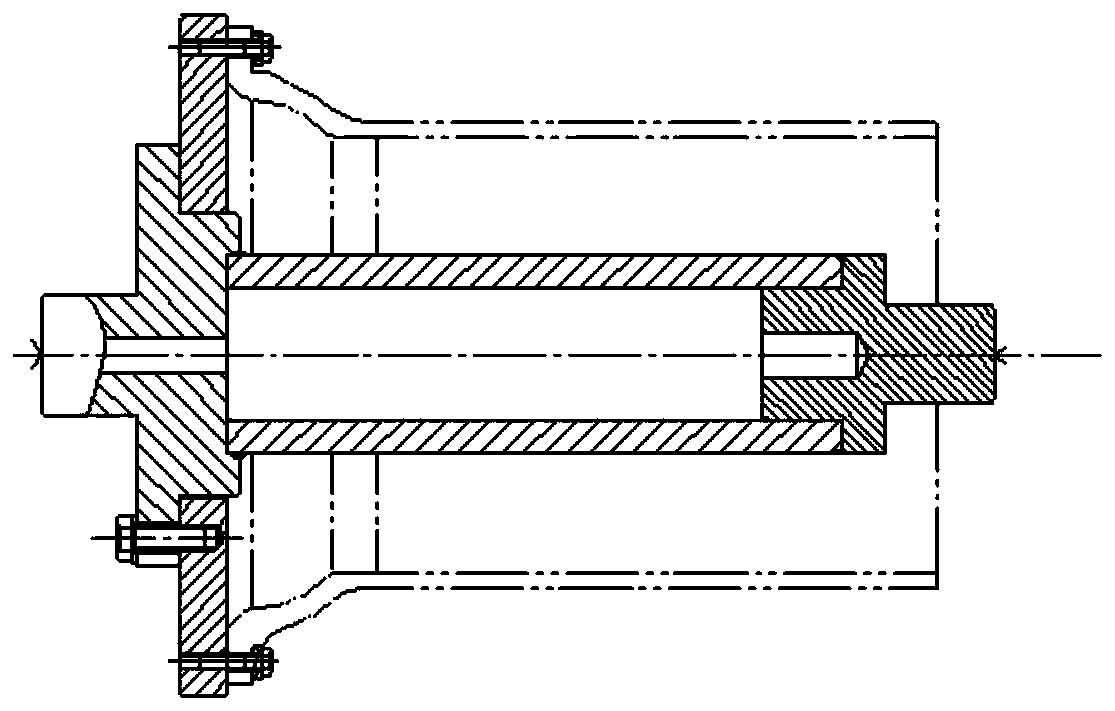

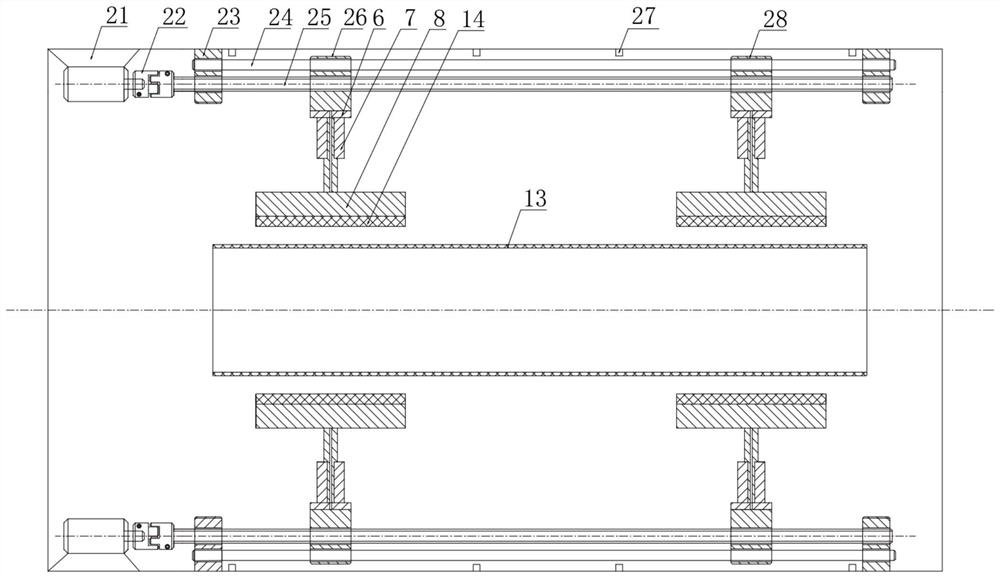

A system and method for clamping the outer wall of thin-walled cylindrical parts by turning

ActiveCN109128237BReduce clamping deformationExpansion mandrelsEffective solutionThin walled cylinder

The invention belongs to the field of machining, and provides a clamping system and method for turning the outer wall of a thin-wall cylindrical part. The clamping system comprises a center shaft, a fixed baffle, compression springs, studs, gaskets, adjusting nuts, connecting rods, elastic bodies, a movable baffle, a locating nut, a locking nut, connecting bolts and other components. The clampingsystem is suitable for thin-wall cylindrical parts of multiple inner diameter sizes, the clamping system is divided into a radial auxiliary supporting structure and an axial locating and clamping structure, and clamping deformation of the thin-wall cylindrical part is effectively reduced. According to the clamping system, the axial clamping force / radial supporting force can be adjusted according to different workpiece axial and radial rigidities and the magnitude of the axial clamping force / radial supporting force and workpiece deformation can be measured. The clamping system is simple in structure, reliable in locating and wide in application range, the supporting force, the clamping force and workpiece deformation can be controlled and measured, and the effective solution method is provided for machining and clamping of small and medium size thin-wall cylindrical components.

Owner:DALIAN UNIV OF TECH

Vacuum adsorption clamp and adsorption method for clamping thin-wall spherical shell type micro component

ActiveCN113695937ASolve the deformationSolve the clamping problemWork clamping meansMilling equipment detailsSuction forceEngineering

The invention provides a vacuum adsorption clamp and an adsorption method for clamping a thin-wall spherical shell type micro component, and relates to the technical field of clamping of thin-wall spherical shell type micro components. The vacuum adsorption clamp and the adsorption method are provided for solving the problems that in the machining process of uniformly distributing micro pit structures on the whole surface of the thin-wall spherical shell type micro component, an existing clamping mode is difficult to operate, a control part is complex, consequently, spherical shell deformation is large, and the repeated positioning precision is low. According to the technical key points, a vacuum suction head is detachably connected with the adsorption end of a vacuum adsorption clamp body in a sealed mode, and the hole diameter of a vacuum cavity in the vacuum adsorption clamp body in the axial direction of the vacuum adsorption clamp body is decreased from the connecting end to the adsorption end; and the vacuum cavity serves as a main air source channel, and an auxiliary air source connector communicating with the vacuum cavity is formed in the vacuum adsorption clamp body. When the vacuum adsorption clamp is adopted to adsorb the thin-wall spherical shell type micro component, the specific structure shape of the suction head and the vacuum negative pressure are calculated and checked. A clamp chuck is suitable for flexibly adjusting the vacuum degree according to the deformation condition of a thin-wall spherical shell, that is, the suction force of the clamp chuck is adjusted, clamping deformation is reduced, and the machining precision is guaranteed.

Owner:HARBIN INST OF TECH

Control method of grinding distortion of outer diameter of guide barrel of auto bank unit of helicopter

InactiveCN111331446AIncrease contact areaReduce clamping deformationRevolution surface grinding machinesSeat surface grinding machinesGrindingProcessing accuracy

The invention belongs to the mechanical technical field and provides a control method of grinding distortion of the outer diameter of a guide barrel of an auto bank unit of a helicopter. The control method comprises the following steps of measuring a distortion high-low point area on a rough machining surface of a part and manually polishing a high point area and a transitional area correspondingto a positioning surface of the part; and adjusting a clamping force of a tightening bolt in the positioning hole of the machined part to improve the clamping distortion of the part. In the machiningprocess, the method guarantees that the precision of the positioning surface of a thin-walled sprayed part meets a 100%grinding demand and increases the contact area of the part and a tool and reducesthe clamping distortion of the part by controlling the clamping force in the distortion area, and further has a self-remedy improving function to grinding distortion of the part to a certain extent.The machining precision and the percent of pass of the part are improved.

Owner:HARBIN DONGAN ENGINE GRP

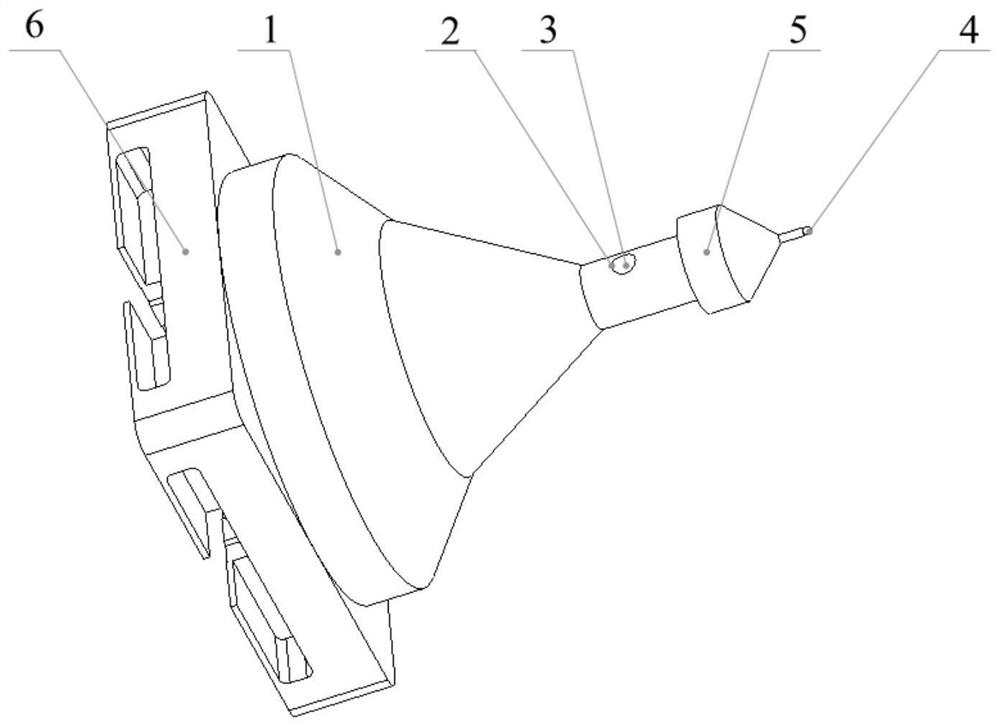

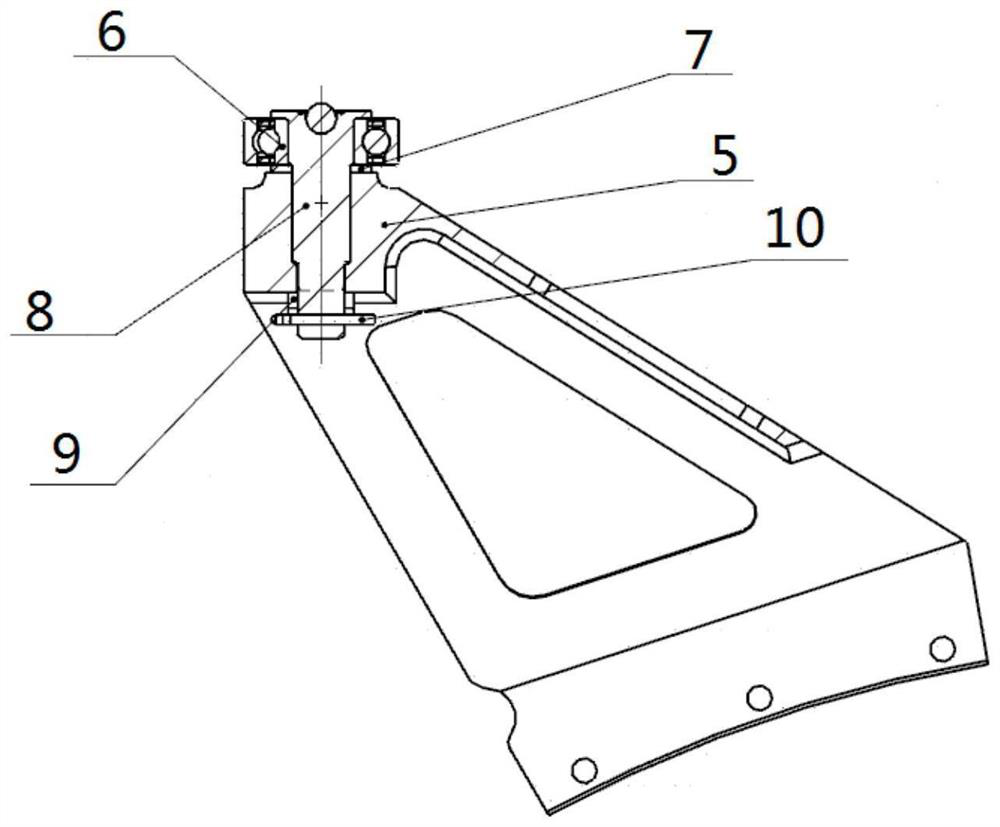

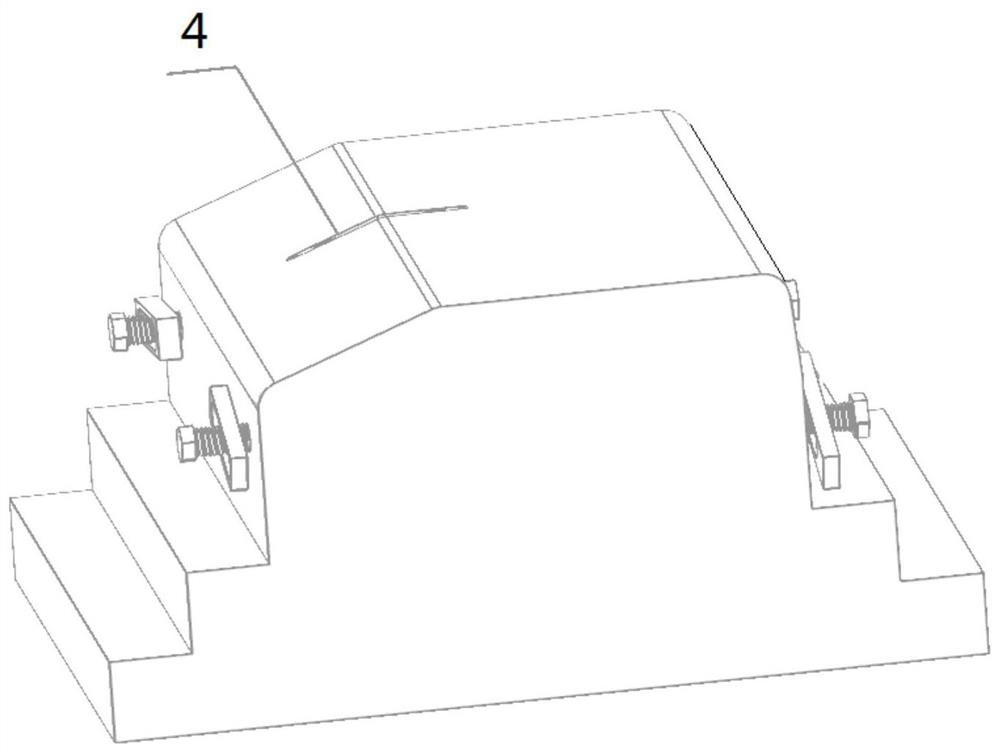

Pulley support machining clamp and machining method

ActiveCN113399947AImprove firmnessImprove machining accuracyPositioning apparatusMetal-working holdersNumerical controlWire cutting

The invention discloses a pulley support machining clamp and machining method. The machining clamp comprises a base, a pressing plate, a screw and a nut, a continuous supporting face is arranged on the surface of the base, and the supporting face extends from a mounting side hole in the left end of a pulley support to a mounting side hole in the right end of the pulley support. During machining, two datum planes are linearly cut on a pulley support casting blank, then the pulley support is clamped through the clamp, a support left end arc-shaped face and a support right end arc-shaped face are milled on a five-axis numerical control milling machine, then a bearing mounting end face is milled, a pin shaft hole is drilled and bored, and finally the mounting side hole is drilled. The machining clamp is simple in structure and firm in clamping, the pulley support is not prone to deformation and easy to measure, by means of the machining method, machining of all machining elements can be completed through one-time clamping, the machining efficiency is high, and the quality is guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

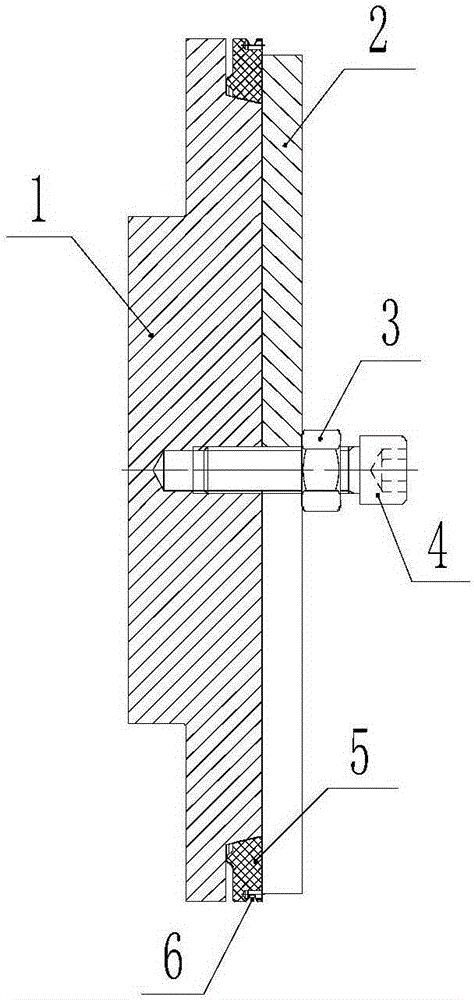

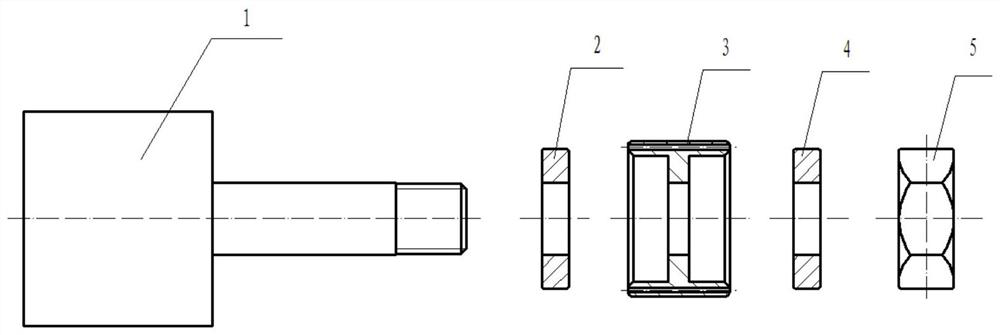

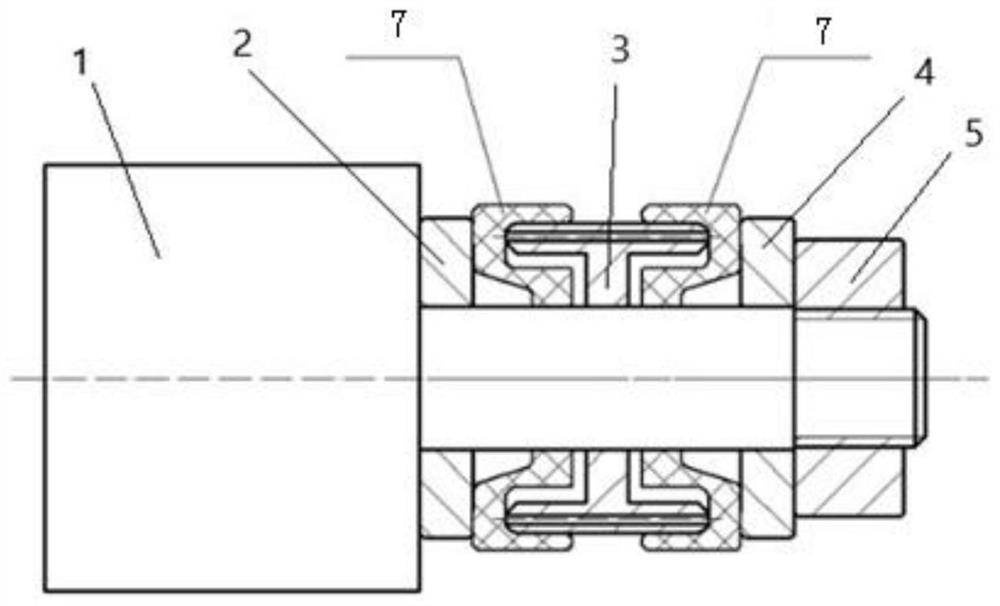

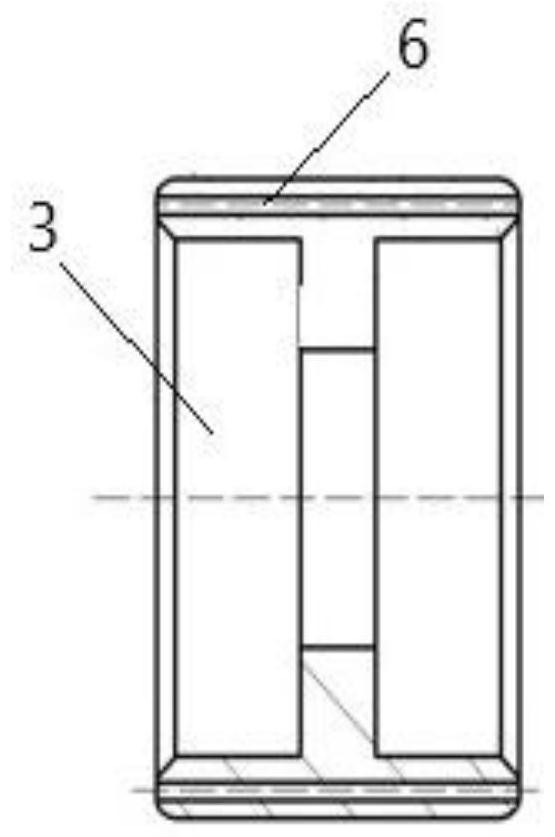

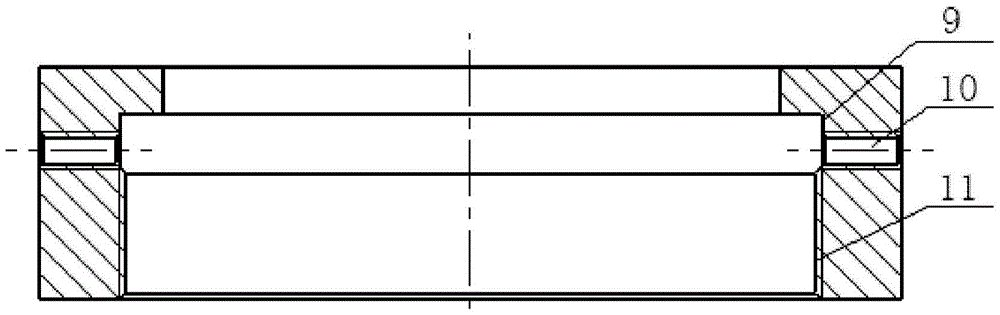

External grinding machining device for thin-wall non-metal part with inner ring groove and clamping method

ActiveCN112605738AAvoid weak areasReduce clamping deformationRevolution surface grinding machinesEngineeringCylindrical grinding

The invention belongs to the field of machining, and relates to an external grinding machining device for a thin-wall non-metal part with an inner ring groove and a clamping method. The external grinding machining device comprises a mandrel, a bushing and a nut, wherein the bushing and the nut are sequentially arranged on the mandrel in a sleeving mode; the bushing is a bidirectional concave bushing and is of an annular cylinder structure, grooves are formed in the two end faces of the bushing, the longitudinal section of the bushing is in an I shape, and exhaust holes are formed in the bushing; and the external grinding machining device further comprises a first gasket and a second gasket which are arranged on the mandrel in a sleeving mode and arranged at the two ends of the bushing correspondingly, and the first gasket and the second gasket are the same in size and structure. According to the external grinding machining device for the thin-wall non-metal part with the inner ring groove and the clamping method, the specially-designed bidirectional concave bushing, the inner wall and the groove bottom of the inner ring groove of the part and the right end face of the part are positioned and clamped, and the mandrel is used for auxiliary positioning, so that the problems of uneven clamping stress and grinding deformation are solved, the qualification rate of the part is improved, and the stable and reliable quality is ensured.

Owner:XIAN AERO ENGINE CONTROLS

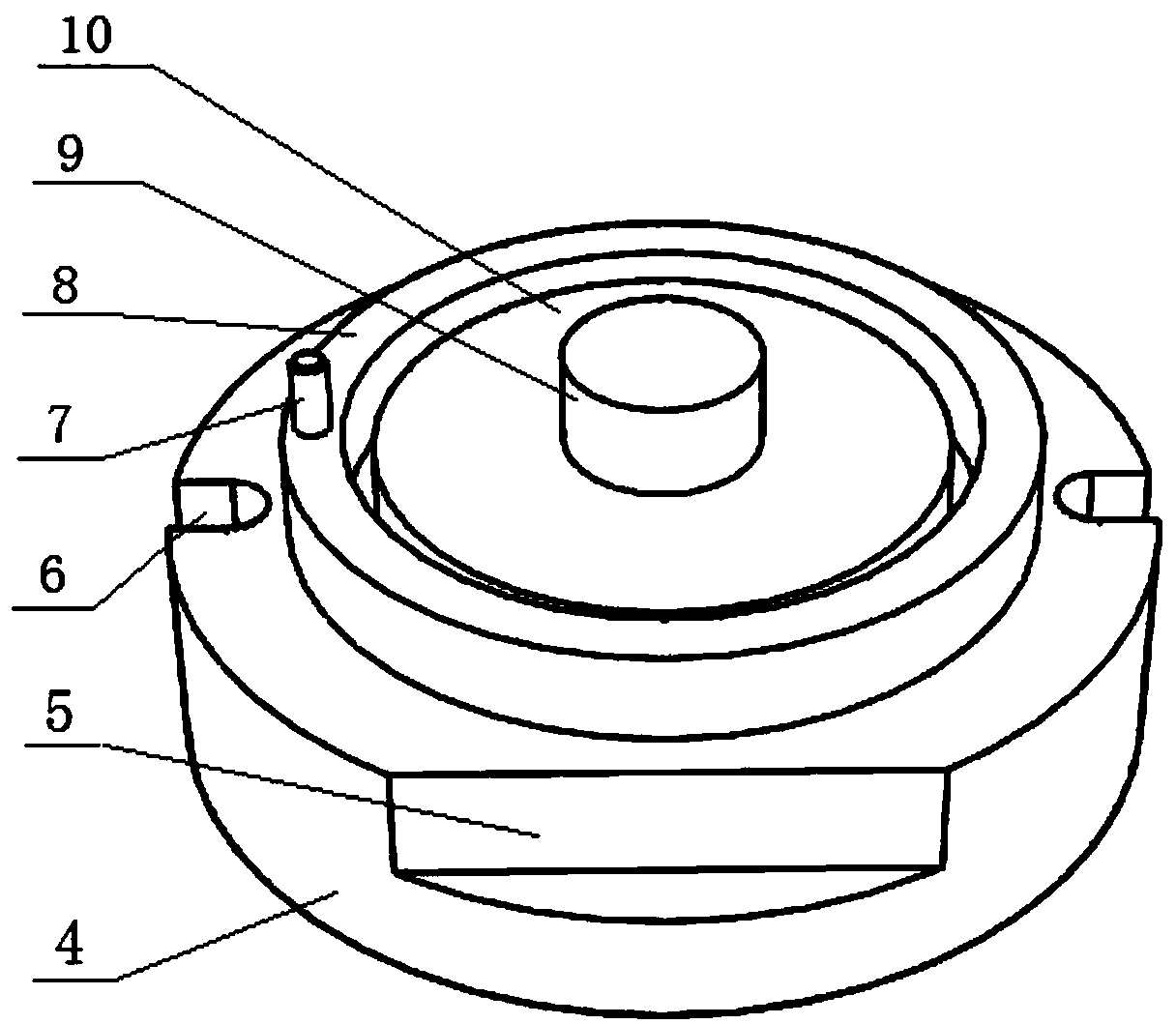

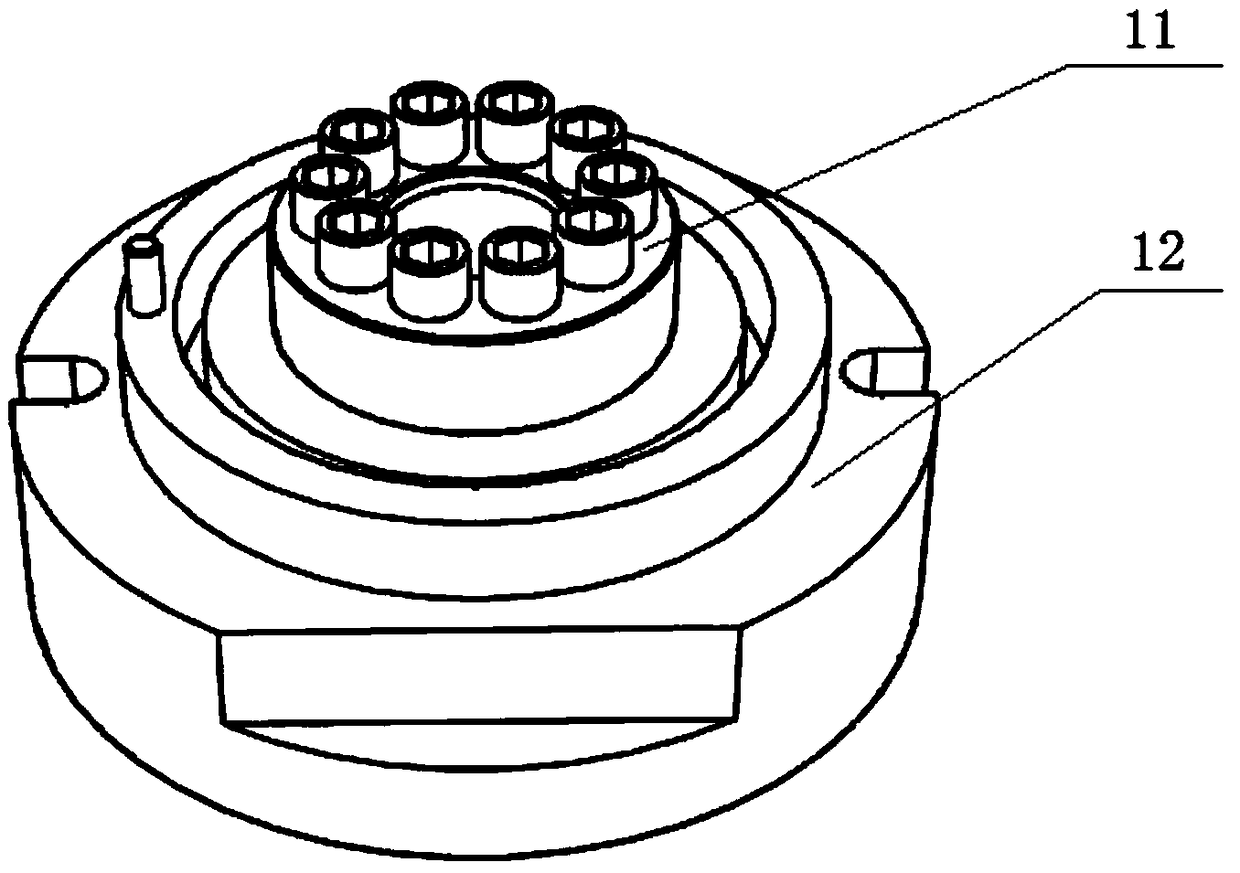

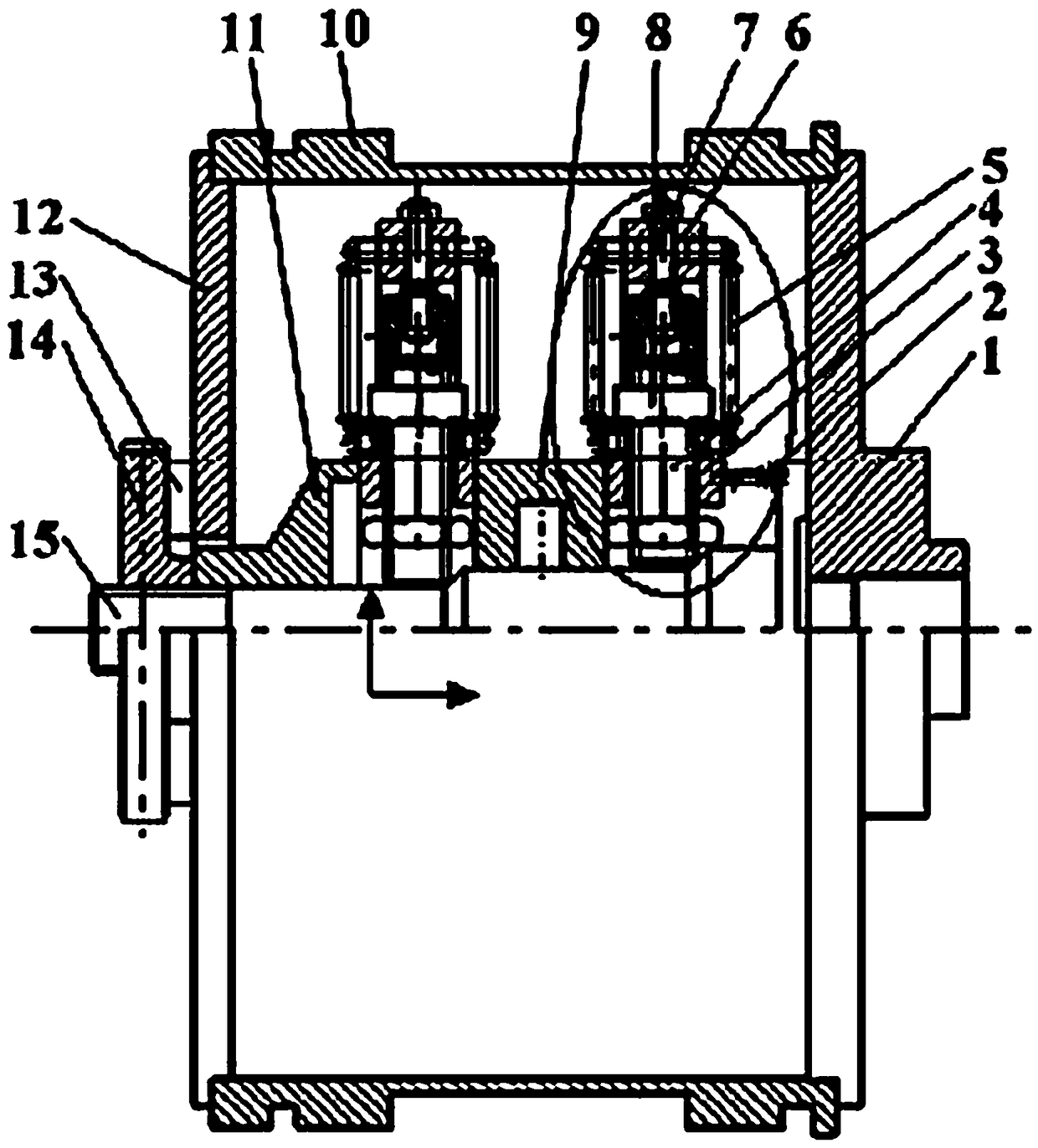

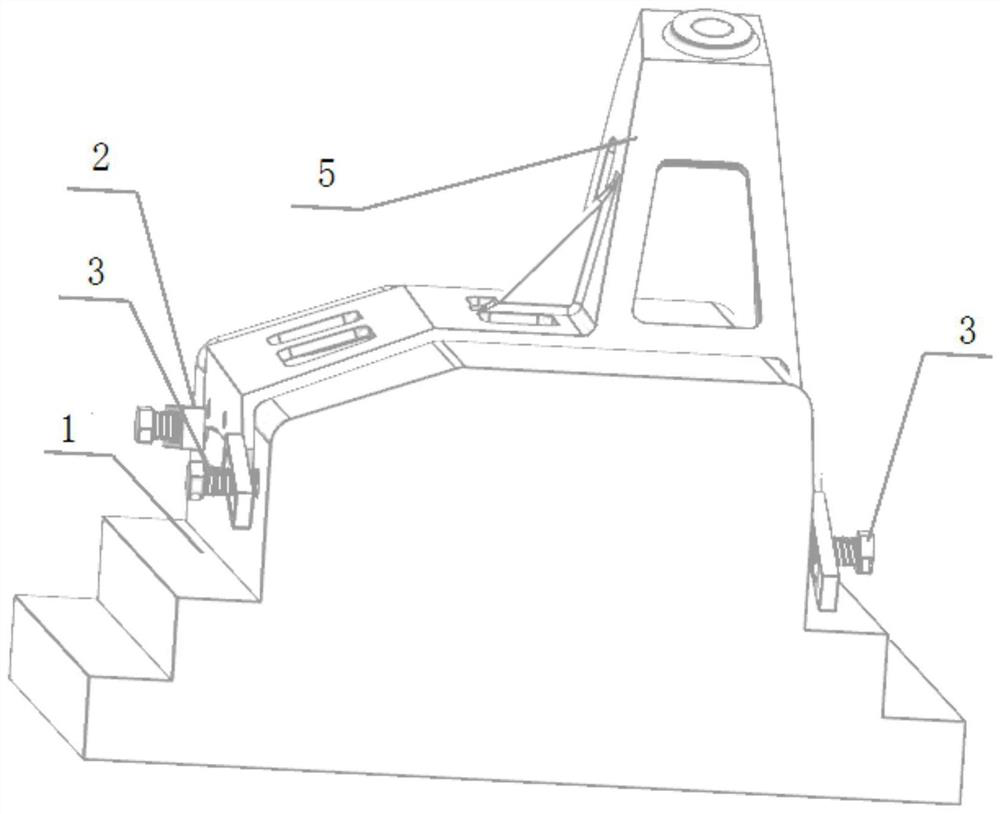

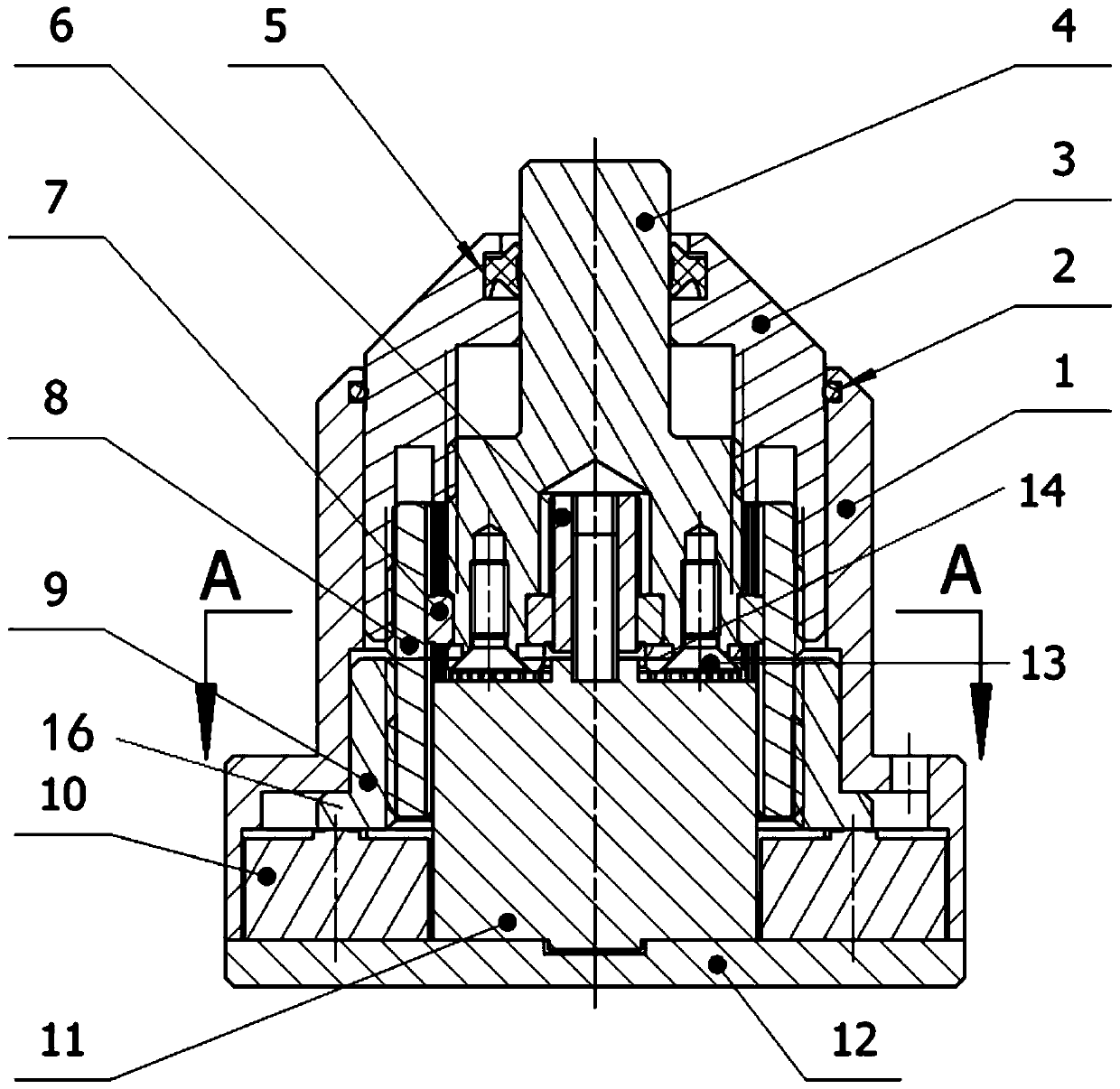

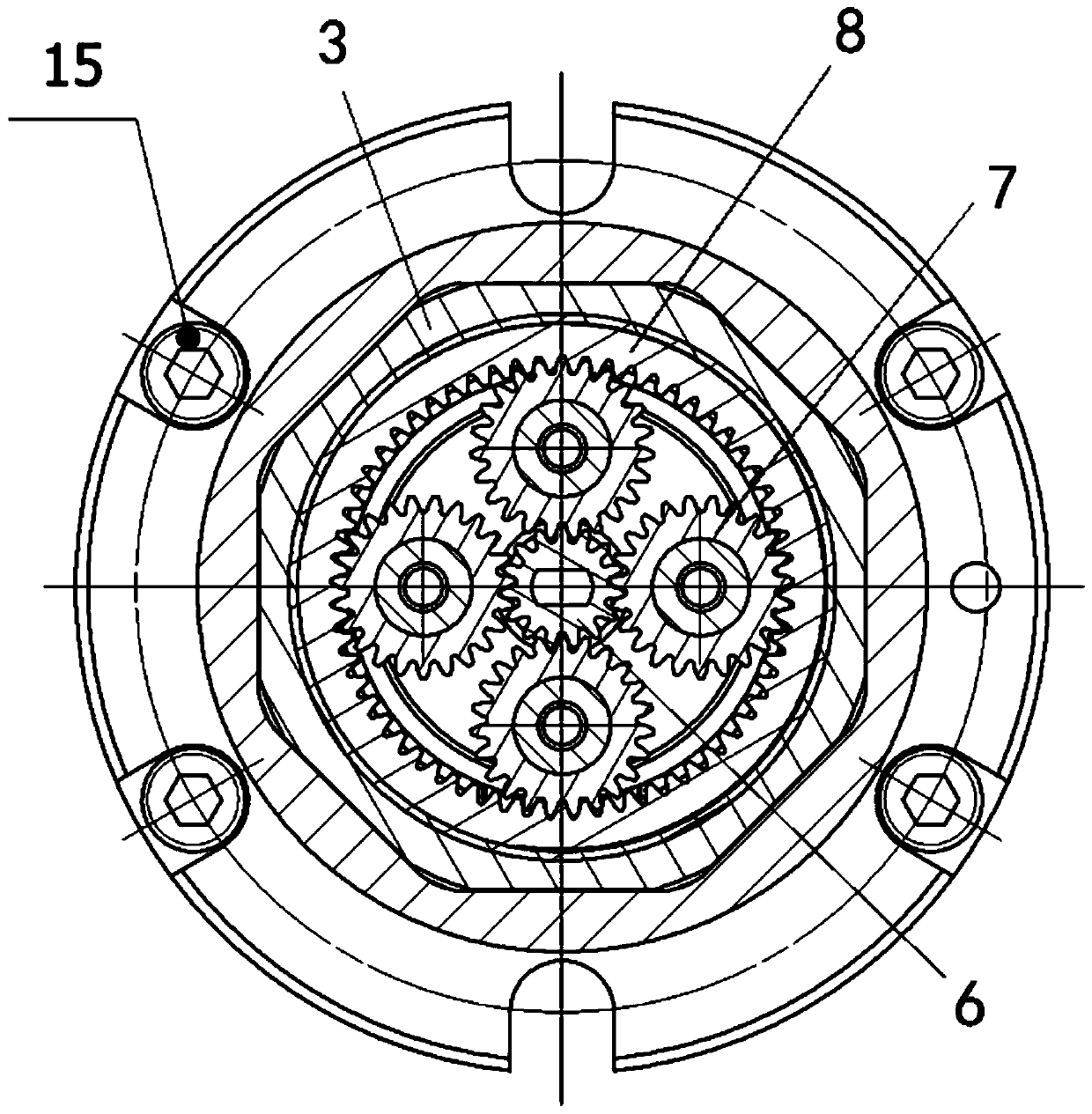

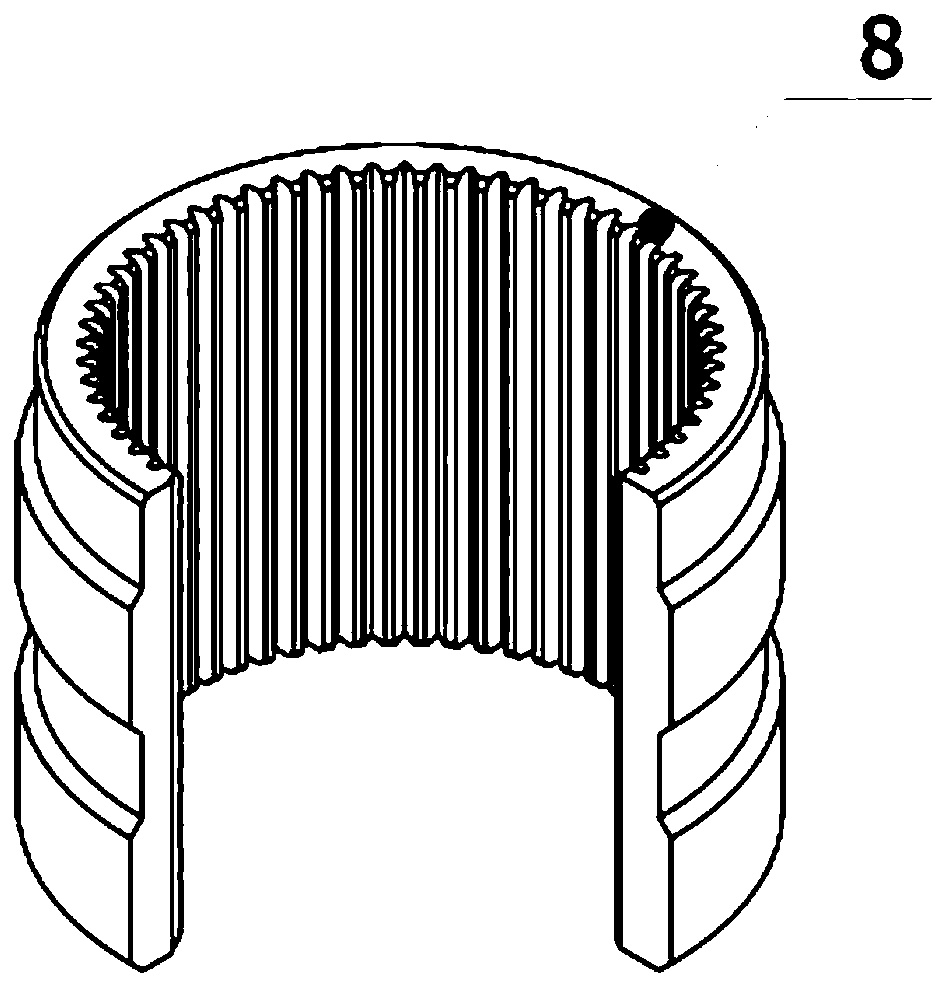

Planet differential type automatic moment varying electric control device

ActiveCN110701270AWide range of applicationsReduce clamping deformationGearingWork holdersPhysicsElectric machinery

The invention relates to a planet differential type automatic moment varying electric control device. The planet differential type automatic moment varying electric control device solves the problemsthat an existing automobile part automatic frock clamp is complex in structure, and inconvenient to maintain or replace later. The planet differential type automatic moment varying electric control device comprises a fixing bottom seat, a micro motor, a planet wheel assembly, a thread differential motion assembly and a pressure sensor, wherein the planet wheel assembly comprises a sun wheel, an axle type planet carrier and planet wheels, the thread differential motion assembly comprises a top cover, a differential thread sleeve and a differential thread inner gear ring, the sun wheel is connected with an output shaft of the micro motor, the planet wheels are arranged in the peripheral direction of the sun wheel, and respectively engaged with the sun wheel and the differential thread innergear ring, inner teeth of the differential thread inner gear ring are engaged with the planet wheels, an external thread at the top end of the differential thread inner gear ring is engaged with the top cover arranged on the periphery of the differential thread inner gear ring and the axle type planet carrier, an external thread at the bottom end of the differential thread inner gear ring is engaged with the differential thread sleeve, the axle type planet carrier is connected with the top cover through a thread, the top end of the axle type planet carrier stretches out of the top cover, and the pressure sensor is arranged at the bottom end of the differential thread sleeve.

Owner:BAOJI FAST GEAR

A magnetic clamp adopting cladding clamping

ActiveCN110732905BImprove clamping work efficiencyImprove efficiencyPositioning apparatusMetal-working holdersElectric machineSteel ball

Owner:荆门禾硕精密机械有限公司

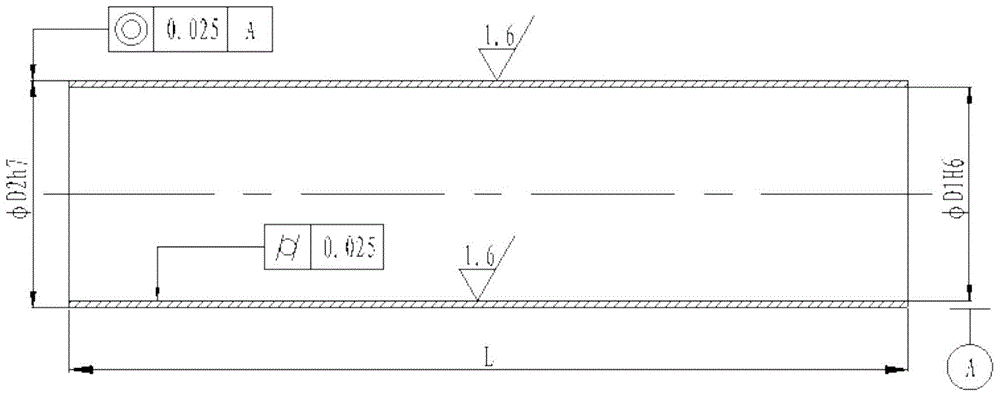

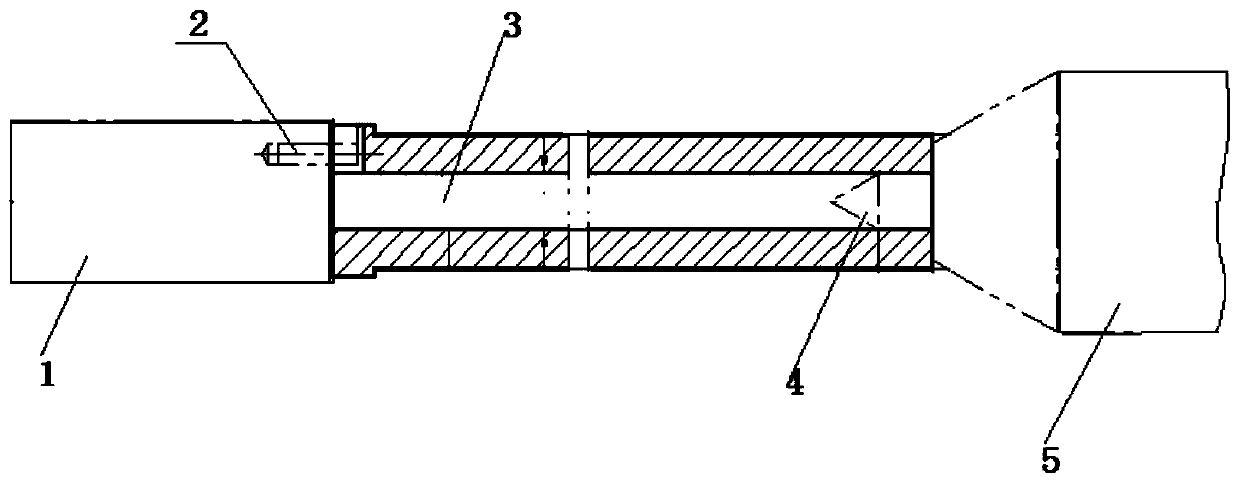

Lathe fixture used for machining ensuring for hard-pipe slender shaft parts

PendingCN110385597AAvoid Inner Hole StrainReduce clamping deformationTailstocks/centresPositioning apparatusEngineeringMechanical engineering

The invention discloses a lathe fixture used for machining ensuring for hard-pipe slender shaft parts. The lathe fixture used for machining ensuring for the hard-pipe slender shaft parts comprises a fixed tip and a movable tip, wherein the fixed tip comprises a fixed main shaft clamping part, a fixed part location clamping part and a part transmission pin, wherein the fixed part location clampingpart is arranged at the front end of the fixed main shaft clamping part; one end of the part transmission pin is arranged at the front end of the fixed main shaft clamping part; the movable tip comprises a standard movable tip and a movable part location clamping part; and the movable part location clamping part is arranged at the front end of the standard movable tip. The lathe fixture used for machining ensuring for the hard-pipe slender shaft parts is capable of avoiding pull damage to inner holes of the hard-pipe slender shaft parts well, so that the clamping deformation of the parts is reduced, and the purpose of machining ensuring with coaxiality (Phi0.05) is solved well, and the pass percent is 100%; and in addition, the lathe fixture used for machining ensuring for the hard-pipe slender shaft parts has the characteristics of being rapid to clamp and detach, and free from damage to the location inner holes, and the machining efficiency is increased by more than four times.

Owner:贵州新安航空机械有限责任公司

A clamping device for elastic material radial milling

InactiveCN104259899BMake sure the axes are coaxialIncrease contact areaPositioning apparatusMetal-working holdersInterference fitNumerical control

The invention relates to a clamping device for elastic material radial milling. The clamping device for elastic material radial milling comprises a base body, square plates, pin bolts, a cover plate and nuts, wherein the radial positioning surface of the base body and an inner hole of a part are in interference fit. A numerical control vertical type processing center with a numerical control dividing head is adopted; the base body is mounted on a working table of the numerical control dividing head; the axis of the base body is aligned to be coaxial with the axis of the numerical control dividing head; a part to be processed is mounted on the radial positioning surface of the base body; the part to be processed is fixed by tightly screwing the nut through a suitable force of a torque wrench; square holes of the part are firstly processed into round holes, then each pin bolt is respectively arranged in every each round hole, and the round holes without the pin bolts are processed into square holes to finish the first processing step; the square plates are respectively arranged in the finished square holes, the pin bolts are disassembled, and finally the round holes are processed into square holes to finish the second processing step. The clamping device for elastic material radial milling is low in clamping deformation, reliable in performances and convenient to assemble and disassemble, improves milling efficiency, and is suitable for radial milling of the elastic materials which are difficult in clamping and produced in batches.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

A hydraulically controlled gear transmission fixture

ActiveCN105290852BGuaranteed machining accuracyHigh positioning accuracyPositioning apparatusMetal-working holdersControl systemCam

The invention discloses a hydraulic control tooth type transmission clamp. The clamp comprises a base; a positioning ring is fixed to the base; an ejecting block is automatically expanded through a hydraulic control system; the hydraulic control system comprises a basic double-action cylinder, a first pulley and a cam; a piston of the basic double-action cylinder pushes a supporting block; the supporting block pushes the first pulley to drive the cam to rotate; a notch of the cam is connected with a second pulley in an abutting manner; and the second pulley is connected with a rotating shaft on the ejecting block through a shaft. The clamp further comprises linear pressing plate oil cylinders uniformly distributed along the circumference of a workpiece; oil inlet and outlet pipe pressing plate oil cylinder pressing oil pipes and pressing plate releasing oil pipes of the linear pressing plate oil cylinders are installed at the bottom of the base; and energy accumulators for pressure compensation are installed on the oil inlet and outlet pipe pressing plate oil cylinder pressing oil pipes, and the part pressing process is completed through pressure adjustment. The hydraulic control tooth type transmission clamp has the beneficial effects that a hydraulic control tool is adopted to guarantee gapless positioning of a part, the positioning precision of the part is improved, a hydraulic clamping mechanism can guarantee that the pressing force of the part is uniform, clamping deformation of the part is reduced, and the machining precision of the part is ensured.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Disc type thin-walled parts milling device

ActiveCN103567513BReduce processing deformationImprove machined surface qualityMilling equipment detailsEngineeringMechanical engineering

The invention relates to a milling and clamping device for disc type thin-wall parts. The milling and clamping device comprises a base body, a back hat and two screws, wherein one end of the base body is in threaded connection with the back hat, and the screws are screwed into two threaded holes of the back hat to abut on the base body. The milling and clamping device has the advantages of small clamping deformation, reliable performance, low cost, convenient in assembly and disassembly, increases the milling efficiency, and is suitable for difficult-clamping and mass-produced the disc type thin-wall parts.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Variable-diameter thin-wall plastic inner container vacuum adsorption clamp

PendingCN113370109AAvoid plastic deformationReduce manufacturing costWork holdersHydraulic cylinderCircular disc

The invention provides a variable-diameter thin-wall plastic inner container vacuum adsorption clamp. The requirements for clamping position precision and roundness during secondary machining of a thin-wall plastic inner container are considered, and the clamping precision is improved while the roundness of the inner container is guaranteed. The vacuum adsorption clamp is mainly characterized in that three vacuum adsorption V-shaped blocks which are evenly arranged on the circumference are installed on three synchronous hydraulic cylinders, and small adsorption discs are evenly arranged on the three vacuum adsorption V-shaped blocks. For thin-wall plastic inner containers with different diameters, when the synchronous hydraulic cylinders move and the vacuum adsorption V-shaped blocks are clamped, the two groups of small adsorption discs on each vacuum adsorption V-shaped block are always tightly attached to the outer wall of the inner container; and meanwhile, the other small adsorption discs which are not attached are closed. The small adsorption discs share one vacuum pipeline, after vacuumizing of a vacuum pump, adsorption force is evenly distributed on each small disc, and due to the fact that the vacuum adsorption V-shaped blocks are evenly distributed in the circumferential direction, the adsorption force of the discs is offset, and clamping deformation caused by uneven clamping force to the inner container is avoided.

Owner:BEIJING UNIV OF CHEM TECH

Magnetic fixture adopting coating clamping

ActiveCN110732905AImprove clamping work efficiencyImprove efficiencyPositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a magnetic fixture adopting coating clamping. The magnetic fixture comprises a bottom-closed outer cover cylinder, a workpiece tray, a steel ball accommodating tank, a ring separation plate, a first electromagnet, an electromagnetic oscillator, a steel ball circulating pump, a pump driving motor and a supply pipe; the outer cover cylinder is provided with an inner cylinderedge; the first electromagnet is fixed at the middle part of the steel ball accommodating tank through a magnet protective cover; the workpiece tray is fixed on the magnet protective cover; reflux holes are formed in the bottom of the workpiece tray at intervals; dispersion holes are formed in the upper end of the ring wall of the workpiece tray at intervals; a control valve is arranged on the outer wall of the workpiece tray; an annular dispersion cavity is formed among the ring separation plate, the outer wall of the workpiece tray, the inner wall of the outer cover cylinder and the inner cylinder edge; the dispersion holes communicate with the dispersion cavity; one end of the supply pipe communicates with the steel ball circulating pump; and the other end of the supply pipe communicates with the dispersion cavity. The magnetic fixture can adapt to magnetic workpieces and nonmagnetic workpieces, so that the application range is greatly widened, and the clamping work efficiency is improved.

Owner:荆门禾硕精密机械有限公司

A reverse-pull fixture device for processing thin-walled gearbox casings

ActiveCN113290401BReduce clamping deformationGuaranteed machining accuracyWork clamping meansPositioning apparatusHydraulic cylinderSteel ball

Owner:ZHEJIANG ZHONGCHAI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com