Disc type thin-walled parts milling device

A thin-walled part and disc-type technology, applied in the field of mechanical processing, can solve the problems of affecting the quality of the processed surface, unstable processing process, and aggravated processing deformation, so as to improve milling efficiency, improve the quality of processed surface, and small clamping deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

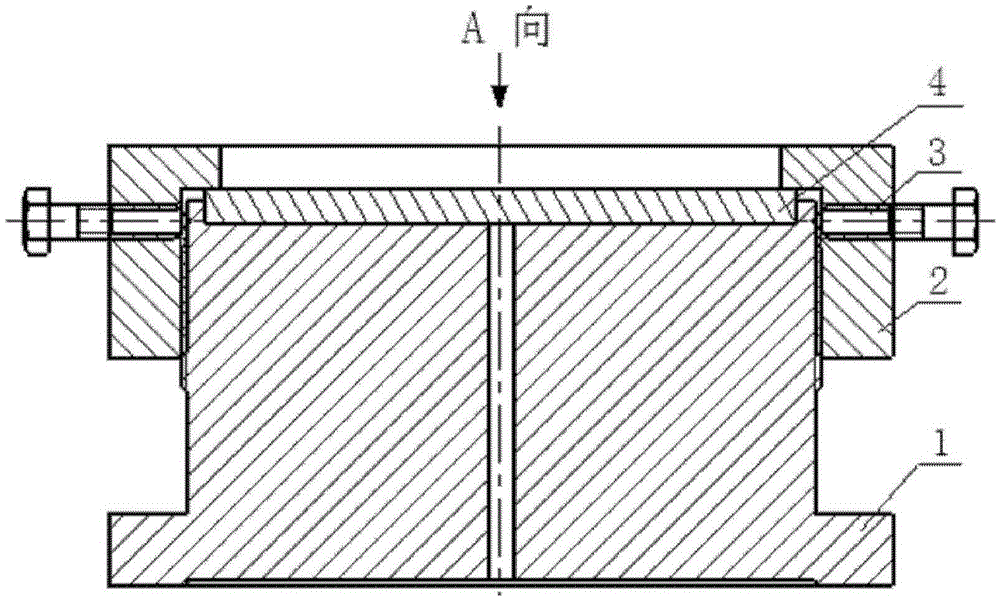

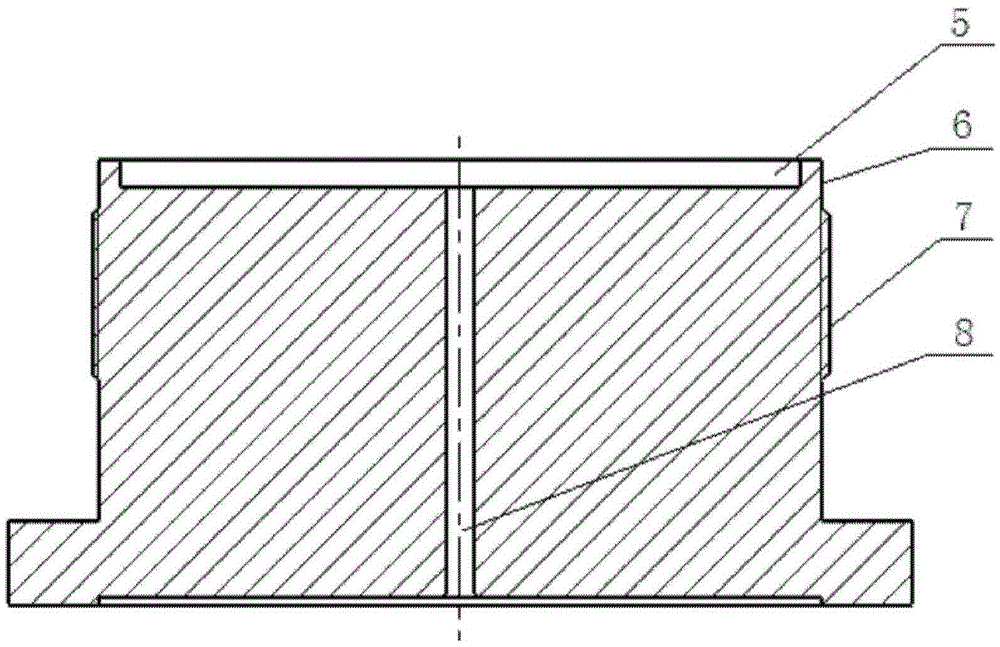

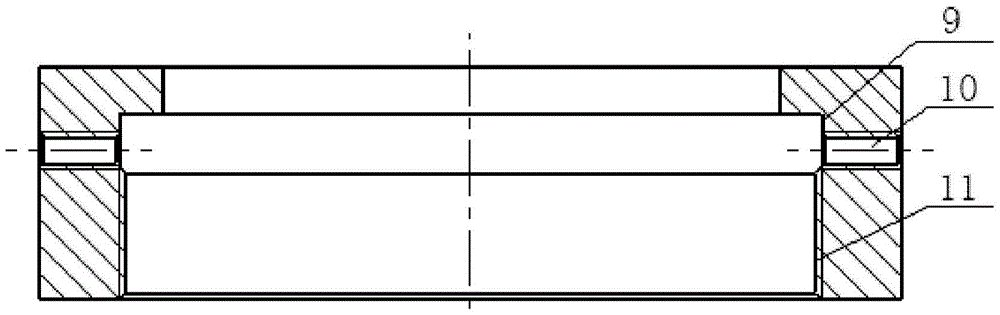

[0022] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended Figure 1 to Figure 4 Shown, the specific embodiment of the present invention will be further described.

[0023] Such as figure 1 As shown, the disc-type thin-walled part milling device of the present invention includes: a base 1 , a back cap 2 , and two screws 3 . The base 1 is provided with an external thread 7 with a pitch of 1.5 mm, and the back cap 2 is provided with an internal thread 11 with a pitch of 1.5 mm, and the external thread 7 of the base 1 is threadedly connected with the internal thread 11 of the back cap 2, and the back cap 2 is provided with an internal thread 11 with a pitch of 1.5 mm. The cap 2 presses the part 4 to be processed. The screw 3 is screwed into the two threaded holes 10 on the back cap 2, and the screw tightening surface 6 is tightened against the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com