Lathe fixture used for machining ensuring for hard-pipe slender shaft parts

A technology for parts processing and lathe fixtures, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy strain, parts clamping, disassembly difficulties, hard pipe threaded inner hole accuracy and coaxiality up to To avoid problems such as requirements, to avoid strain, improve processing efficiency, and quickly disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

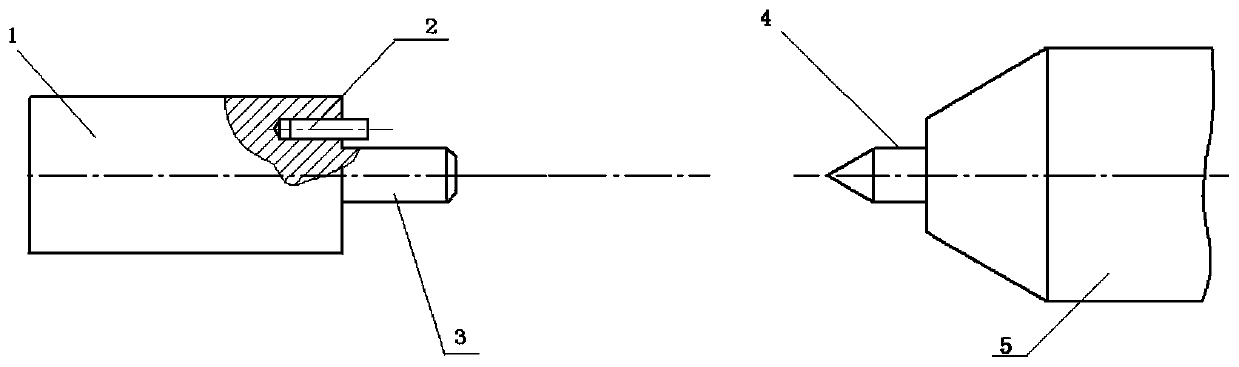

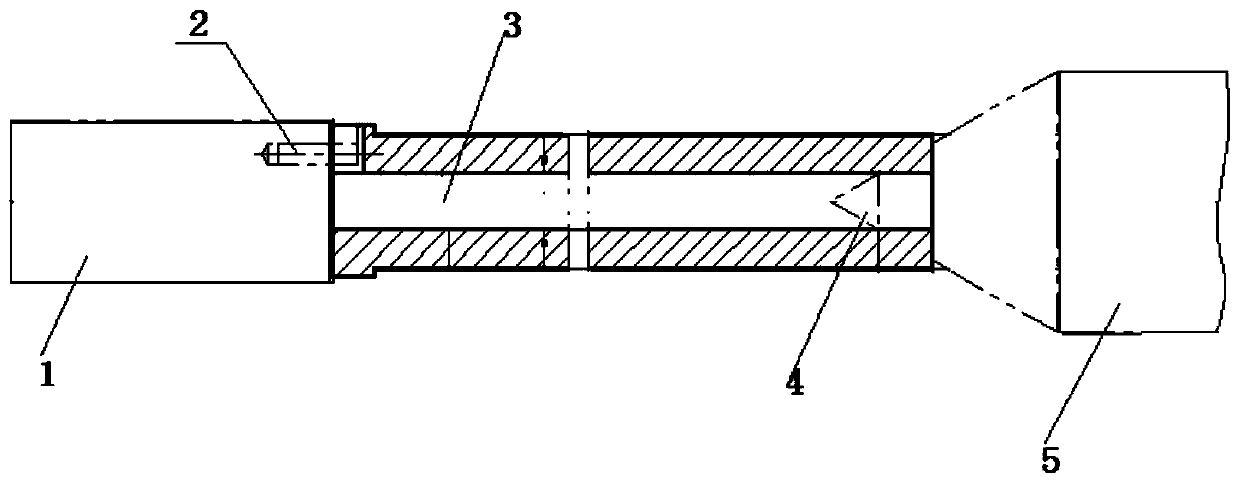

[0015] The present invention will be further introduced below in conjunction with the accompanying drawings. A lathe fixture used for the processing of hard tube slender shaft parts according to the present invention includes a fixed center and a live center. The fixed center includes a fixed spindle for clamping Part 1, fixed part positioning and clamping part 3 and part transmission pin 2, during processing, part transmission pin 2 drives the part to rotate (open slot is designed at the end of the part, which will be cut off in the subsequent process), eliminating the rotation caused by cutting during processing Part deformation caused by increasing the axial pressure of the part, the fixed part positioning and clamping part 3 is arranged at the front end of the fixed spindle clamping part 1, and one end of the part transmission pin 2 is movably arranged at the fixed spindle clamping part 1 At the front end, the movable tip includes a standard movable tip 4 and a movable part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com