A reverse-pull fixture device for processing thin-walled gearbox casings

A fixture device and gearbox technology, which is applied to clamping devices, manufacturing tools, positioning devices, etc., can solve problems such as easy deformation, clamping workpiece deformation, and no clamping position, so as to increase processing convenience and reduce clamping Deformation, the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

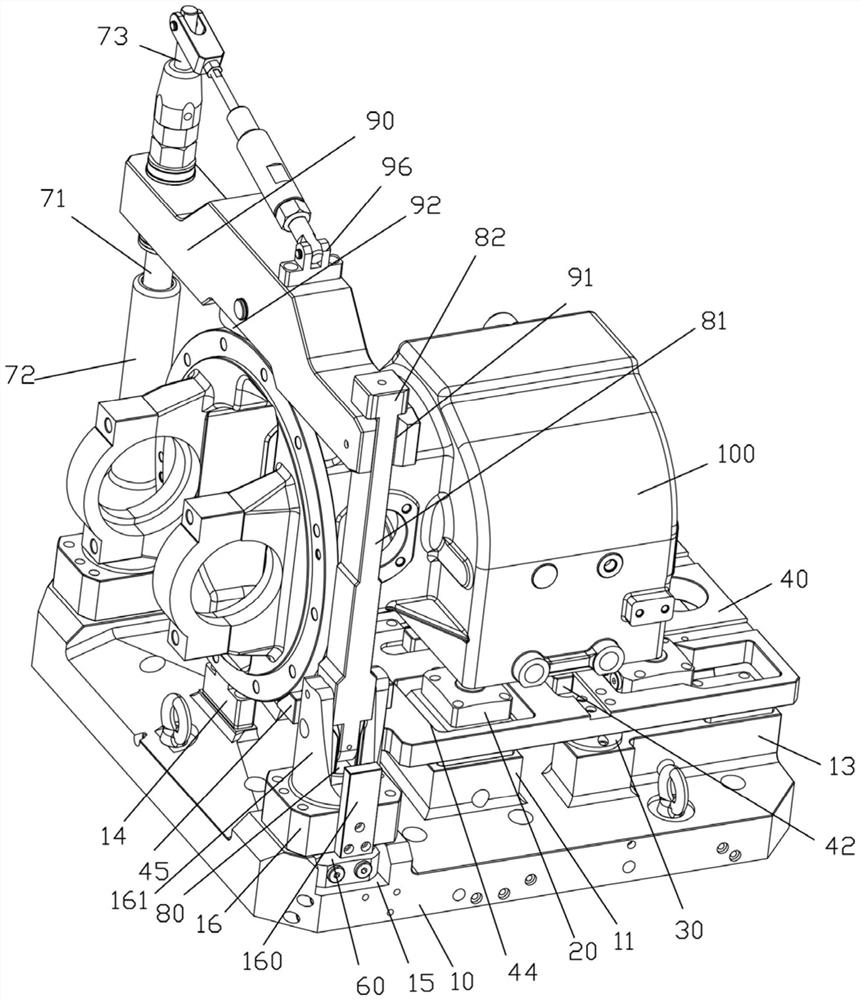

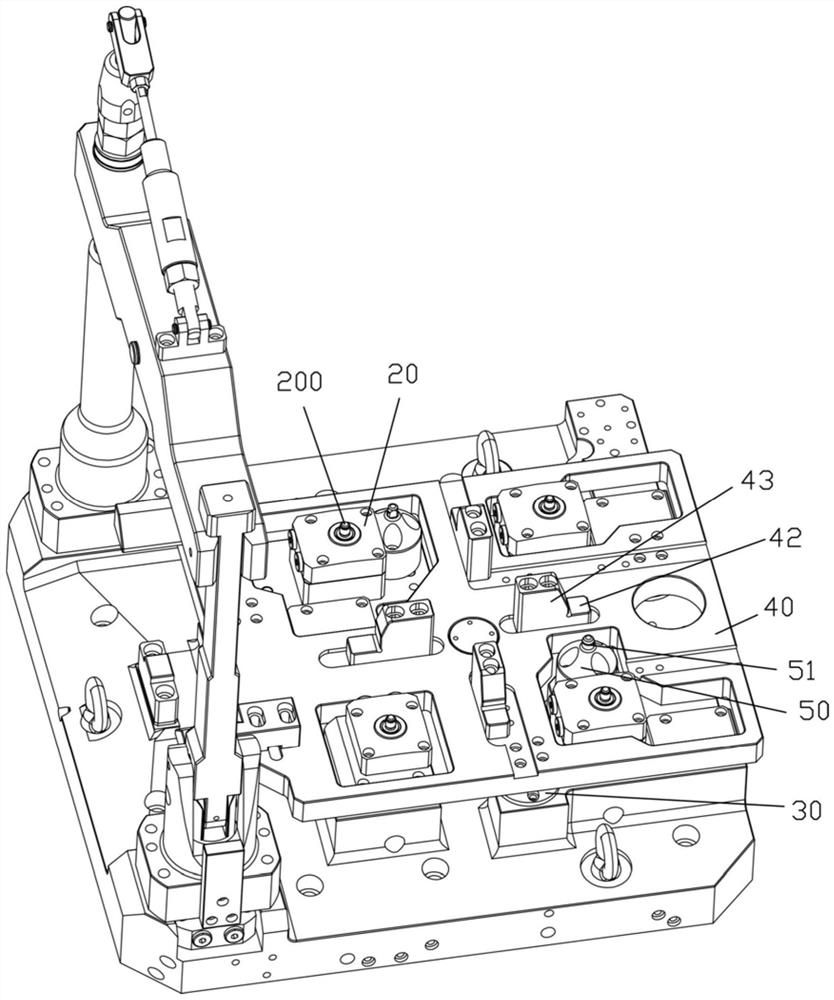

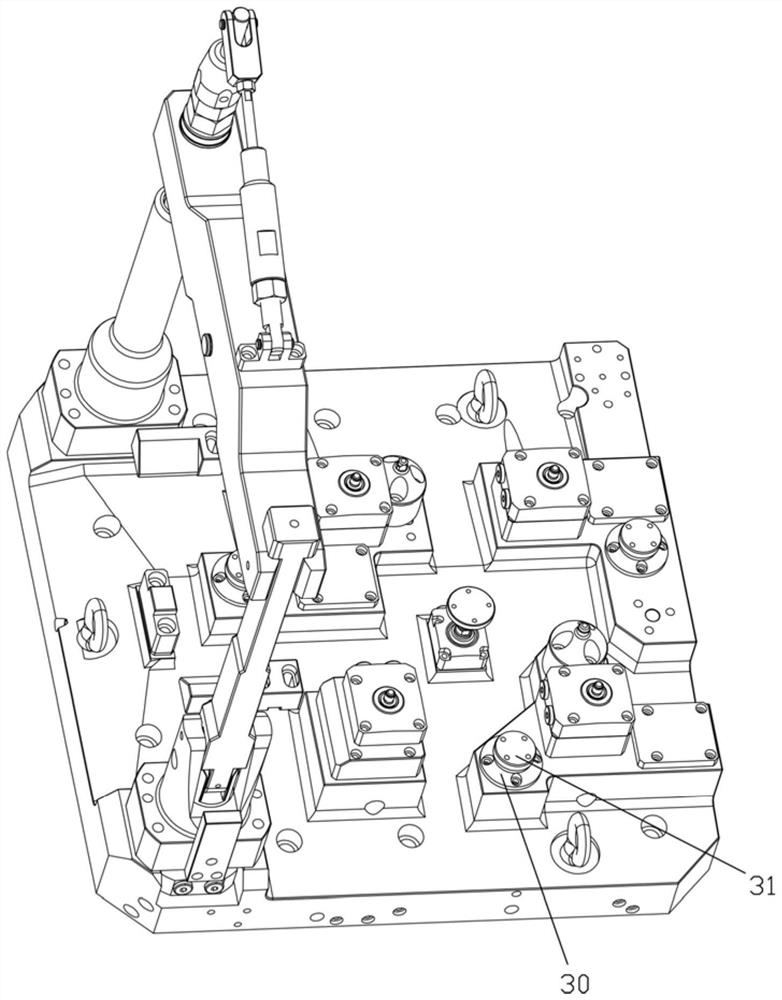

[0027] Examples, see as Figure 1 to Figure 8 As shown, a reverse-pull clamp device for processing a thin-walled gearbox case includes a fixed installation base plate 10, and at least four steel ball locking hydraulic cylinders 20 are installed on the top surface of the fixed installation base plate 10. Connection screw holes 101 are formed on the bottom surfaces of the four side plates of the thin-walled gearbox case 100 , the top screw joints of the traction bolts 200 are screwed into the corresponding connection screw holes 101 , and the bottom of the traction bolts 200 Insert the corresponding steel ball locking hydraulic cylinder 20 into the hole in the middle of the top end, and the steel ball inserted inside the hole of the steel ball locking hydraulic cylinder slot 201.

[0028] Further, a plurality of lifting cylinders 30 are installed on the top surface of the fixed installation base plate 10 , a push fixing plate 31 is fixed on the top of the push rod of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com