Variable-diameter thin-wall plastic inner container vacuum adsorption clamp

A technology of vacuum adsorption and variable diameter, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as unevenness, clamping deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

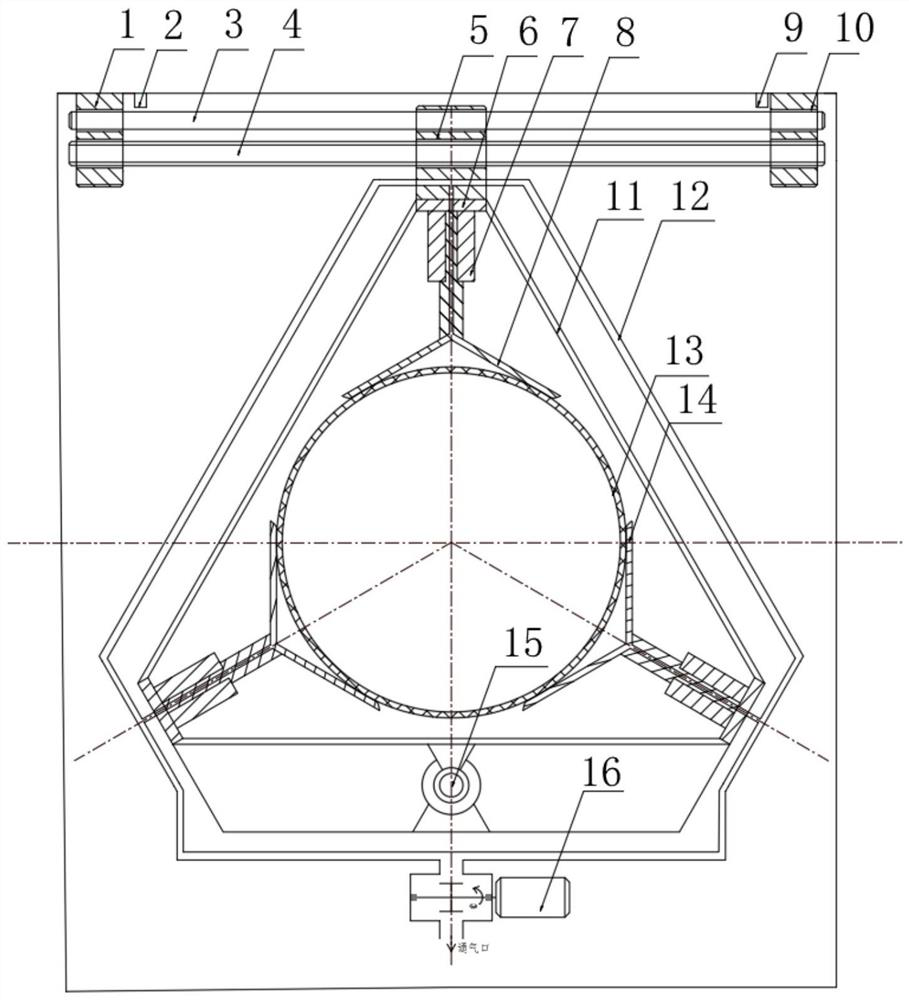

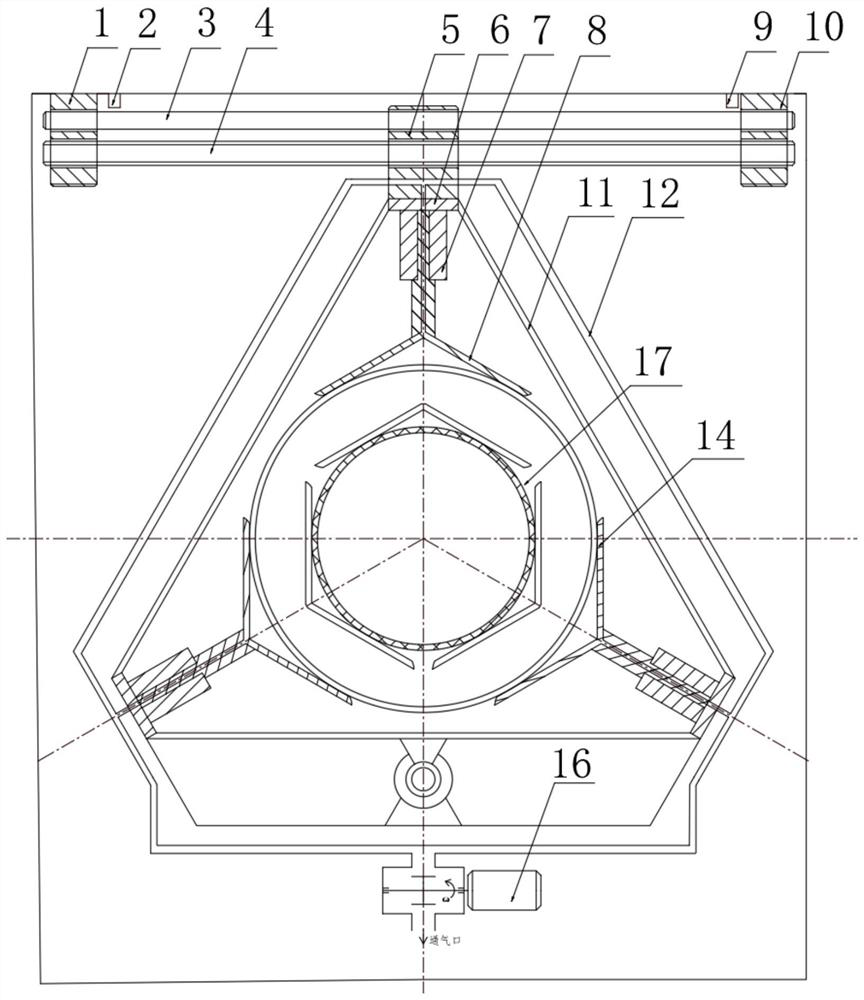

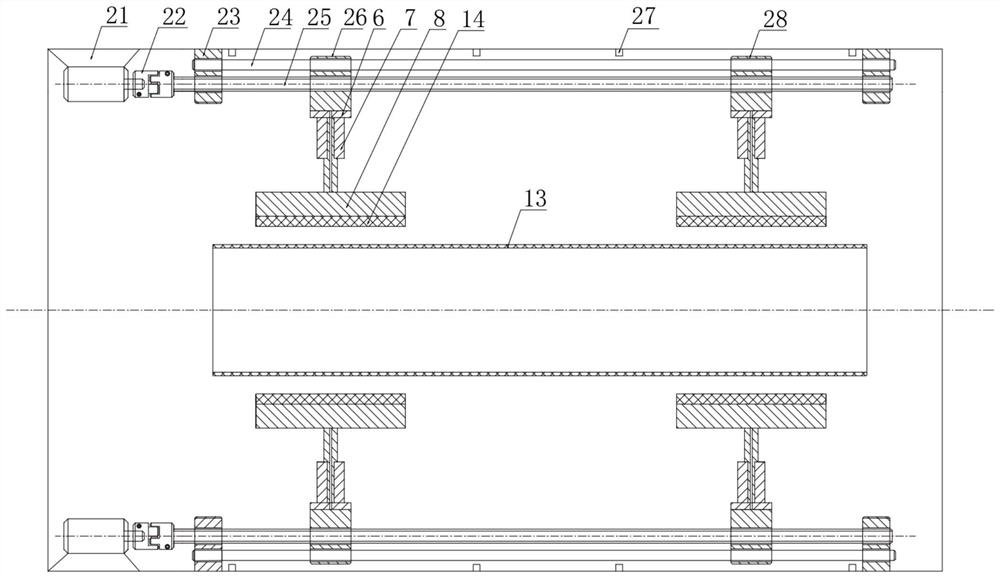

[0028] The variable-diameter thin-walled plastic liner vacuum adsorption fixture of the present invention, such as figure 1 and figure 2 As shown, the main features of the structure are: three vacuum adsorption V-shaped blocks 8 are arranged in a 120° circumferential direction. The adsorption small discs 14 are evenly distributed on the three vacuum adsorption V-shaped blocks 8, the three vacuum adsorption V-shaped blocks 8 move toward the center of the inner tank 13, the adsorption small disks 14 are tangent to the outer wall of the inner tank 13, and the vacuum adsorption V-shaped blocks are 8 Continue to move until the adsorption small disc 14 is closely attached to the outer wall of the inner tank 13. At this time, the vacuum adsorption V-shaped block 8 stops moving. 13 is tightly adsorbed on the vacuum adsorption V-shaped block 8, so that it is subjected to the clamping force of the evenly distributed load, and the clamping of the inner tank 13 is completed.

[0029]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com