Wear-proof casing clamp with adjustable external diameter

An adjustable and wear-resistant sleeve technology, applied in the direction of grinding workpiece supports, can solve the problems of easy deformation of clamping, reduced work efficiency, strain on the inner hole of the workpiece, etc., and achieves improved clamping efficiency, simple and reasonable structure, and convenience. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

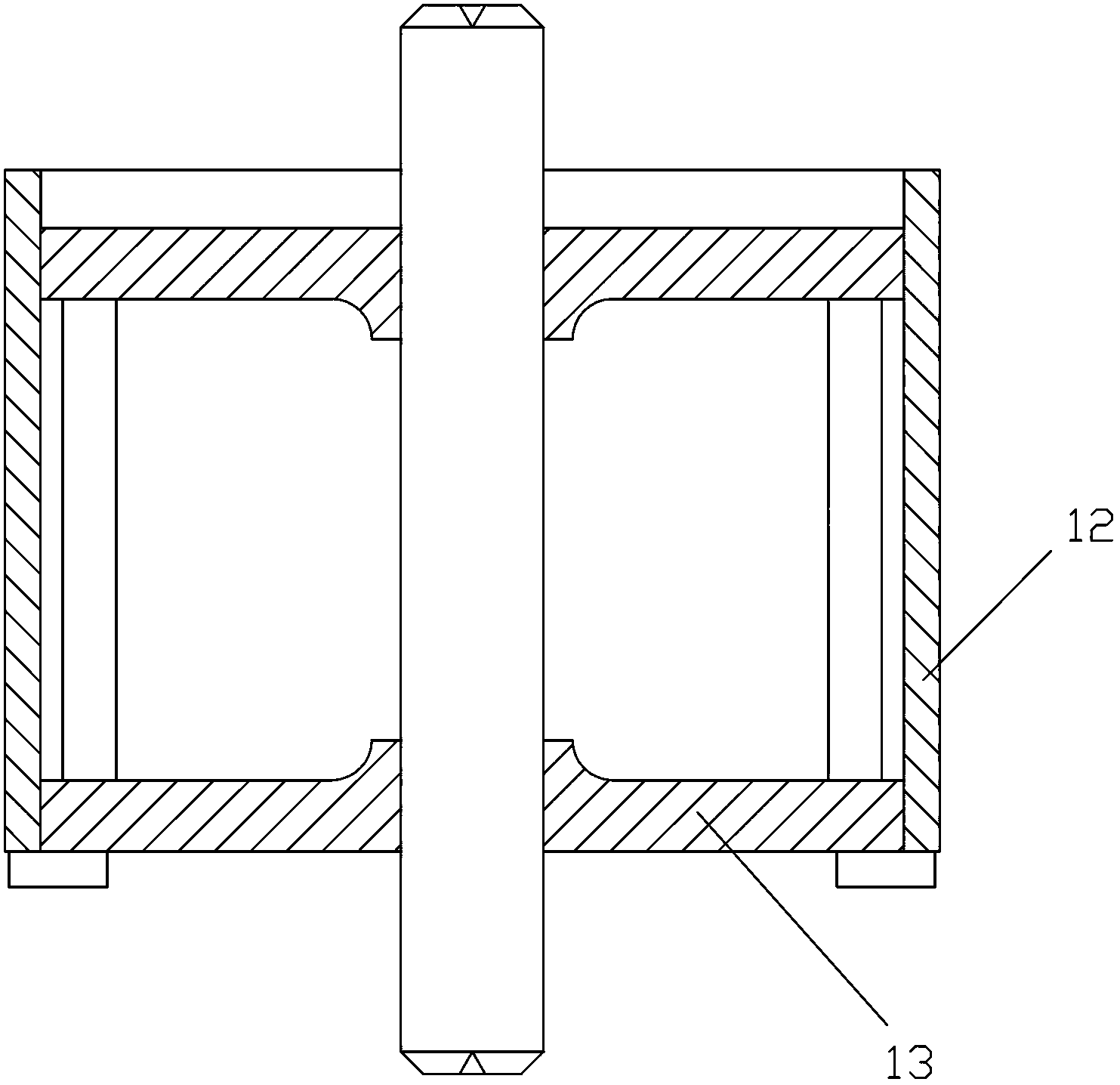

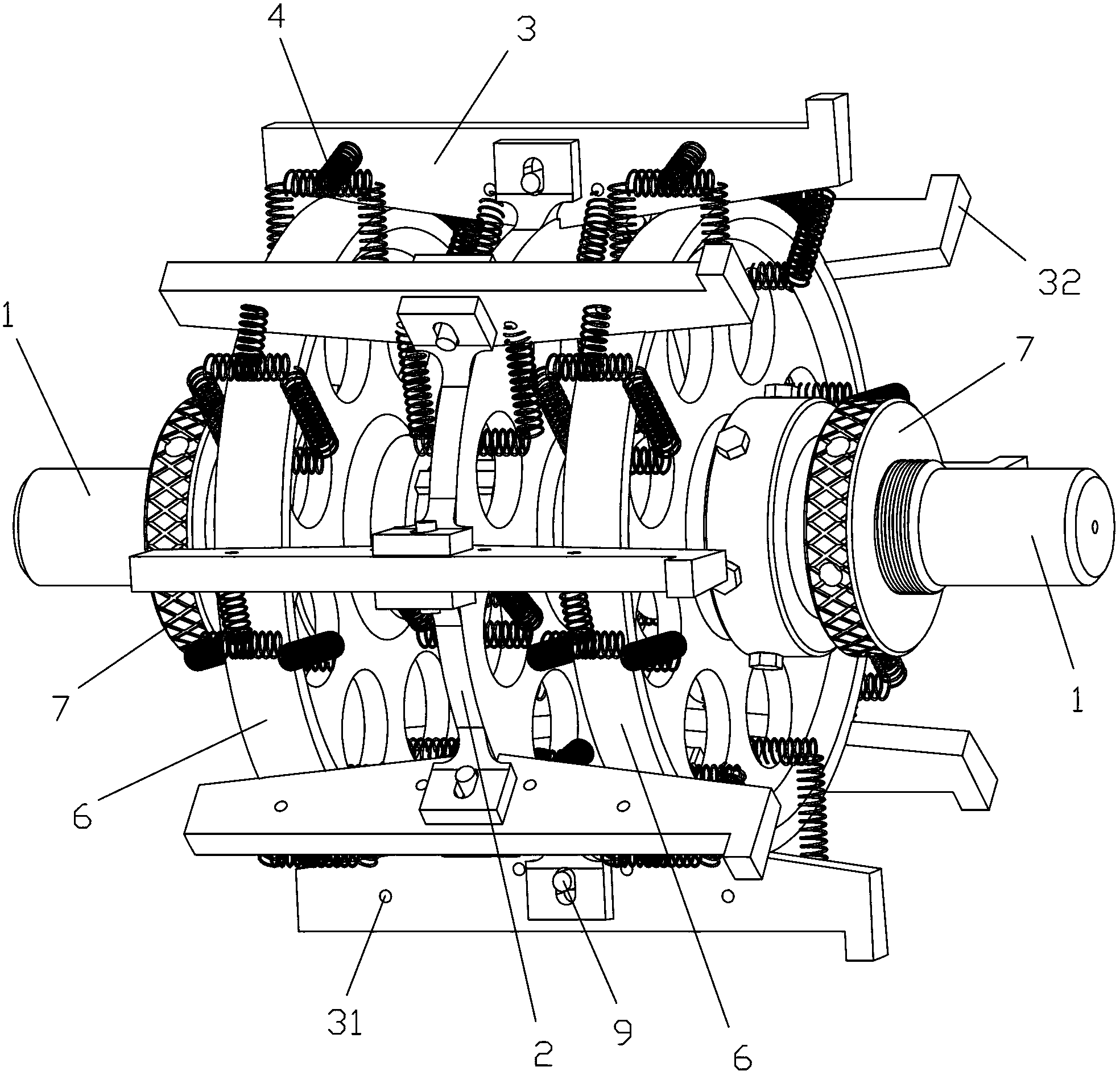

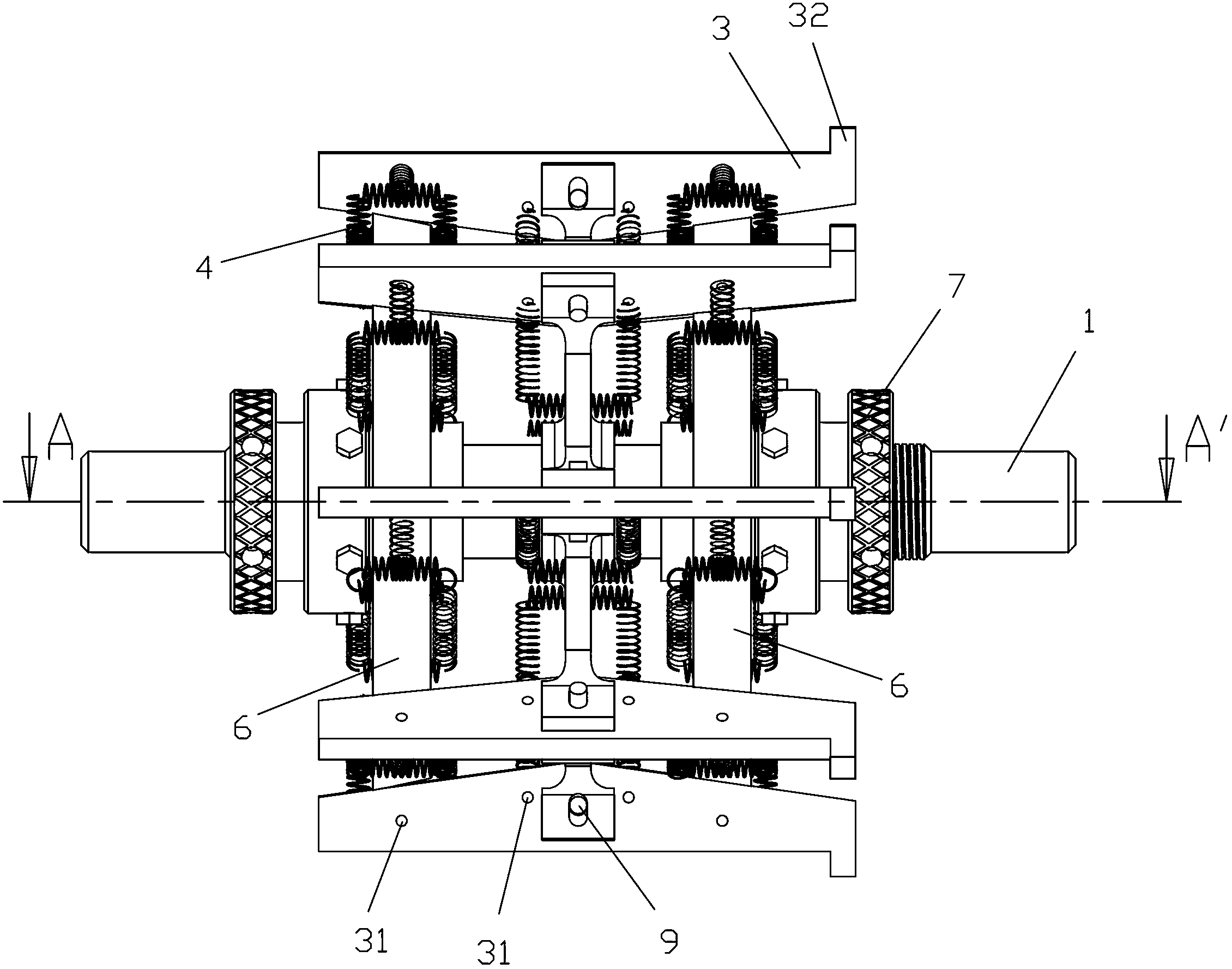

[0023] refer to Figure 2~Figure 8 , a wear-resistant sleeve fixture with adjustable outer diameter of the present invention, which includes a mandrel 1 matched with the top of the machine tool, and a central hole with a protective cone is reserved on the end face of the mandrel 1, and the central hole is used for connecting with the machine tool. The center part of the mandrel 1 is fixedly installed with a support frame 2, and the support frame 2 is fixedly installed on the mandrel 1 through a transition fit through the difference between the assembly hole on the support frame 2 and the tolerance level of the mandrel 1. Of course, The support frame 2 can be fixed on the mandrel 1 through oblique keys or pins. Compared with the fixed installation method of oblique keys or pins, the use of transition fit to fix the support frame 2 on the mandrel 1 will not affect the strength of the mandrel 1. It is greatly weakened; the outer peripheral surface of the support frame 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com