Special processing device of injection machine moulding board

A technology for processing devices and injection molding machines, applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of uneven force on the template, low efficiency, easy loosening, etc., to reduce clamping deformation and ensure The effect of locking strength and increasing the swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

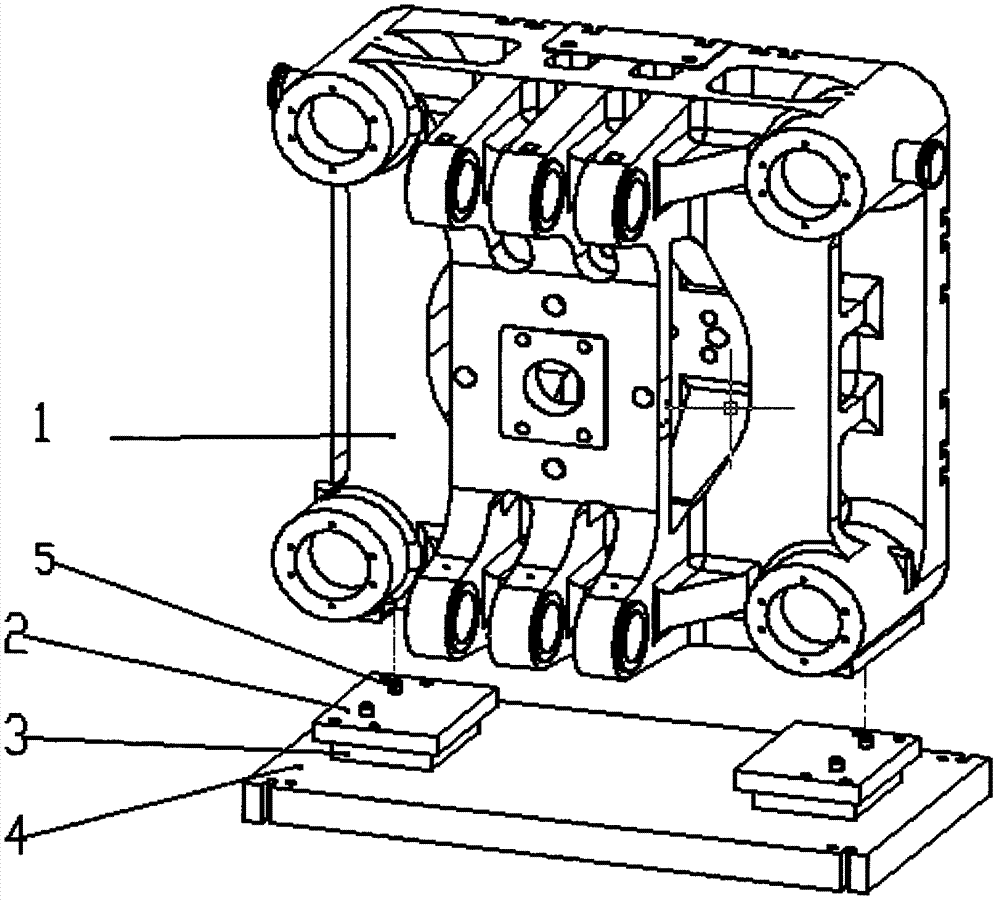

[0011] like figure 1 Shown, a kind of special processing device of injection molding machine formwork, it comprises injection molding machine formwork (1), top plate (2), transition plate (3), base plate (4), positioning pin (5); Described base plate (4 ) is welded with the transition plate (3), the base plate (4) is locked on the machine table, the top plate (2) is welded with the transition plate (3), and the positioning pin (5) passes through The positioning pin holes on the top plate (2) are matched and fixed together, the injection molding machine template (1) is closely attached to the top plate (2) through the positioning pins (5), and the injection molding machine template (1) and the top plate ( 2) Completely fixed by locking bolts.

[0012] Action principle:

[0013] Put the special processing device on the working table of the machine tool to straighten and flatten it, and fix it on the working table through bolts. The positioning pins on the top plate can realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com