A system and method for clamping the outer wall of thin-walled cylindrical parts by turning

A thin-walled cylinder and clamping technology, which is applied in the field of machining, can solve the problem that workpieces with various inner diameters cannot be clamped, cannot be adjusted separately for axial clamping force/radial support force, and cannot measure axial clamping force. / Radial support force and other issues, to achieve a wide range of applications, reduce the effect of clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

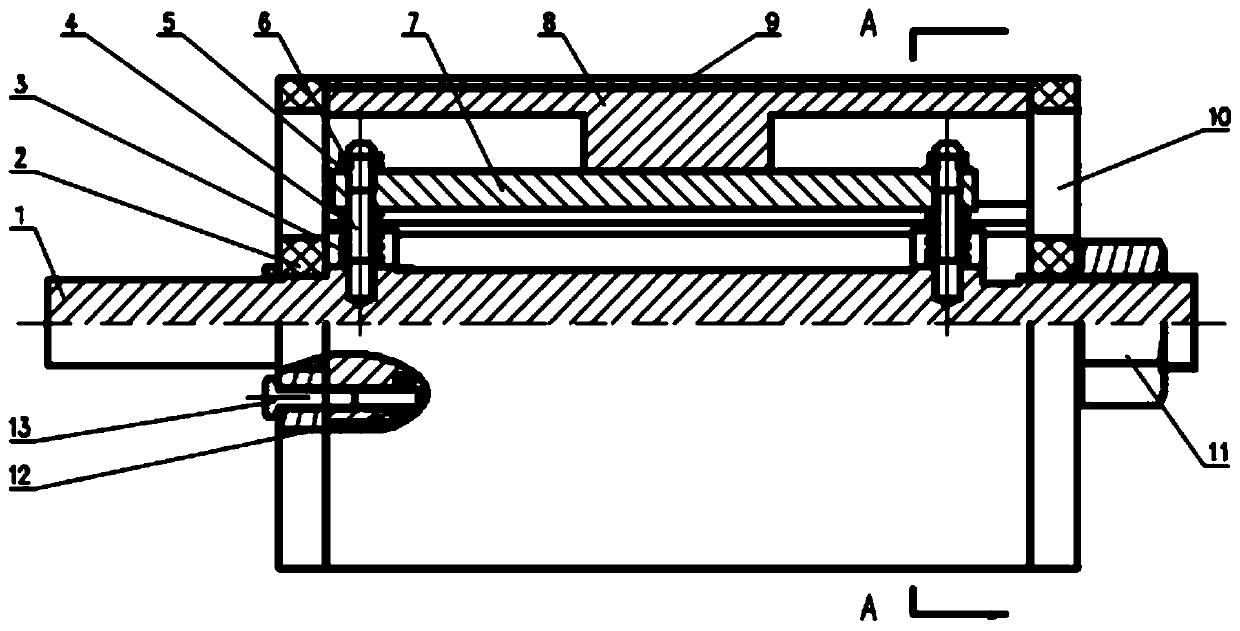

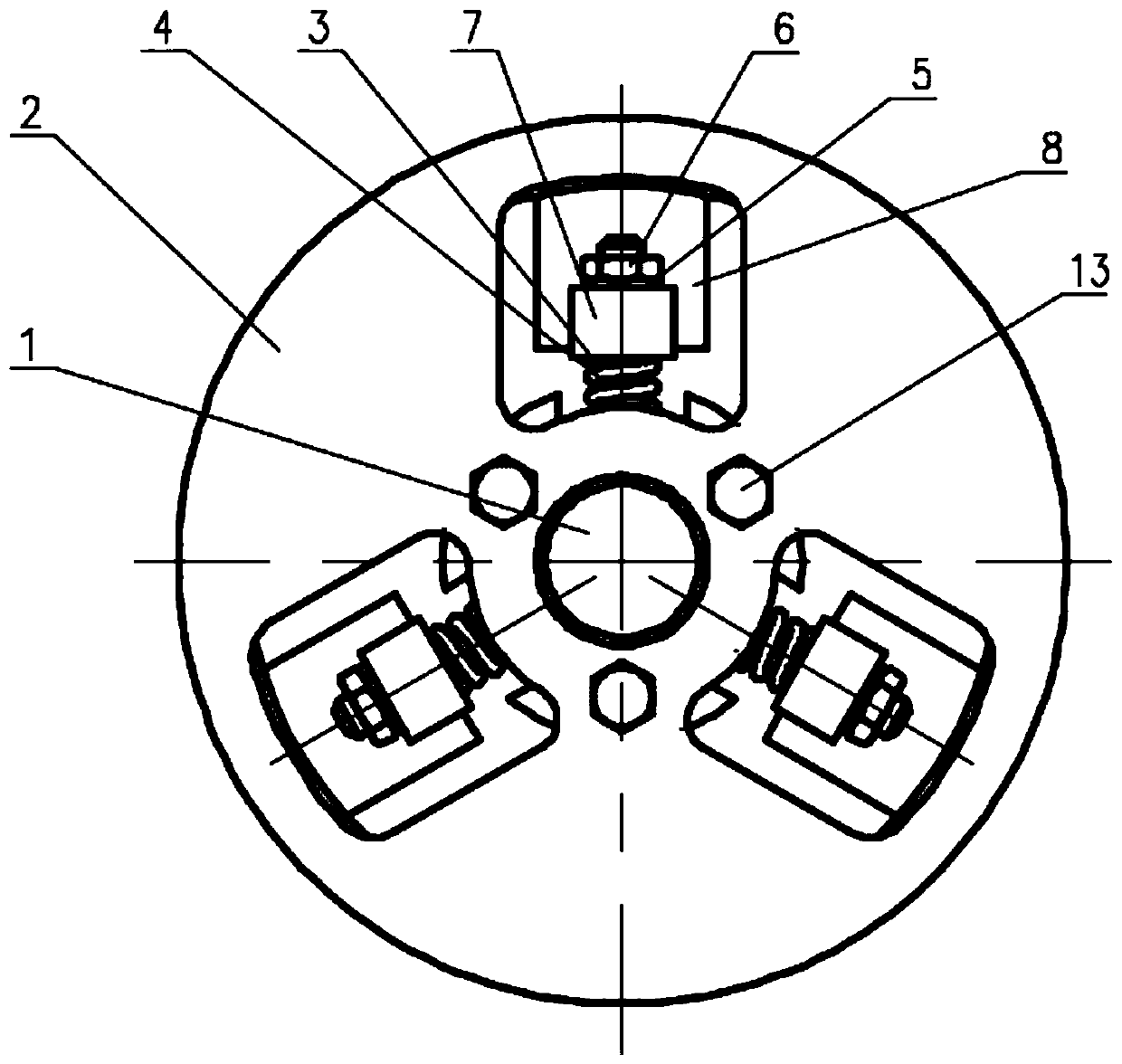

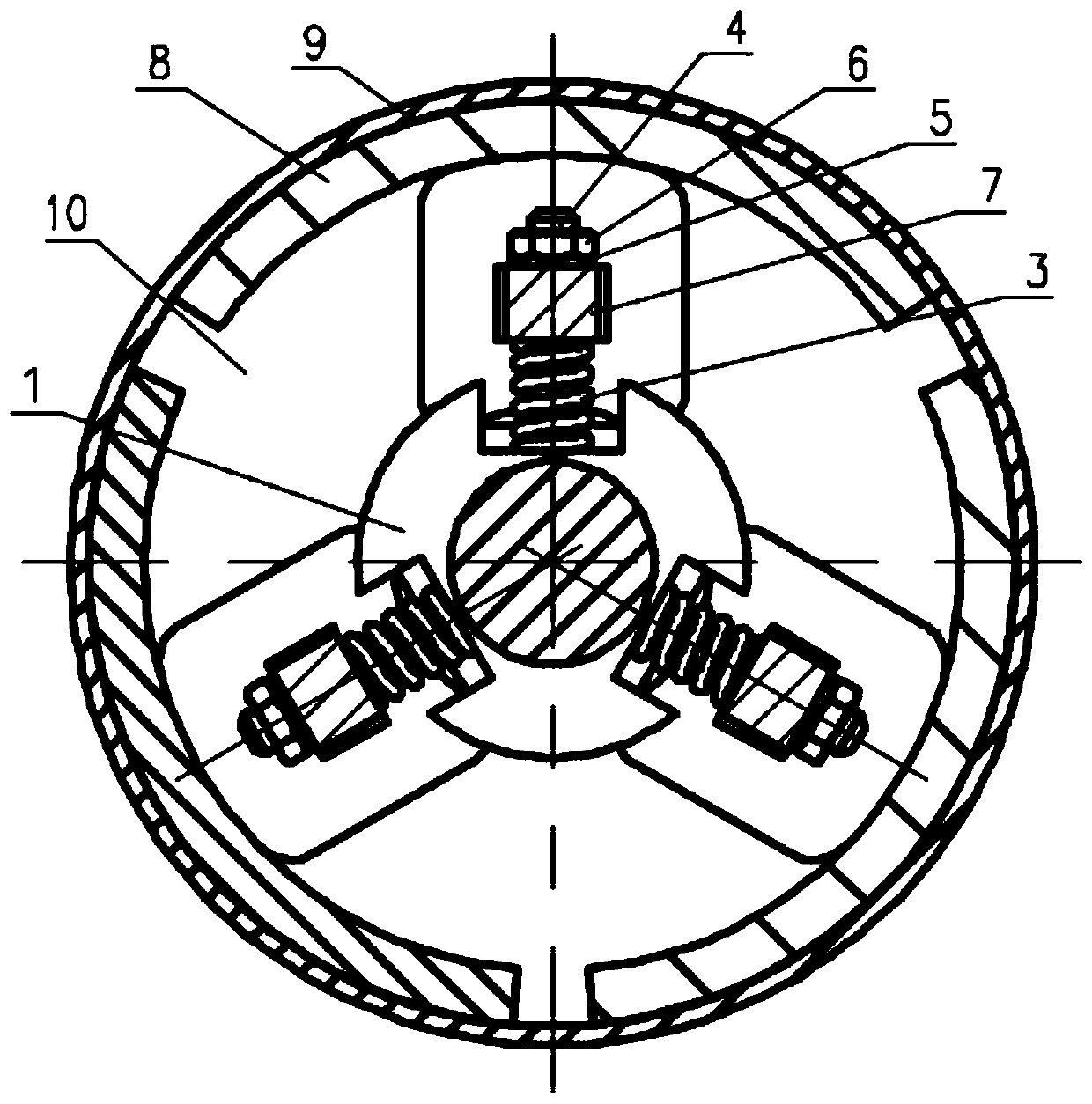

[0041] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0042] Such as Figure 1 to Figure 7As shown, the present invention is a clamping system for processing the outer wall of a thin-walled cylinder. Body 8, workpiece 9, movable baffle 10, positioning nut 11, lock nut 12 and connecting bolt 13;

[0043] A method for clamping the outer wall of a thin-walled cylindrical part by turning, including two parts: radial auxiliary support and axial clamping;

[0044] The specific steps of radial auxiliary support are as follows:

[0045] (1) By rotating the adjusting nut 6, under the action of the compression spring 3, the connecting rod 7 drives the elastic body 8 to move radially until it contacts the inner wall of the workpiece 9 and exerts a certain supporting force. The size of the supporting force is adjusted by rotating the adjusting nut 6 To achieve stepless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com