A hydraulic automatic fixture for turning motor casings

A motor shell and automatic technology, which is applied in the field of fixtures for CNC machine tool processing, can solve the problems of insufficient control of clamping force, poor dynamic balance performance of manual fixtures, affecting the machining accuracy of parts, etc. The effect of strong rigidity and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

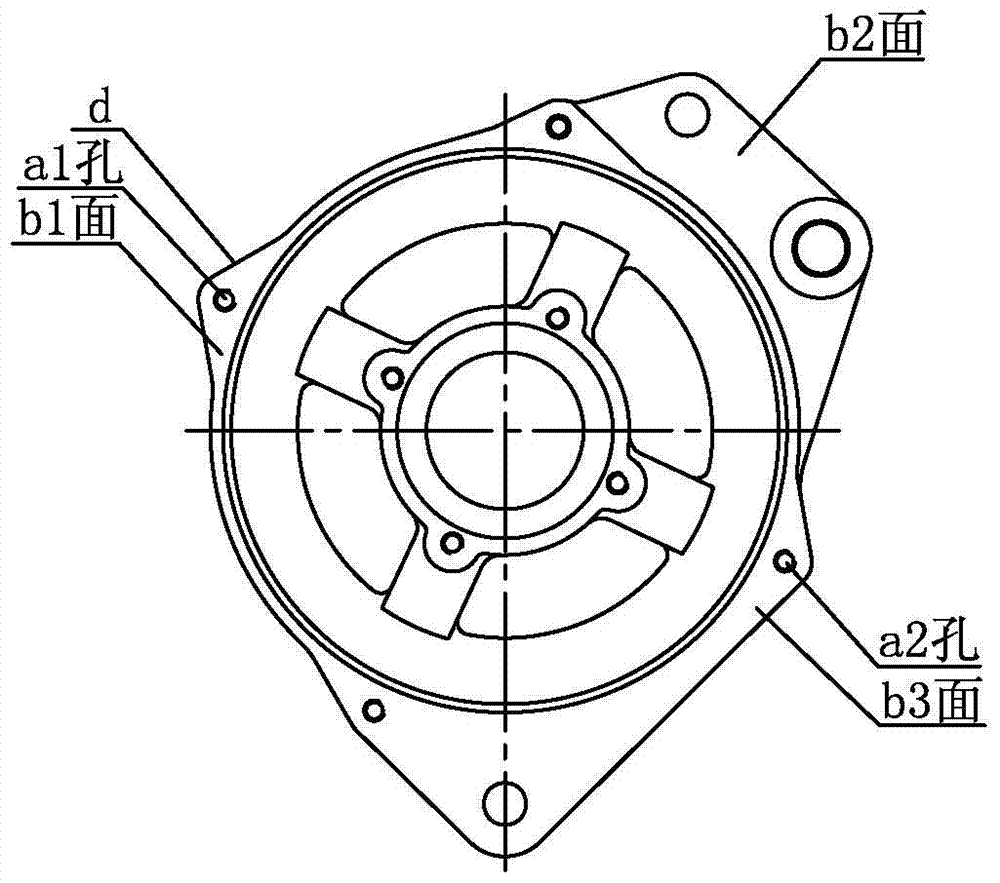

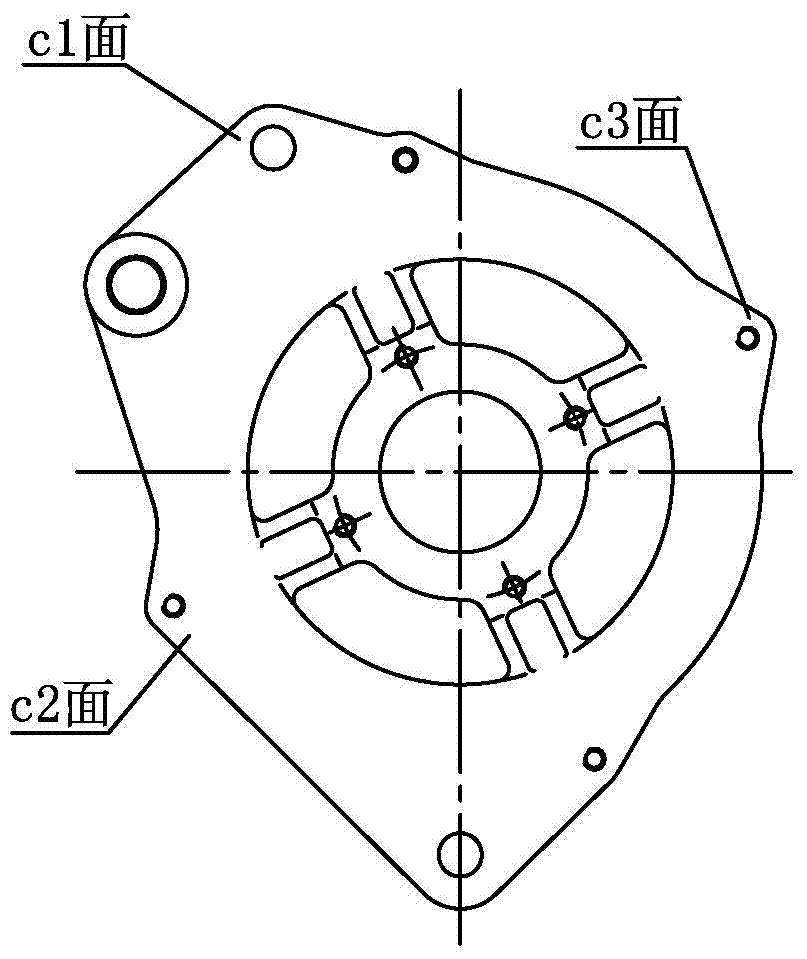

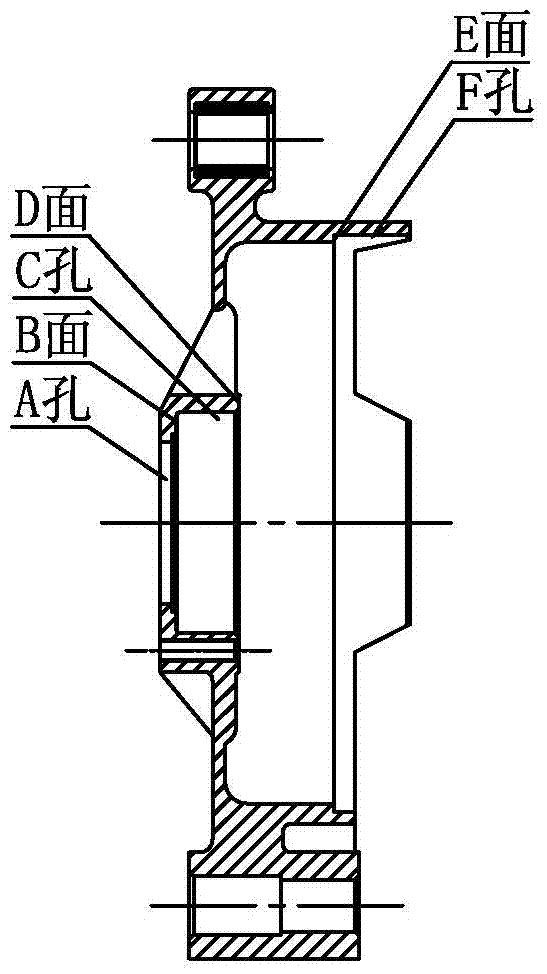

[0024] As shown in the figure, the hydraulic automatic fixture for turning motor casings includes a hollow clamp body 1, and a packing 2 is installed on one side of the clamp body 1, and a joint with the main shaft (not shown in the figure) is opened on the packing 2. The taper hole 21 of the packing with matching outer diameter, several hexagon socket head screws 22 for screwing the main shaft are installed on the packing 2, the packing 2 and the main shaft are fixedly connected by several hex socket head cap screws 22, the other side of the clamp body A flange cover 3 is installed, and the outer end of the flange cover 3 is provided with an error-proof limiting block 31. The shape is compatible, and the flange cover 3 is provided with an indexable clamping mechanism. The clamping mechanism is connected with a tie rod 5. One end of the tie ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com