Planet differential type automatic moment varying electric control device

An electronic control device, differential technology, applied in the direction of electromechanical device, transmission device, transmission device parts, etc., can solve the problems of complex structure and inconvenience, and achieve the effect of simple tooling, wide application range and overcoming high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

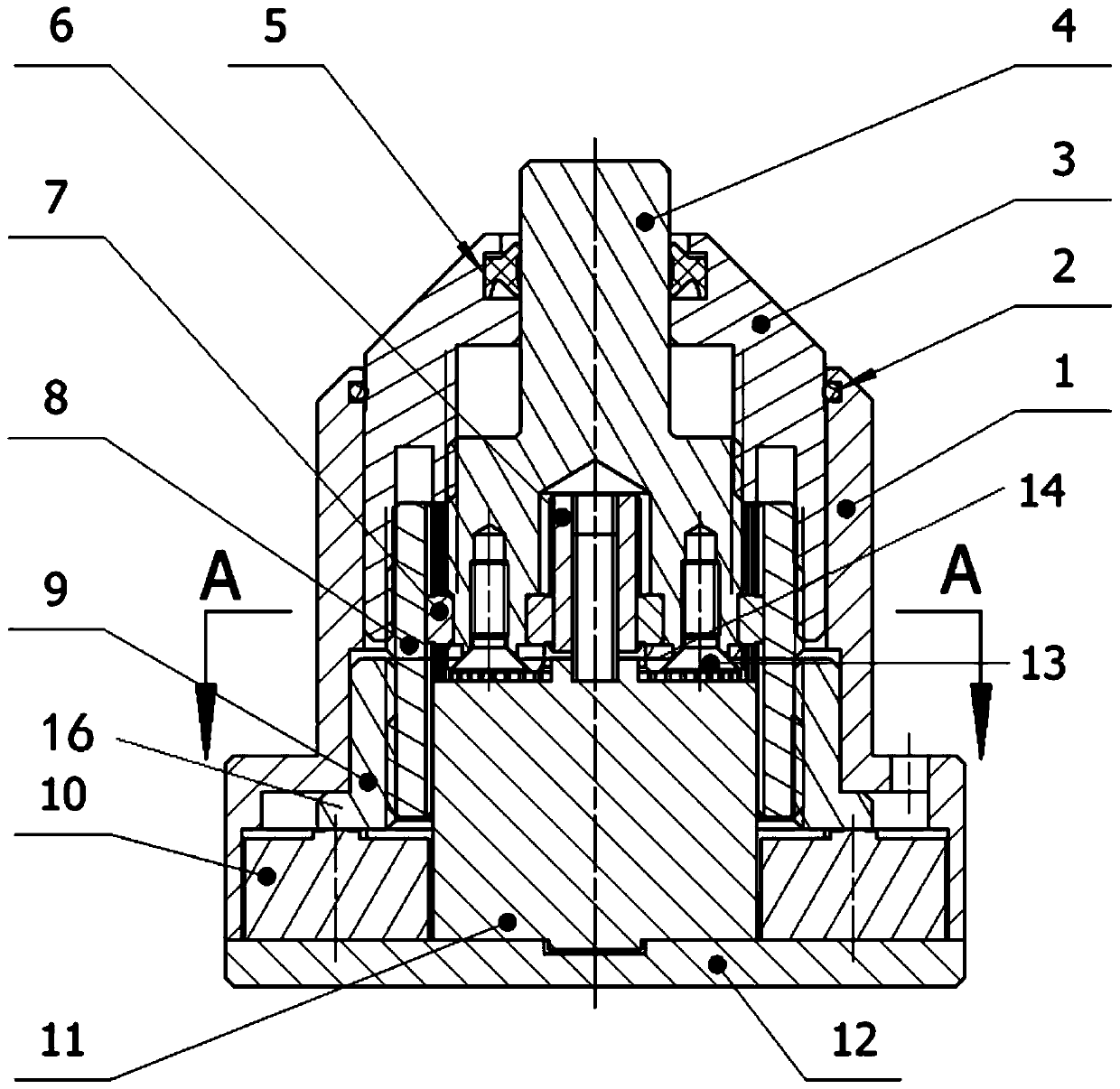

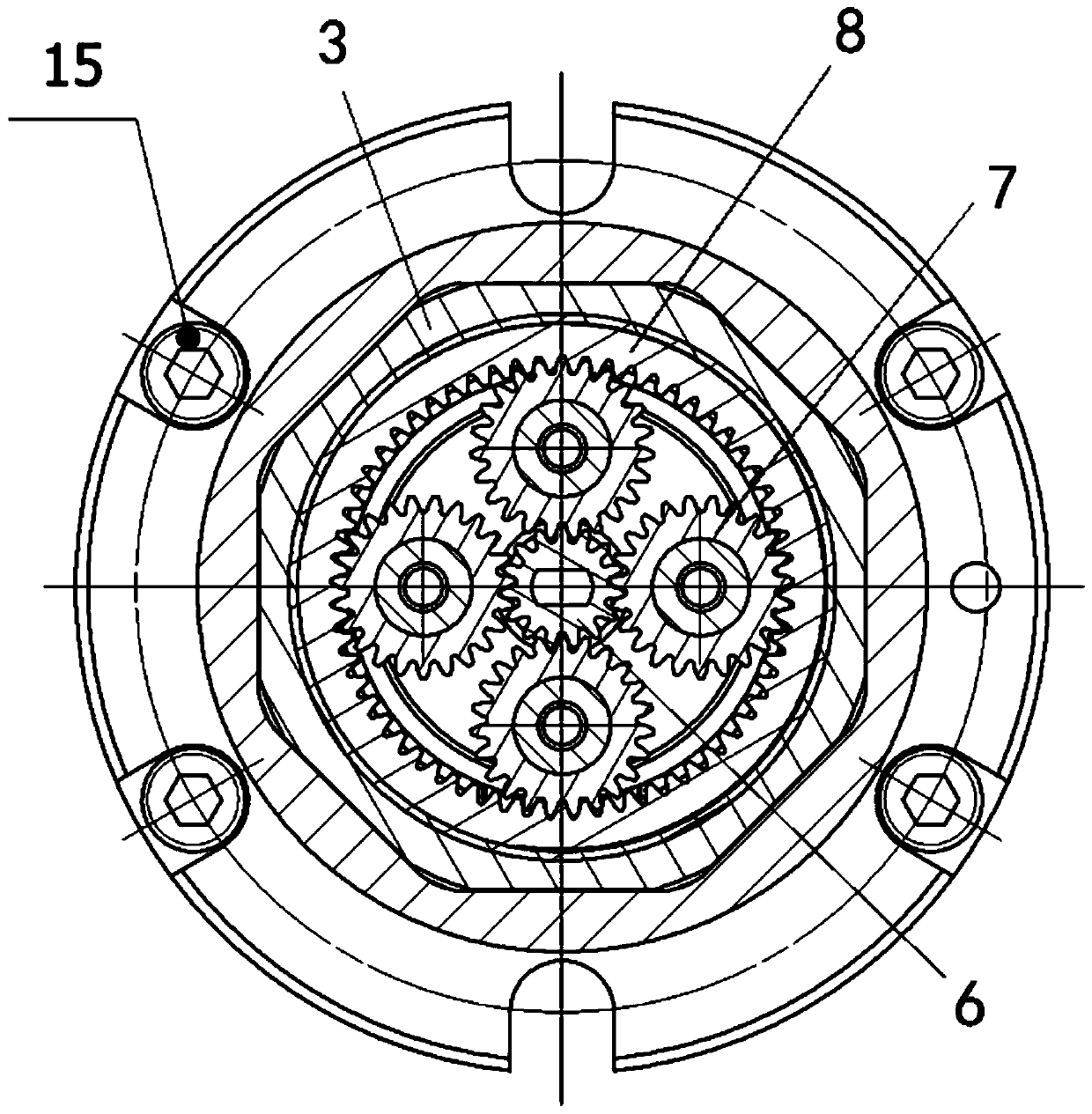

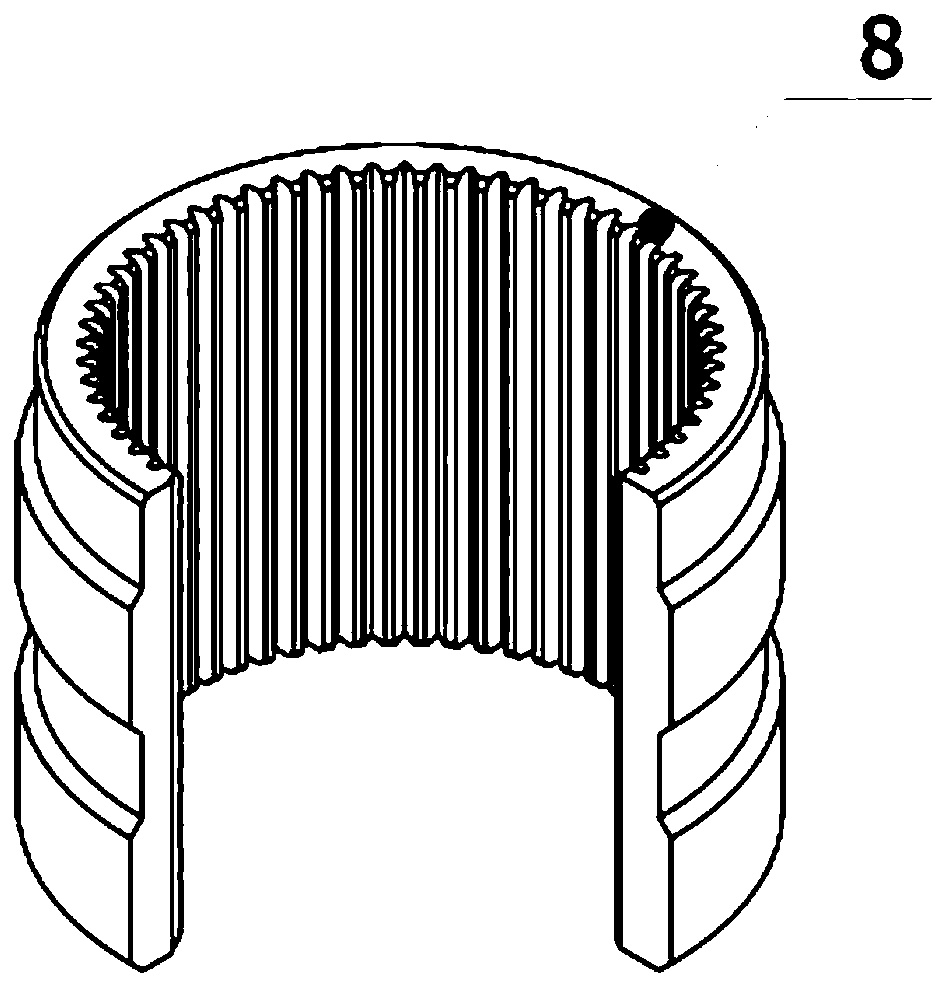

[0028] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The planetary differential self-variable torque electronic control device provided by the present invention uses the sun gear as the power input end of the electric control device. The shaft planet carrier and the planetary gear can be fixed and movable according to the ingenious structure of the present invention. Automatic switching state, that is, the output of different speeds and torques. Due to the size limitation of the electronic control device, it is impossible to use a complex planetary structure. The present invention greatly simplifies its structure through the principle of thread differential, realizes a large speed ratio reduction, and also realizes a self-locking function.

[0030] Such as Figure 1 to Figure 5 As shown, the planetary differential self-torque electronic control device provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com