Positioning and clamping device for automobile hub outer flange processing

An automobile wheel hub, positioning and clamping technology, which is applied to the chuck and other directions, can solve the problems of large reassembly error of the fixture and positioning device, product clamping deformation, and workpiece clamping accuracy reduction, etc. The effect of reducing clamping deformation and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

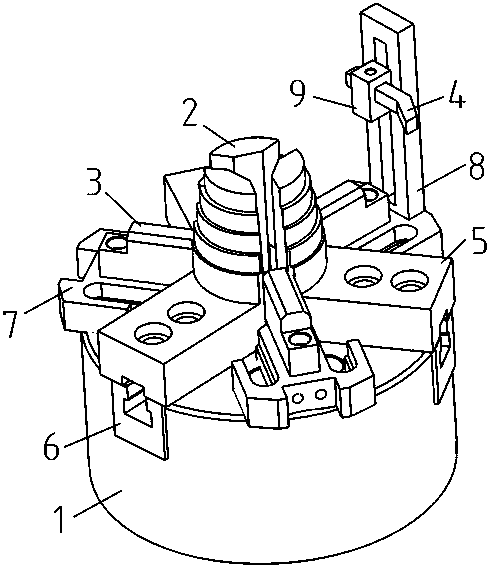

[0016] Such as figure 1 As shown, a processing and positioning clamping device for the outer flange of an automobile hub includes a hydraulic chuck 1, and three clamping parts are arranged on the top surface of the chuck, and each clamping part includes a base 5 and a fan-shaped claw 2. The jaws 2 are arranged on the base 5, and the clamps are positioned on the top surface of the chuck through the base 5, and the three clamps are concentric on the top surface of the chuck and coaxial with the chuck 1 at equiangular intervals. Set, the chuck 1 includes a first slider 6 arranged under each base 5, the base 5 is fixedly connected with the first slider 6, and the hydraulic chuck 1 pushes the slider through a hydraulic power device. The first slider 6 telescopically slides radially so as to drive the three clips to synchronously telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com