Pulley support machining clamp and machining method

The technology of a pulley bracket and processing method is applied in the direction of manufacturing tools, metal processing equipment, metal processing machine parts, etc., which can solve problems such as difficult clamping and measurement, long processing cycle, and overall complexity, so as to reduce the number of clamping switching, The effect of improving processing efficiency and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

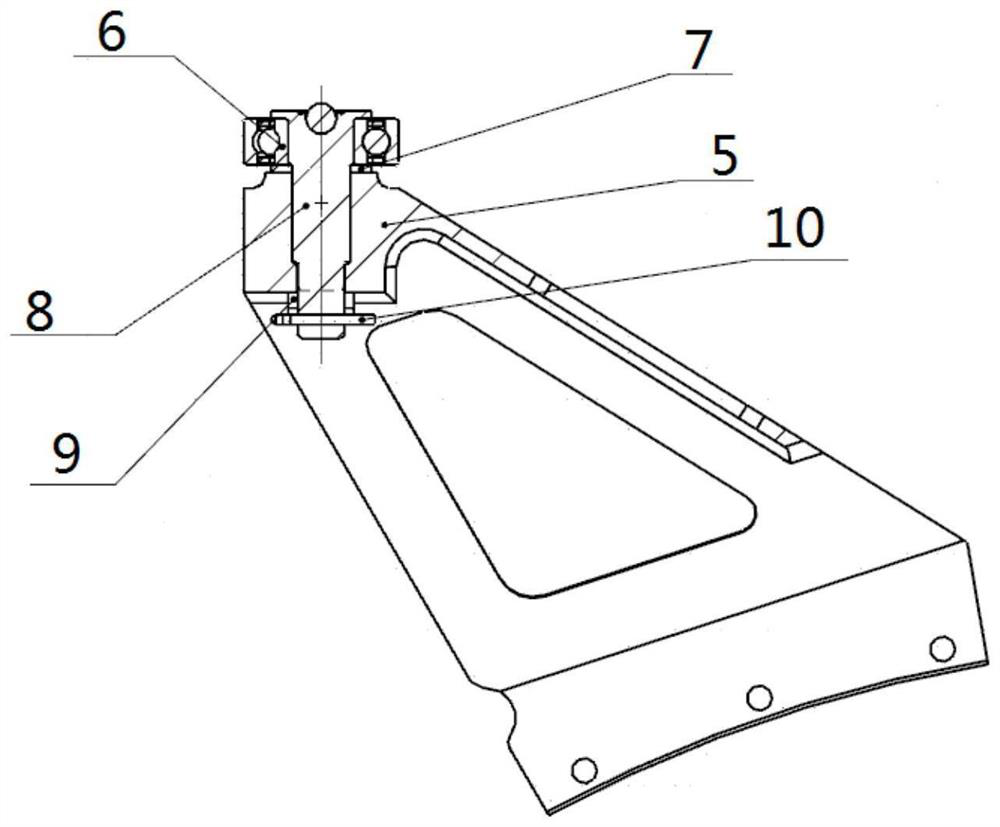

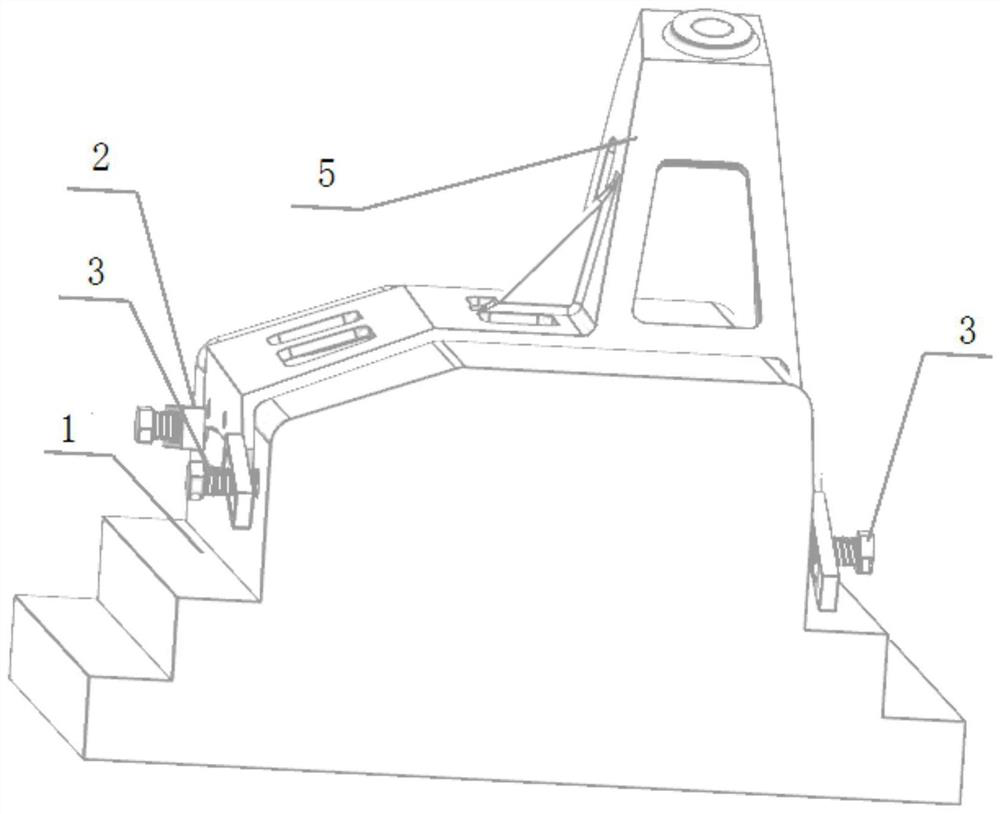

[0042] see figure 1 , The pulley bracket 5 is equipped with a ball bearing 6, a washer 7, a pin subassembly 8, a flower nut 9 and a cotter pin 10. The blanks of the pulley bracket 5 are all castings made of ZTC4, and the casting is a special-shaped cavity, wherein there is a protrusion 57 in the special-shaped cavity, and there is a clip greater than 90° between the two inner surfaces connected by the protrusion 57. horn. like Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com