Machining method for thin-wall circular ring part

A processing method and ring technology, applied in the field of mechanical processing, can solve the problems of affecting the dimensional accuracy and shape accuracy of the workpiece, affecting the dimensional accuracy of the workpiece, weak strength, etc., so as to improve the surface roughness and dimensional accuracy, ensure the processing quality and processing. Efficiency, the effect of improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0034] A processing method for thin-walled circular parts, comprising the following steps:

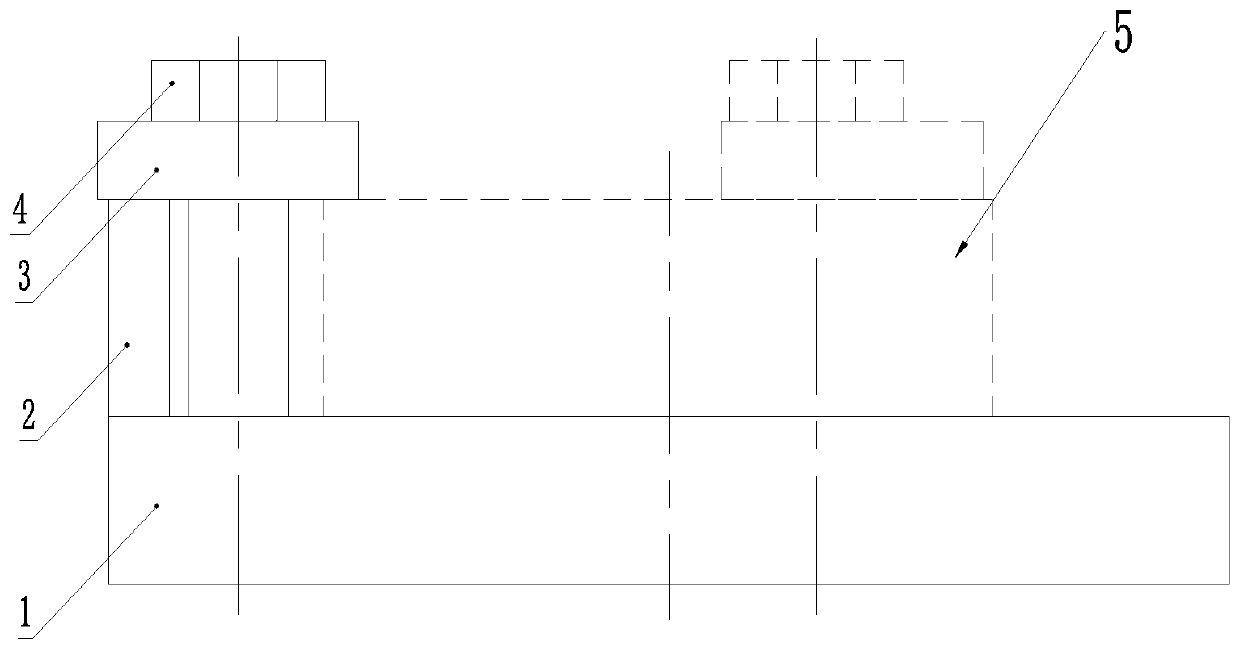

[0035] Step 1, use the pipe material for blanking, and perform heat treatment on the blanked pipe material, remove step 2, perform rough turning on the pipe material to become workpiece 5, and perform stress relief heat treatment on workpiece 5 after rough turning;

[0036] Step 3, use conventionally processed soft jaws to clamp the outer circle of the workpiece 5, semi-finish the inner hole, outer circle and end face of the workpiece 5, and finally cut off to ensure the total length of the workpiece 5;

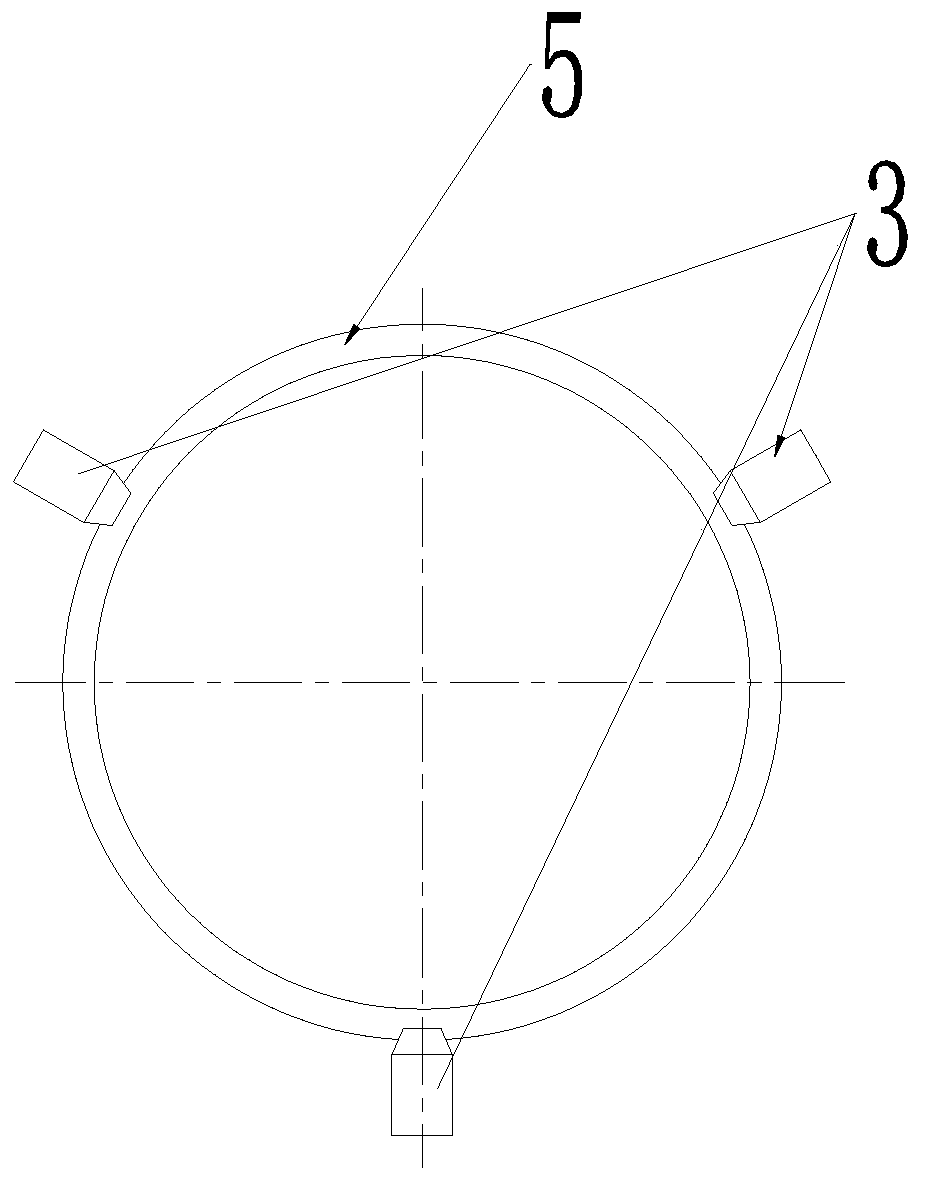

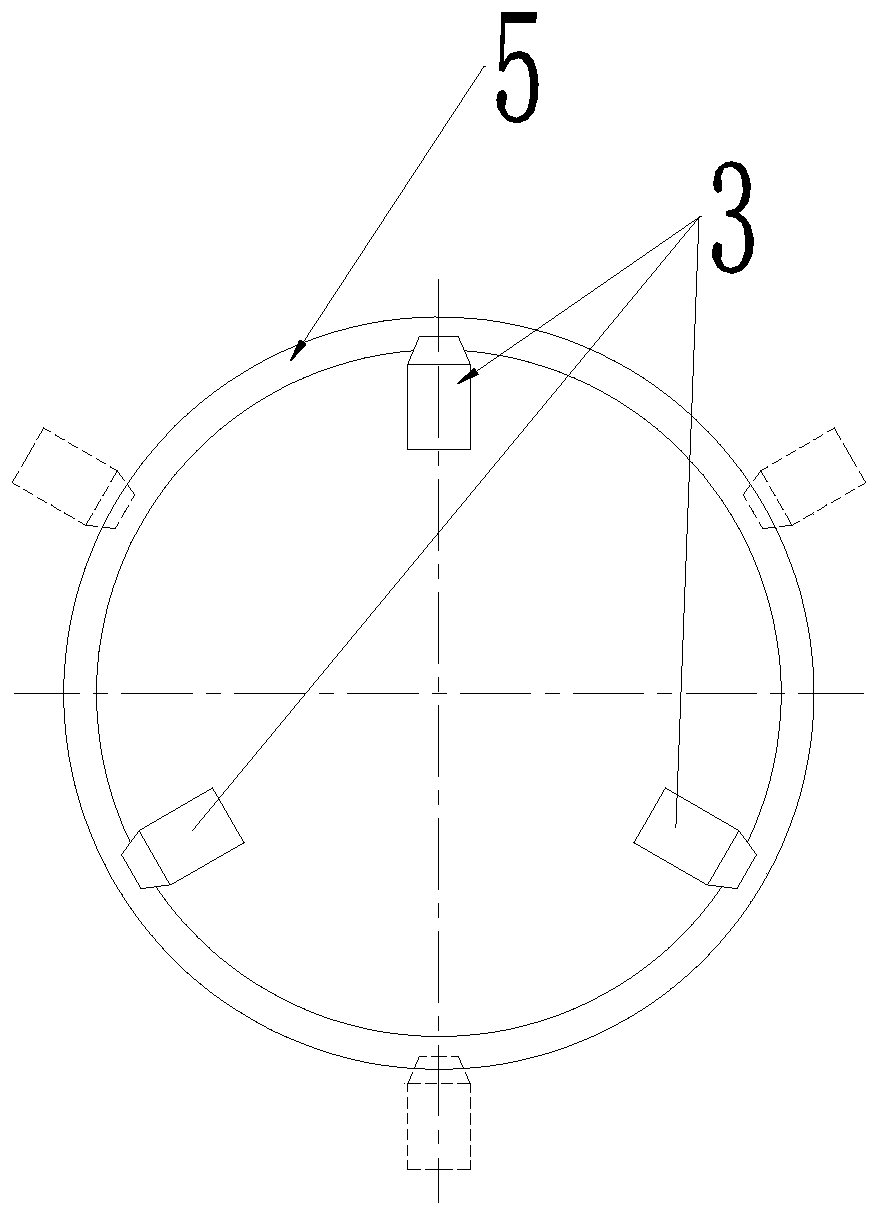

[0037] Step 4, after the workpiece 5 is cooled, press the workpiece 5 on the disc 1 from the end face;

[0038] Step five, press the workpiece 5 on the disc 1, and use the pressure plate 3 to fasten the workpiece 5 on the disc 1 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com