Deformation control method of large-size titanium alloy locking ring

A deformation control and locking ring technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of complex structure and operation of deformation control devices, and failure to fundamentally solve the deformation of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The heat treatment deformation control method of the TC4 large size locking ring with an inner diameter of 1460mm and an outer diameter of 2000mm includes the following steps:

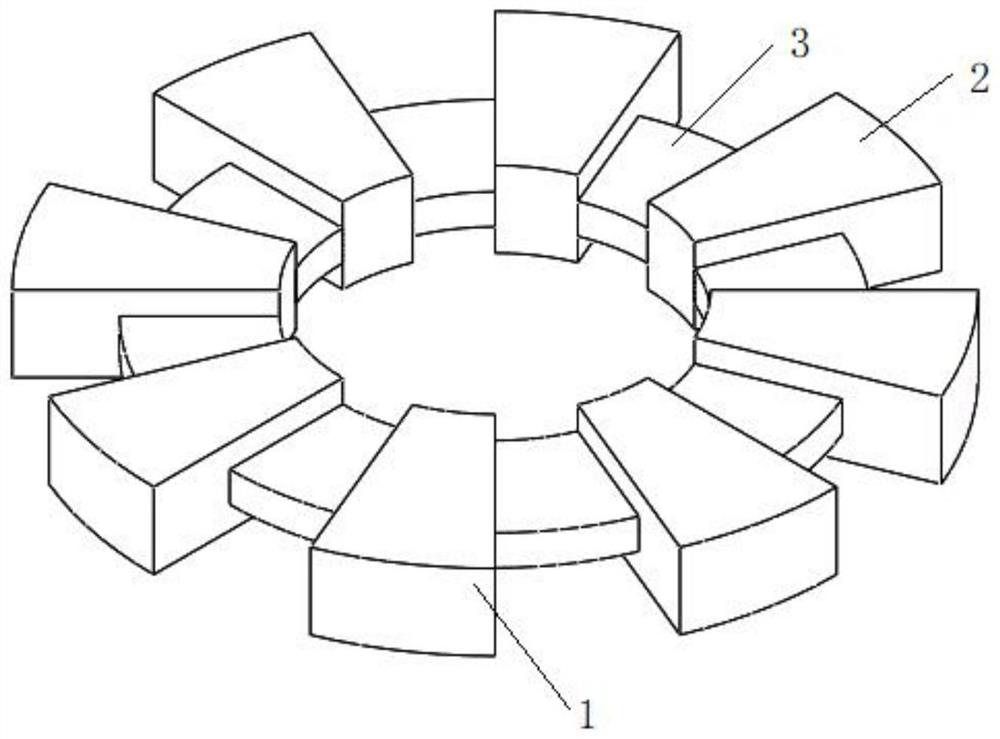

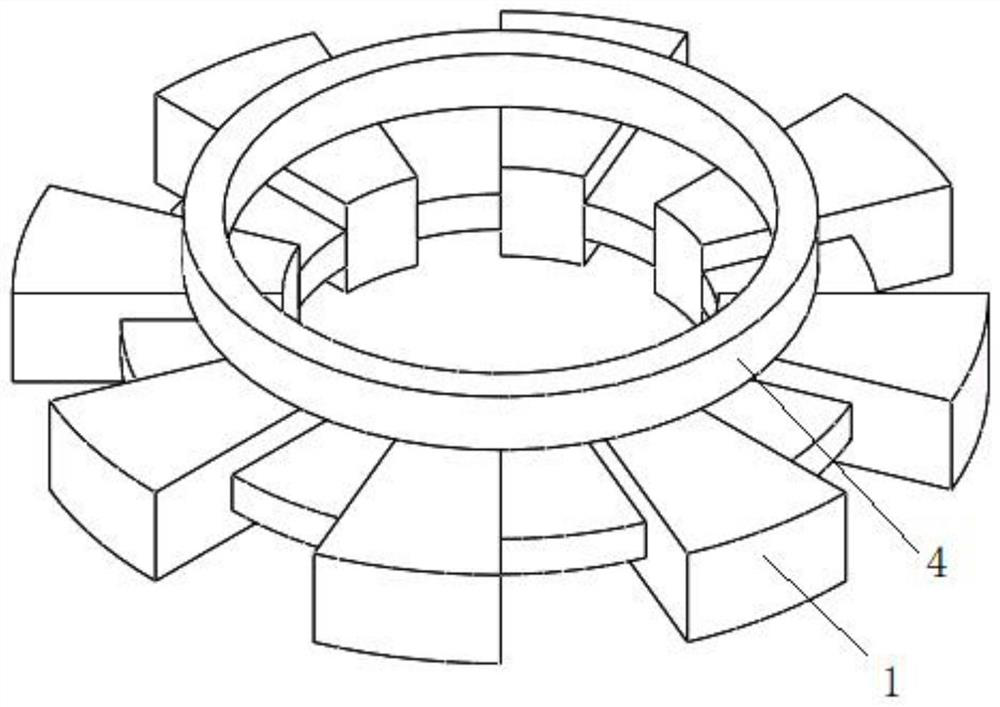

[0026] 1. Processing of positioning platform: the outer diameter of the fan-shaped main body is 2300mm, the inner diameter is 1100mm; the outer diameter of the connecting body is 2150mm, the inner diameter is 1100mm; the surface flatness is ≤±0.1mm. The fan-shaped main body is composed of a plurality of fan-shaped units 1 with identical shapes and sizes, and the connecting body is composed of a plurality of fan-shaped units 2 with identical shapes and sizes. To form the positioning platform, the axial height of the sector unit 2 is smaller than that of the sector unit 1, and the upper and lower surfaces of all the sector units 1 are flush through the sector unit 2. The middle part of the positioning platform is hollowed out. The fan-shaped main body and connecting body are welded by automatic a...

Embodiment 2

[0033] The heat treatment deformation control method of the TC4 large size locking ring with an inner diameter of 1460mm and an outer diameter of 2000mm includes the following steps:

[0034] 1. Processing of positioning platform: the outer diameter of the fan-shaped main body is 2300mm, the inner diameter is 1100mm; the outer diameter of the connecting body is 2150mm, the inner diameter is 1100mm; the surface flatness is ≤±0.1mm. The fan-shaped main body is composed of a plurality of fan-shaped units 1 with identical shapes and sizes, and the connecting body is composed of a plurality of fan-shaped units 2 with identical shapes and sizes. To form the positioning platform, the axial height of the sector unit 2 is smaller than that of the sector unit 1, and the upper and lower surfaces of all the sector units 1 are flush through the sector unit 2. The middle part of the positioning platform is hollowed out. The fan-shaped main body and connecting body are welded by automatic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com