A conformal drying method for 3D printing direct-writing shaped ceramic bodies

A 3D printing, ceramic body technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problem of easy cracking and deformation, affecting product dimensional accuracy and yield, and ceramic green body warping deformation, etc. problems, to achieve the effect of improving the forming dimensional accuracy, shortening the drying process cycle, and reducing warpage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a method for conformal drying of a 3D printing direct-writing shaped ceramic green body, comprising the following steps:

[0027] 1) Take 20g of pseudoboehmite, 2.4g of 10% dilute acetic acid, 18g of distilled water, and 0.075g of scallop powder, and mechanically stir at a speed of 100r / min for 30min to obtain alumina ceramic slurry; put the alumina ceramic slurry into In the direct writing 3D printer, in order to reduce the stress on the bottom of the ceramic blank, it is easy to separate from the printing base plate, keep moisture, and prevent the ceramic blank from cracking. A layer of polyethylene PE hydrophobic film is evenly laid on the printing base plate. Print ceramic blanks;

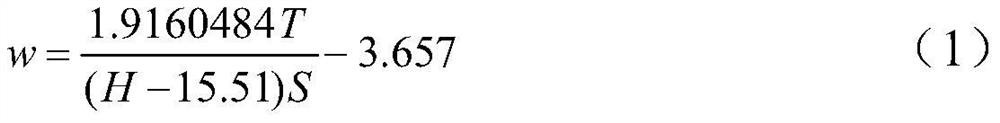

[0028] 2) After the 3D printing is completed, put the ceramic blank and the printed bottom plate into a constant temperature and humidity environment, and select the temperature and humidity that should be set for the constant temperature and humidity drying process accordi...

Embodiment 2

[0036] Embodiment 2, a method of conformal drying for 3D printing direct-writing shaped ceramic bodies, comprising the following steps:

[0037] 1) Take 20g of pseudoboehmite, 2.4g of 10% dilute acetic acid, 18g of distilled water, and 0.075g of scallop powder, and mechanically stir at a speed of 100r / min for 30min to obtain alumina ceramic slurry; put the alumina ceramic slurry into In the direct writing 3D printer, a layer of polypropylene PP hydrophobic film is evenly laid on the printing base plate, and the ceramic blank is 3D printed on the hydrophobic film;

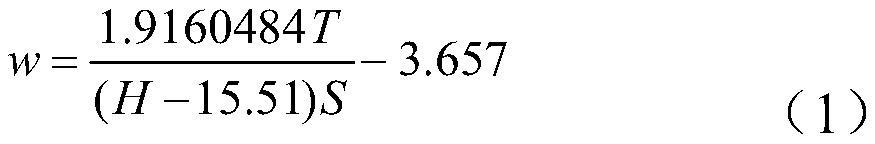

[0038] 2) After the 3D printing is completed, put the ceramic blank and the printed bottom plate into a constant temperature and humidity environment, and select the temperature and humidity that should be set for the constant temperature and humidity drying process according to the warpage relationship obtained by MATLAB calculation and fitting experimental data:

[0039]

[0040] In the formula, w is the warpag...

Embodiment 3

[0046] Embodiment 3, a method of conformal drying for 3D printing direct-writing shaped ceramic bodies, comprising the following steps:

[0047] 2) Take 20g of pseudoboehmite, 2.4g of 10% dilute acetic acid, 18g of distilled water, and 0.075g of scallop powder, and mechanically stir at a speed of 100r / min for 30min to obtain alumina ceramic slurry; put the alumina ceramic slurry into In the direct writing 3D printer, a layer of fluorinated polyethylene hydrophobic film is evenly laid on the printing base plate, and the ceramic blank is 3D printed on the hydrophobic film;

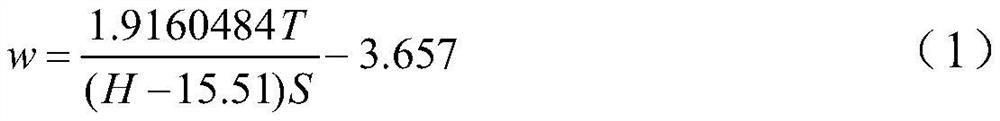

[0048] 2) After the 3D printing is completed, put the ceramic blank and the printed bottom plate into a constant temperature and humidity environment, and select the temperature and humidity that should be set for the constant temperature and humidity drying process according to the warpage relationship obtained by MATLAB calculation and fitting experimental data:

[0049]

[0050] In the formula, w is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com