A trench manufacturing method for improving warpage of silicon wafer

A manufacturing method and warpage technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as stress fragments on silicon wafers, failure to complete operations normally, and affect production tape-out, etc., to achieve warpage Uniformity, ensuring smoothness, and improving the effect of warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0029] The invention provides a method for manufacturing grooves for improving the warpage of silicon wafers, which mainly includes the following steps:

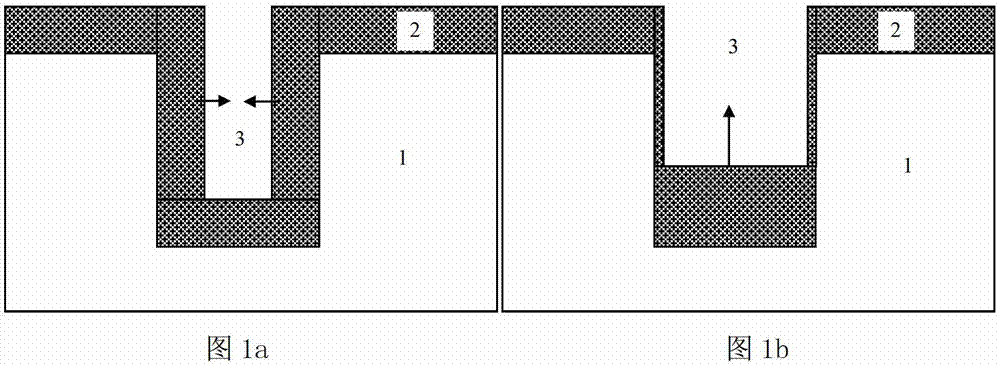

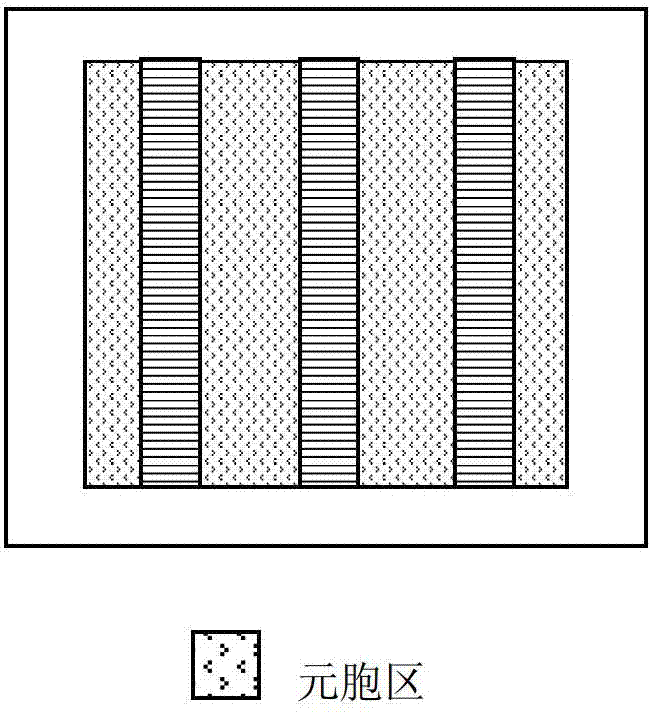

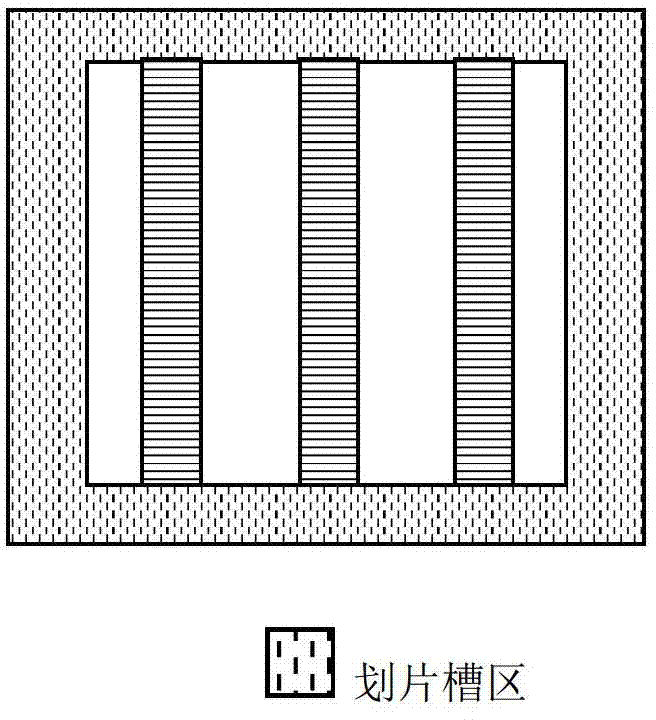

[0030] 1.1 Lay out a certain pattern and a certain area of groove B in the scribing groove of the silicon wafer; the pattern of the groove B in the scribing groove area can be n times rotationally symmetrical, that is, strip shape, square, circle shape, circular ring and their combined graphics; the graphics of the groove B in the scribing groove area can be n-time rotationally symmetric graphics, and the n-time rotationally symmetric graphics refer to rotating a graphic around a straight line by an m* After an angle of (360° / n), it coincides with the initial figure, and this figure is called a rotationally symmetric figure, and this straight line is called the n-time rotational symmetry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com