Patents

Literature

37results about How to "Eliminate dislocations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

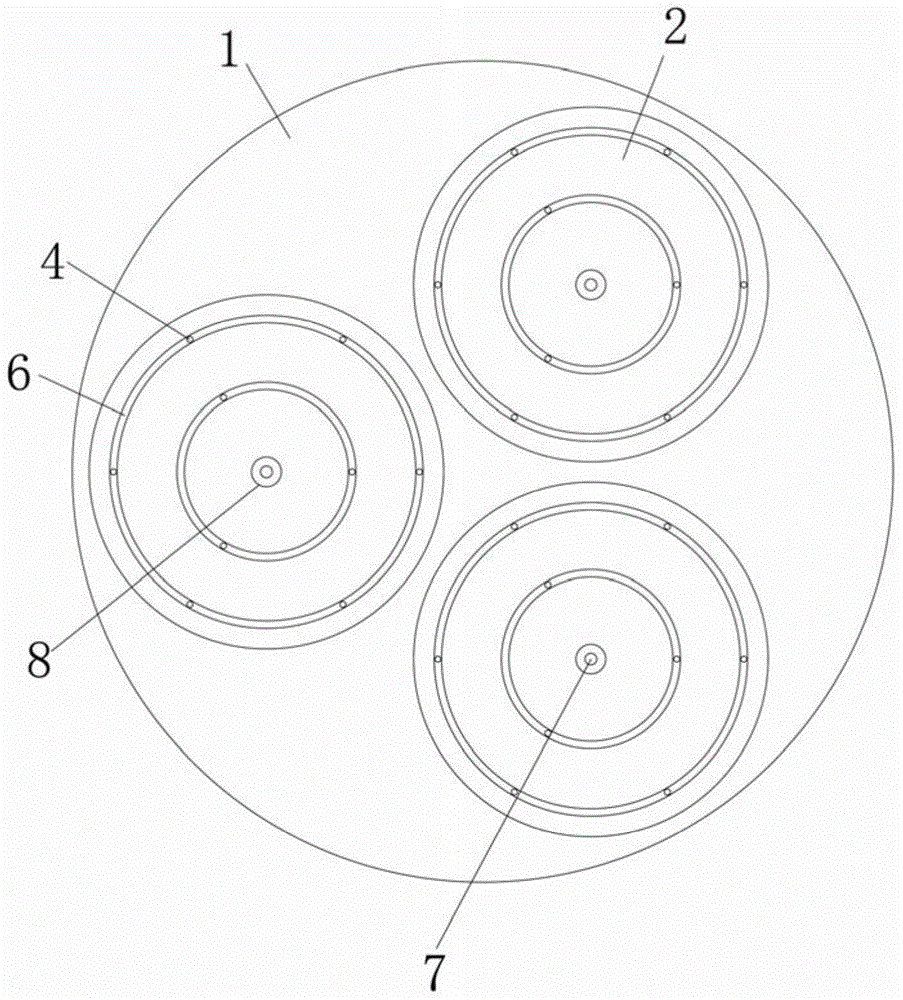

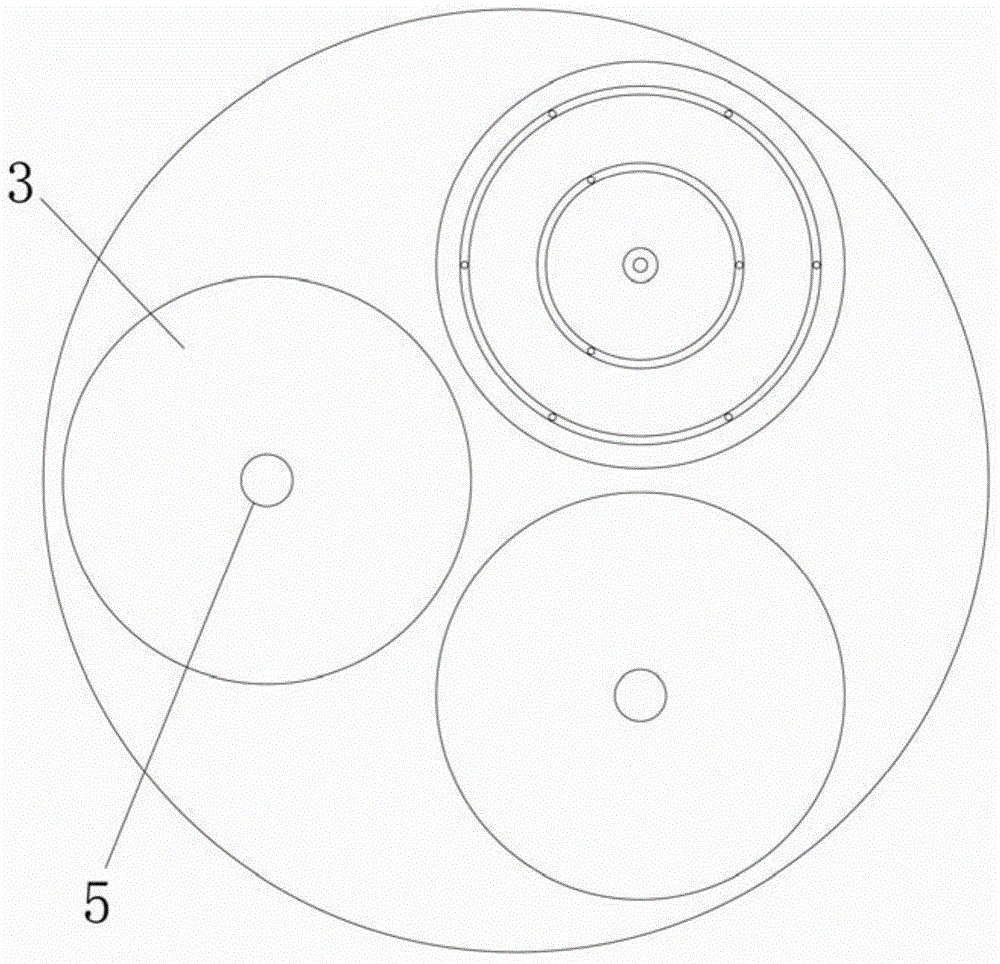

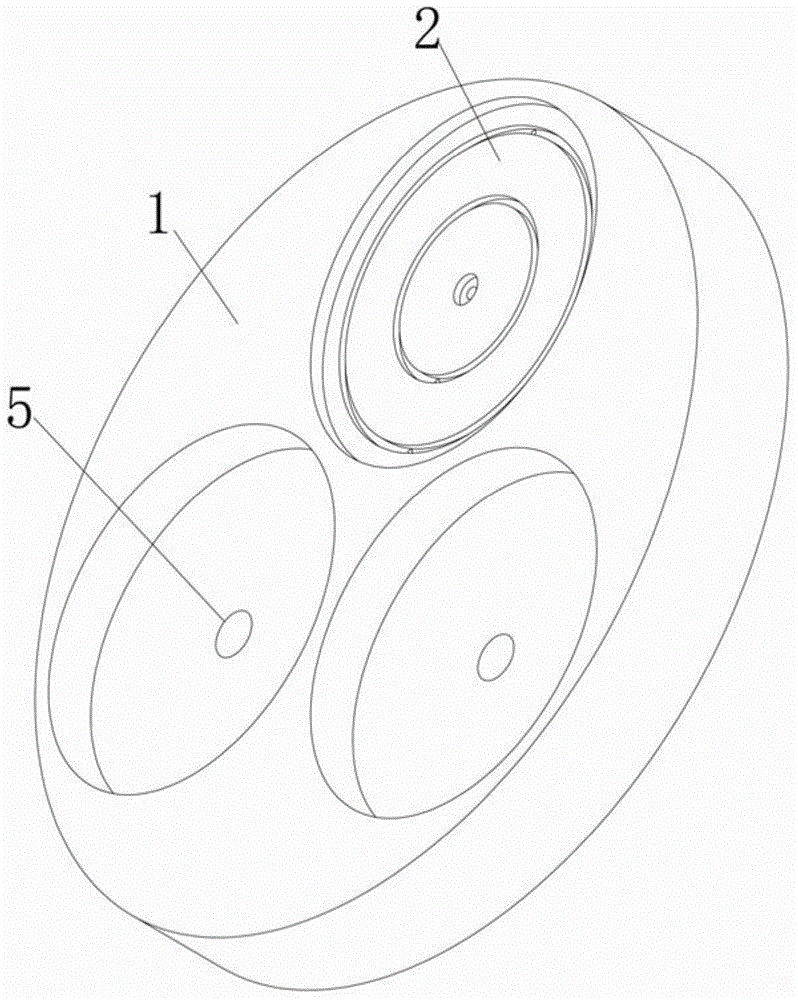

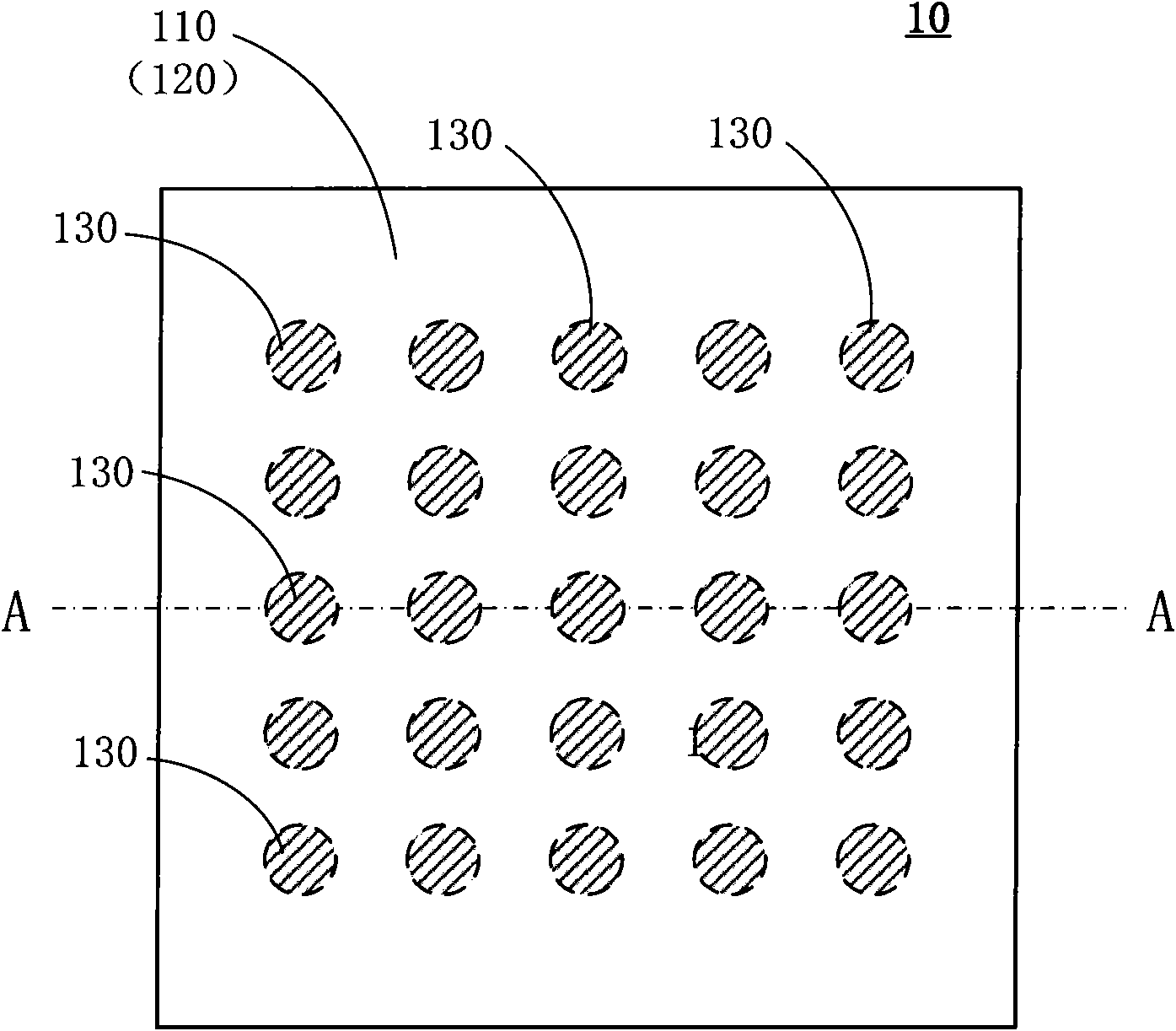

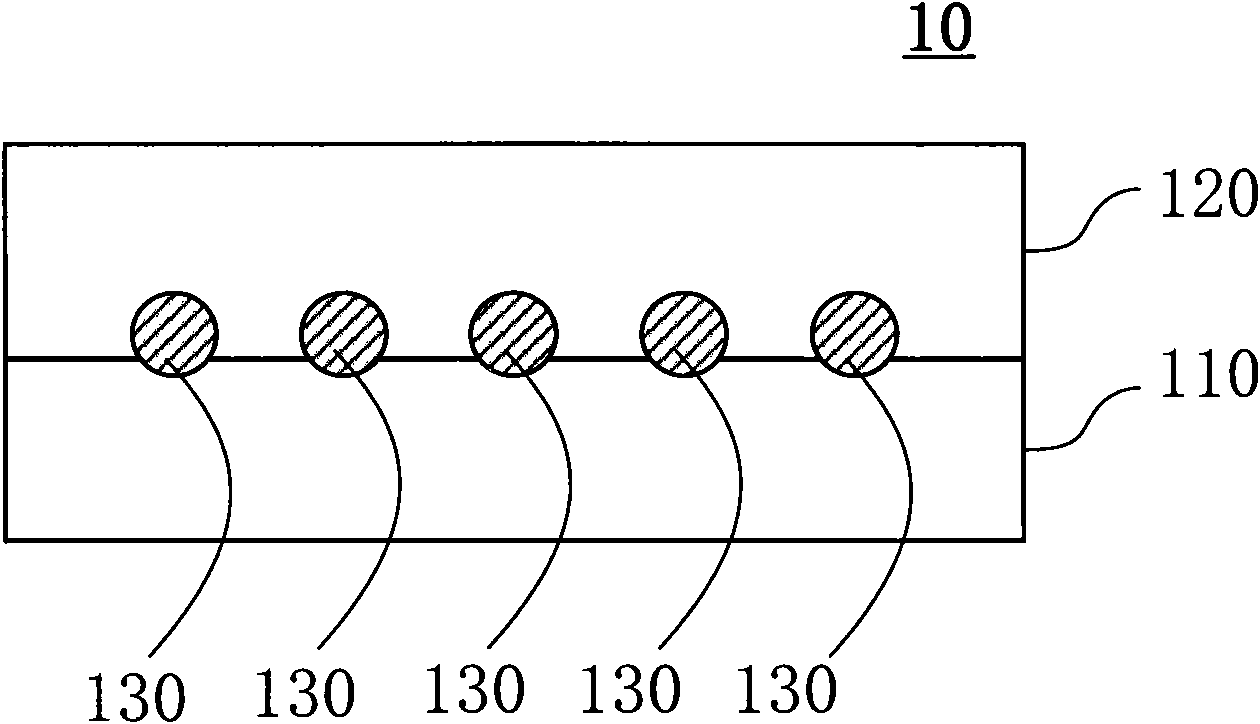

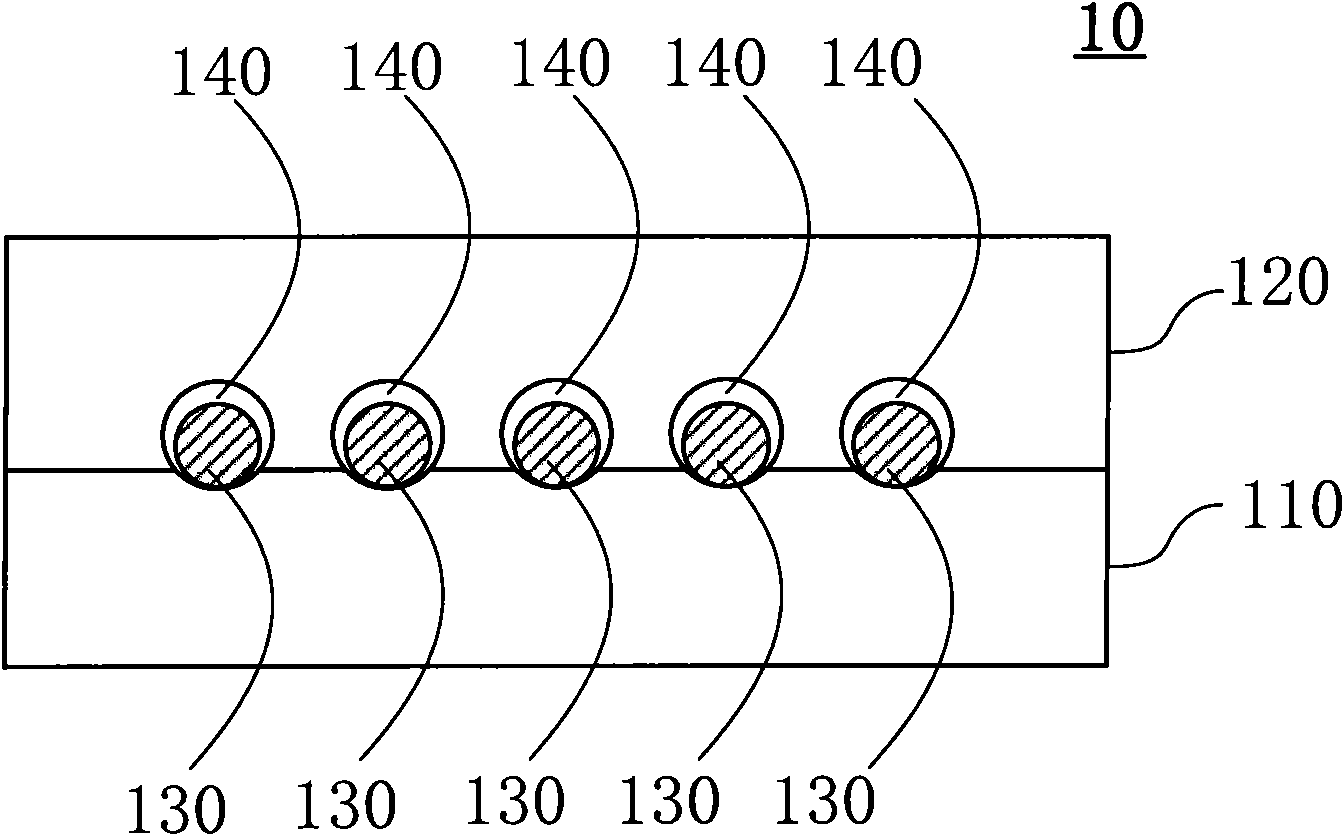

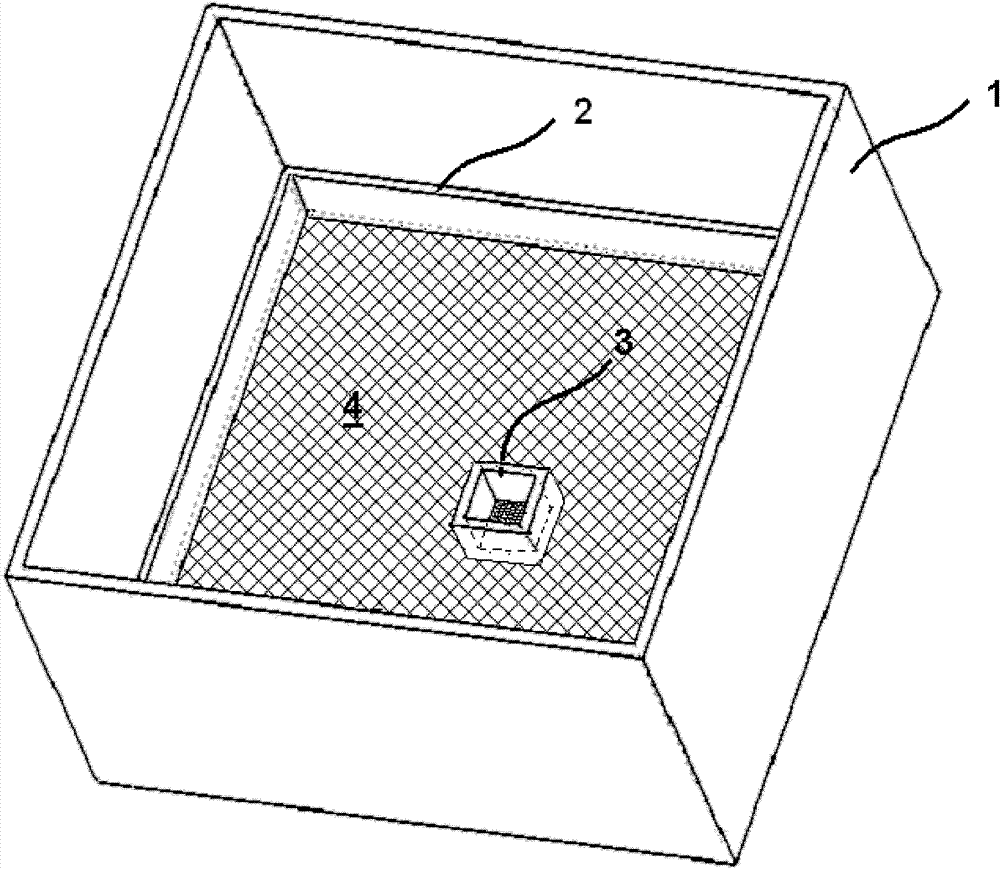

Tray capable of eliminating warping of wafers

InactiveCN104538333AStable and reliable temperature fieldStable and reliable flow fieldSemiconductor/solid-state device manufacturingLattice mismatchEngineering

The invention discloses a tray capable of eliminating warping of wafers. The tray comprises a base body and bases, a plurality of concave pits are formed in one side face of the base body, and one base is arranged in each concave pit. The bases are embedded in the corresponding concave pits, gaps are kept between the bases and the bottoms of the concave pits, and the overall height of the bases is smaller than the depth of the concave pits. A plurality of air suction holes are formed in the upper surfaces of the bases, and after the wafers are sucked on the bases, the overall combined height of the wafers and the bases is smaller than the depth of the concave pits. A vacuumizing channel communicated with the air suction holes is formed in each base, and the vacuumizing channels penetrate through the lower surfaces of the bases. Air exhaust holes are formed in the bottoms of the concave pits, a vacuumizing channel communicated with the air exhaust holes is formed in the base body, and the vacuumizing channel penetrates through the other side face of the base body and can be connected with an outside vacuumizing device. According to the tray, the wafers can be flatly attached to the bases, the epitaxial wafer warping problem caused by thermal mismatch and lattice mismatch can be effectively solved, the temperature in the wafers is uniform, and the subsequent technology processes are facilitated.

Owner:REDSOLAR NEW ENERGY TECH

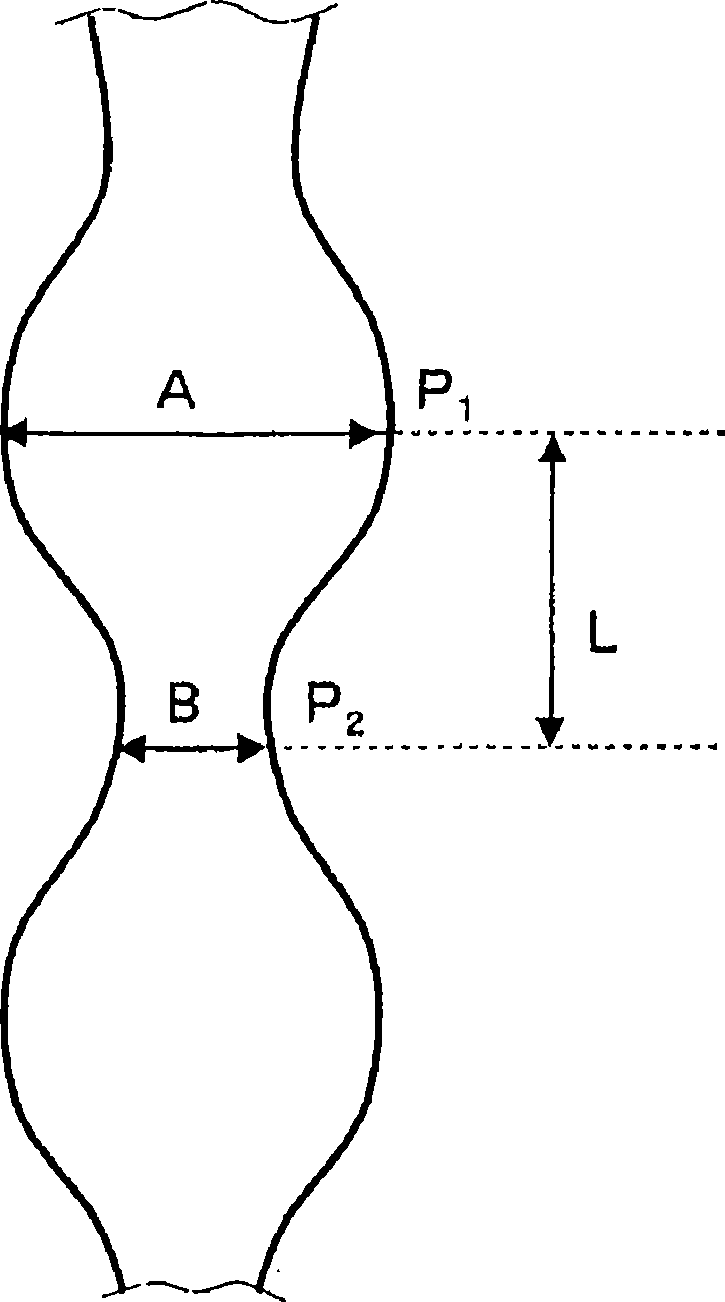

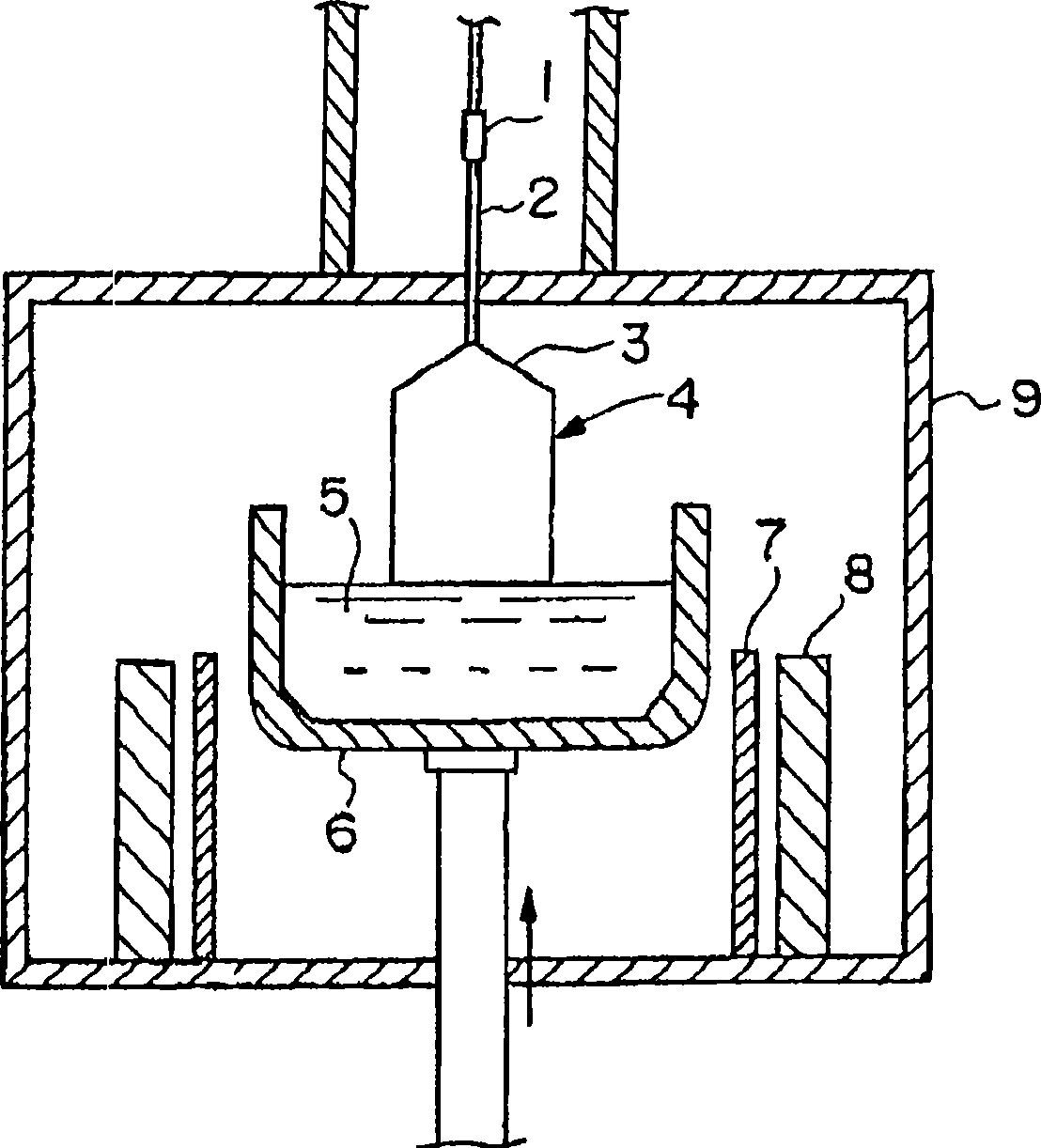

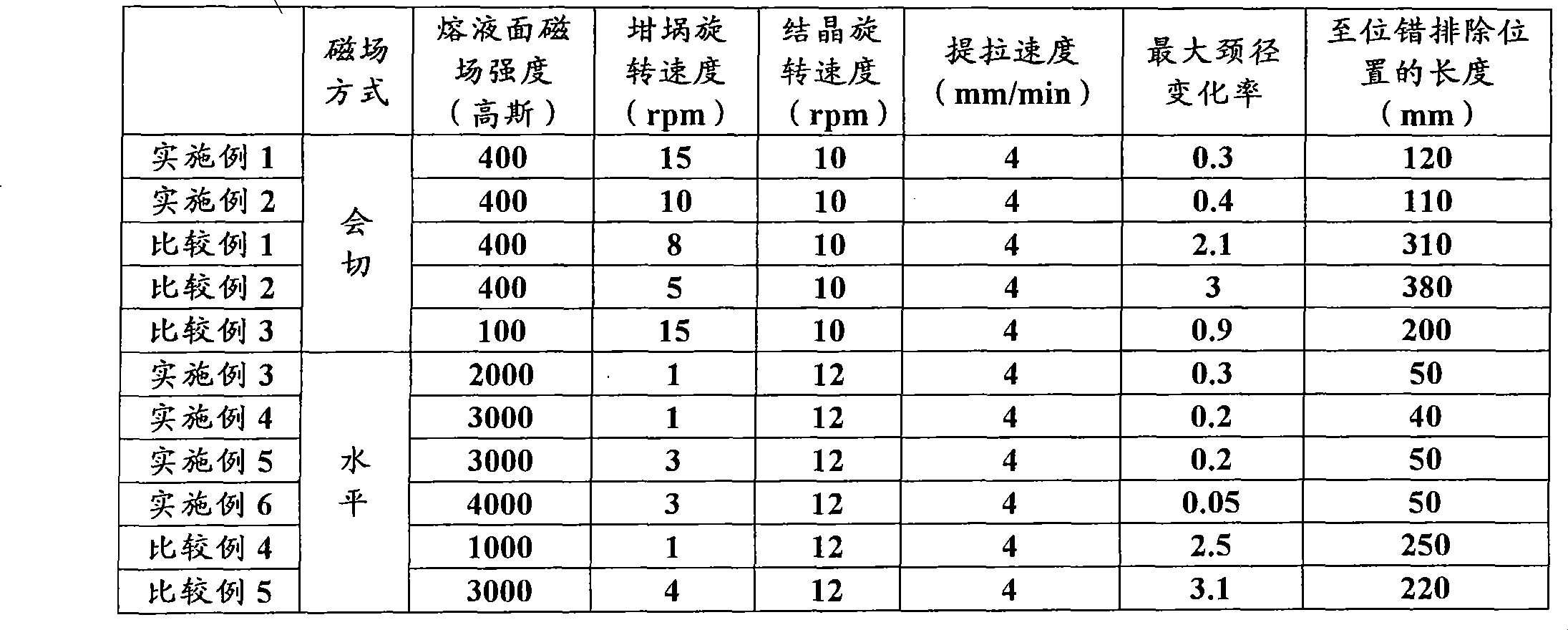

Method of pulling up silicon single crystal

InactiveCN101363132AInhibition rate of changeEliminate dislocationsPolycrystalline material growthBy pulling from meltDislocationSeed crystal

The invention provides a method of pulling up a silicon single crystal in which a variation rate of a neck diameter is controlled to be within a predetermined range, and a dislocation in a neck is eliminated. When pulling up the silicon single crystal, a single crystal with a predetermined crystal diameter is grown by bringing a seed crystal into contact with a material silicon melt, pulling up the seed crystal, growing the neck, and then increasing a diameter. The above-mentioned neck diameter is increased and decreased to grow the neck, during which a neck diameter variation rate is greater than or equal to 0.05 and less than 0.5, assuming that a value obtained in such a manner that a neck diameter difference (A-B) between adjoining inflection points is divided by a neck length L between the above-mentioned inflection points P1 and P2 is the neck diameter variation rate.

Owner:TOSHIBA CERAMICS CO

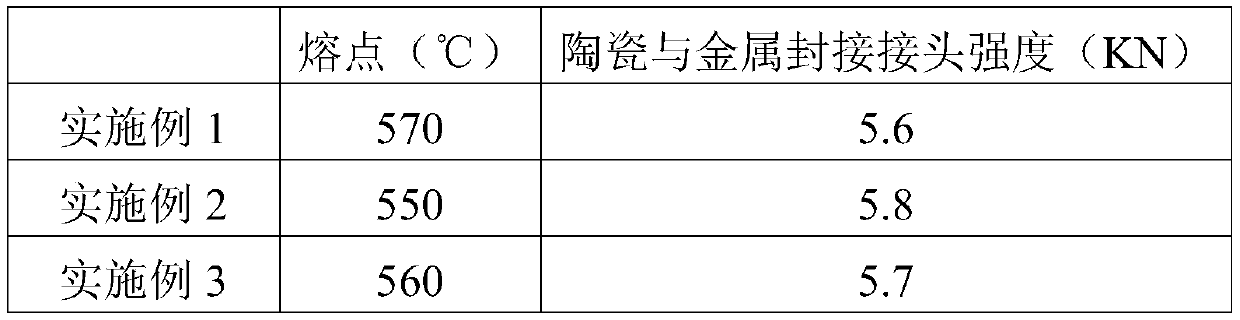

Multi-element alloy brazing filler metal for vacuum sealing

InactiveCN110129611ALow melting pointEasy to processWelding/cutting media/materialsSoldering mediaOxidation resistantAlloy

The invention discloses a multi-element alloy brazing filler metal for vacuum sealing. The multi-element alloy brazing filler metal comprises the following metal elements of, in percentage by mass, 50%-63.5% of Ag, 24%-28% of Cu, 9%-14% of In, 2%-5% of Ge, 1%-2% of Ga, 0.3%-0.5% of Y, and 2%-0.5% of Ce; and the preparation method of the multi-element alloy brazing filler metal comprises the following steps of smelting, hot rolling blooming, solution treating, cold rolling, annealing and finish machining. The brazing filler metal prepared by the preparation method is low in melting point, highin cleanliness, high in tensile strength and good in oxidation resistance.

Owner:WUXI RIYUE ALLOY MATERIALS

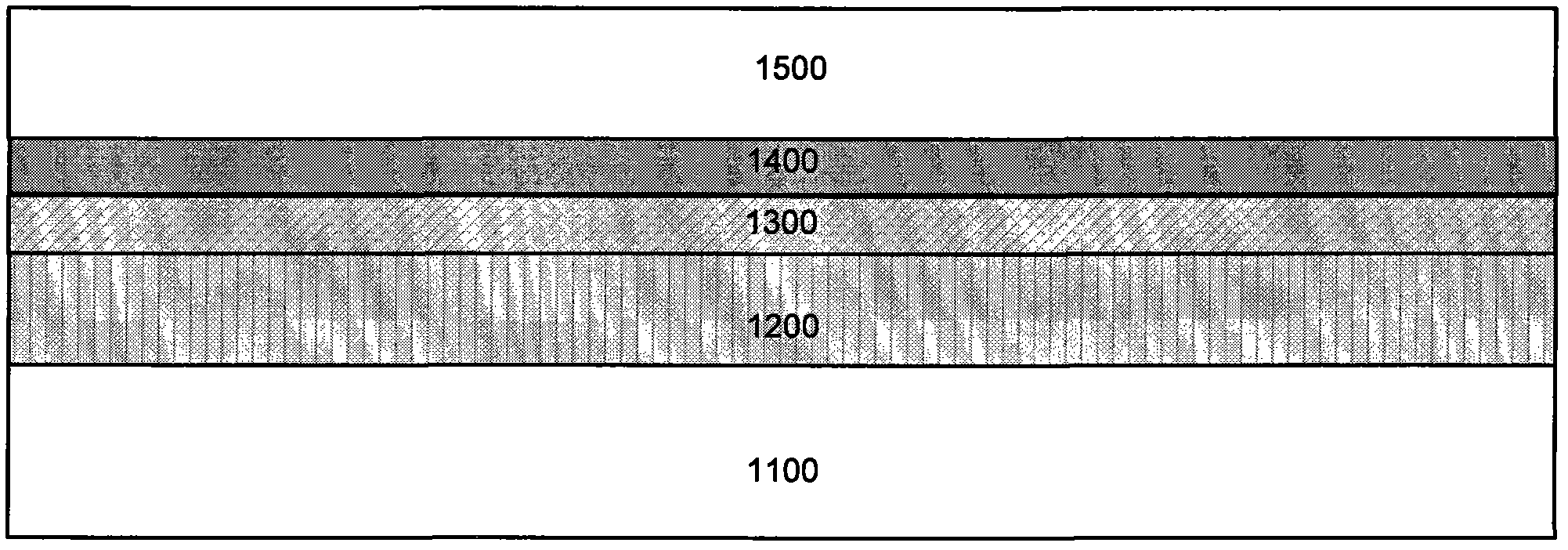

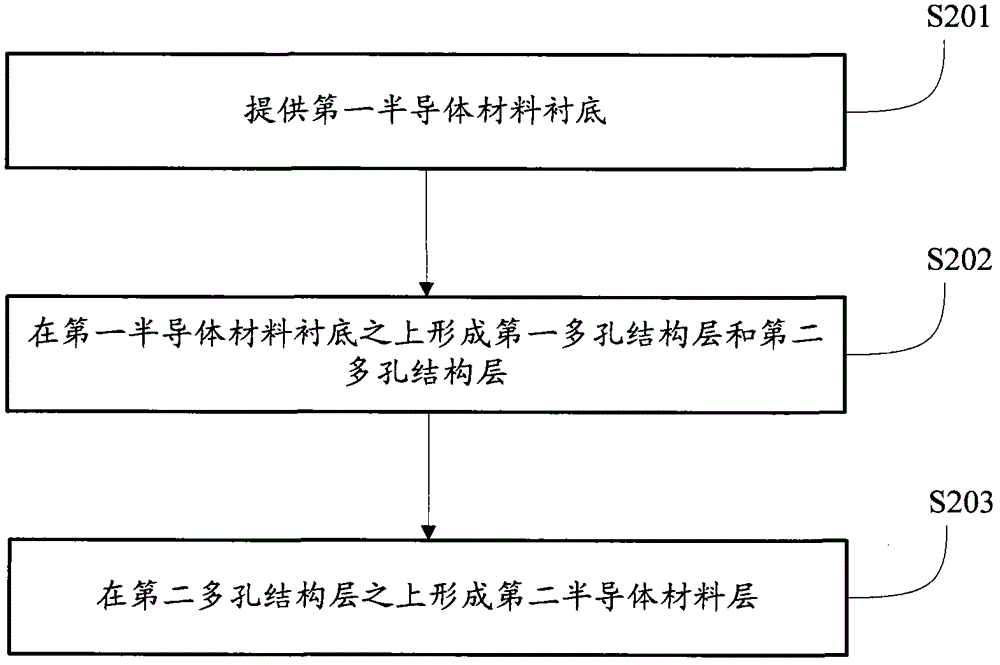

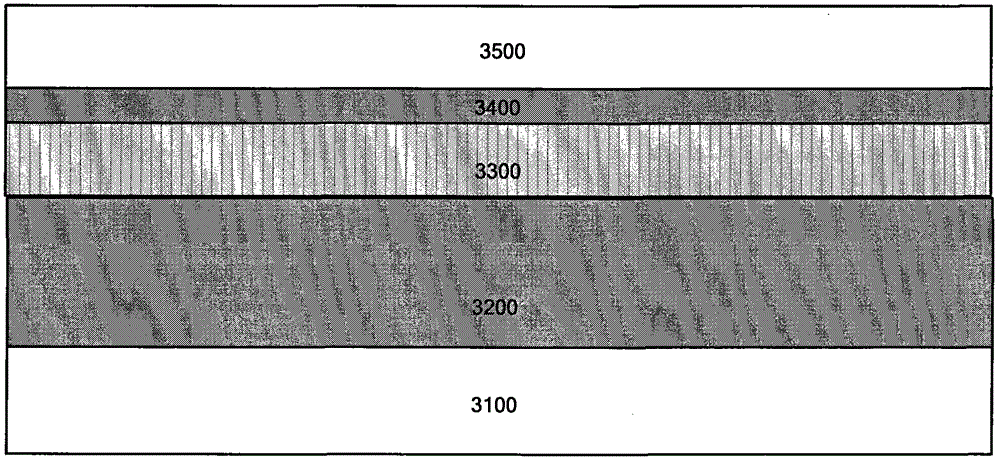

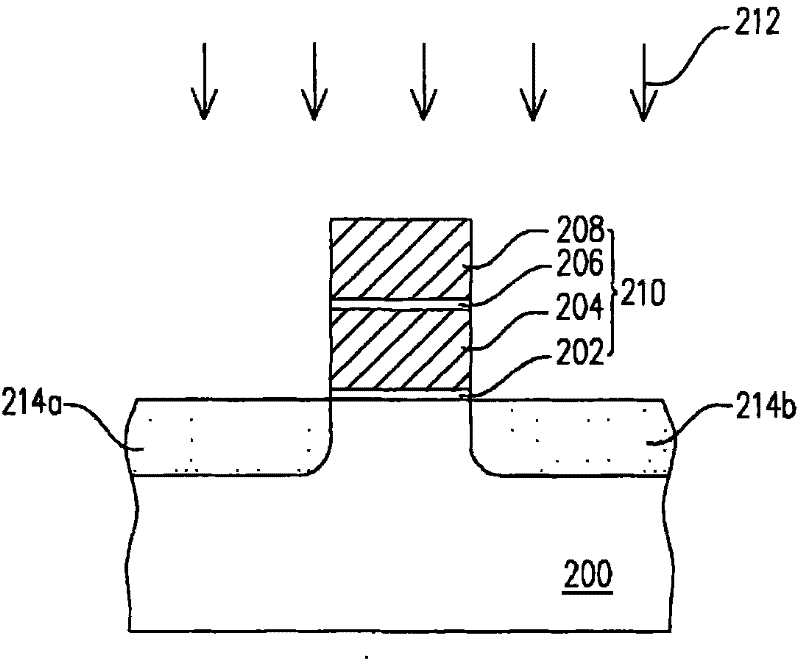

Semiconductor structure and forming method thereof

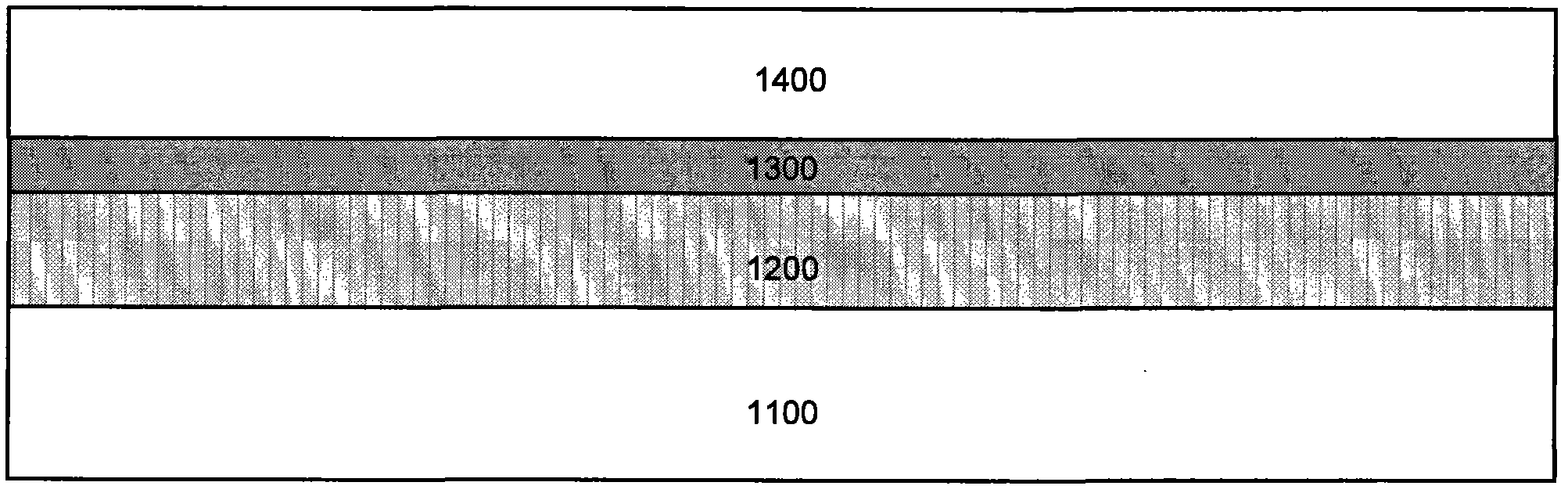

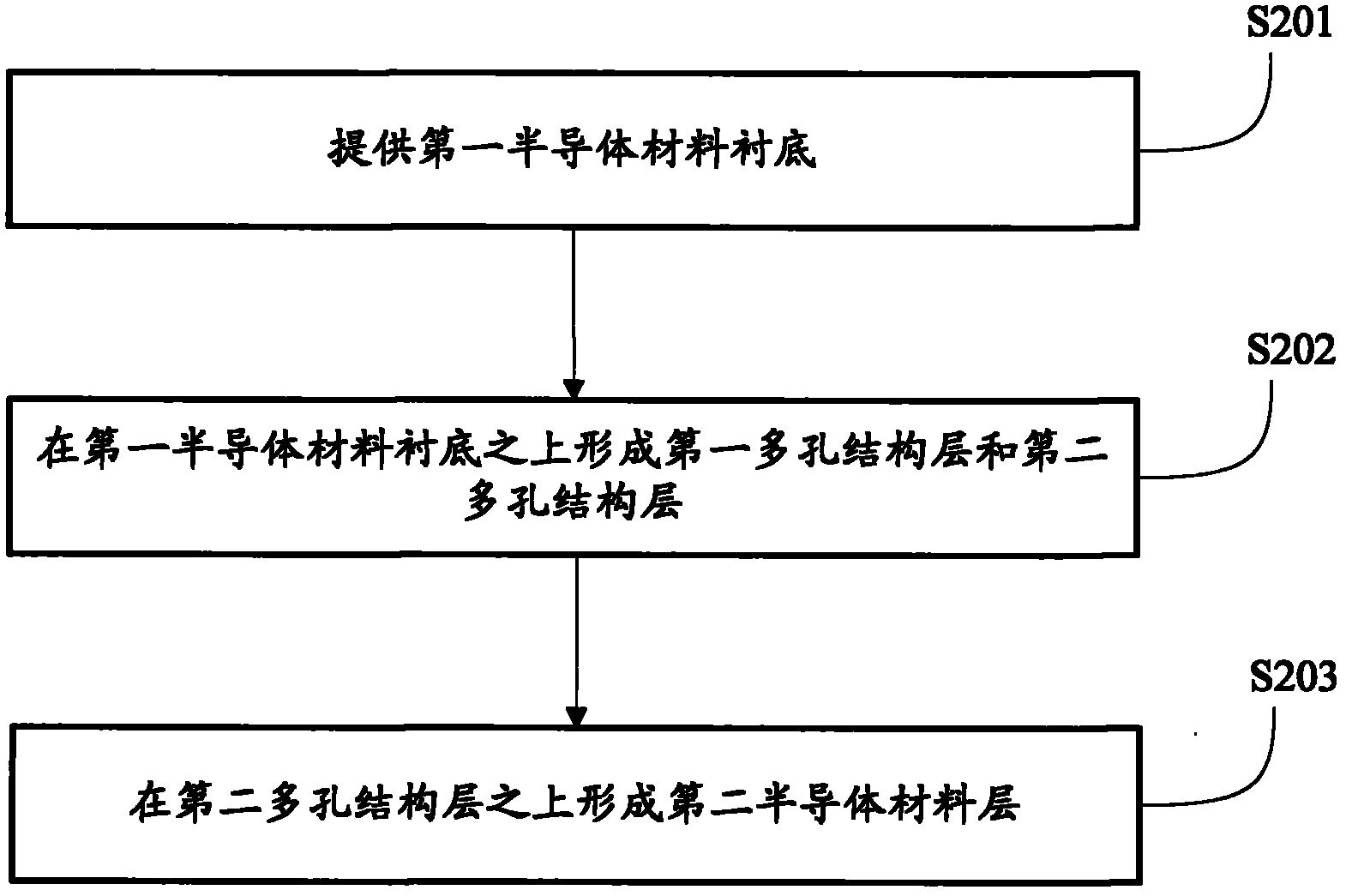

ActiveCN102104060AGuaranteed integrityQuality improvementAnodisationPolycrystalline material growthPorositySemiconductor materials

The invention provides a semiconductor structure comprising a first semiconductor material substrate, a first porous structure layer, a second porous structure layer and a second semiconductor material layer, wherein the first porous structure layer is formed on the first semiconductor material substrate; the second porous structure layer is formed on the first porous structure layer; the porosity and the aperture of the second porous structure layer are both less than the porosity and the aperture of the first porous structure layer; and the second semiconductor material layer is formed on the second porous structure layer. The invention can release the thermal mismatch stress of Si materials and epitaxial materials through the porous structure layers, prevent the problems of cracking and the like of an epitaxial film with larger thickness and enhance the quality of an epitaxial film crystal, thereby extending an epitaxial material layer (such as GaN and the like) which has large thickness and higher thermal mismatch stress with the Si materials on a Si substrate; and in addition, the porous Si materials can be removed in a subsequent process, therefore a subsequent device process can not be influenced.

Owner:安徽长飞先进半导体有限公司

Substrate with self-stripping function and method for stripping epitaxial layer

InactiveCN102034764APeel off without residueShort processing cycleSemiconductor/solid-state device detailsSolid-state devicesElastomerThermoplastic elastomer

The invention discloses a substrate with a self-stripping function, comprising a supporting substrate and an epitaxial layer arranged on the surface of the supporting substrate, wherein the supporting substrate has a first thermal expansion coefficient; the epitaxial layer has a second thermal expansion coefficient; the substrate further comprises a thermoplastic elastomer arranged at the interface of the supporting substrate and the epitaxial layer and has the third thermal expansion coefficient; and the function for stripping the epitaxial layer can be achieved by changing the temperature of the thermoplastic elastomer in the stripping layer. As an optional technical scheme, the third thermal expansion coefficient is smaller than the smaller one of the first thermal expansion coefficient and the second thermal expansion coefficient or greater than the greater one of first thermal expansion coefficient and the second thermal expansion coefficient. The technical scheme of the invention has the advantages of realizing the stripping process with low cost, high efficiency and no damage to the epitaxial layer.

Owner:SUZHOU NANOWIN SCI & TECH

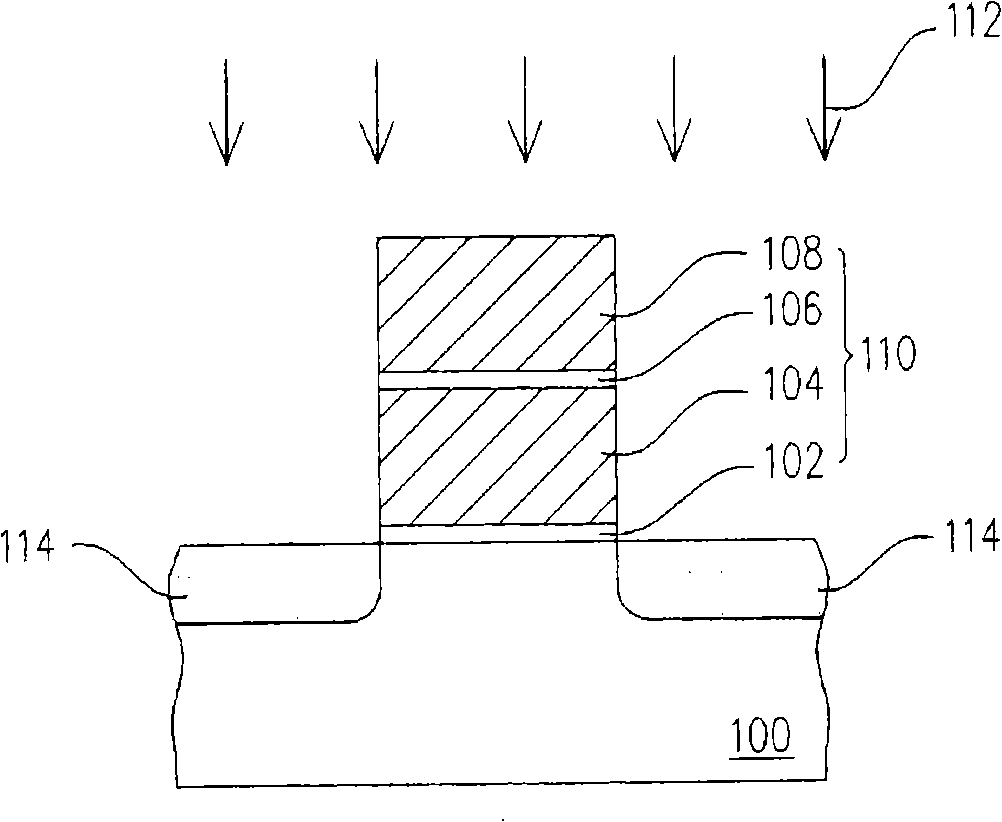

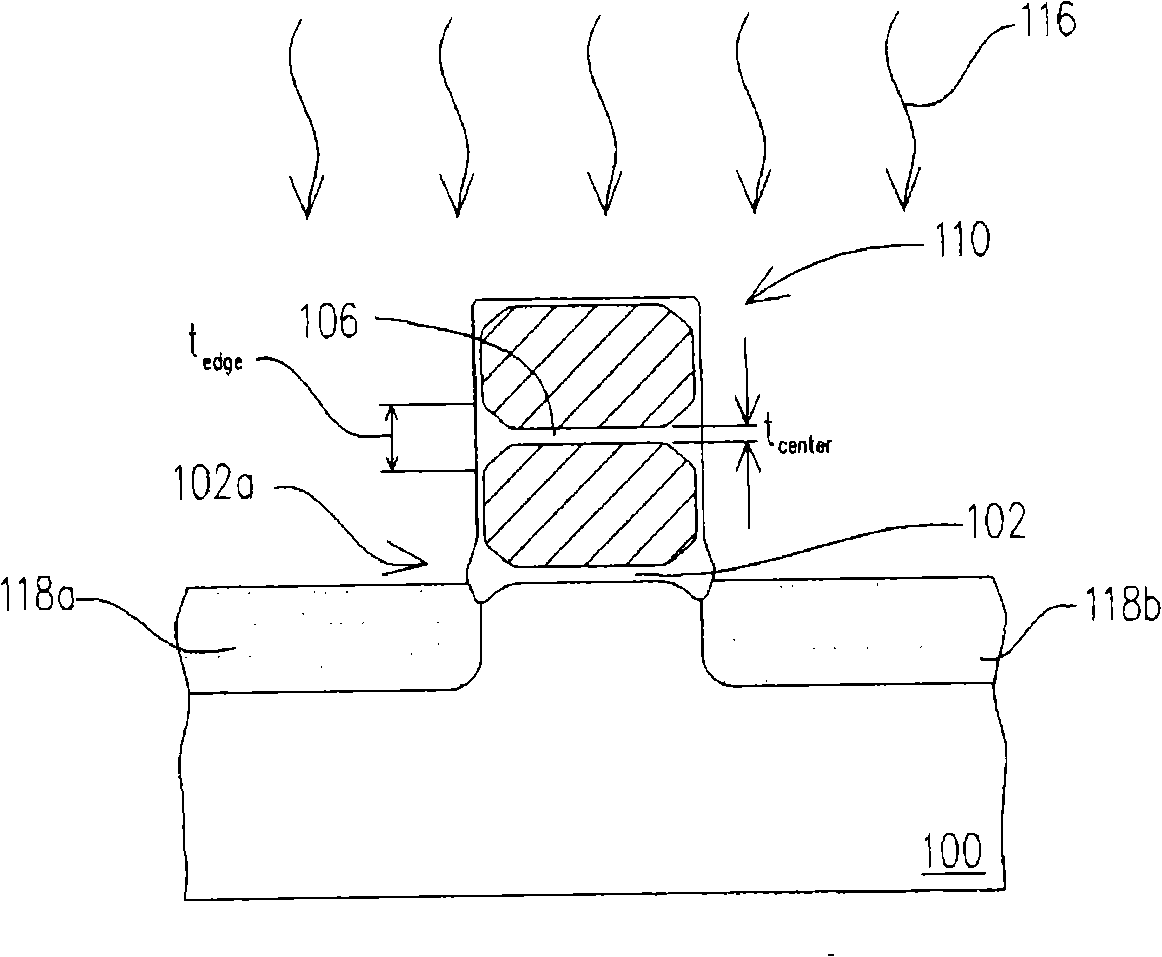

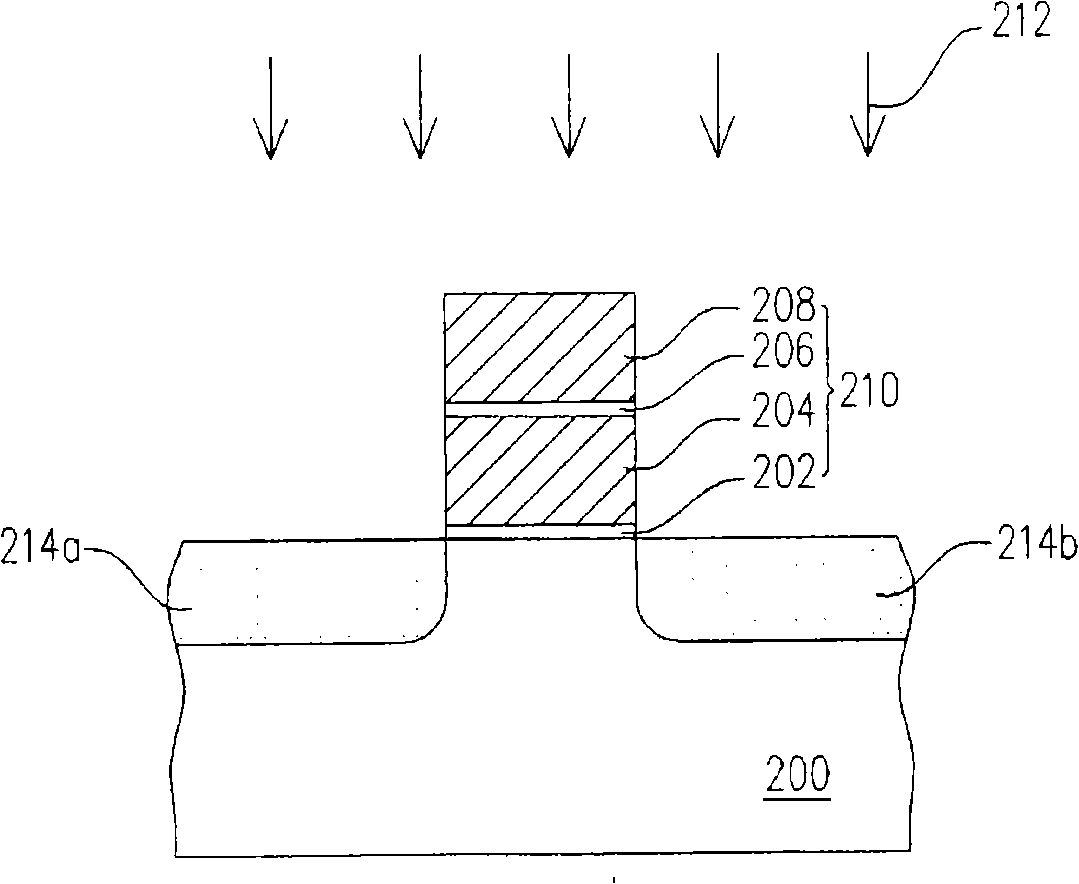

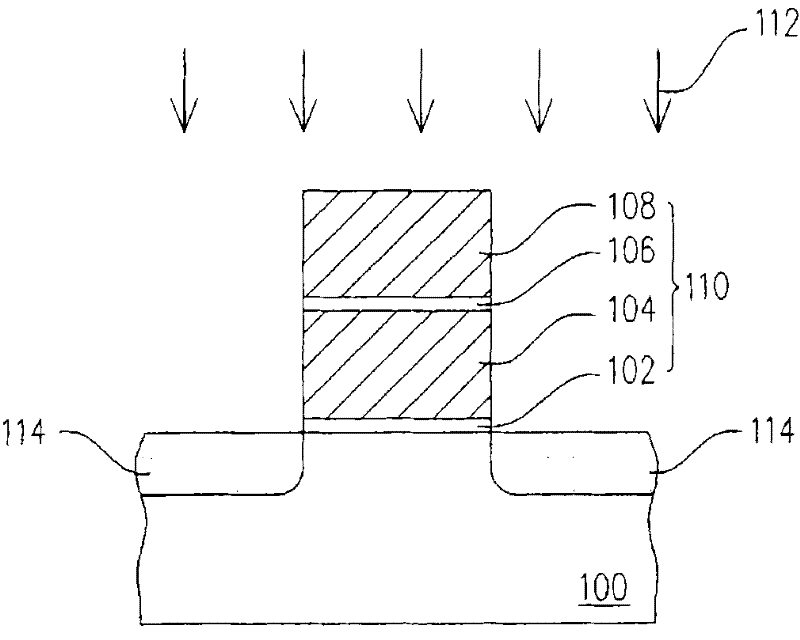

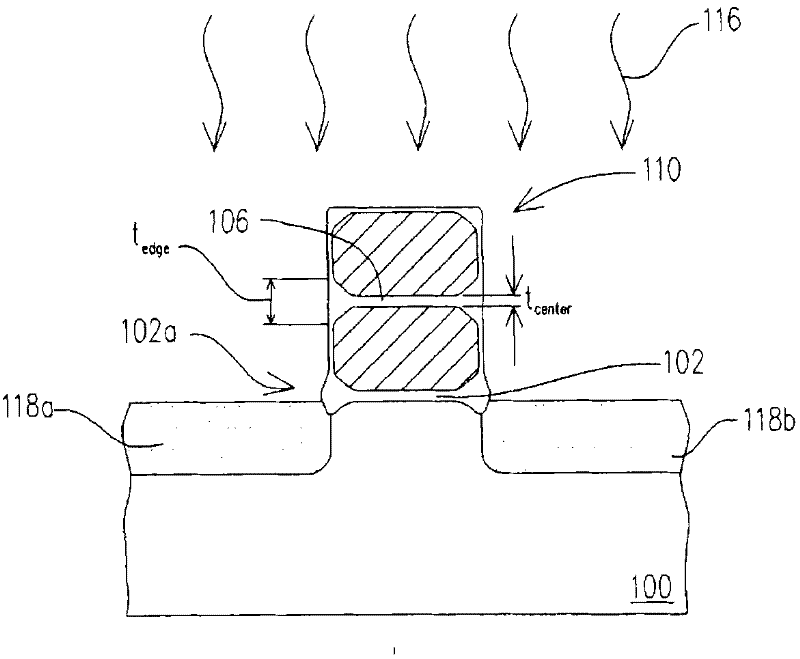

Flash memory and manufacturing method therefor

ActiveCN101359694AImprove data retentionImprove erase performanceSolid-state devicesSemiconductor devicesEngineeringMedia layer

Disclosed is a flash memory, comprising a substrate, a stack structure arranged on the substrate, a source electrode, a drain electrode and a source terminal spacing layer; wherein the stack structure is composed of a tunnel oxide layer, a charge storage layer arranged on the tunnel oxide layer, an inter-gate medium layer arranged on the charge storage layer and a control grid arranged on the inter-gate medium layer. The source electrode and the drain electrode are arranged in the substrate respectively at two sides of the charge storage layer. The source terminal spacing layer is arranged on one side wall of the stack structure, which is close to the source electrode, so as to prevent the parts of the tunnel oxide layer and the inter-gate medium layer, which are close to the source electrode, from being oxidized again, which leads to the increase of the thickness.

Owner:MACRONIX INT CO LTD

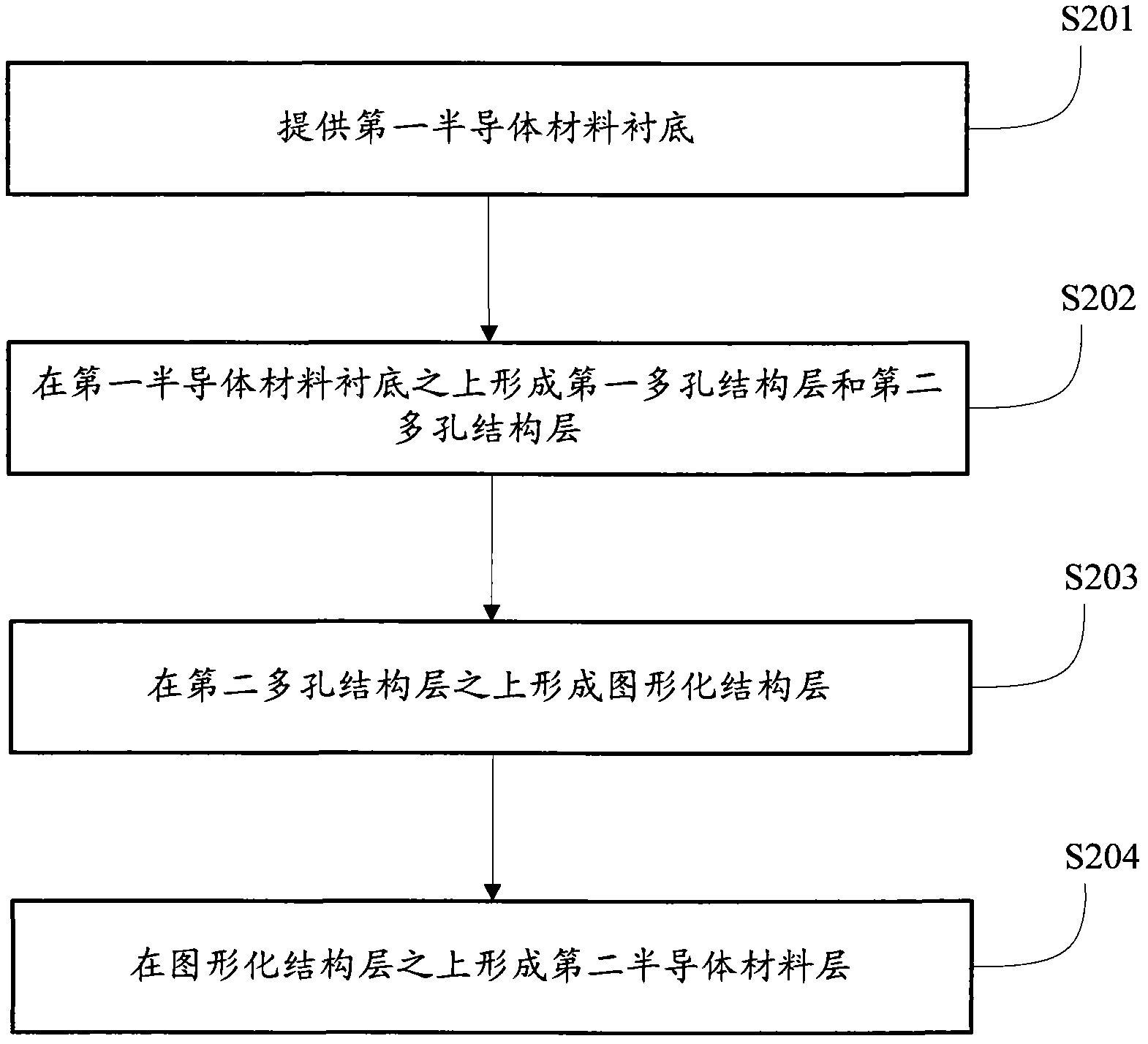

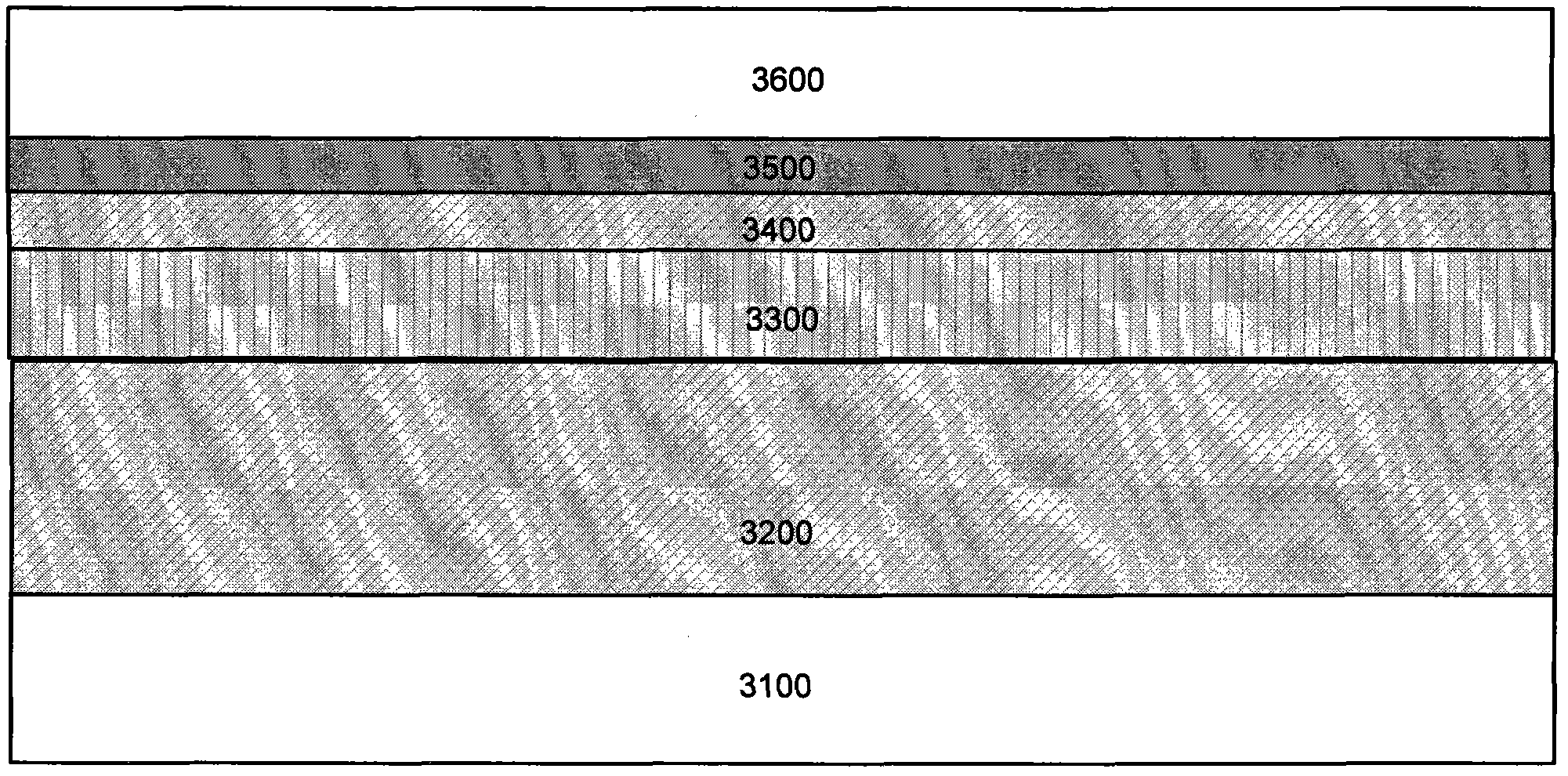

Semiconductor structure and forming method thereof

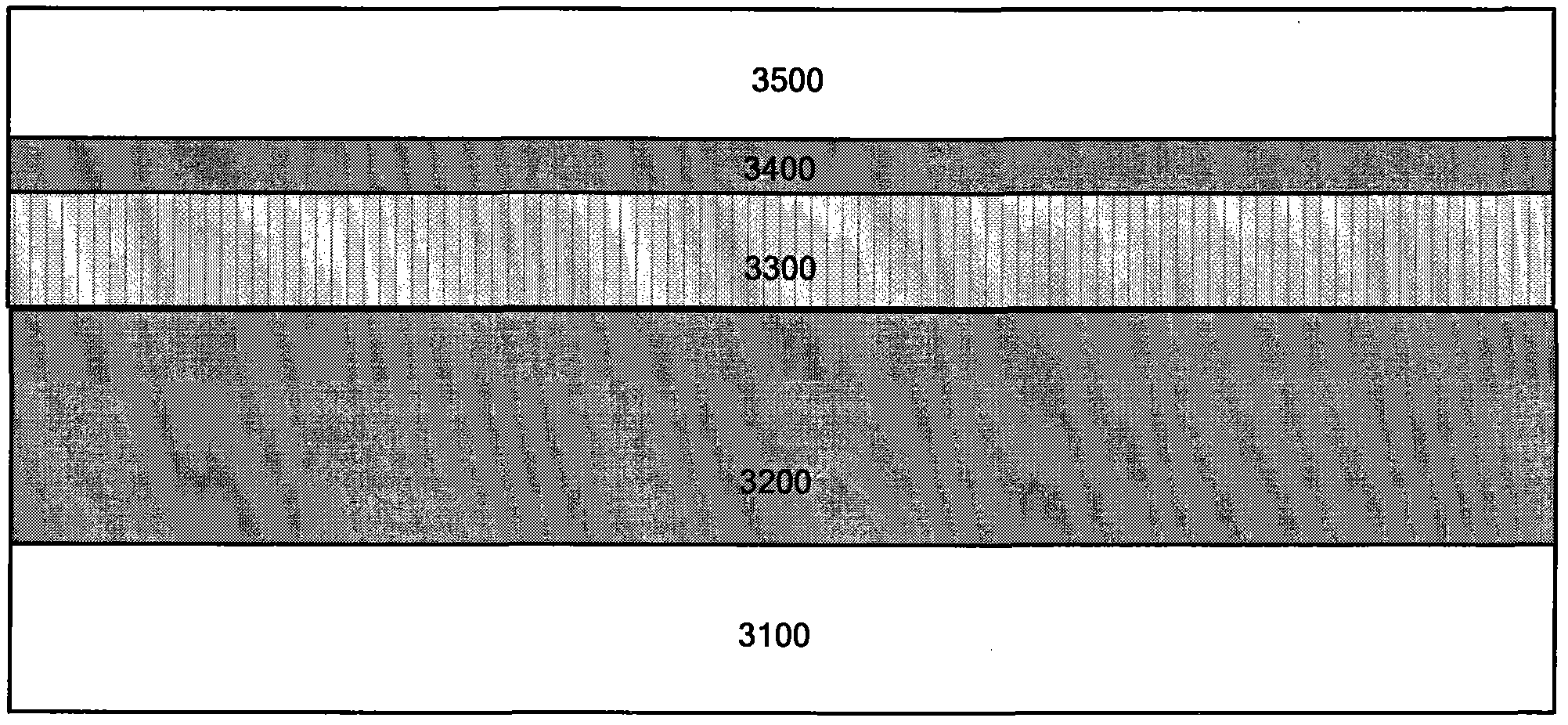

InactiveCN102064186AControl releaseGuaranteed integritySemiconductor/solid-state device manufacturingSemiconductor devicesPorositySemiconductor materials

The invention provides a semiconductor structure which comprises a first semiconductor material substrate, a first porous structure layer formed on the top layer of the first semiconductor material substrate, a second porous structure layer formed on the first porous structure layer, a graphical structure layer formed on the second porous structure layer and a second semiconductor material layer formed on the graphical structure layer, wherein the porosity and aperture of the second porous structure layer are both less than the porosity and aperture of the first porous structure layer. The thermal mismatch stress of Si material and epitaxial material can be released through the porous structure layer, the problems of cracking of an epitaxial film under relatively large thickness and the like are prevented, and the quality of the epitaxial film crystal is improved. According to the invention, a large-thickness epitaxial material layer (such as GaN and the like) in relatively large thermal mismatch stress with the Si material can be extended on the Si substrate, and the porous Si material can be removed in subsequent processes, thereby avoiding influence on the subsequent device processes.

Owner:王楚雯 +1

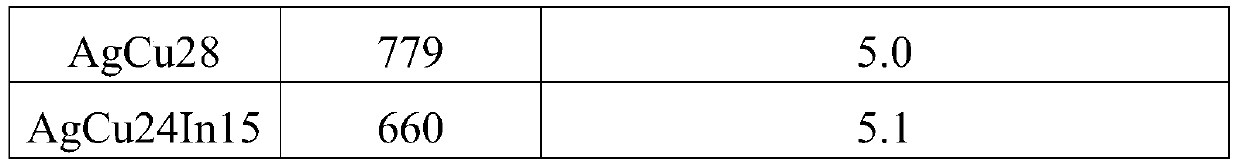

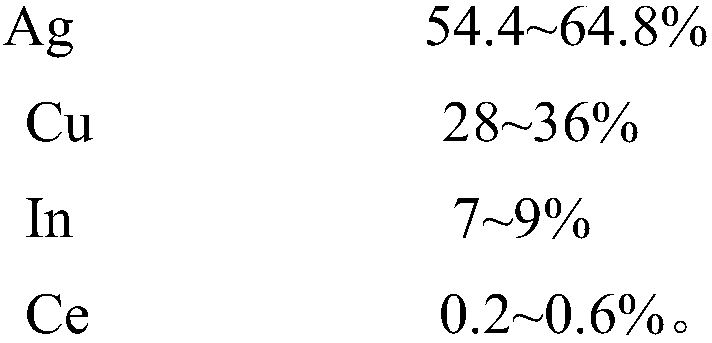

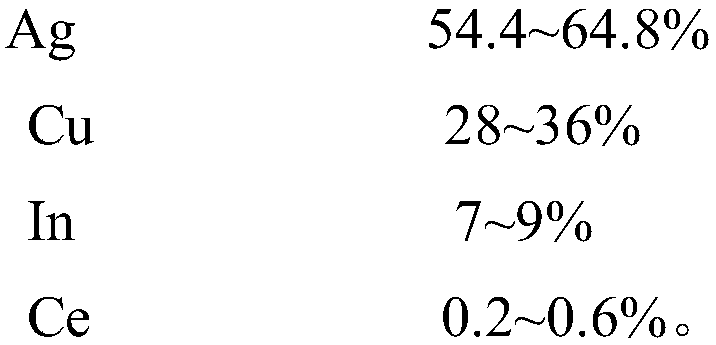

Alloy brazing filler metal for vacuum sealing and connection

InactiveCN109175785ALow melting pointEasy to processWelding/cutting media/materialsSoldering mediaAlloyFiller metal

The invention discloses an alloy brazing filler metal for vacuum sealing and connection. Metal elements of the alloy brazing filler metal comprise, by mass percentage, 54.4-64.8% of Ag, 28-36% of Cu,7-9% of In and 0.2-0.6% of Ce. The prepared alloy brazing filler metal is low in fusion point, high in cleanliness and tensile strength and good in oxidation resistance.

Owner:WUXI RIYUE ALLOY MATERIALS

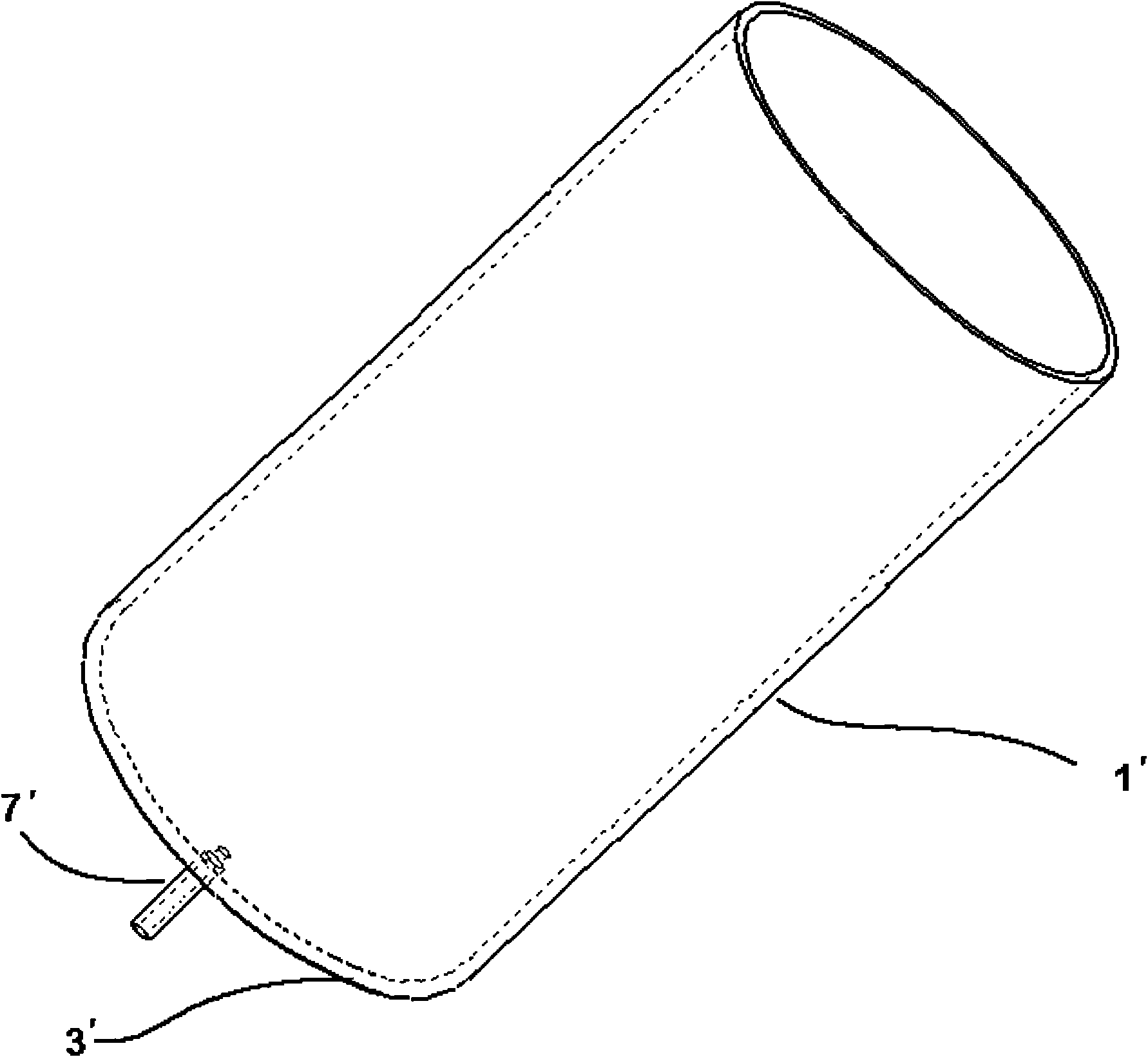

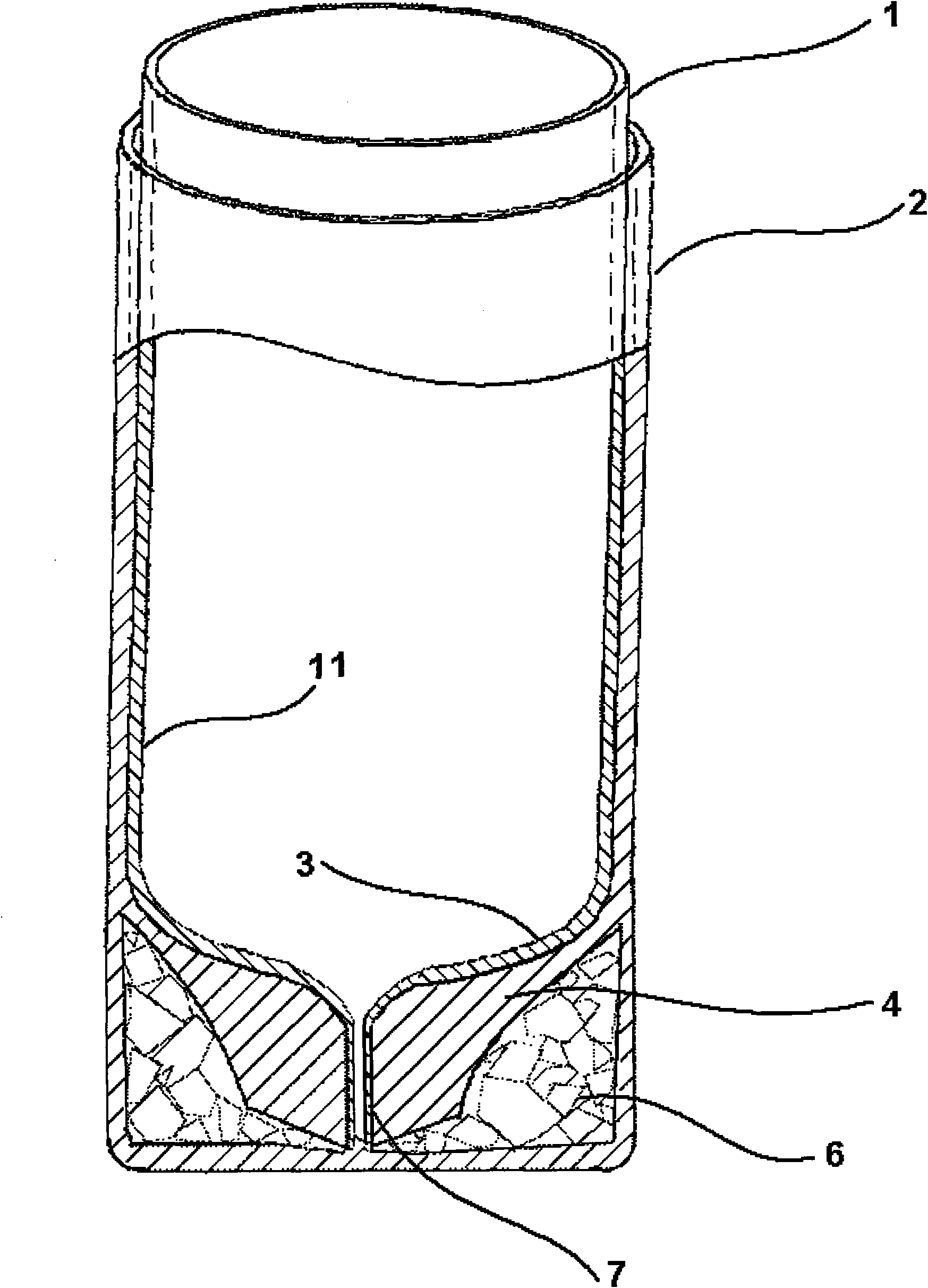

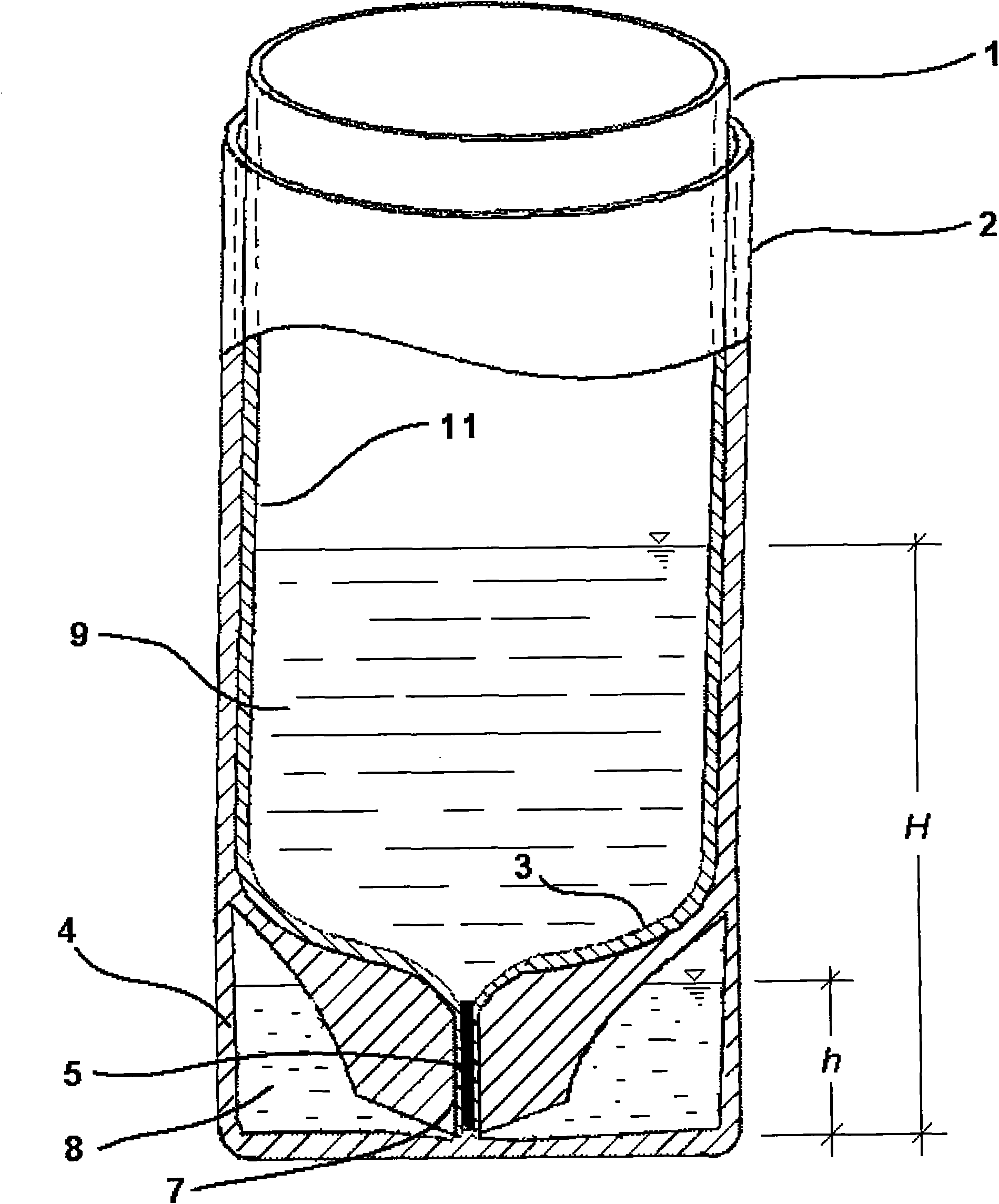

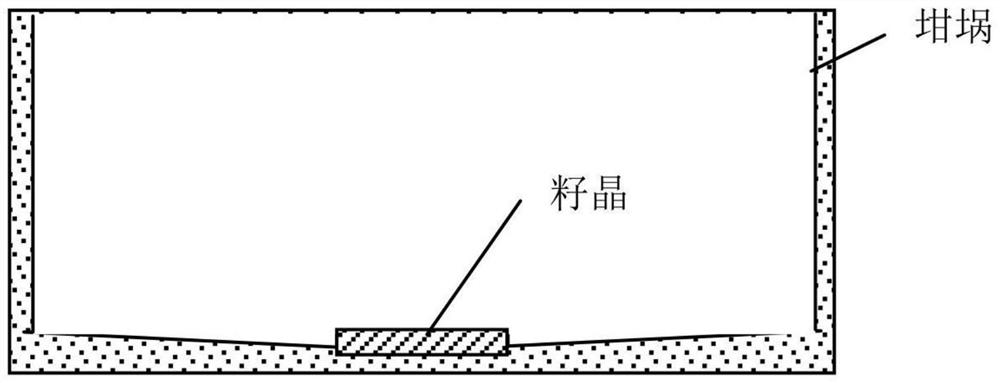

Double-layer crucible for growing silicon single crystals by directional solidification method

InactiveCN101886288AGuaranteed efficient growthInhibit growthFrom frozen solutionsDirectional solidificationSingle crystal growth

The invention discloses a double-layer crucible for growing silicon single crystals by a directional solidification method, which comprises an outer crucible and an inner crucible nested into the outer crucible, wherein the inner crucible comprises an inner crucible main body and an inner crucible bottom; the outer crucible comprises an outer crucible main body and an outer crucible bottom; the inner crucible bottom is provided with a seed crystal sleeve for placing seed crystals; the outer crucible bottom is provided with an anti-leakage cavity; an anti-leakage agent is placed in the anti-leakage cavity; and the internal cavity of the inner crucible main body is communicated with the anti-leakage cavity through the internal cavity of the seed crystal sleeve. The anti-leakage agent is not reacted with silicon and is immiscible with the silicon, the density of the anti-leakage agent is more than 2.4g / cm<3>, and the melting temperature of the anti-leakage agent is less than 1,410 DEG C. The double-layer crucible can effectively solve the seed crystal placing problem, realizes silicon single crystal growth by the directional solidification method, meanwhile can furthest prevent molten silicon from leaking from the seed crystal sleeve, has low cost and a simple structure, and is easy to process.

Owner:GREENERGY CRYSTAL TECH

Preparation method for false tooth alloy material

A preparation method for a false tooth alloy material comprises the particular steps that (1) raw materials are put into a vacuum medium-frequency induction furnace to be melted, the heat is kept for 30-60 min, then the materials are poured into a mold and cooled for 30-40 min through cooling water to the room temperature, and a rough ingot is obtained; (2) the rough ingot is put into the vacuum medium-frequency induction furnace again, the temperature is raised to 850-870 DEG C and kept for 5-10 h, then the rough ingot is poured into a mold and cooled for 80-100 min through cooling water to the room temperature, and a fine ingot is obtained; (3) the fine ingot is subjected to aging treatment, and is firstly kept at the temperature of 200-250 DEG C for 10-12 h, then the temperature is raised to 500-570 DEG C and kept for 5-8 h, and the temperature is slowly decreased to the room temperature at the speed of 2-3 DEG C / min. The preparation method for the false tooth alloy material is high in strength, good in corrosion resistance and small in harm to the human body, thereby solving the problems that precious metal is expensive, and non-precious alloy harms the human body.

Owner:谭华

Thermal treatment method for formed weld joint of drill rod

ActiveCN105219944AGood performanceIncrease productivityFurnace typesHeat treatment furnacesFriction weldingWelding joint

The invention provides a thermal treatment method for a formed weld joint of a drill rod. The thermal treatment method comprises the following steps that firstly, annealing treatment is carried out on a weld joint zone which is formed between a drill rod pipe body and a connector through friction welding; then the annealed drill rod is placed in air to be cooled until the drill rod is cooled to the room temperature; and finally the cooled drill rod is subjected to tempering treatment. By means of the thermal treatment method, as tempering sorbite is formed, the structure of the weld joint of the drill rod is finer, and the problem of cracks in the weld joint of the small drill rod is completely solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

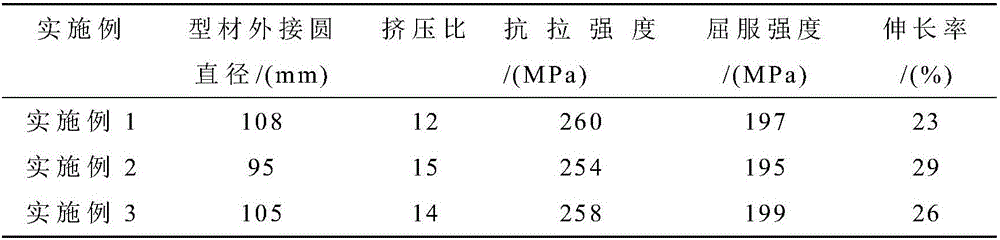

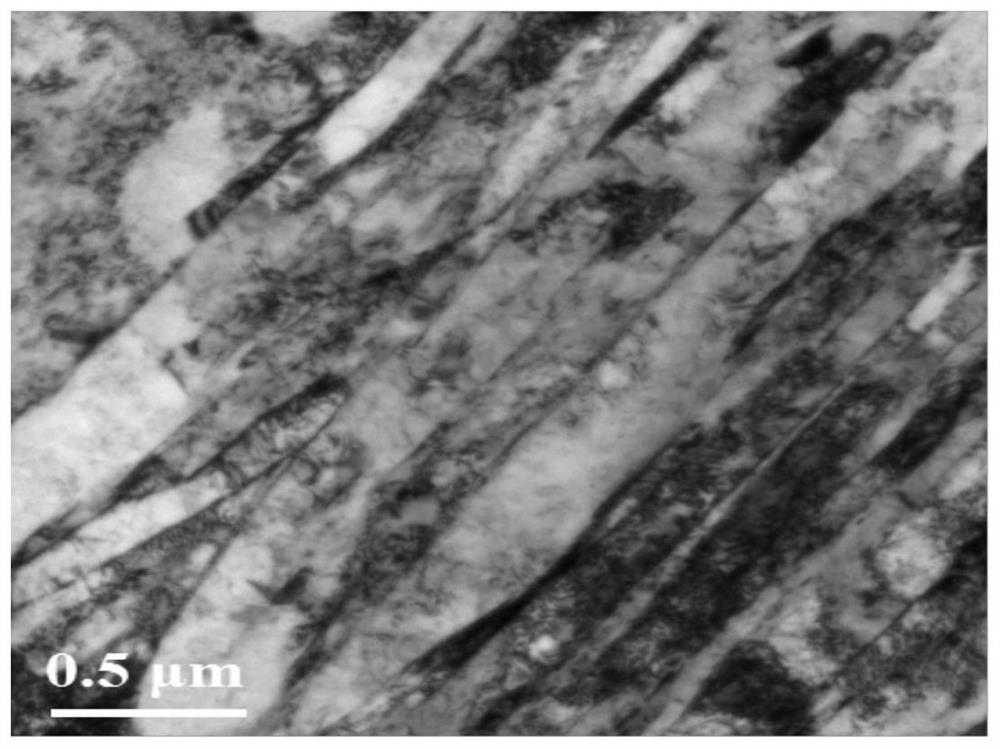

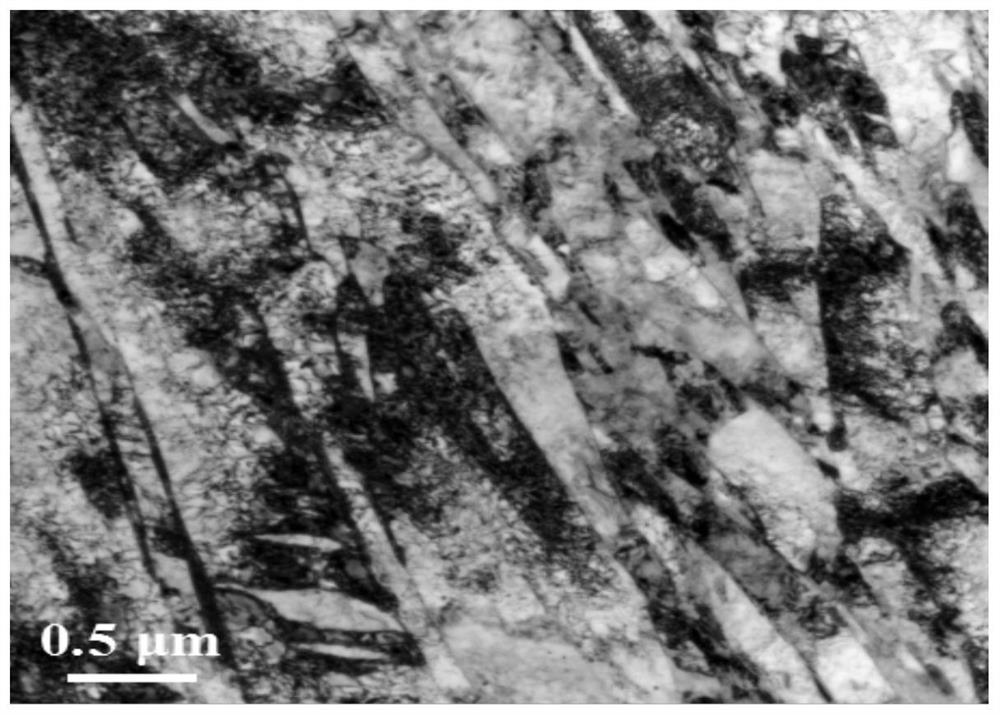

Secondary hot-extrusion technology of AQ80M magnesium alloy profiles

The invention discloses a secondary hot-extrusion technology of AQ80M magnesium alloy profiles. The secondary hot-extrusion technology comprises the steps: 1) performing double-stage homogenizing treatment to magnesium alloy billets after peeling; 2) heating the magnesium alloy billets to 340-420 DEG C after double-stage homogenizing pretreatment, holding the magnesium alloy billets for 1-3 h at 340-420 DEG C, performing primary hot-extrusion deformation at the extrusion ratio of 2:9 and the extrusion speed of 1.5-6 mm / s to obtain bars; 3) heating the magnesium alloy bars obtained in 3) to 340-380 DEG C, holding the magnesium alloy bars for 1-3 h at 340-380 DEG C, performing secondary hot-extrusion deformation at the extrusion ratio of 12:15 and the extrusion speed of 4-12 mm / s to obtain magnesium alloy triangular profiles; 4) performing thermal treatment to the magnesium alloy triangular profiles obtained in 3) to obtain final products. According to the secondary hot-extrusion technology disclosed by the invention, the triangular profiles with the circumscribed circle diameter of 95-108 mm and the length of at least 5000 mm can be obtained, the high-temperature tensile strength of the magnesium alloy triangular profiles after thermal treatment is >= 250 MPa, the yield strength is >= 195 MPa, and the elongation is >= 23%.

Owner:HUNAN JINGE NEW MATERIAL

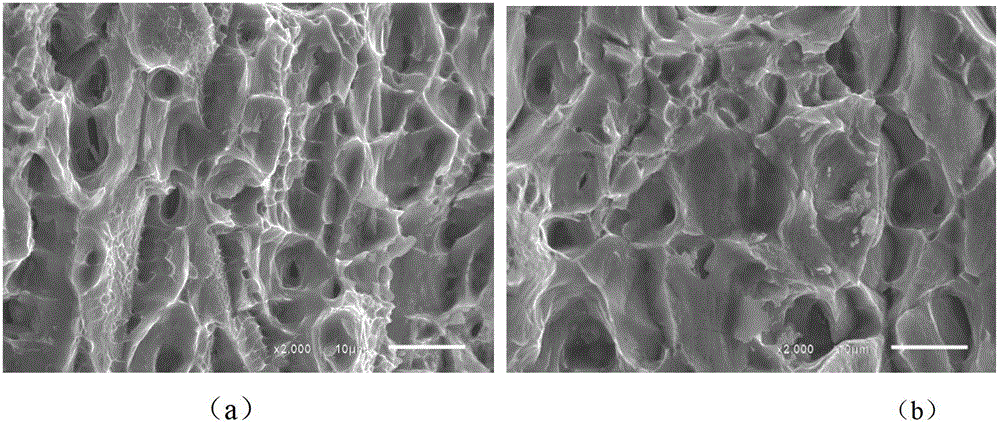

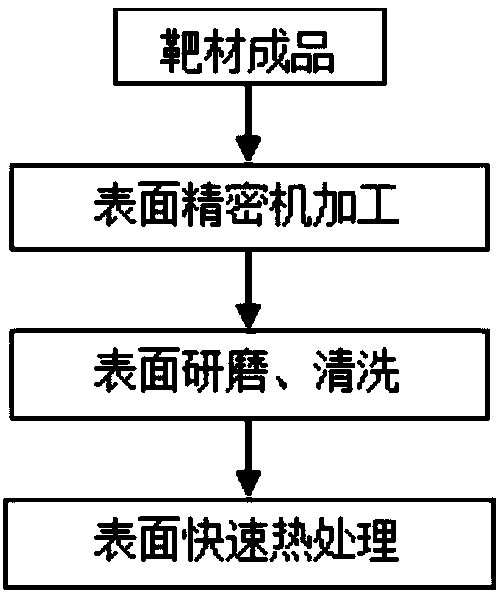

Preparation method of high-purity dense magnesium oxide target material based on rapid surface heat treatment

The invention provides a preparation method of a high-purity dense magnesium oxide target material based on rapid surface heat treatment. The method comprises the following steps: taking magnesium oxide powder as the raw material, taking zirconium oxide spheres as media, carrying out planetary ball milling of the raw material, and sieving the milled powder via a 200-mesh sieve; carrying out cold isostatic pressing of the sieved powder to obtain a magnesium oxide pressed blank; sintering the magnesium oxide pressed blank in vacuum, carrying out surface precision machining of the target material according to the needed target material size till the surface roughness of the target material is less than or equal to 0.8 micron after vacuum sintering is ended to obtain a magnesium oxide target material; and grinding the surface of the magnesium oxide target material, then washing and finally carrying out rapid surface heat treatment under the vacuum condition by using a continuous wave laser heat treatment method, a scanning electron beam method or a non-coherent wideband frequency light source method to obtain the high-purity dense magnesium oxide target material based on rapid surface heat treatment. The magnesium oxide target material prepared by the method is high in purity, high in density and consistent in surface layer structures and inner layer structures; and the preparation method is simple, green, environmentally-friendly and energy-saving, and is short in preparation time.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

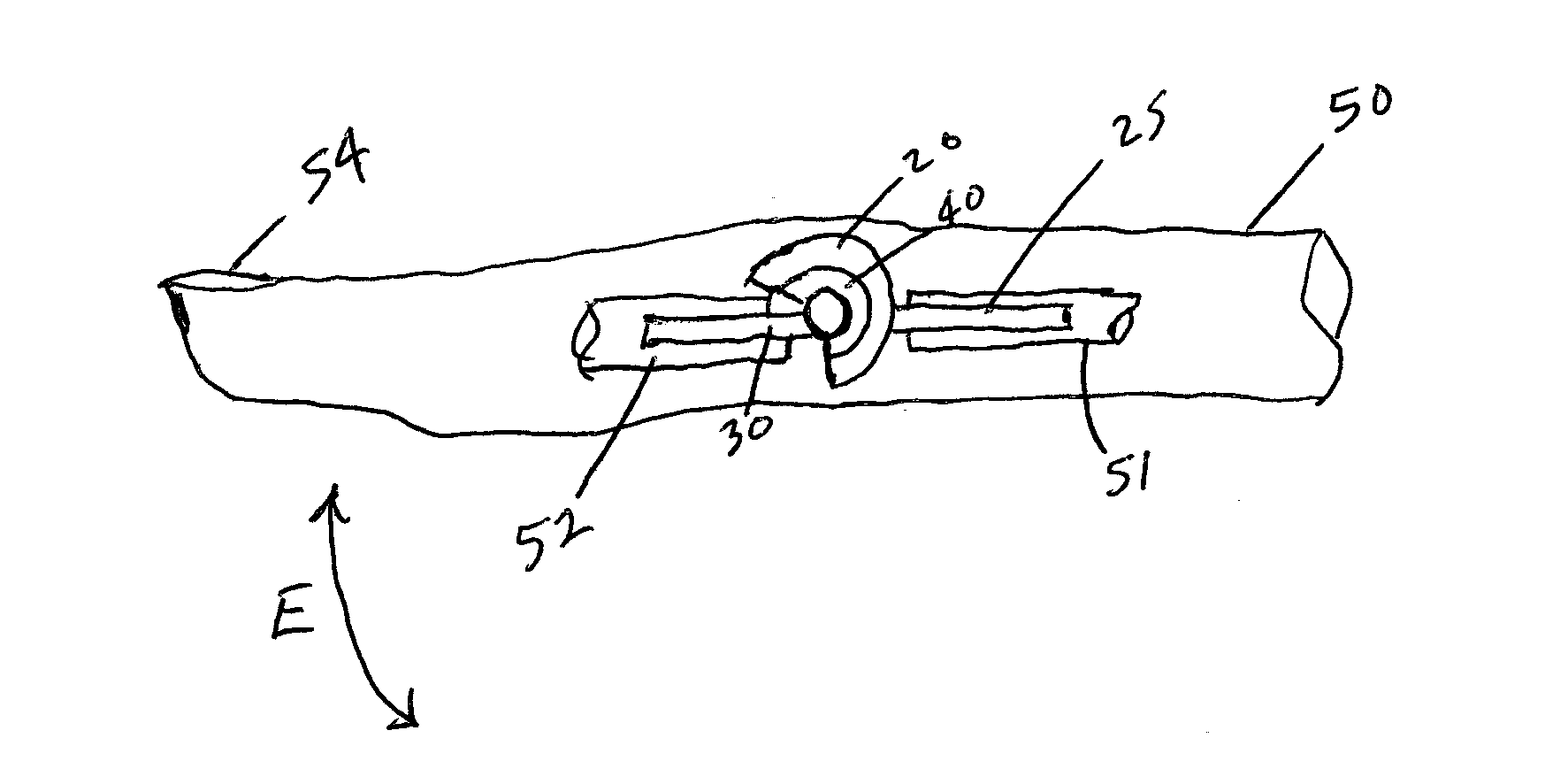

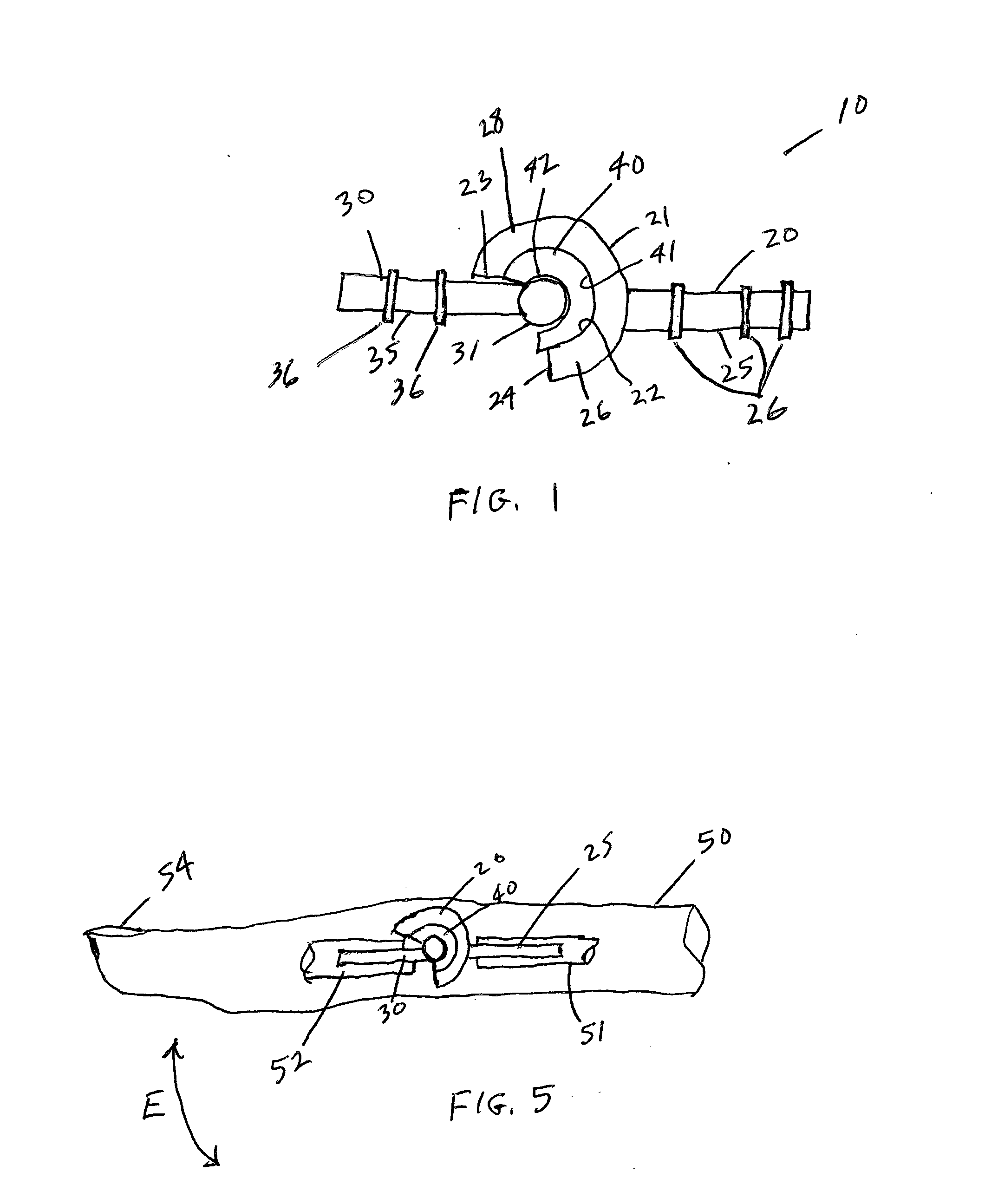

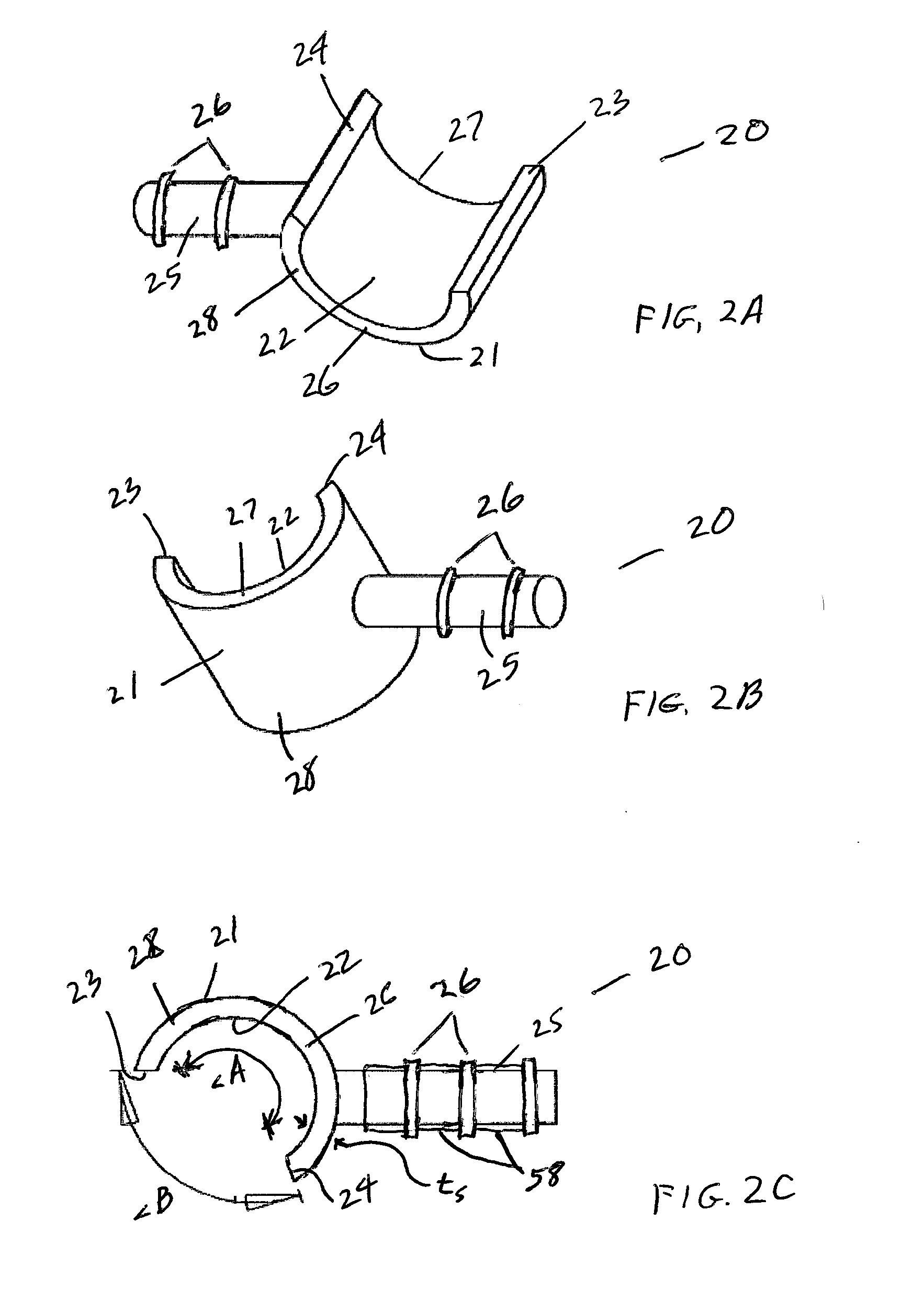

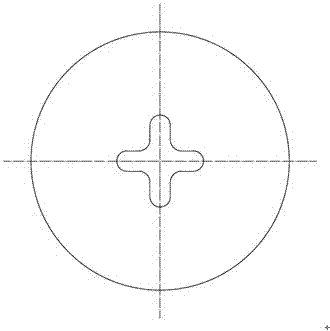

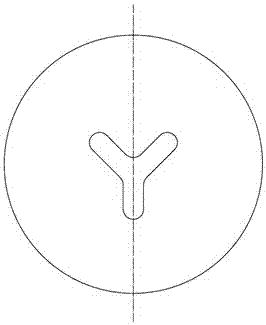

Implants and Methods of Making and Using the Same

InactiveUS20130066436A1Eliminate material failure and joint dislocationLong implant lifeFinger jointsAnkle jointsBiomedical engineeringImplant

Owner:DESA JONATHAN

A seeding method for growing sapphire crystals by Kyropoulos method

InactiveCN105019023BEasily brokenImprove yieldPolycrystalline material growthUsing seed in meltEngineeringSymmetric structure

The invention relates to a seeding method for growth of sapphire crystal with a KY (Kyropoulos) method. A non-rotating symmetric structure of a radiation heat dissipation opening of seed crystal is used, and the seeding method comprises following steps during seeding: (1), the seed crystal is immersed 3-5 mm below the liquid level of melt; (2), a crystal plate grows out from the seed crystal preferentially towards one side after the heat dissipation opening adopting the non-rotating symmetric structure dissipates heat; (3), the seed crystal is lifted and pulled at an average lifting and pulling speed being 3-12 mm / h, alternate instant lifting is adopted in the lifting and pulling process, the seed crystal is rotated by a given angle, and a crystal plate grows out again in the heat dissipation direction after alternate instant lifting, so that next instant lifting is facilitated; (4), the step (3) is carried out repeatedly until the length of a crystal section reaches 60-80 mm, the crystal section adopting a spiral structure is formed, and when the equivalent diameter of the cross section of a solid-liquid interface reaches 40-60 mm, seeding is finished. The seeding method has the advantages as follows: the spiral seeding structure can be obtained, defects and dislocation of the seed crystal can be eliminated to the largest extent, breaking cannot be caused easily, the yield of crystal can be increased, and industrial production is facilitated.

Owner:JIANGSU CEC ZHENHUA CRYSTAL TECH

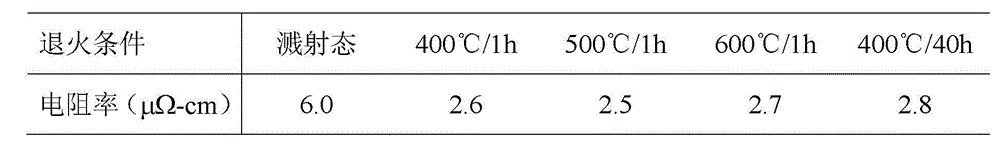

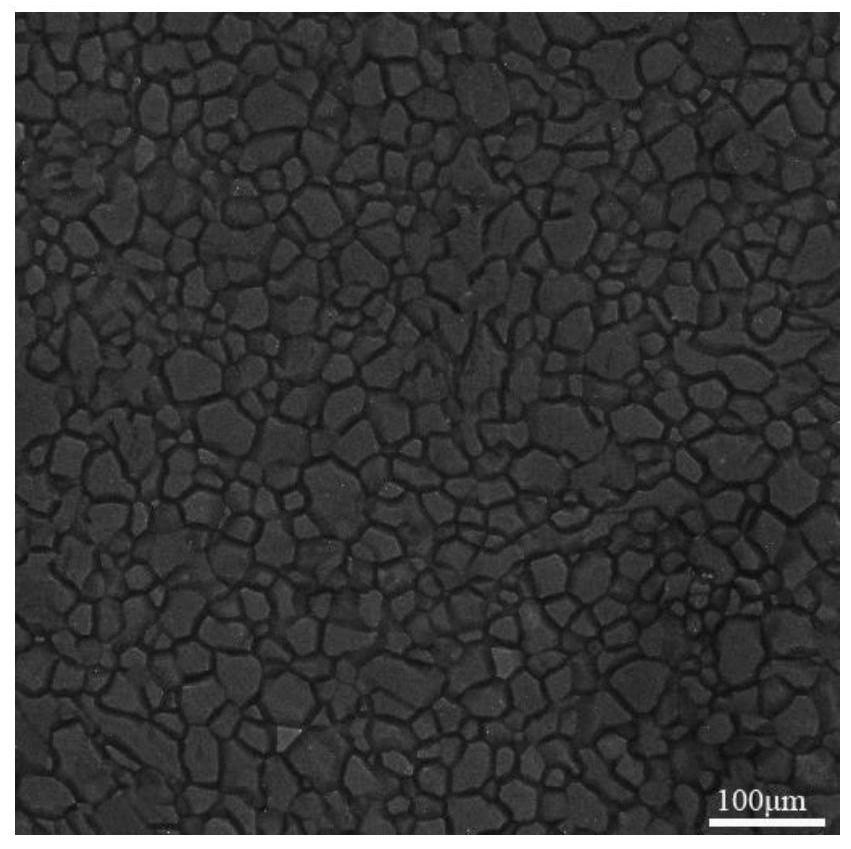

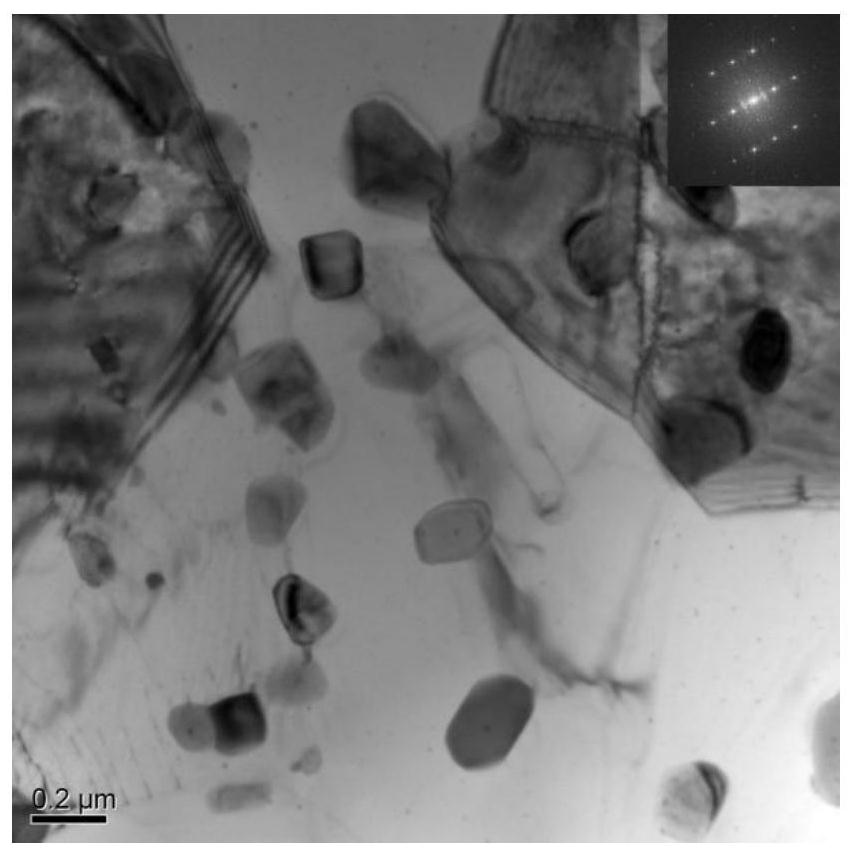

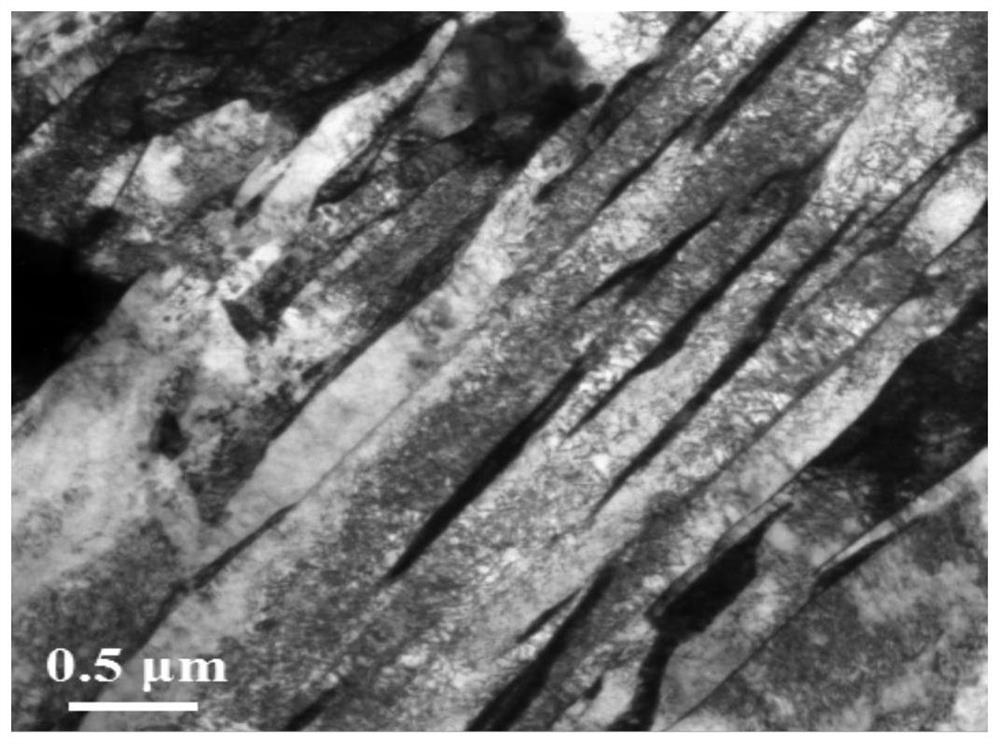

Low resistivity high thermal-stability copper-nickel-molybdenum alloy film and producing method thereof

InactiveCN103237910BEliminate scattering effectsLow resistivityVacuum evaporation coatingSputtering coatingAlloy thin filmEnthalpy of mixing

A Cu—Ni—Mo alloy thin film, including Ni as a solution element and Mo as a diffusion barrier element. Ni and Mo are co-doped with Cu. The enthalpy of mixing between Mo and Cu is +19 kJ / mol, and the enthalpy of mixing between Mo and Ni is −7 kJ / mol. The atomic fraction of Mo / Ni is within the range of 0.06-0.20 or the weight faction of Mo / Ni within the range of 0.10-0.33. The total amount of Ni and Mo additions is within the range of 0.14-1.02 at. % or wt. %. A method for manufacturing the alloy thin film is also provided.

Owner:DALIAN UNIV OF TECH

A kind of preparation method and product of high thermal conductivity deformed magnesium-tin alloy

ActiveCN109778089BEliminate segregationLow thermal conductivitySolution treatmentThermal conductivity

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

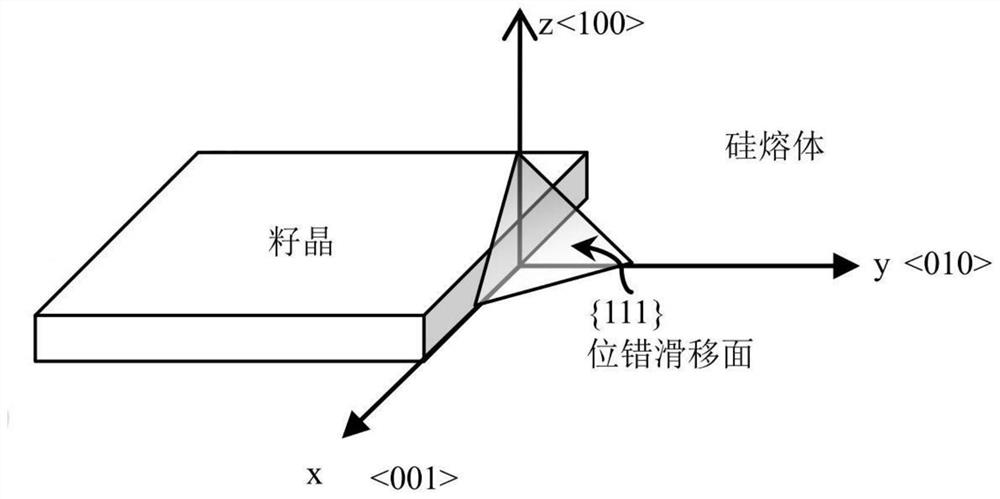

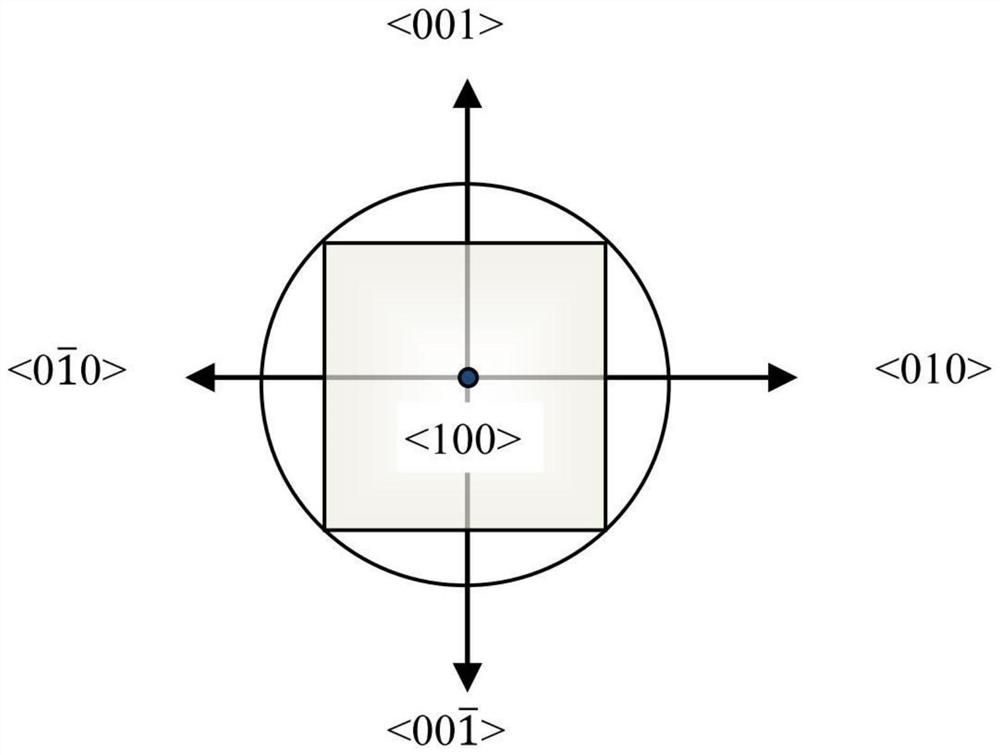

A seed crystal preparation method and laying method for ingot single crystal

ActiveCN112519014BReduce the possibilityThe probability of occurrence of dislocations is lowBy pulling from meltFine working devicesSingle crystal growthDislocation

The invention discloses a method for preparing a seed crystal for ingot single crystal and a laying method thereof. It specifically includes the following steps: in the seed crystal growth stage, firstly determine the crystal direction corresponding to the crystal growth direction, and perform vertical growth along the determined crystal growth direction, and adopt the preparation method of dislocation-free single crystal to carry out, the seed The crystal grows into a rod; in the seed crystal processing stage, the seed crystal rod must first be cut into a bar with a square cross-section along the growth direction of the seed crystal corresponding to the crystal direction; after the rod is cut, the seed crystal is cut into a seed crystal After the block is cut, the seed crystal block is ground, chamfered, and then washed with alkali to eliminate the damaged layer on the surface of the seed crystal during processing. The beneficial effects of the present invention are: polycrystalline nucleation will not occur, and the possibility of polycrystalline nucleation of cast single crystals is eliminated from the source; 50% of dislocations in seed crystals can be eliminated, and during the entire growth process of single crystals In this way, the probability of dislocation generation can be minimized.

Owner:史珺

Double-layer crucible for growing silicon single crystals by directional solidification method

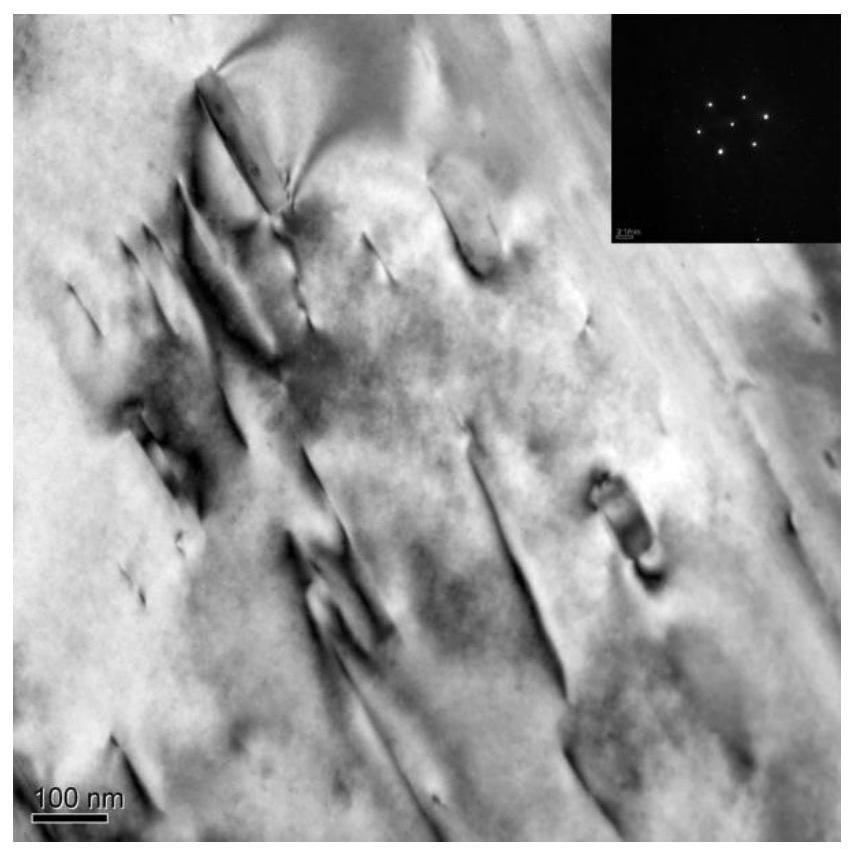

InactiveCN101886288BFix placement issuesEliminate dislocationsFrom frozen solutionsDirectional solidificationSingle crystal growth

Owner:GREENERGY CRYSTAL TECH

Semiconductor structure and forming method thereof

ActiveCN102104060BGood removal effectAvoid crackingAnodisationPolycrystalline material growthPorositySemiconductor materials

Owner:安徽长飞先进半导体有限公司

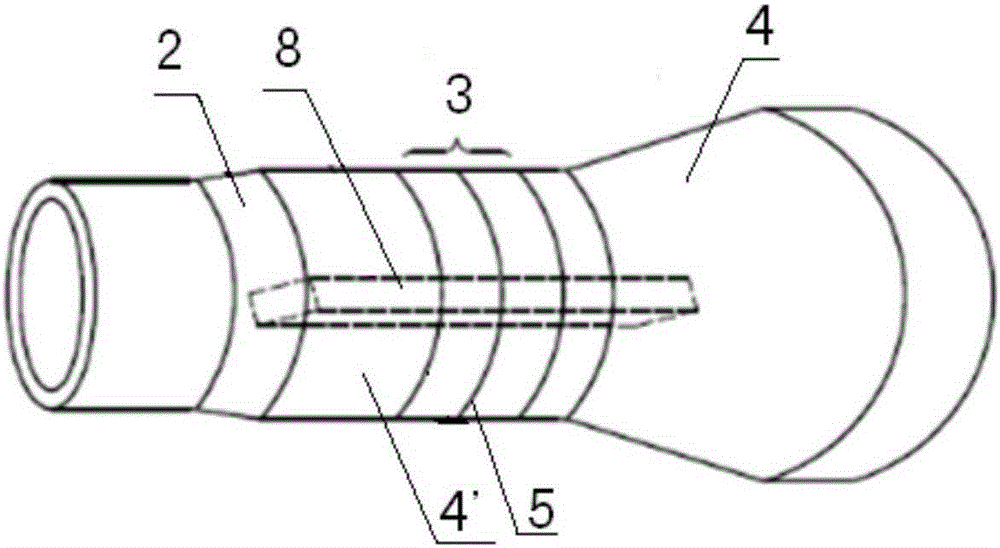

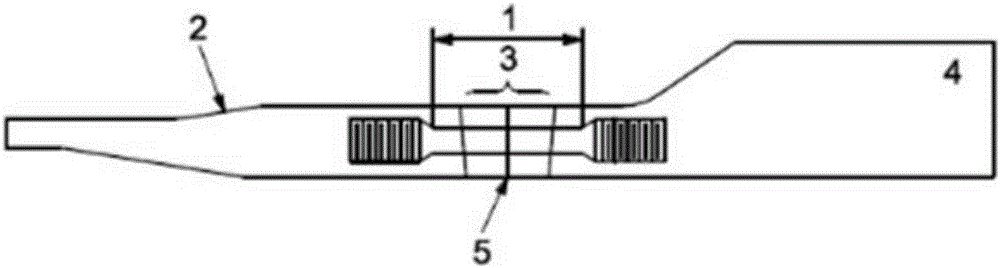

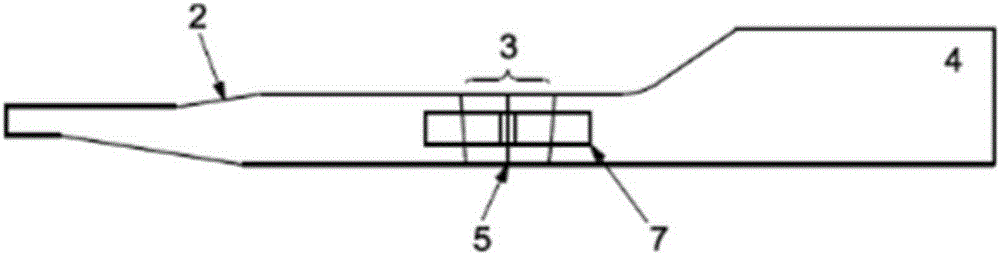

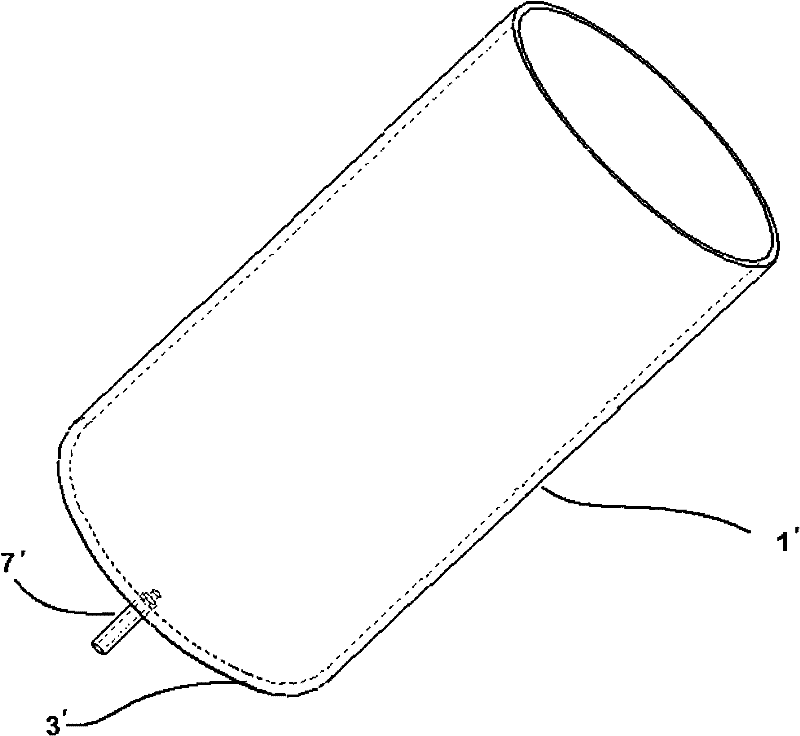

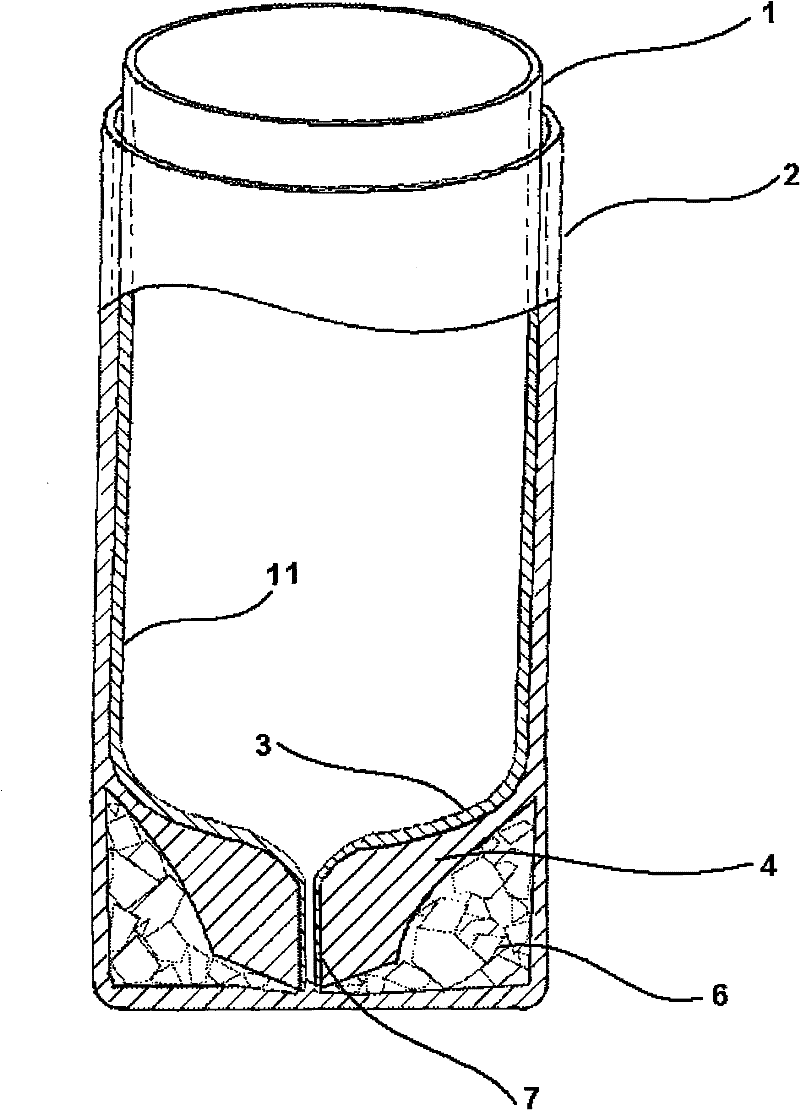

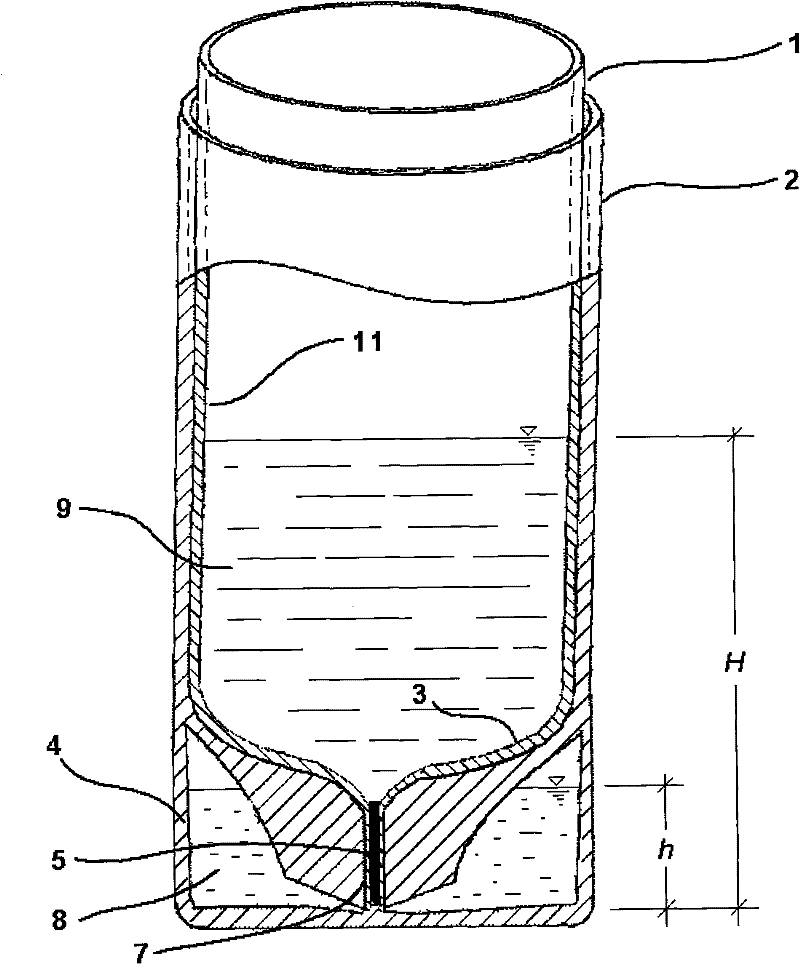

Seeding mold for growing silicon crystals by using orientated solidification method and crystal growing method

InactiveCN102146580BLow costEasy to processPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationMonocrystalline silicon

The invention discloses a seeding mold for growing silicon crystals by using an orientated solidification method and a crystal growing method. The seeding mold is arranged at the internal bottom of a quartz crucible and comprises a seed crystal container and a sealing liquid container, wherein the sealing liquid container consists of cavities connected to the periphery of the seed crystal container and is used for accommodating a sealing substance; and the seed crystal container is provided with a first cavity for accommodating seed crystals. A method for growing monocrystalline silicon / similar monocrystalline silicon by adopting the seeding mold comprises the following steps of: arranging or setting the seeding mold at the bottom of the quartz crucible; arranging the sealing substance and the seed crystals in the sealing liquid container and the seed crystal container respectively; putting a silicon raw material into the quartz crucible; and growing monocrystals / similar monocrystals by adopting orientated solidification. By adopting the seeding mold and the crystal growing method, the problem of placement of the seed crystals can be solved without changing the structures of the conventional orientated solidification and quartz crucible, dislocation of the seed crystals in the seeding process is eliminated, and the spontaneous nucleation phenomenon of melt from the bottom wallface of the crucible is avoided. The seeding mold has low cost and is easy to process.

Owner:GREENERGY CRYSTAL TECH

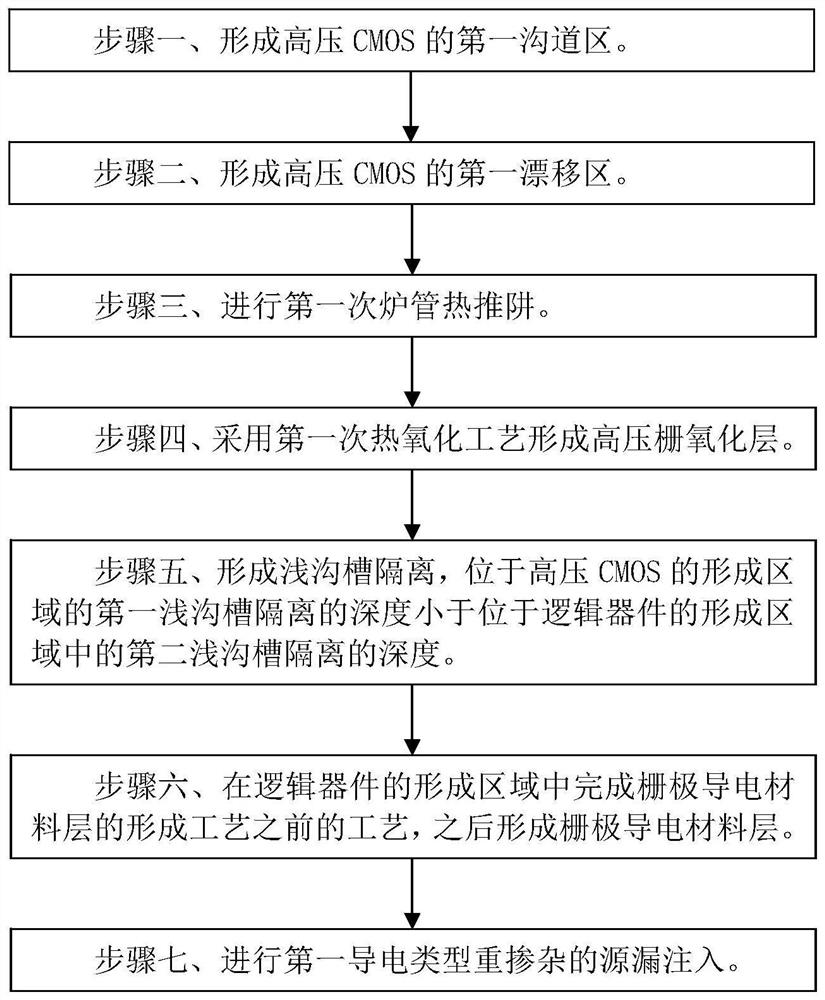

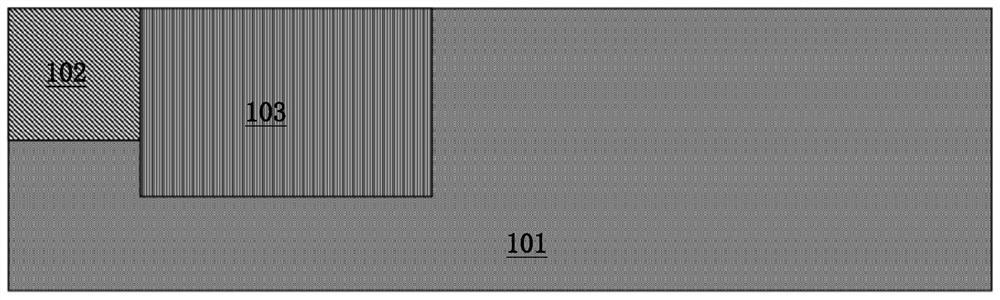

Process integration method for integrating high-voltage CMOS (complementary metal oxide semiconductor) in logic process

PendingCN114242658AReduce defectsEliminate dislocationsSemiconductor/solid-state device manufacturingCMOSPhysical chemistry

The invention discloses a process integration method for integrating a high-voltage CMOS (Complementary Metal Oxide Semiconductor) in a logic process. The process integration method comprises the following steps of: 1, forming a first channel region of the high-voltage CMOS; step 2, forming a first drift region of the high-voltage CMOS; step 3, carrying out primary furnace tube hot drive-in; 4, forming a high-voltage gate oxide layer by adopting a first thermal oxidation process; 5, forming shallow trench isolation, wherein the depth of the first shallow trench isolation in the formation region of the high-voltage CMOS is smaller than that of the second shallow trench isolation in the formation region of the logic device; 6, completing a process before the formation process of the gate conductive material layer in the formation region of the logic device, and then forming the gate conductive material layer; and step 7, performing heavily doped source-drain injection of the first conductive type. According to the invention, the stress generated by the thermal process required by the high-voltage CMOS on the active region can be eliminated, so that the defects of the active region caused by the stress are eliminated, and the quality of the high-voltage gate oxide layer and the performance of the high-voltage CMOS are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A kind of heat treatment method of drill pipe forming weld

ActiveCN105219944BEasy to useSolve crackingFurnace typesHeat treatment furnacesFriction weldingRoom temperature

The invention provides a thermal treatment method for a formed weld joint of a drill rod. The thermal treatment method comprises the following steps that firstly, annealing treatment is carried out on a weld joint zone which is formed between a drill rod pipe body and a connector through friction welding; then the annealed drill rod is placed in air to be cooled until the drill rod is cooled to the room temperature; and finally the cooled drill rod is subjected to tempering treatment. By means of the thermal treatment method, as tempering sorbite is formed, the structure of the weld joint of the drill rod is finer, and the problem of cracks in the weld joint of the small drill rod is completely solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

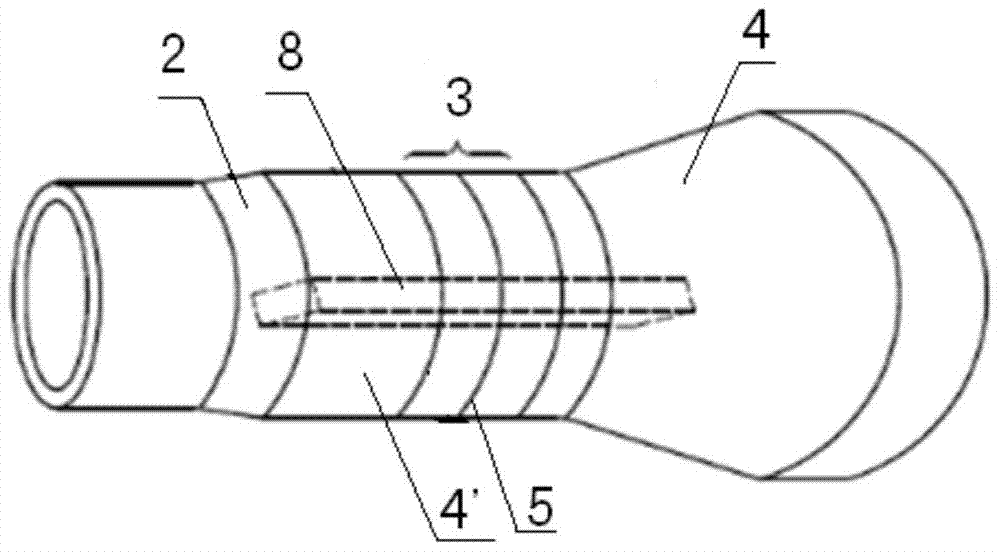

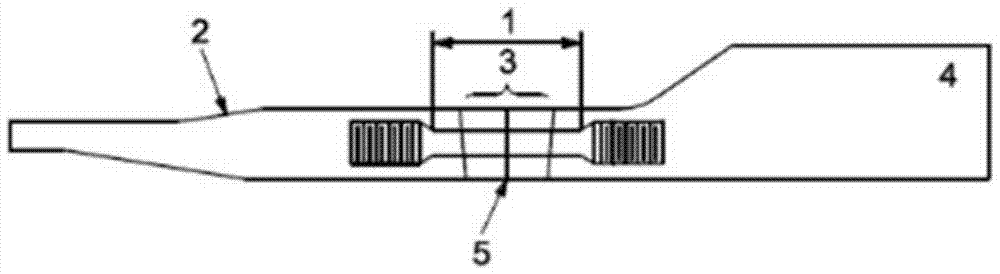

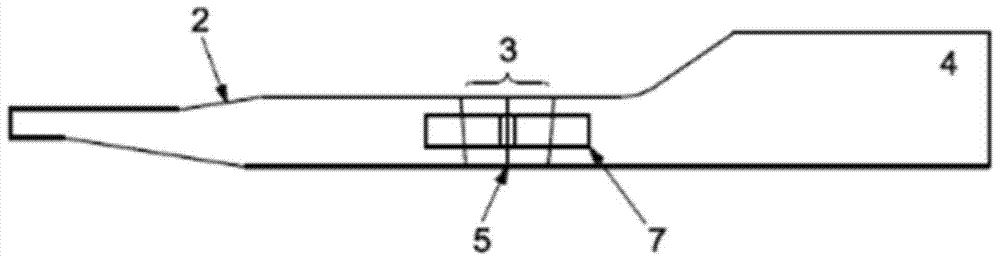

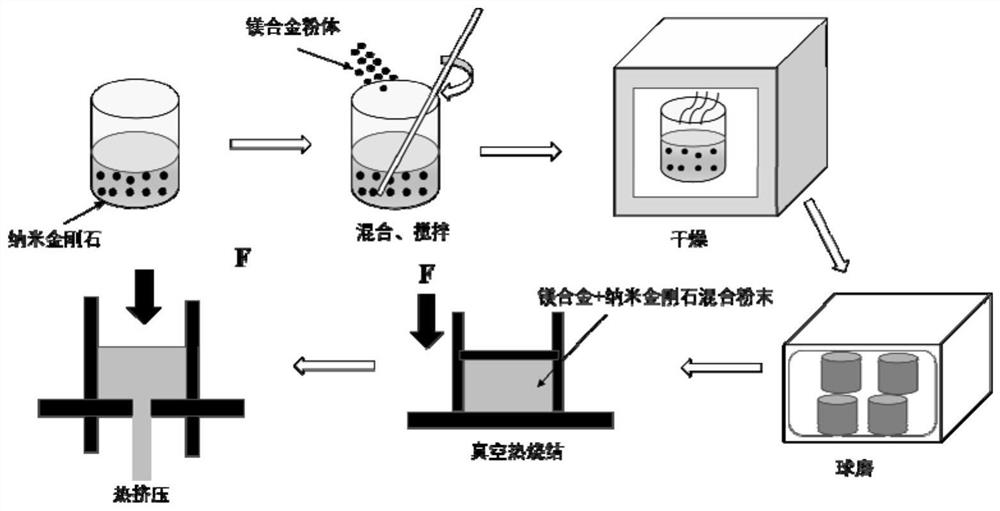

A method for improving the thermal conductivity of magnesium-based composite materials with nano-diamond and magnesium-based composite materials

ActiveCN110551909BEvenly dispersedImprove thermal conductivityThermal dilatationMagnesium matrix composite

The invention discloses a method for improving thermal conductivity of a magnesium-based composite material by nano diamond and the magnesium-based composite material. The preparation method comprisesthe steps of firstly, uniformly dispersing the nano diamond in a magnesium alloy matrix by an ultrasonic dispersion method, sintering ball-milled powder in a vacuum hot-pressing sintering furnace toobtain a sintered blank, increasing diamond activity at a nano level by high-temperature and high-pressure treatment, and further forming a layer of carbide between the nano diamond and the magnesiumalloy matrix. Therefore, the interface bonding strength is improved, interface defects are reduced, and the interface thermal conductivity is improved. The preparation method is simple to operate andeasy to realize, and the slight carbonization reaction between the nano diamond and the magnesium alloy matrix is realized through high temperature and high pressure. The magnesium-based composite material prepared by the method has the advantages that on one hand, the diamond particle reinforced magnesium-based composite material obtains high thermal conductivity, has low thermal expansion coefficient matched with a semiconductor material, and has good application prospects.

Owner:QINGHAI UNIVERSITY

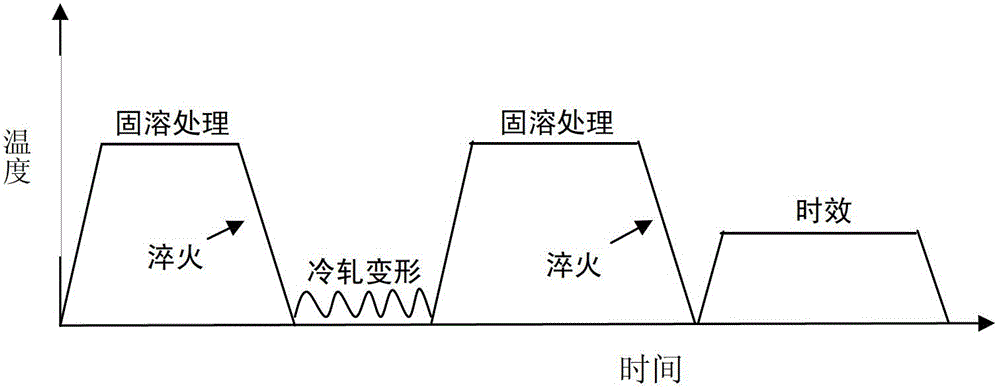

A deformation heat treatment method for improving the tensile properties of 6000 series aluminum alloy sheet

ActiveCN103343304BPreserve the aging strengthening effectHigh strengthSolution treatmentUltimate tensile strength

The invention belongs to the technical field of aluminum alloy deformation heat-treatment and discloses a deformation heat-treatment method for improving tensile properties of a 6000-series aluminum alloy thin plate. The deformation heat-treatment method is suitable for improvement of a 6000-series aluminum alloy thin plate. Aiming at further improving tensile properties of a 6000-series aluminum alloy thin plate, the invention provides the deformation heat-treatment method. The deformation heat-treatment method is mainly characterized by comprising the following steps of before final molding of a 6000-series aluminum alloy thin plate, carrying out solution treatment, carrying out quenching, carrying out large-deflection cold rolling so that required thin plate thickness is obtained, carrying out solution treatment, carrying out quenching and carrying out peak aging treatment. The deformation heat-treatment method can greatly improve strength of the 6000-series aluminum alloy thin plate and maintain good plasticity.

Owner:SUZHOU JIALIANYA IND

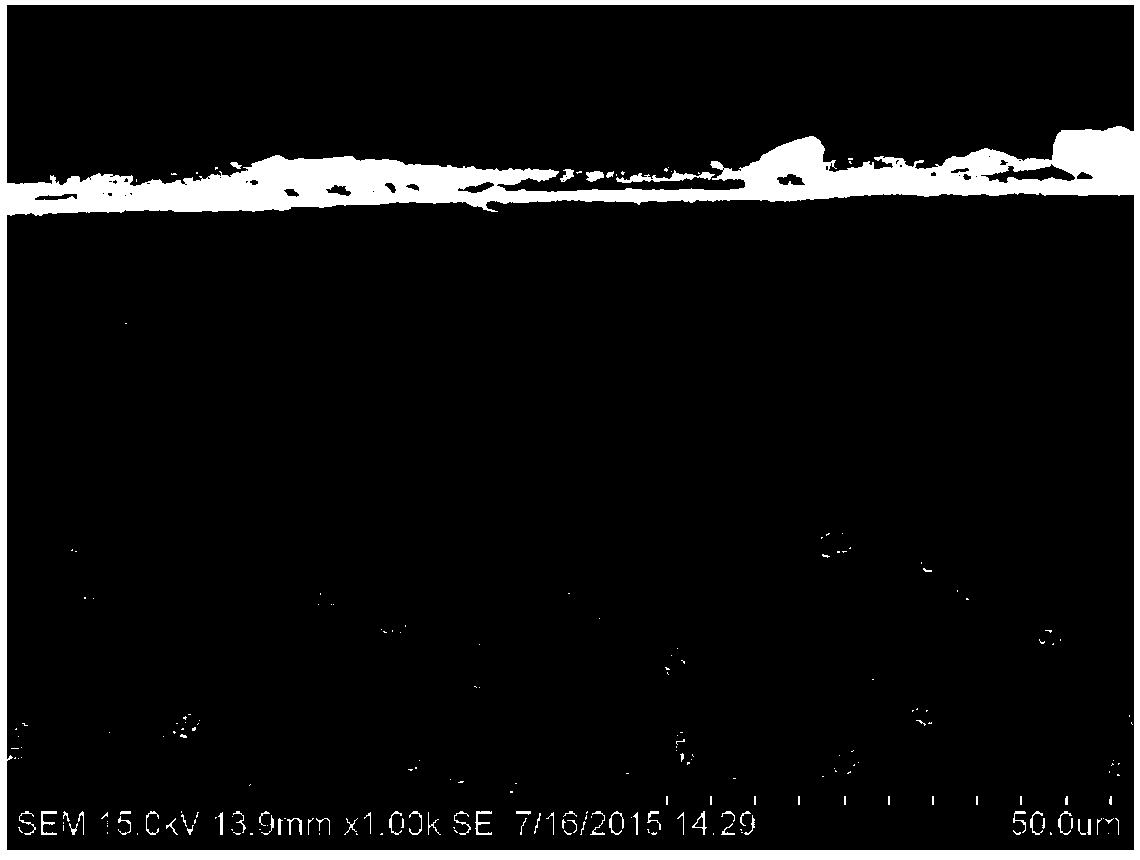

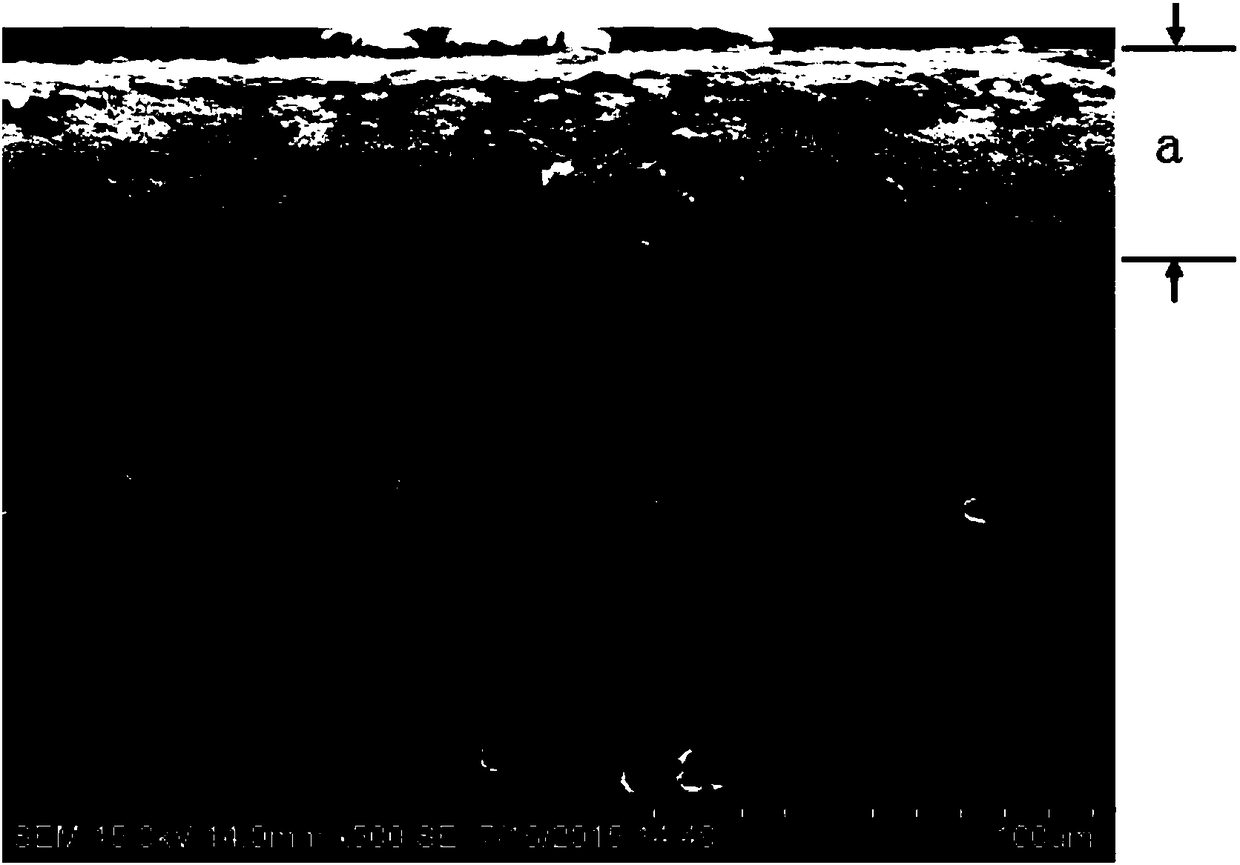

A surface treatment method for high-purity metal sputtering target

ActiveCN106755891BStress reliefEliminate dislocationsFurnace typesHeat treatment furnacesSurface cleaningCase hardening

The invention belongs to the technical field of preparation and processing of a target material, and particularly relates to a surface treatment method of a high pure metal sputtering target material. The surface treatment method comprises the following steps: the target material is firstly subjected to surface precision machining, surface grinding and surface cleaning and then subjected to rapid surface heat treatment by adopting a continuous wave laser heat treatment method, an electron beam scanning method or noncoherent broadband frequency light source method, a hardened layer on the surface of the target material recrystallizes through the skin effect generated by rapid heat treatment, stress and dislocation in the hardened layer is eliminated, and a recrystallization texture basically consistent with the matrix is obtained. The surface treatment method is simple in process, high in speed, high in universality, suitable for target materials of different sizes, free of material pollution during the preparation process, low in material loss and environment friendly.

Owner:GRIKIN ADVANCED MATERIALS

Flash memory and manufacturing method thereof

ActiveCN101359694BImprove data retentionImprove erase performanceSolid-state devicesSemiconductor devicesEngineeringMedia layer

A flash memory includes a substrate, a stack structure located on the substrate, a source electrode and a drain electrode, and a source terminal spacer layer, wherein the stack structure includes a tunnel oxide layer, a charge storage layer located on the tunnel oxide layer, and a charge storage layer located on the tunnel oxide layer. an inter-gate dielectric layer on the storage layer and a control gate located on the inter-gate dielectric layer. The source electrode and drain electrode are located in the substrate on both sides of the charge storage layer. The source end spacer layer is located on the side wall of the stack structure close to the source to prevent the tunnel oxide layer and the inter-gate dielectric layer from being re-oxidized near the source end and causing an increase in thickness.

Owner:MACRONIX INT CO LTD

H13 steel hard surface surfacing layer heat treatment method

PendingCN113373290AEliminate Welding DefectsImprove organizationArc welding apparatusFurnace typesWelding residual stressHeat conservation

The invention discloses an H13 steel hard surface surfacing layer heat treatment method. H13 steel is used as a welding base body for surfacing, a prepared hard surface surfacing layer is subjected to finish machining so as to reach the size required by a mold, the machined mold is subjected to tempering treatment and air cooling to the room temperature, and a finished product is obtained. The tempering temperature ranges from 250 DEG C to 650 DEG C, and the tempering heat preservation time ranges from 0.5 h to 6 h. According to the method, the welding defects such as dislocation, welding residual stress and uneven structural components in the hard surface surfacing layer on the H13 steel surface are eliminated through post-welding tempering heat treatment. The structure and mechanical properties of the surfacing layer are improved by reasonably controlling the tempering temperature, the heat preservation time and the heating rate.

Owner:TIANJIN UNIV

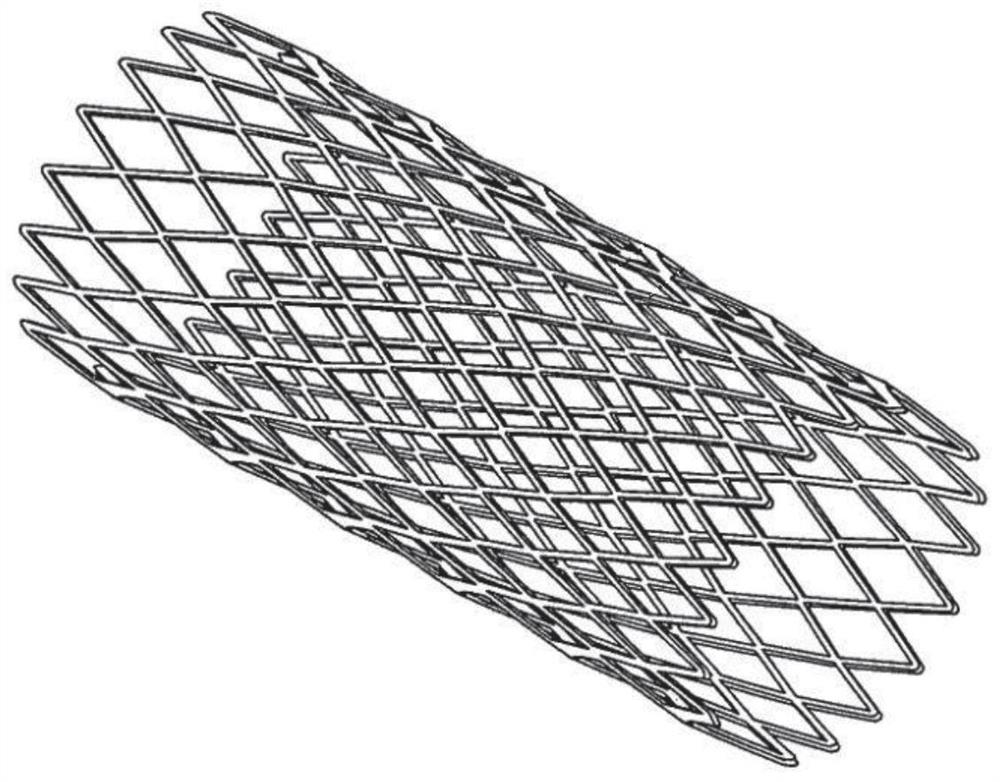

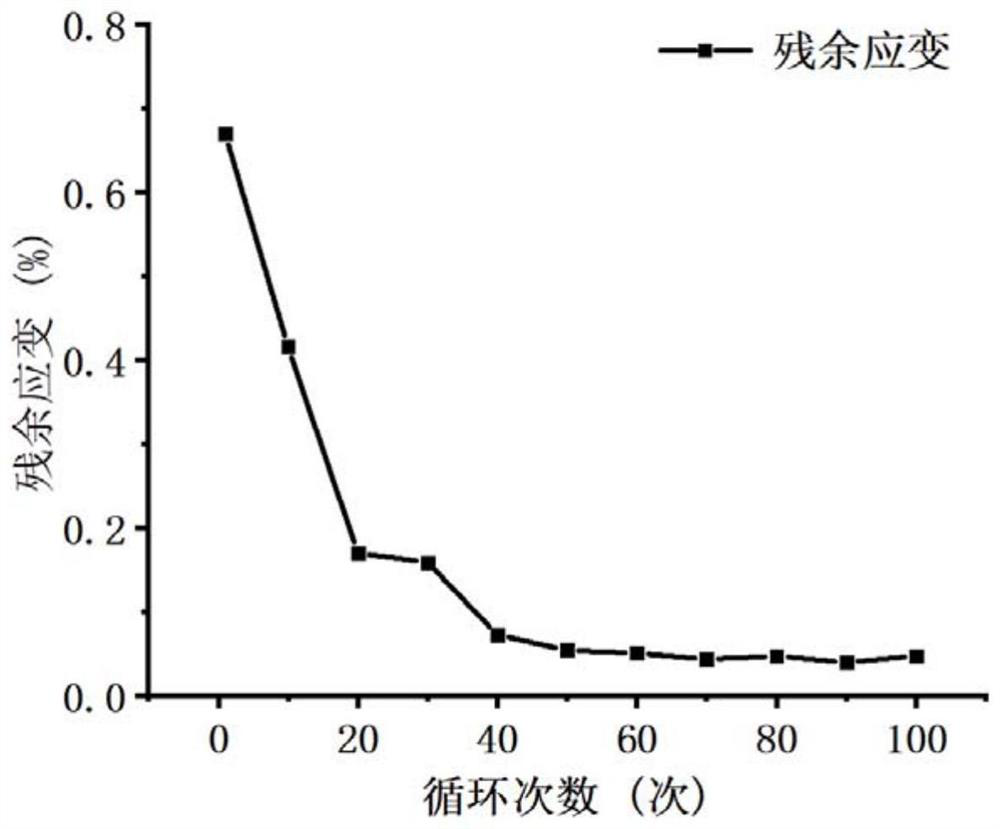

Nickel-titanium alloy preparation method for improving radial stability and medical device

InactiveCN113046665AImprove fatigue resistanceUniform internal organizationStentsFurnace typesNitinol stentTitanium alloy

The invention discloses a nickel-titanium alloy preparation method for improving the radial stability and a medical device. A nickel-titanium alloy stent with microdefects in a preset structure is subjected to shaping and post-treatment through a multi-step heat treatment process method. The method comprises the following steps: performing annealing treatment to enable the internal structure of the nickel-titanium alloy stent to be recovered, recrystallized and shaped, eliminating the defects of dislocation and the like in the stent, enabling the internal structure of the nickel-titanium alloy stent to be uniform, and re-dissolving a Ni-rich precipitated phase; carrying out strain cycle shrinkage on the stent in the radial direction; and finally, carrying out low-temperature aging treatment on the stent, so that a nanoscale component non-uniform structure is uniformly formed in the alloy, and the anti-fatigue performance of radial cyclic shrinkage deformation of the nickel-titanium alloy stent is remarkably improved.

Owner:江苏盛玛特新材料科技有限公司

A kind of preparation method of ternary alloy sealing material

The invention discloses a preparation method of a ternary alloy sealing material. The ternary alloy sealing material comprises, by mass, 60-67% of Ag, 25-30% of Cu and 8-12% of In. The preparation method comprises the steps that 99.99% Ag and a 99.9% Cu pipe are obtained, and 99.99% In is placed in the 99.9% Cu pipe; the raw materials are placed in a vacuum medium-frequency smelting furnace, vacuumization is performed till vacuum pressure reaches 0.02-0.04 MPa, and inert gas is input after temperature is increased to reach 1000-1100 DEG C; heat preservation is performed for 20-30 min, and sufficient stirring and casting are performed through the medium-frequency furnace; a cast ingot is laced in a vacuum annealing furnace for annealing, the temperature is 600-700 DEG C, the heat preservation time is 2-5 h, and the cast ingot is taken out after the temperature reaches 60 DEG C; and annealing is performed after the cast ingot is calendered by 1-2 mm, the temperature is 500-600 DEG C, heat preservation time is 2-3 h, inert gas is input, and the cast ingot is rolled to 0.1-0.12 mm after being cooled. The sealing material is high in cleanliness and good in welding performance.

Owner:WUXI RIYUE ALLOY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com