A seeding method for growing sapphire crystals by Kyropoulos method

A technology of sapphire crystal and Kyropoulos method, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc. It can solve the problems of seeding not completely eliminating dislocations and poor crystal quality, so as to increase energy consumption and improve crystal finished products rate, to avoid the effect of melting back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention is a seeding method for growing sapphire crystals by Kyropoulos method, said method comprising the steps of:

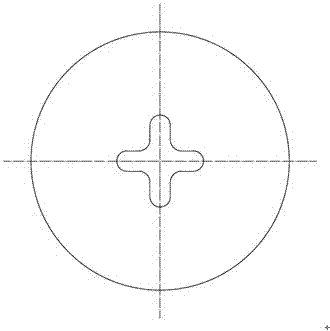

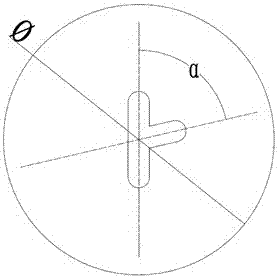

[0036] Step 1: Set as image 3 The non-rotationally symmetrical structure of the opening shown adopts the non-rotationally symmetrical included angle structure, and the upper heat reflecting structure with an included angle of 75 degrees is installed in the Kyropoulos sapphire growth equipment;

[0037] Step 2: Vacuum the crystal growth furnace loaded with raw materials to a vacuum of ~10 -3 Pa;

[0038] Step 3: Control the temperature of the crystal growth furnace to 2000-2100°C through a heater, and wait until the sapphire raw material is melted into a melt.

[0039]Step 4: Put the seed crystal, test the temperature, adjust the power or voltage, so that the seed crystal does not melt and grow when it contacts the melt, dip the seed crystal into the liquid surface of the melt for 3mm; use the pulling speed of 3mm / h, 1mm The instant lif...

Embodiment 2

[0044] The present invention is a seeding method for growing sapphire crystals by Kyropoulos method, said method comprising the steps of:

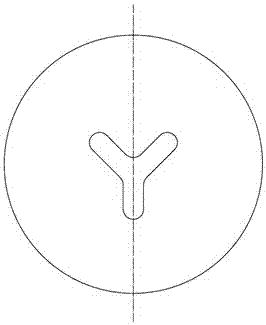

[0045] Step 1: Set as Figure 4 The non-rotationally symmetrical structure of the opening shown is installed in the Kyropoulos sapphire growth equipment with a "T"-shaped upper heat reflection structure rotated 90 degrees counterclockwise;

[0046] Step 2: Vacuum the crystal growth furnace loaded with raw materials to a vacuum of ~10 -3 Pa;

[0047] Step 3: Control the temperature of the crystal growth furnace to 2000-2100°C through a heater, and wait until the sapphire raw material is melted into a melt.

[0048] Step 4: Put the seed crystal, test the temperature, adjust the power or voltage, so that the seed crystal does not melt and grow when it contacts the melt, dip the seed crystal into the liquid surface of the melt for 3mm; use the pulling speed of 6mm / h, 1mm The instant lifting height and the clockwise rotation at a given angle...

Embodiment 3

[0053] The present invention is a seeding method for growing sapphire crystals by Kyropoulos method, said method comprising the steps of:

[0054] Step 1: Set as Figure 5 The non-rotationally symmetrical structure of the opening shown is installed in the Kyropoulos sapphire growth equipment with an "L"-shaped upper heat reflection structure;

[0055] Step 2: Vacuum the crystal growth furnace loaded with raw materials to a vacuum of ~10 -3 Pa;

[0056] Step 3: Control the temperature of the crystal growth furnace to 2000-2100°C through a heater, and wait until the sapphire raw material is melted into a melt.

[0057] Step 4: Put the seed crystal, test the temperature, adjust the power or voltage so that the seed crystal does not melt and grow when it contacts the melt, dip the seed crystal into the liquid surface of the melt for 5mm; use the pulling speed of 8mm / h, 1mm The instantaneous lifting height and the counterclockwise rotation of a given angle of 15 degrees are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com